A temperature control panel helps you keep your systems running smoothly by monitoring and adjusting temperature levels within your equipment. If you work in a factory, data center, or any busy facility, you know how important temperature control is for safety and efficiency. Just look at these numbers:

| Innovation | Benefit |

|---|---|

| AI-enabled temperature systems | Reduce temperature swings by up to 50%, boosting product quality and saving energy. |

| Wireless controllers | Cut installation costs by 30–40% and work well in tough environments. |

| Smart control strategies | Achieve 20–30% energy savings through intelligent management. |

Linkwell stands out as a trusted partner, offering UL and IEC certified panels that meet strict safety and quality standards. Many global companies rely on Linkwell for reliable temperature solutions.

Key Takeaways

- Temperature control panels ensure precise temperature regulation, enhancing safety and efficiency in various industries.

- Using advanced technology like PID controllers helps reduce temperature swings, saving energy and extending equipment life.

- Linkwell panels offer reliable performance with certified safety features, making them suitable for tough environments.

- Regular maintenance and monitoring of temperature control panels prevent costly breakdowns and ensure smooth operations.

- Choosing the right temperature control panel tailored to your needs can significantly improve operational effectiveness and reduce costs.

Temperature Control Panel Overview

What is a Temperature Control Panel

A temperature control panel is your go-to solution for keeping equipment and processes at the right temperature. You use it to manage heating or cooling in all sorts of systems, from industrial machines to medical storage rooms. This panel acts like the command center for temperature, making sure everything stays within safe and efficient limits.

You might wonder what sets a temperature control panel apart from other control panels. Take a look at this table to see the main features that make it unique:

| Feature | Description |

|---|---|

| Accuracy | Maintains precise temperature without overworking your equipment. |

| Compatibility | Works with many types of heating and cooling devices. |

| Components | Includes specialized parts for effective temperature regulation. |

| Control Types | Offers both manual (open loop) and automatic (closed loop) adjustments. |

You’ll find temperature control panels in places where temperature really matters. Here are some common systems that rely on them:

- Medical storage

- IT equipment rooms

- Industrial production lines

Advanced temperature control systems help you keep tight tolerances and react quickly to changes. They’re especially important in areas where you can’t afford temperature swings—like medical storage, IT rooms, and busy production lines.

Linkwell Electrics stands out in this field. With over 15 years of experience and a team of more than 160 professionals, Linkwell delivers high-quality electrical control panels that meet strict international standards like IEC 61439 and UL 508A. You get products made from top materials, such as stainless steel and polycarbonate, and you benefit from modular designs that make installation and future upgrades easy.

Key Functions of Temperature Control Panels

When you use a temperature control panel, you get more than just basic temperature management. These panels perform several key functions that help your business run smoothly:

- Safety and Compliance: You protect your products and equipment. For example, in food processing, the panel prevents spoilage. In healthcare, it keeps sensitive devices safe.

- Energy Efficiency: You save money by optimizing energy use. The panel helps your equipment last longer and reduces your utility bills.

- Operational Effectiveness: You keep your processes running at the right temperature, which means fewer breakdowns and better results.

You’ll see temperature control panels in many industries, including:

- Industrial applications

- Commercial buildings

- Medical facilities

- Laboratories

- Automotive manufacturing

The demand for these panels keeps growing. Companies want smarter, more efficient solutions. Trends like stricter energy regulations, new technology (like IoT and real-time monitoring), and the push for automation all drive the need for advanced temperature control. Businesses also look for panels that integrate easily with their existing systems and help them stay competitive.

If you choose Linkwell, you get panels with grounding design, explosion-proof certification, and a 100% on-time delivery record. The modular design supports DIN rail mounting, so you can expand or rewire as your needs change. You can trust Linkwell to deliver reliable, safe, and efficient temperature control solutions for your business.

How Temperature Controllers Work

Temperature Control Units and Sensors

When you look inside a temperature control panel, you’ll find a mix of smart devices working together to keep everything at the right temperature. The heart of this setup is the temperature control unit, which acts as the brain for the whole system. It constantly checks the temperature and decides when to heat or cool.

You’ll see several types of temperature sensors in modern panels. Each one has its own strengths, and you’ll often find them in different industries:

- Thermocouples

- RTDs (Resistance Temperature Detectors)

- Thermistors

- Semiconductor-based integrated circuits (IC)

- Thermopiles (infrared thermal sensors)

- Digital thermal sensors

Thermocouples are everywhere. They work fast and handle a wide range of temperatures, so you’ll spot them in factories and even in home appliances. These sensors use the Seebeck effect, which means they create a small voltage when the temperature changes. RTDs, especially those made with platinum, are super accurate. Their resistance changes as the temperature shifts, and they’re great for jobs where you need precise readings. Thermistors are sensitive and pick up even tiny changes in temperature, making them perfect for tight control.

Accuracy matters a lot in temperature control. Platinum RTDs can be accurate within +/- 0.3°C at 0°C, while some thermocouples might have a deviation of +/- 2.2°C. If you need even tighter control, Class A RTDs can get as close as +/- 0.15°C. International standards like IEC 60584-1:2013 and IEC 60751:2008 help make sure these sensors meet strict tolerance bands. Calibration can make them even more reliable.

Tip: The right temperature sensor helps you avoid costly mistakes and keeps your equipment running longer.

Step-by-Step Operation of Temperature Controllers

So, how does a temperature controller work? Let’s break it down step by step, so you can see how everything comes together to keep your system at the desired temperature.

- Unpack and Inspect: You start by unpacking your temperature control unit and checking for any damage.

- Mount the Controller: Next, you mount the controller inside your panel or cabinet.

- Wire the Controller: You connect the wiring, making sure each terminal matches the diagram.

- Connect Sensors: Attach the temperature sensor to the controller. This sensor will keep an eye on the actual temperature.

- Power Up: Turn on the system and make sure everything lights up as expected.

- Initial Configuration: Set your setpoint, which is the temperature you want to maintain.

- PID Tuning: If you’re using a pid temperature controller, you’ll tune the PID settings. This step helps the controller react quickly and accurately to changes, so you don’t overshoot or lag behind.

Here’s what happens during normal operation:

- The temperature sensor measures the current temperature and sends that data to the controller.

- The controller compares this reading to your setpoint.

- If the temperature is too high, the controller tells the system to cool. If it’s too low, it signals the system to heat.

- The controller uses feedback mechanisms to keep things steady. Sensors like thermistors and RTDs provide real-time updates, while the control system calculates the difference between the setpoint and the actual temperature.

- Actuators, such as heaters or thermoelectric devices, respond to the controller’s commands and adjust the heat output.

If you use digital temperature controllers, you get even more precision. These controllers can store multiple setpoints, run smart monitoring, and even connect to your building’s automation system.

Linkwell’s temperature control panels stand out because they use certified components and offer smart monitoring features. Here’s a quick look at what sets them apart:

| Feature/Certification | Description |

|---|---|

| UL, CE, RoHS | Meets strict safety and quality standards |

| ATEX, IEC/EN 60079 | Works in hazardous locations and tough industrial environments |

| Customization | Lets you choose voltage, size, airflow, and branding |

| Smart Monitoring | Gives you programmable controls for better energy efficiency and equipment safety |

With Linkwell, you get a temperature control panel that’s ready for anything. You can trust the certified parts, enjoy easy customization, and benefit from smart monitoring that keeps your equipment safe and efficient.

Note: A well-tuned PID controller helps you avoid temperature swings, save energy, and extend the life of your equipment.

If you want to keep your processes running smoothly, understanding how temperature controllers work is key. You’ll get better results, fewer breakdowns, and more control over your environment.

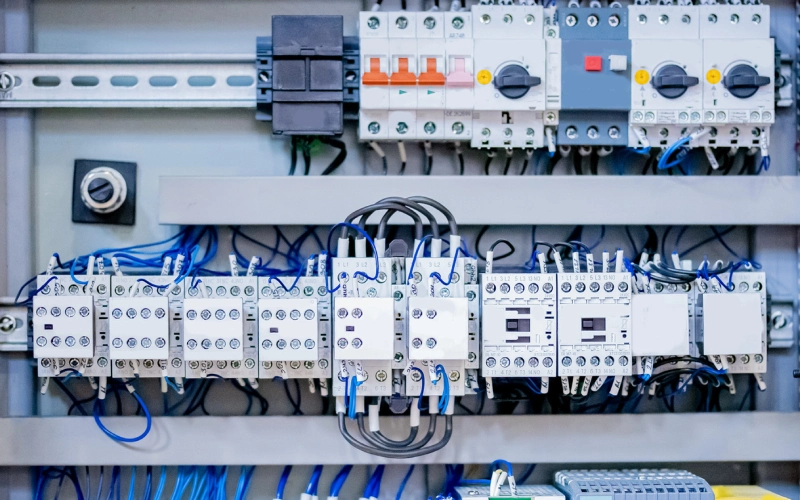

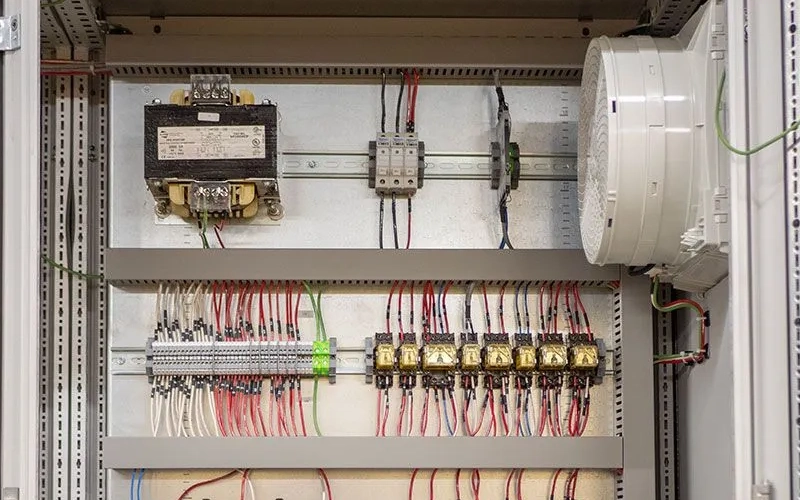

Main Components of Temperature Control Panels

Temperature Controller and Thermostat

When you open a temperature control panel, you’ll see several important parts working together to keep your system running smoothly. The temperature controller acts as the brain. It constantly checks the temperature and decides when to heat or cool. You set your desired temperature, and the controller uses sensors to measure the current temperature. If the temperature drifts from your set point, the controller sends signals to heating or cooling elements to bring it back in line. This process keeps your environment stable and safe.

The thermostat works closely with the temperature controller. It acts as a switch, turning the heating or cooling devices on or off based on the temperature. In many panels, you’ll also find a pid temperature controller. This advanced device uses a special algorithm called PID (Proportional, Integral, Derivative) to make tiny adjustments. With a pid, you get more precise temperature control and fewer swings above or below your target.

Here’s a quick look at some essential components and what they do:

| Component | Function |

|---|---|

| Power Supply | Delivers power to all control electronics and current sources. |

| Thermoelectric | Moves heat using current flow, can cool or heat depending on direction. |

| Resistive Heater | Produces heat through current, relies on the environment to get rid of extra heat. |

You’ll also find relays, which act like traffic cops, directing power to the right devices at the right time. Sensors, such as RTDs or thermocouples, feed real-time temperature data to the controller. All these parts work together to keep your temperature control units accurate and reliable.

Electrical Devices and Safety Features

You want your temperature control panel to be safe and dependable. That’s why Linkwell uses certified parts and modular layouts. Each panel follows strict industry standards, including:

- UL508A Certification for industrial control panels

- IEC standards for safety and reliability

- NFPA 79 for proper grounding and wiring

Linkwell’s modular design means you get clear labeling, terminal strips, and easy installation. Cabinets are IP-rated, so you can use them outdoors or in dusty places without worry.

Safety features matter, too. Here are some best practices you should follow:

- Place heat-sensitive parts lower in the panel to use natural convection.

- Choose a cabinet big enough for good airflow and heat dissipation.

- Calculate your heat load carefully to pick the right cooling solution.

- Monitor your equipment to catch problems early.

- Prevent condensation with proper sealing and humidity control.

With these features, you protect your system from overheating, short circuits, and other hazards. You also make sure your temperature control stays steady, even in tough environments. Linkwell’s panels give you peace of mind with built-in grounding, short-circuit protection, and reliable connections. You get a temperature control unit that’s ready for anything.

Types of Temperature Control Panels

When you look at temperature control panels, you’ll notice that not all of them work the same way. Some use simple methods, while others rely on advanced technology to keep your temperature steady. Let’s break down the main types so you can see which one fits your needs.

On/Off Temperature Control

On/Off temperature control is the most basic method you’ll find. Think of it like a light switch. The temperature controller turns the heater or cooler on when the temperature drops below or rises above your set point. Once the temperature hits your target, the system shuts off. This method works well for simple applications where you don’t need super precise control.

Here’s a quick look at how On/Off control stacks up:

| Advantages | Disadvantages |

|---|---|

| Cost-effectiveness | Issues with precision |

| Simplicity | Potential temperature swings |

| Widely used | Not for precise control |

You might use On/Off control in small heating systems or basic cooling setups. It’s easy to set up and doesn’t cost much. However, you may notice the temperature swings a bit, which isn’t ideal if you need tight control.

Proportional and PID Temperature Controllers

If you want more accuracy, you’ll want to check out proportional and PID temperature controllers. Proportional controllers adjust the amount of heat based on how far the temperature is from your set point. The closer you get, the less heat the system adds. This helps reduce swings and keeps things steadier.

PID controllers take things even further. PID stands for Proportional, Integral, and Derivative. This type of controller looks at the current temperature, how long it’s been off target, and how quickly it’s changing. It makes smart adjustments to keep your temperature right where you want it. You’ll see PID temperature controllers in places where precision matters, like industrial ovens or sensitive lab equipment.

Here’s a table to help you compare:

| Feature/Aspect | Proportional Controllers | PID Controllers |

|---|---|---|

| Response to Error | Immediate response | Combines immediate, past, and future predictions |

| Error Correction | Current error only | Current, past, and predicted errors |

| Stability | May have steady-state error | Reduces steady-state error |

| Use Cases | Simple heating systems | Industrial and precise applications |

| Performance | Less stable under changing conditions | More stable and responsive |

Tip: If you need to keep your temperature steady for critical equipment, a PID controller is your best bet.

No matter which method you choose, Linkwell offers customizable temperature control solutions for every industry. You get panels certified for safety and reliability, including CE, UL, RoHS, and ATEX. Linkwell’s designs help you maintain stable temperatures, protect your equipment, and lower your energy bills. You can trust their panels to handle heat, cool, and everything in between.

Applications and Benefits of Temperature Control

Industrial Uses and Efficiency

You see temperature control panels everywhere in industry. These panels help you manage temperature in furnaces, ovens, autoclaves, incubators, heating chambers, and vacuum drying or environmental chambers. You rely on them to keep your equipment running safely and efficiently.

In the pharmaceutical industry, temperature control keeps your products within strict quality standards. You avoid costly mistakes and keep your equipment working smoothly. In chemical manufacturing, you use temperature control to create safe and efficient reactions. This improves your process and helps you deliver better results. Oil and gas operations depend on temperature control to optimize extraction and processing. You get more efficiency and better output.

Temperature control panels let you adjust heat quickly. You can use a pid controller to fine-tune your system. This means you keep your temperature steady, even when conditions change. You avoid overheating and prevent damage to your equipment. When you need to cool things down, the panel responds fast. You protect your products and save energy.

Tip: A well-designed temperature control panel helps you reduce downtime and improve your bottom line.

Linkwell Electrical Control Panel Advantages

When you choose Linkwell, you get more than just a temperature control solution. You get reliability, safety, and support that make your job easier. Operators have reported nearly 100% uptime during winter after installing Linkwell heaters. You keep your system running and build trust with your users.

Charging stations using Linkwell panels have seen charging times drop from three hours to one hour at -7°C. You double your service capacity and keep your customers happy. Linkwell heaters also prevent electrical short circuits and corrosion. You create a safer environment for everyone.

You protect your assets for the long term. By controlling humidity and temperature, Linkwell panels extend the life of your equipment. You spend less on maintenance and avoid unexpected breakdowns. Linkwell gives you energy-efficient designs, certified safety, and 24/7 support. You get peace of mind and better results every day.

| Advantage | What You Get |

|---|---|

| Energy Efficiency | Lower power bills and reduced heat loss |

| Operational Reliability | Fewer breakdowns and consistent performance |

| Safety Assurance | Protection against short circuits and corrosion |

| Long-term Asset Protection | Extended equipment lifespan |

| Expert Support | Fast help and custom solutions |

If you want a temperature control panel that works for you, Linkwell delivers every time.

You now know why temperature control panels matter for your business. Here are the key takeaways:

- You get precise temperature regulation and better energy efficiency.

- Your equipment stays protected and lasts longer.

- You enjoy safer operations and smoother processes.

- You can monitor and control everything remotely.

With Linkwell, you benefit from digital monitoring, proactive alerts, and real-time data. You also get expert advice, strong after-sales support, and a wide range of cooling solutions. Reach out to Linkwell today to find the right temperature control panel for your needs!

FAQ

How do I choose the right temperature control panel for my facility?

Start by listing your equipment and their temperature needs. Think about your environment and safety requirements. You can contact Linkwell for expert advice and custom solutions that fit your exact needs.

Can I install a temperature control panel myself?

You can handle basic installation if you have electrical experience. For complex setups or industrial systems, you should call a professional. Linkwell offers support and guidance to make sure you get it right.

What maintenance does a temperature control panel need?

Check your panel every six months. Look for dust, loose wires, or signs of overheating. Clean filters and test sensors. Regular maintenance keeps your system safe and running smoothly.

Are Linkwell panels suitable for outdoor use?

Yes! Linkwell offers weatherproof panels with IP55 to IP67 ratings. You can use them outdoors or in harsh environments. Just pick the right enclosure for your application.