One-Stop Cabinet Component Manufacturer of Low Voltage Electrical Components & Automation Solutions

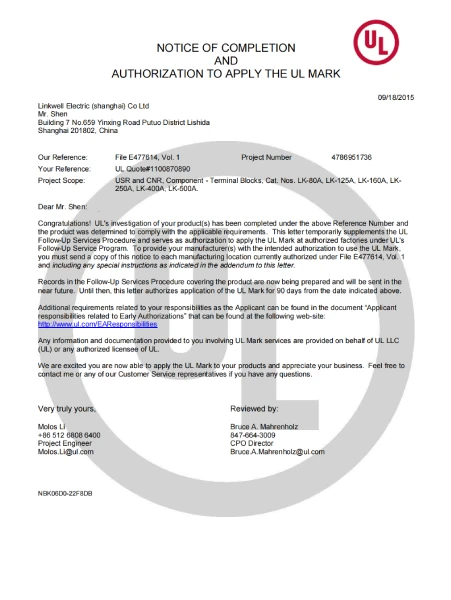

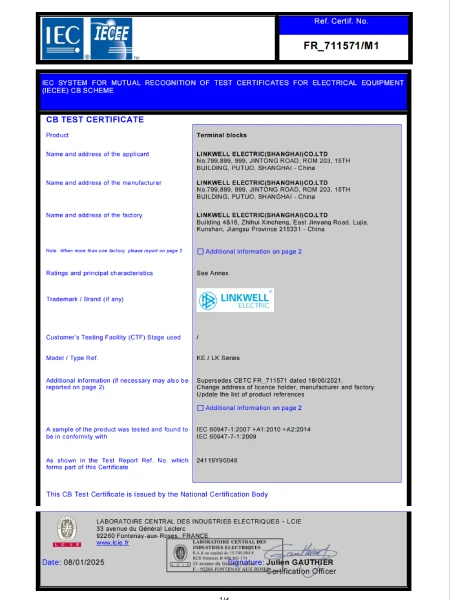

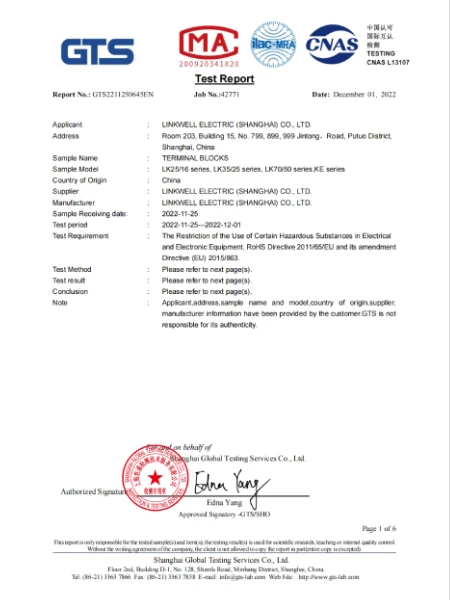

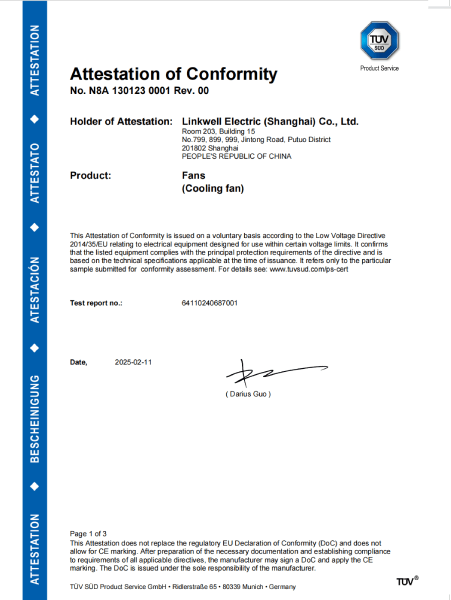

- UL listed, CE, IP, NEMA, IK, CCC, ATEX, IECEx, SAA Certifications.

- Many Solutions for the Automotive Industry, Commercial, Residential, Transportation, Food Industries.

- Cooperate with Schneider, ABB, SIEMENS and Noark on assembled enclosure service.

- After-sales Service Offices Worldwide, Including the United States, Australia, South Korea, Tanzania, etc.

About Linkwell

LINKWELL ELECTRIC is a global cabinet component manufacturer for low-voltage electrical components and automation solutions, serving switchgear panel builders and industries worldwide. With decades of expertise, we design and manufacture high-quality panel accessories—including ventilation systems, control transformers, terminal blocks, and wiring ducts—supported by a one-stop supply chain integrating self-production and strategic partnerships.

Trusted by ABB, Siemens, Schneider Electric, and clients in over 100 countries, we prioritize sustainable quality, competitive pricing, and rapid delivery. Beyond products, we act as your dedicated industrial partner, offering customized solutions and 24/7 support to ensure seamless project success. Together, we innovate for a smarter, more efficient industrial future.

China's leading OEM ODM manufacturer

Main Products

BIONICS

SAVING

EFFICIENCY

PROOFING

NOISE

Fan and Filter

| ABS or PC-ALLOY plastic |

| 5 standard mounting size |

| Easy-open for quicker maintenance |

| Build-in nuts for more fan sizes |

Cabinet Air Conditioner

| For indoor and outdoor application |

| Cooling power 500w~5000w |

| R134a refrigerant, RS485 interface |

| Side mounting or embedded mounting |

Roof fan Filter

| 19 inch rack-mounted fan (1U) |

| 6 types design |

| Metal or plastic cover |

| Air flow 415~3150 m³ |

Thermostat and Hygrostat

| AC DC Wide voltage |

| Mechanic and electronic structure |

| Single/Dual Contact |

| Tool-free adjust |

Advanced Production Equipment

Our state-of-the-art production equipment ensures precision, efficiency, and consistency across every cabinet component we manufacture. By integrating advanced automation and strict quality control, we deliver low voltage electrical components that meet global standards and support reliable performance in critical applications.

Equipped with cutting-edge machinery and modern testing systems, our facility enhances productivity while maintaining exceptional accuracy. This investment in advanced equipment allows us to offer flexible customization, faster lead times, and durable solutions tailored to the evolving needs of automation industries.

Strict Quality Control

Quality is at the heart of everything we produce. Each component undergoes rigorous inspection at multiple stages of production, from raw material selection to final assembly. Our dedicated quality team ensures every item meets international standards before leaving the factory.

By combining advanced testing equipment with strict inspection protocols, we guarantee reliable, long-lasting performance of our cabinet components. This commitment to quality not only minimizes defects but also provides customers with the confidence and assurance they need in demanding applications.

Why Partner With Us

Certifications

We invite you to evaluate the quality of our product firsthand. By covering a nominal shipping fee, you will receive your samples promptly.

One-Stop Sourcing

Simplify your procurement process with our comprehensive portfolio—your trusted one-stop source for high-quality lifting solutions.

Custom-Engineered Solutions

Our in-house engineers collaborate with you to design and manufacture custom cabinet component tailored to your project’s unique specifications.

Quality

We take quality seriously, and rigid controls-random checks and third-party verification-make sure that this is so at all times.

Direct-from-Manufacturer

Purchase directly from the manufacturer to enjoy better pricing while avoiding unnecessary middlemen fees and extra commissions.

20 Years of Export Experience

Leveraging 20 years of global expertise, we guarantee the seamless, efficient, and on-time, every time delivery of your orders, anywhere in the world.

Certification

Exhibition

Applications

LINKWELL ELECTRIC for a variety of industries to provide comprehensive quality solutions.The products are widely used in wind power, photovoltaic, energy storage applications, power and electricity, charging piles, automation robots, infrastructure, high-tech industries and other related fields.

Wind Power Generation

LINKWELL’s thermostats, heaters, and terminal blocks ensure reliability in wind farms’ harsh environments. Our IP65-rated ventilation systems prevent dust ingress, while corrosion-resistant wiring ducts maintain stable connections. Designed for extreme temperatures (-40°C to 85°C), these components minimize downtime, supporting continuous operation in remote, high-vibration installations.

Photovoltaic Power Generation

For solar energy systems, LINKWELL provides control transformers and junction boxes with high UV resistance. Our low-loss transformers optimize DC/AC conversion efficiency, and flame-retardant terminal blocks ensure safe, durable connections in inverters and combiner boxes, even under prolonged sunlight exposure.

Energy Storage

LINKWELL’s modular terminal blocks and heat-resistant wiring ducts streamline battery management systems (BMS). Customizable transformers enable precise voltage regulation, while compact ventilation fans prevent overheating in confined energy storage cabinets, enhancing safety and scalability for grid-scale solutions.

Electric Power

From substations to smart grids, LINKWELL’s HV/LV control transformers and panel heaters ensure stable power distribution. Anti-arc terminal blocks reduce short-circuit risks, and high-strength wiring ducts organize cabling in switchgear, meeting IEC standards for reliability in critical infrastructure projects.

Charging Pile

LINKWELL equips EV charging stations with shockproof terminal blocks, waterproof ventilation fans, and surge-protected control transformers. Our solutions withstand frequent plugging cycles and outdoor weather fluctuations, ensuring 24/7 operational stability and compliance with global EV charging safety protocols.

High-tech

LINKWELL ELECTRIC provides advanced electrical products tailored for high-tech applications, ensuring precision, reliability, and seamless integration with sophisticated systems. Our solutions empower industries such as semiconductors, AI, and IoT, supporting the rapid development of technology with superior performance and durability.

Infrastructure

LINKWELL ELECTRIC delivers high-quality products designed for urban construction, transportation networks, and smart city projects. With a focus on resilience and adaptability, our solutions enhance the reliability of critical infrastructure, contributing to the sustainable development of communities worldwide.

Automated Robot

Automation and robotics are transforming industries by improving productivity and precision. We supplies high-performance electrical components that meet the rigorous demands of automated robots, enabling seamless operation in manufacturing, logistics, and beyond. Our products enhance efficiency, reduce downtime, and support the advancement of intelligent automation systems.

Honest Reviews from our Customers

Jane Anderson

Global Electrical Solutions, Germany

“LINKWELL’s cooling fans and climate control systems have been highly reliable in our projects. Their certifications and strict quality control give us confidence, and fast delivery helps us keep schedules on track.”

we’re here to all your questions

Here you will find quick answers to the most common questions about our products, certifications, customization, and services. If you need more details, our team is ready to assist you anytime.

Enclosure air conditioners are widely used in electrical control cabinets, telecom equipment, CNC machines, and power distribution boxes. They ensure stable internal temperatures in high-heat environments, protecting sensitive electronics from overheating, dust, and humidity. Our factory designs enclosure cooling systems suitable for industrial automation, data centers, and outdoor cabinets, where continuous and reliable thermal management is critical for performance and equipment lifespan.

Choosing the right enclosure fan depends on cabinet size, heat load, airflow requirements, and environmental conditions. We recommend considering IP protection ratings, noise level, and energy efficiency. At our factory, we produce high-performance cooling fans engineered to maintain stable airflow while extending component life. For harsh or dusty environments, we advise pairing fans with filters or thermostats for better control and protection.

UL-certified products meet Underwriters Laboratories (UL) safety standards, recognized globally. For cabinet components, UL certification ensures fire resistance, electrical safety, and durability. As a factory, we provide UL-compliant cooling fans, heaters, transformers, and lighting solutions, giving customers confidence that our products meet international quality and safety requirements. UL-certified parts are especially important for projects in North America and other regions requiring strict compliance.

Cabinet components include cooling fans, enclosure air conditioners, thermostats, heaters, LED lights, control transformers, and wire ducts. Each plays a vital role in maintaining a stable operating environment for sensitive electrical equipment. As a manufacturer, we supply a complete range of enclosure accessories, enabling customers to design cabinets with optimal thermal management, safety, and energy efficiency, tailored for industrial, telecom, and automation applications.

Our cabinet cooler systems are engineered for reliable operation in ambient temperatures up to 55°C, depending on the model. For more extreme conditions, we recommend specialized high-temperature air conditioners or forced ventilation systems. By integrating thermostats and heaters, our solutions ensure a stable internal climate, preventing condensation in cold weather and overheating in hot environments. This balance helps extend the lifespan of electronic components.

Yes, we fully support on-site and third-party factory inspections. Customers are welcome to visit our Kunshan, Jiangsu facility to review production lines, quality control processes, and testing equipment. We also accommodate video inspections for overseas clients. Our factory follows ISO-certified quality management systems, ensuring every cabinet component—from fans to transformers—meets international standards before shipment. Transparency and reliability are core values of our manufacturing process.