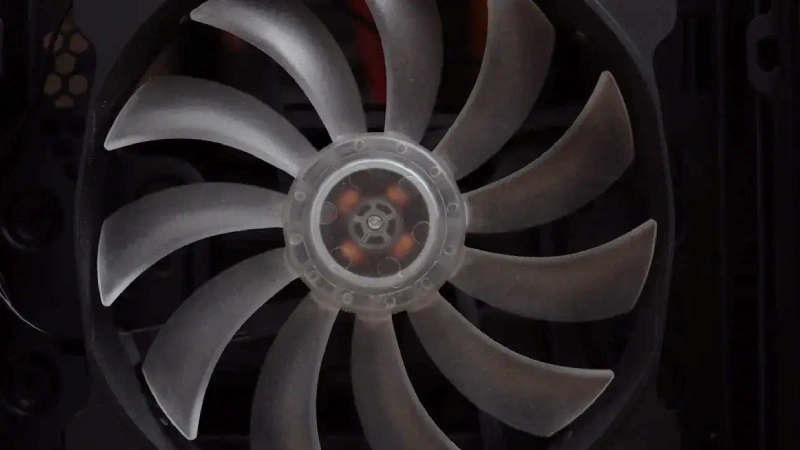

You might wonder what keeps your cabinet air conditioner running smoothly. Air conditioner fan motor bearings sit at the heart of the system. These small parts support the fan and keep it spinning without trouble. Air conditioner fan motor bearings reduce friction, letting the fan move easily and quietly. Recent engineering studies show that edge modification on air conditioner fan motor bearings cuts down wear and boosts reliability. Unlike compressor bearings, motor bearings focus on airflow, helping your control panel AC stay healthy and efficient.

Key Takeaways

- Air conditioner fan motor bearings are crucial for smooth operation. They reduce friction, allowing the fan to spin easily and quietly.

- Ball bearings last longer and handle higher speeds than sleeve bearings. Choose ball bearings for demanding environments to improve efficiency and reduce energy use.

- Regular maintenance, including lubrication, is essential for extending the lifespan of fan bearings. Inspect them every three to six months to prevent costly breakdowns.

- Watch for signs of bearing failure, such as odd noises or warm air from vents. Early detection can save you from bigger issues down the line.

- Selecting high-quality bearings, like those from Linkwell, ensures reliable performance and longevity for your air conditioning system.

Air Conditioner Fan Motor Bearings Types

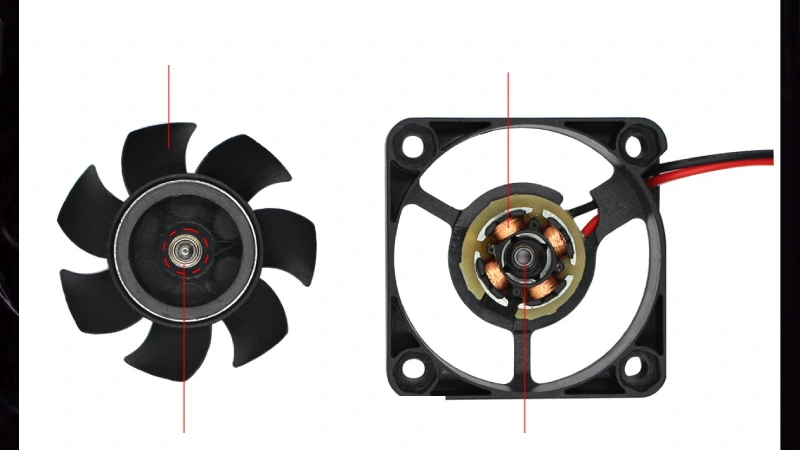

When you look inside a cabinet or control panel air conditioner, you will find two main types of bearings that keep the fan spinning: ball bearings and sleeve bearings. Each type has its own strengths and works best in different situations. Let’s break down what makes them unique and how they affect your air conditioner’s performance.

Ball Bearings

Ball bearings use small metal balls held between two rings. These balls roll as the fan turns, which cuts down on friction and helps the fan move smoothly. You will notice that ball bearings can handle higher speeds and heavier loads. They also last much longer than sleeve bearings, especially in tough industrial environments.

Here’s a quick comparison to help you see the difference:

| Feature | Ball Bearing |

|---|---|

| Lifespan | Up to 10 times longer than sleeve bearings |

| Noise Levels | Slightly higher than sleeve bearings |

| Starting Torque | Slightly higher |

| Operating Temperature | Up to 120°C (248°F) or more |

| Cost | Higher initial cost |

| Durability | More durable, handles higher loads and speeds |

| Friction | Lower, thanks to rolling motion |

| Mounting Orientation | Can be mounted horizontally or vertically |

Tip: Ball bearings are perfect if you need your air conditioner to run for long hours or in hot, demanding places. They also help reduce energy use because they create less friction.

You will often find ball bearings in industrial air conditioners because they keep the fan running smoothly, even when the system faces shocks or vibrations. They also need less maintenance over time.

Sleeve Bearings

Sleeve bearings work differently. They use a smooth sleeve that fits around the fan shaft. A thin layer of lubricant keeps things moving. This design makes sleeve bearings very quiet, especially at low speeds. They also cost less up front.

Here’s how sleeve bearings compare:

| Feature | Sleeve Bearing |

|---|---|

| Lifespan | 30,000 to 70,000 hours on average |

| Noise Levels | Lower, especially at low speeds |

| Starting Torque | Lower |

| Operating Temperature | Up to 70°C (158°F) |

| Cost | More cost-effective |

| Durability | Less durable, wears out faster |

| Friction | Higher, especially as lubricant breaks down |

| Mounting Orientation | Best for vertical mounting |

Note: Sleeve bearings work well if you want a quiet fan and your air conditioner does not face high temperatures or heavy use. But they may need more attention as they age, especially if the lubricant starts to wear out.

You might notice that sleeve bearings can wear down faster if your air conditioner runs hot or if you move the fan around. Over time, this can lead to more noise and even wobbling.

Recommended products

Linkwell Fan Bearings Features

When you choose Linkwell, you get fan bearings designed for reliability and long life. Linkwell uses top-grade bearings that meet strict industry standards. Many of their fans use dual ball bearings, which means you get smooth operation and less downtime.

Here are some features you will find in Linkwell’s fan bearings:

- High-performance motor systems for efficient cooling.

- NMB ball bearings for smooth, quiet operation and long lifespan.

- F-class insulation (IEC61858) for safety during heavy use.

- IP ratings for protection against dust and water.

- Temperature resistance up to 180°C for stable performance.

- Lifespans reaching 50,000 hours or more.

| Model | Bearing Type | Rated Voltage | Protection Code | Size (mm) | Lifespan (hours) |

|---|---|---|---|---|---|

| FK5527 | Ball | 220/240V, 110/120V | IP54 | 325x325x134 | 50,000+ |

Choosing the right fan bearings from Linkwell helps protect your investment and keeps your air conditioner running smoothly, even in the toughest industrial settings.

Importance of Fan Bearings in AC Performance

Efficiency and Airflow

You want your cabinet or control panel air conditioner to work at its best. The type and quality of fan bearings play a huge role in how well your cooling systems move air. When you use high-quality ball bearings, you get greater efficiency and a longer lifespan compared to ordinary sleeve bearings. Fans with ball bearings keep running even when temperatures rise above 90°F (32°C). Sleeve bearing fans, on the other hand, can fail quickly if they lose lubrication in hot conditions.

- High-quality ball bearings reduce friction, which means your fan spins more easily.

- Less friction leads to better airflow and lower energy use.

- Worn or poorly lubricated bearings increase friction, making the fan work harder and use more power.

| Bearing Type | Efficiency Impact | Lifespan Impact |

|---|---|---|

| High-Quality Ball | Reduces friction, enhances airflow | Longer lifespan under high temperatures |

| Ordinary Sleeve | Increases friction, decreases airflow | Shorter lifespan due to lubrication loss |

When you choose the right bearings, you help your cooling systems run smoothly and save energy. Research from the National Renewable Energy Laboratory shows that well-maintained fans can cut energy use by up to 30%. That’s a big difference for any industrial setup. You get better fan efficiency and more reliable fan performance, which keeps your equipment cool and your costs down.

Noise and Smooth Operation

No one likes a noisy air conditioner, especially in a control room or industrial workspace. The type of fan bearings you pick affects how much noise your cooling systems make. Sleeve bearings start out quieter, but they get louder as they wear out. Ball bearings and dual ball bearings might sound a bit louder at first, but they keep a steady noise level over time, even in changing temperatures.

| Bearing Type | Initial Noise Level | Noise Over Time | Best Use Case |

|---|---|---|---|

| Sleeve Bearings | Quieter | Louder faster | Offices, residential areas |

| Ball Bearings | Slightly louder | Consistent | Industrial, temperature changes |

| Dual Ball Bearings | Slightly louder | Consistent | Stable, demanding environments |

You want your cooling systems to run smoothly. Fan bearings support the fan shaft and cut down on friction. This keeps the fan spinning without jerks or stops. When you use the right bearings and keep them clean and well-lubricated, you get quiet, steady airflow. Advanced blade designs and top-notch bearings, like those from Linkwell, help keep noise low and airflow high. That means your workspace stays comfortable and your equipment stays protected.

System Lifespan

If you want your air conditioner to last, you need to pay attention to the bearings. The lifespan of your cooling systems depends a lot on how well you care for the fan bearings. Most blower motors last 10 to 15 years, but with regular maintenance, you can stretch that to 15 or even 20 years. Regular checks and timely lubrication help you spot problems early and keep your system running longer.

- Most blower motors last 15-20 years with proper care.

- Neglecting maintenance can lead to overheating and early failure.

- A well-maintained DX air conditioning unit can last at least 15 years, and up to 20 years with regular attention.

- Air conditioners can reach 15 to 20 years of service life if you keep up with maintenance.

Linkwell knows how important reliability is in industrial applications. That’s why their fans use ball bearing technology to minimize friction and boost bearing lifespan. Their fans feature tough aluminum housings and high-quality bearings, so you get a longer lifespan even in tough environments. When you choose Linkwell, you invest in cooling systems that keep working year after year.

Tip: Regular inspection and maintenance of your fan bearings can add years to your system’s lifespan and help you avoid costly breakdowns.

Identifying Fan Bearing Problems

Signs of Bearing Failure

You might notice your cabinet air conditioner acting up, but how do you know if the fan bearings are the problem? Here are some clear signs of worn bearings you should watch for:

- Warm air coming from the vents. The fan isn’t pushing cool air like it should.

- No airflow at all. Sometimes the fan stops spinning completely.

- Odd noises from the fan, such as buzzing or grinding. These sounds often mean trouble with the motor or fan blades.

- The fan starts and stops randomly. This could point to electrical or motor issues.

- The breaker keeps tripping. If your AC draws too much power, the bearings might be to blame.

If you spot any of these issues, it’s a good idea to check the fan bearings first. Catching problems early can save you from bigger headaches down the road.

Impact on AC Operation

When fan bearings start to fail, your air conditioner’s performance drops fast. Let’s look at some common causes of worn bearings and how they affect your system:

| Cause of Bearing Problems | Impact on Performance |

|---|---|

| Lubrication Failure | Overheating and less efficiency. |

| Contamination | Lower efficiency and possible failure. |

| Misalignment | Overheating and system disruptions. |

| Improper Mounting | Faster wear and high temperatures. |

Here’s what happens when the bearings go bad:

- The condenser fan motor fails, so airflow across the coils drops.

- The refrigerant doesn’t cool down enough, making it tough for your AC to keep the right temperature.

- The system may shut down often to avoid overheating.

You might also hear grinding or squealing noises, notice the outdoor unit overheating, or see your cooling efficiency drop. These problems can lead to frequent shutdowns, especially on hot days. If you keep your bearings in good shape, your air conditioner will run smoother and last longer.

Maintenance and Regular Maintenance Tips

Inspection and Lubrication

You want your air conditioner to run smoothly year after year. That means you need to follow regular maintenance routines for your fan bearings. Start by inspecting the bearings every few months. Look for signs of wear, noise, or overheating. If you notice anything unusual, it’s time to take action.

Lubrication plays a huge role in keeping your bearings healthy. You should always use high-quality grease for industrial air conditioners. Here are some top choices:

- NLGI #2 lithium-based grease

- Mobil Ronex

These greases help your bearings last longer and reduce friction. When you check the pillow block, shut down the fan and inspect the amount and condition of grease. Meticulous maintenance prevents forces that could shorten bearing life, especially in high-speed centrifugal fans. Regular maintenance is crucial because these machines work hard and wear out fast.

Tip: Never skip lubrication during your maintenance schedule. A well-lubricated bearing means less noise, smoother airflow, and fewer breakdowns.

Choosing and Replacing Bearings

Picking the right bearings makes a big difference in your air conditioner’s performance. You need to consider the temperature, humidity, and dust in your workspace. Linkwell helps you with this process by offering detailed information about different types of bearings. Their team gives you maintenance tips tailored to your environment.

When it’s time to replace bearings, follow these steps:

- Shut off the power and let the system cool.

- Remove the fan cover and locate the bearings.

- Check the size and type before ordering replacements.

- Install new bearings and apply fresh grease.

- Test the fan for smooth operation.

Linkwell’s technical support team is ready to guide you through every step. They make sure your equipment stays in top shape. You can rely on their maintenance guidelines for best results. Regular maintenance and the right bearings keep your air conditioner running efficiently.

Note: If you ever feel unsure about replacing bearings, reach out to Linkwell’s support team for expert advice.

You play a big part in keeping your cabinet air conditioner running strong. Fan motor bearings help your system stay efficient and reliable. When you take care of them with regular lubrication, you cut down on friction and heat. This simple step keeps your AC working longer and helps you avoid early failures.

| Best Practices for Industrial Fan Bearing Maintenance |

|---|

| Install Bearings Well: Ensure proper alignment and secure fasteners. |

| Lubricate Bearings Properly: Adhere to manufacturer guidelines for lubrication. |

| Check Alignment Regularly: Prevent wear and energy loss through regular checks. |

| Monitor Temperature & Vibration: Identify overheating or abnormal vibrations. |

| Prevent Contamination: Keep bearings clean from dust and moisture. |

You can see big improvements right away—lower bearing temperatures, less noise, and fewer breakdowns. When you choose trusted brands like Linkwell, you get quality bearings that help your air conditioner last. Make bearing care a priority and your equipment will thank you.

FAQ

What happens if you ignore fan bearing maintenance?

If you skip maintenance, your air conditioner can get noisy and lose efficiency. The fan might stop working. You could face expensive repairs. Regular checks help you avoid these problems.

How often should you lubricate fan motor bearings?

You should check and lubricate bearings every three to six months. If your AC runs in a dusty or hot place, inspect it more often. Proper lubrication keeps your fan running smoothly.

Can you replace fan bearings yourself?

You can replace fan bearings if you have basic tools and follow safety steps. Always turn off the power first. If you feel unsure, ask Linkwell’s support team for help.

Why do industrial ACs use ball bearings more than sleeve bearings?

Ball bearings last longer and handle higher speeds. Industrial ACs need reliable airflow and durability. Ball bearings work better in tough environments and help your system run efficiently.

What signs show your fan bearings need attention?

Listen for grinding or buzzing sounds. Feel for warm air instead of cool. Watch for the fan stopping or starting randomly. These signs mean you should inspect your bearings soon.