You want your control cabinet to run cool, save energy, and stay reliable. Counter flow heat exchanger and control cabinet air conditioning offer a smarter way to manage heat. With this setup, you can reach approach temperatures as low as 1-2°F, so you get more hours of free cooling than old-school systems. You might notice these technical highlights:

- Baffle spacing matters for better efficiency.

- Laminar counter flow setups beat parallel flows.

- Flow velocity and baffle spacing impact heat transfer and pressure drops.

- Hybrid optimization methods, like Artificial Neural Networks, push performance even further.

Key Takeaways

- Counter flow heat exchangers provide efficient cooling by maintaining a high temperature difference, leading to better heat transfer and energy savings.

- These systems fit well in tight spaces, maximizing cooling power without crowding your electronics, making them ideal for control cabinets.

- Using counter flow designs results in tighter temperature control, reducing the risk of overheating and extending the life of your equipment.

- Counter flow heat exchangers outperform parallel and crossflow systems, offering higher cooling capacity and better energy efficiency.

- Choosing a counter flow heat exchanger means enjoying more hours of free cooling, lower energy bills, and reliable performance for your control cabinet.

Counter flow heat exchanger and control cabinet air conditioning

What is a counter flow heat exchanger

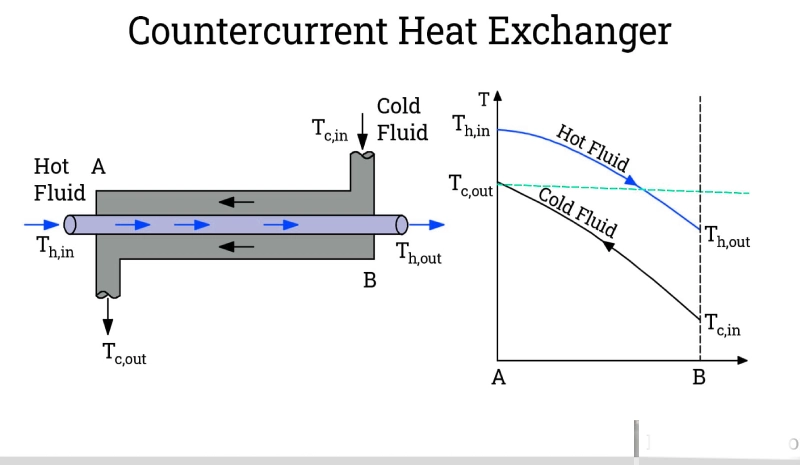

You might wonder what makes a counter flow heat exchanger special. In this system, two fluids move in opposite directions—one hot, one cold. This setup keeps a steady temperature difference along the entire path, which boosts heat transfer. You get more efficient cooling because the temperature gap never drops off.

- A counter flow heat exchanger works by letting the hot and cold fluids pass each other in reverse directions.

- This design keeps the temperature difference high, so heat moves from the hot side to the cold side more easily.

- In counter flow heat exchanger and control cabinet air conditioning, this means you can keep your electronics at the right temperature with less effort.

You will see these systems used in control cabinets because they deliver precise temperature control and high thermal efficiency. They help you get the most out of your cooling system, even when space is tight.

Why control cabinets need efficient cooling

Control cabinets pack a lot of electronics into a small space. All those components generate heat, and if you let it build up, you risk equipment failure. Efficient cooling is not just a nice-to-have—it is essential.

- Efficient cooling stops overheating, which can cause your equipment to break down.

- Keeping the temperature steady helps your electronics last longer.

- Studies show that about 65% of IT equipment problems come from poor cooling.

Tip: Heat can shorten the life of your electronics and hurt performance. If you do not remove heat fast enough, small issues can turn into big failures. That is why counter flow heat exchanger and control cabinet air conditioning is so important.

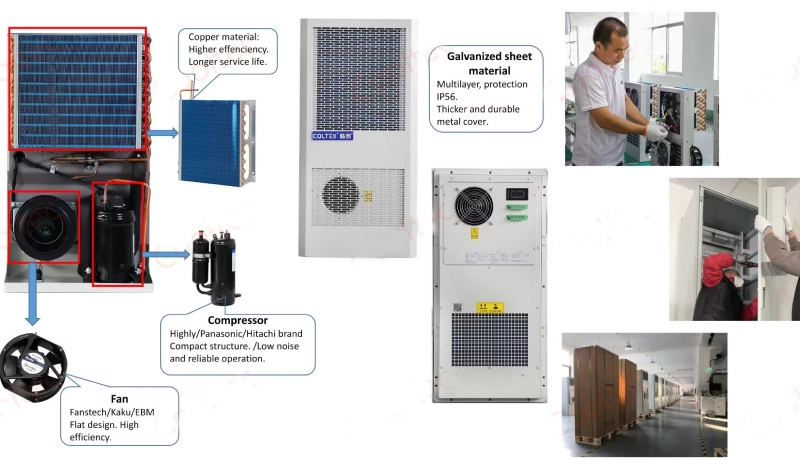

You also need solutions that fit into tight spaces. Take a look at some key features that make counter flow heat exchanger and control cabinet air conditioning a smart choice:

| Design Feature | Benefit for Space-Constrained Environments |

|---|---|

| High heat transfer area per unit volume | Enhances heat transfer efficiency in limited space |

| Compact design | Fits well in restricted spaces, ideal for control cabinets |

| High thermal effectiveness | Maximizes heat recovery, crucial in small installations |

| Allowable pressure drops | Ensures reliability and safety in confined areas |

Control cabinets face tough thermal challenges from both inside and outside. The counter flow heat exchanger and control cabinet air conditioning combo helps you tackle these problems head-on, keeping your systems cool, reliable, and efficient.

How counter flow heat exchangers work

Counterflow mechanism

You might wonder how the counterflow mechanism actually works inside your control cabinet. In a counter flow heat exchanger, the hot and cold air streams move in opposite directions. This setup keeps the temperature difference between the two streams high all the way through the unit. Because of this, you get more efficient heat transfer and better cooling.

Take a look at how the counterflow design boosts performance:

| Feature | Description |

|---|---|

| Heat Exchange Efficiency | The counterflow mechanism allows for a heat recovery efficiency of up to 95%. |

| Airflow Design | Airflows pass each other in a counterflow direction, maximizing heat exchange time. |

| Energy Recovery | The system effectively recycles energy, reducing overall energy consumption and improving COP. |

When you use a counter flow heat exchanger, you get more hours of free cooling. The system recycles energy, so your control cabinet uses less power. This means you save money and keep your electronics safe.

Tip: If you want high thermal efficiency and lower energy bills, the counterflow mechanism is your best friend.

Heat transfer efficiency

Let’s talk about heat transfer efficiency. In a counter flow heat exchanger, the temperature difference stays steady, so heat moves from the hot side to the cold side more easily. You get even heat transfer across the entire unit, which means your control cabinet stays cool without sudden temperature spikes.

Researchers have found that the counterflow mechanism streamlines the simulation of thermal performance in cooling towers. Experiments show that the cooling tower effectiveness matches predicted results within about 5%. When you use spiral coils, you get even better mixing and higher convective heat transfer coefficients. This leads to high thermal efficiency and better temperature control.

- You get improved temperature distribution.

- The system handles turbulence well, so heat transfer stays strong.

- High thermal efficiency means your control cabinet works better and lasts longer.

If you want reliable cooling and high thermal efficiency, the counter flow heat exchanger is a smart choice. You get steady heat transfer, better energy savings, and a safer environment for your electronics.

Benefits of counter flow heat exchanger in control cabinet air conditioning

Higher COP and energy savings

You want your control cabinet to run efficiently and save on energy bills. The counter flow heat exchanger gives you a real boost in both areas. When you use this design, you get a higher coefficient of performance (COP), which means your system does more cooling with less energy. That’s a win for your wallet and for the environment.

- Counter flow heat exchangers provide about 20% higher cooling capacity than cross-flow systems.

- You can expect 15%–23% higher dew-point and wet-bulb effectiveness under the same conditions.

- These systems show enhanced effectiveness as you increase the mass flow rate, so you get better cooling when you need it most.

You might notice that cross-flow systems sometimes have a slightly higher energy efficiency ratio, but the overall performance and cooling power of the counter flow heat exchanger make it the top choice for control cabinets. You get more hours of reliable operation and less risk of overheating.

Note: Many counter flow heat exchangers meet strict industry standards like UL certification per ANSI Standard 1995 and AHRI performance certification. These certifications give you peace of mind that your system will perform as promised.

Better temperature control

Precise temperature control keeps your electronics safe and extends their life. The counter flow heat exchanger helps you avoid hot spots and sudden temperature swings. You get steady, even cooling across the whole cabinet.

Here’s what studies have found about temperature control in these systems:

| Study | Findings |

|---|---|

| Zhao et al. | Developed a PI-lead compensation controller for precise temperature control, showing the value of pre-control for high precision. |

| Lawton et al. | Introduced a thermal gradient attenuator, which improved temperature stability in liquid flow systems. |

| Microchannel Heat Exchangers | Showed strong ability to dissipate heat in compact spaces, making them ideal for precise temperature management. |

You can see how these features translate into real-world benefits. Your control cabinet stays at the right temperature, even when the workload changes. This level of control means fewer failures and longer equipment life.

Space efficiency

Space is always tight inside a control cabinet. You need a cooling solution that fits without crowding your electronics. The counter flow heat exchanger delivers high efficiency in a compact package. You get more cooling power per square inch, so you can use your space for what matters most—your equipment.

- The design offers a high heat transfer area per unit volume, which boosts efficiency in small spaces.

- You get superior thermal performance compared to parallel flow and cross flow designs.

- Effectiveness values for counter flow configurations range from 1.036 to 1.059, showing real improvements in cooling performance.

You also benefit from designs that follow strict standards, like UL Type 4(X) certification and GR-487 compliance. These certifications mean your cooling system is safe, reliable, and ready for tough environments.

Tip: When you choose a counter flow heat exchanger, you get a cooling system that works harder, saves energy, and fits where you need it. That’s smart engineering for your control cabinet.

Comparing counter flow heat exchanger to other types

Parallel flow vs. counter flow

When you look at parallel flow and counter flow heat exchangers, you notice big differences in heating performance. In a parallel flow design, both fluids enter from the same side and move together. This setup causes the temperature difference to drop quickly, which lowers heating efficiency. You might see uneven heating and less control over the process.

A counter flow heat exchanger works differently. The fluids enter from opposite ends and move against each other. This keeps the temperature difference high along the whole path. You get better heating transfer, higher efficiency, and tighter control. The result is improved performance for your control cabinet.

Take a look at this table to see how the two compare:

| Metric | Counter-Flow Exchanger | Parallel Flow Exchanger |

|---|---|---|

| Cooling Capacity | 20% higher | — |

| Dew-Point Effectiveness | 15%-23% higher | — |

| Energy Efficiency (COP) | — | 10% higher |

Counter flow heat exchangers enhance the temperature difference between fluids throughout their flow paths. This leads to much better heating transfer efficiency than parallel flow designs. You get lower energy use and more stable heating performance.

Crossflow vs. counter flow

Crossflow heat exchangers send fluids at right angles to each other. This design makes installation easier and costs less. However, you trade off heating performance and efficiency. Crossflow models often struggle to match the heating performance of counter flow heat exchangers, especially in control cabinets.

- Crossflow heat exchangers are less thermally efficient, especially for high heating performance needs.

- Counter flow heat exchangers reach up to 92% efficiency and deliver better temperature control, even at lower flow rates.

- Crossflow units are longer and cheaper but cannot match the compact size and heating performance of counter flow models.

Here’s a quick comparison:

| Feature | Crossflow Heat Exchanger | Counter-flow Heat Exchanger |

|---|---|---|

| Heat Transfer Efficiency | Lower | Higher |

| Effectiveness | Lower | Higher |

| Temperature Approaches | Wider outlet difference | Closer outlet temperatures |

| Pressure Drop | Lower | Higher |

| Size | Longer | More compact |

| Equipment Cost | Lower | Higher |

When you choose a counter flow heat exchanger, you get better heating performance, higher efficiency, and a more reliable system. You also spend less time on maintenance because these units have fewer moving parts. If you want the best performance for your control cabinet, the counter flow design stands out.

You want your control cabinet to stay cool, run efficiently, and last longer. Counter flow heat exchangers help you reach these goals. They boost thermal efficiency by keeping a strong temperature gradient. You also get better reliability because the design reduces thermal stress. Here’s why you should consider this solution:

- You save space and energy with a compact, high-performance design.

- The system delivers tighter temperature control, which protects your electronics.

- You meet strict performance standards with less effort.

Choosing a counter flow heat exchanger gives your control cabinet a real advantage.

FAQ

How does a counter flow heat exchanger improve air conditioning in control cabinets?

You get better air conditioning because the counter flow design keeps the temperature difference high. This setup allows for efficient heat exchange, so your cabinet stays cool. You use less energy and enjoy more reliable air conditioning.

Can I use a counter current heat exchanger for high efficiency in small spaces?

Yes, you can. A counter current heat exchanger fits well in tight spots. It delivers high efficiency and effective heat exchange. You get strong air cooling without taking up much room in your control cabinet.

What makes air conditioning with counter flow heat exchangers more reliable?

You avoid hot spots because the air moves in opposite directions. This method gives you even air temperature and better conditioning. Your electronics stay safe, and you get steady performance from your air conditioning system.

How does air flow affect efficient heat exchange in control cabinet air conditioning?

Air flow matters a lot. When air moves smoothly in a counter flow heat exchanger, you get efficient heat exchange. This keeps your cabinet cool and helps your air conditioning work better.

Why should I choose counter flow over other air conditioning methods?

You get more hours of free cooling and better air temperature control. Counter flow air conditioning offers effective heat exchange and higher efficiency. Your system lasts longer and needs less maintenance.