You face big decisions when it comes to picking a 480 to 120 control transformer for your factory or automation setup. The right transformer keeps your control circuits safe and your equipment running smoothly. A poor choice can lead to downtime, safety risks, or extra costs. Certified, high-quality transformers like those from Linkwell offer real advantages:

| Benefit | Description |

|---|---|

| Improved Efficiency | New core and winding designs push efficiency up by as much as 15%. |

| Compliance with Safety Standards | UL/CE-certified models meet strict North American and European safety requirements. |

| Enhanced Operational Reliability | Better insulation means longer transformer life and less maintenance or downtime. |

A reliable transformer means peace of mind and smooth operations.

Key Takeaways

- Choose the right KVA rating by listing all devices and adding a 20% safety margin to prevent overload.

- Select the appropriate phase type—single-phase for smaller loads and three-phase for heavy machinery.

- Look for safety certifications like UL and CE to ensure compliance with industry standards.

- Consider the installation environment; high temperatures and humidity can affect transformer performance and lifespan.

- Plan for future expansion by selecting a transformer with extra capacity to accommodate potential load increases.

What Is a 480V to 120V Transformer?

Control Transformer Basics

You might wonder what makes a 480V to 120V transformer special. This device steps down a high voltage, like 480 volts, to a safer, lower voltage such as 120 volts. You use it to power control circuits in industrial panels. The transformer keeps your control systems running smoothly, even when the main power supply changes.

Let’s look at how a control transformer compares to other types:

| Feature | Control Transformer | Isolation Transformer |

|---|---|---|

| Purpose | Provides stable voltage to control circuits | Primarily for protection and system integrity |

| Voltage Conversion | Converts higher voltages (e.g., 480V) to lower voltages (e.g., 120V) | Does not typically convert voltage levels |

| Inrush Current Handling | Designed to handle short-time inrush currents | Not specifically designed for inrush currents |

| Application | Used in automation and motor control panels | Used for electrical isolation and safety |

A control transformer works using electromagnetic induction. The primary winding connects to the high voltage side. When alternating current flows through this winding, it creates a magnetic field. This field then induces a lower voltage in the secondary winding. The transformer reduces the voltage so your control circuits get the right amount of power. You can count on it to provide stable voltage and keep your relays, contactors, and motor starters working reliably.

Typical Industrial Applications

You see this transformer in many places. It powers control panels in factories, telecom cabinets, and automated machines. You need it for motor control centers, HVAC systems, and conveyor belts. The transformer protects sensitive devices from voltage spikes and keeps everything running safely.

Here are some common uses:

- Supplies safe voltage to control relays and timers.

- Powers signal lights and push buttons on operator panels.

- Supports automation equipment in manufacturing plants.

- Keeps telecom systems and signal stations stable.

When you choose the right transformer, you make sure your equipment stays safe and your operations stay efficient. You also reduce the risk of downtime and costly repairs. That’s why understanding the basics of this transformer is so important for your business.

Key Factors for 480 to 120 Control Transformer Selection

When you choose a 480 to 120 control transformer, you want to get it right the first time. Let’s break down the most important factors so you can make a smart, safe, and cost-effective decision.

Sizing and KVA Rating

Sizing your transformer isn’t just about matching numbers. You need to think about how your equipment works, what it needs now, and what it might need in the future. Here’s a simple way to approach transformer kva ratings:

- List all your loads. Each device—like relays, timers, or contactors—draws a certain amount of power. Motors, for example, often need more power at startup.

- Add a safety margin. It’s smart to add about 20% extra to your kva rating. This covers future expansion or unexpected surges.

- Consider the environment. High temperatures or humidity can affect transformer performance. If your plant gets hot or damp, you may need a higher kva rating.

- Pick a transformer with a bit more capacity than you calculate. This helps you avoid overload and keeps your system running smoothly.

Inrush current is another thing you can’t ignore. When you start up a machine, it can draw a big surge of current. If your 480 to 120 control transformer isn’t sized for this, you risk voltage drops, tripped switches, or even burnout. You want to:

- Avoid voltage drops that can stress your system.

- Prevent mechanical stress that shortens transformer life.

- Make sure protective devices don’t trip unnecessarily.

- Keep your transformer from overheating.

Tip: Always select fuses and overcurrent protection that can handle inrush current. This keeps your system safe and prevents nuisance shutdowns.

If you push a transformer past its kva rating, you’ll see overheating, voltage sag, and even early failure. That’s why proper sizing is so important for any high voltage to low voltage transformer.

Phase Type and Compatibility

You’ll find both single-phase and three-phase options when you shop for a 480v to 120v transformer. The right choice depends on your application. Here’s a quick comparison:

| Feature | Single-Phase Transformers | Three-Phase Transformers |

|---|---|---|

| Design | One primary and one secondary winding | Three sets of windings |

| Load Handling | Good for low-load and household uses | Handles high-power, continuous industrial loads |

| Efficiency | Simple and cost-effective for small systems | More efficient, shares load evenly |

| Applications | Lighting, small machines, residential | Industrial, commercial, power transmission |

| Compatibility | Best for low power demands | Ideal for high-demand applications |

You need to match the transformer phase to your supply and load. Most industrial plants use three-phase power for heavy machinery. For small panels or lighting, single-phase might be enough. Always check your system’s voltage and frequency. Modern transformers, like those from Linkwell, handle all standard international voltages and frequencies, and they’re built to manage inrush current without losing voltage stability.

Safety Features and Certifications

Safety should always come first. You want a 480 to 120 control transformer that protects your people, your equipment, and your investment. Look for these certifications:

| Certification | Importance |

|---|---|

| UL | Meets North American safety standards. |

| CE | Complies with European safety and environmental rules. |

| ISO 9001:2015 | Shows commitment to quality and improvement. |

You should also check for compliance with standards like UL 1446, IEC 62114, and IEC 60505. These cover insulation, thermal performance, and overall electrical safety.

“Functional safety is the critical part of the overall safety of a system or product that depends on the correct execution of specific commands and functions. A functional safety examination involves precise evaluations of safety-related devices and systems.”

Linkwell’s transformers come with UL, CE, and ISO9001 certifications. This means you get reliable, tested products that meet strict global standards. You also get features like overload protection, fusing on both primary and secondary sides, and robust insulation. Properly sized fuses and overload thresholds keep your transformer safe from damage.

Installation and Environment

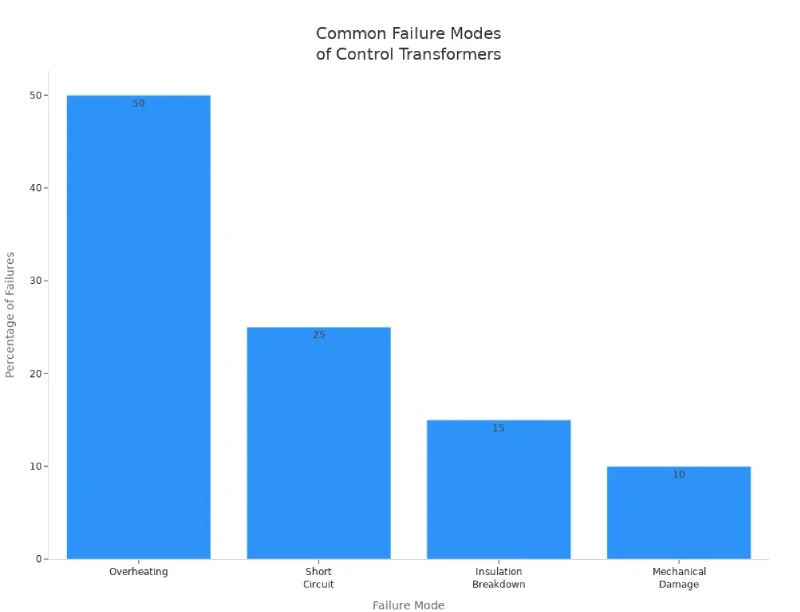

Where you install your transformer matters. Heat, humidity, dust, and altitude can all affect performance and lifespan. If you put a transformer in a hot or damp spot, the insulation can break down faster. This leads to overheating, short circuits, and even failure.

- High temperatures can cut transformer life by up to 35%.

- Humidity weakens insulation and raises the risk of short circuits.

- Dust and pollutants can cause insulation breakdown.

You want a transformer that fits your environment. Linkwell offers models with different mounting options—panel-mount, DIN rail, or enclosed designs. You can also get custom enclosures for harsh conditions. This flexibility means you can protect your transformer and keep it running longer.

Note: Energy-efficient transformers may cost a bit more upfront, but they save you money over time. Lower energy losses mean lower bills and less heat, which also means less maintenance.

Linkwell’s 480 to 120 control transformer line stands out for energy efficiency, strong durability, and customization. You can get models with high inrush VA capability, tight voltage regulation, and short-term overload handling. These features keep your control circuits stable and your equipment safe, no matter what your application looks like.

By focusing on sizing, phase compatibility, safety, and installation, you set yourself up for reliable, long-lasting performance from your 480v to 120v transformer.

Practical Tips for Choosing a 480v to 120v Transformer

Matching to Control Circuits and Loads

You want your 480v to 120v transformer to fit your control circuits like a glove. Start by checking how your existing equipment connects. Most transformers have two 240V primary windings in series for 480V input, and two 120V secondary windings in parallel for the output. This setup matches most 120V control circuits you find in industrial panels.

Here’s a quick checklist to help you avoid common mistakes:

- List every device connected to your transformer, including relays, timers, and contactors.

- Calculate the total load accurately. Missing a device can lead to inefficiency or even equipment failure.

- Don’t oversize your transformer. Bigger isn’t always better. Oversizing means higher costs, wasted energy, and more space needed.

- Keep up with regular maintenance. This keeps your transformer running at its best and extends its life.

Tip: Always match your transformer’s configuration to your control circuit’s needs. This keeps your system efficient and safe.

Ensuring Compliance and Reliability with Linkwell

You can’t ignore safety and compliance when installing a 480v to 120v transformer. Check that your setup meets all requirements:

| Requirement Type | Details |

|---|---|

| High-Voltage Side | UL-compliant lightning arresters and overcurrent protection. |

| Low-Voltage Side | Short-circuit current withstand capability. |

| Grounding Resistance | Must be ≤5Ω. |

A reliable transformer does more than just supply power. It keeps voltage stable, reduces electrical noise, and protects your control circuits from power surges. Linkwell supports you with certified products, expert advice, and fast delivery. Their team brings years of experience and a focus on safety, so you get solutions that meet international standards. You also get high-quality terminal boxes and accessories that boost both compliance and reliability.

Planning for Future Expansion

Think ahead when you choose your 480v to 120v transformer. If you expect your plant to grow, plan for it now. Oversizing gives you room for future load increases, but don’t go overboard. Too much extra capacity can waste energy and money.

Here are some smart ways to prepare:

- Choose a transformer with scalability, like parallel operation capability.

- Look for flexible features, such as multi-voltage primaries or taps.

- Make sure your transformer’s peak efficiency matches your average load.

- Add a safety margin, but keep it balanced to avoid inefficiency.

- Consider maintenance, expected lifespan, and how easy it is to upgrade.

Note: Planning for the future helps you avoid costly upgrades and keeps your system safe and reliable as your needs change.

By following these tips, you set yourself up for a safer, more efficient, and future-ready control system.

Conclusion

You’ve now got the tools to pick the right transformer for your control circuits. Let’s recap the steps you should follow:

- Figure out your load. Write down every device that needs power. Add up the total demand so you know what size transformer you need.

- Think about the future. If you plan to add more machines, choose a transformer with a little extra capacity.

- Check the phase and compatibility. Make sure your transformer matches your power supply and your equipment.

- Focus on safety. Look for UL, CE, and ISO9001 certifications. These show that your transformer meets strict safety standards.

- Consider your environment. Hot, humid, or dusty places need a transformer built for tough conditions.

Remember: A reliable transformer keeps your control circuits running and protects your equipment from costly downtime.

You want a transformer that delivers stable voltage, handles inrush current, and stands up to daily use. Linkwell offers certified products that meet global standards for safety and performance. You also get expert support and fast delivery, so you can keep your projects on track.

If you’re not sure which transformer fits your needs, reach out to Linkwell or talk with a qualified professional. They can help you find a solution that matches your system, your budget, and your safety requirements.

Here’s a quick table to help you remember what matters most:

| Step | Why It Matters |

|---|---|

| Sizing | Prevents overload |

| Safety | Protects people & assets |

| Compatibility | Ensures smooth operation |

| Environment | Extends transformer life |

| Future Planning | Saves money long-term |

Choosing the right transformer is an investment in your plant’s safety and reliability. Take your time, ask questions, and make sure you get the best fit for your application.

You want to make the right call when picking a 480V to 120V control transformer. Here’s a quick checklist to guide you:

- Check the KVA rating to match your power needs.

- Choose the right phase—single or three-phase.

- Look for safety features like overload protection and UL listing.

- Proper sizing keeps your system safe and reliable.

- Certified transformers help you meet industry standards.

- Expert support from Linkwell makes your choice easier.

Need help? Reach out to Linkwell for advice that fits your project.

FAQ

How do I know what KVA rating I need?

Start by listing every device your transformer will power. Add up their total VA (volt-ampere) ratings. Add a 20% safety margin. This helps you pick a transformer that won’t overload or overheat.

Can I use a 480V to 120V transformer outdoors?

Most standard models work best indoors. If you need outdoor installation, ask for a transformer with a weatherproof enclosure. Linkwell offers custom options for harsh environments.

What certifications should I look for?

Look for UL, CE, and ISO9001 certifications. These show your transformer meets strict safety and quality standards. Certified transformers help you pass inspections and keep your team safe.

How often should I check or maintain my transformer?

Check your transformer every six months. Look for dust, loose wires, or signs of overheating. Regular maintenance keeps your system safe and extends transformer life.