When you look inside a control cabinet, you find several key parts working together to keep everything running safely and smoothly. These include power supplies, circuit breakers, disconnect switches, relays, programmable logic controllers, digital meters, pushbuttons, and the cabinet enclosure itself. Each of these control cabinet components plays a role in protecting your equipment, organizing power flow, and making automation easy. Linkwell offers trusted solutions for all these needs, helping you build reliable and efficient systems.

Key Takeaways

- Control cabinets house essential components like power supplies, circuit breakers, and PLCs, ensuring safe and efficient operation of automated systems.

- Regular maintenance of control cabinets, including inspections every six months, helps prevent downtime and extends equipment life.

- Linkwell offers a range of solutions, including cooling fans and modular terminal blocks, to enhance the performance and organization of control cabinets.

- Understanding the role of each component, such as the main breaker for safety and PLCs for automation, is crucial for effective system management.

- Choosing certified products from Linkwell ensures compliance with safety standards, reducing risks and improving reliability in industrial settings.

What Is an Electrical Control Cabinet

Definition and Purpose

When you step into a factory or a power station, you will notice an electrical control cabinet at the heart of every automated system. You use an electrical control cabinet to house all the important devices that keep machines running safely. This cabinet acts as a central hub for power distribution, automation, and protection. You rely on it to manage the flow of electricity, control motors, and keep sensors working.

You find that an electrical control cabinet does more than just hold wires and switches. It protects sensitive electronics from dust, moisture, vibration, and extreme temperatures. You can trust it to shield your equipment and keep workers safe. Inside, you see circuit breakers, relays, PLCs, and meters. Each part works together to make sure your machines operate smoothly. You use an electrical control cabinet to organize power, control signals, and automate processes.

You also notice that an electrical control cabinet helps prevent downtime. It keeps everything neat and easy to maintain. You can quickly spot problems and fix them before they get worse. This means you spend less time troubleshooting and more time getting work done. You depend on an electrical control cabinet to keep your business running efficiently.

Linkwell’s Role in Control Cabinet Solutions

You want your electrical control cabinet to perform at its best. Linkwell gives you a wide range of solutions that meet industry standards. You can choose cooling fans, air conditioners, thermostats, and heaters to keep your cabinet at the right temperature. You use control transformers for precise voltage regulation. Wiring ducts and modular terminal blocks help you organize cables and connections.

Here’s a quick look at what Linkwell offers for your electrical control cabinet:

| Solution Type | Description | Applications |

|---|---|---|

| Cooling Fans | Prevent overheating in confined spaces | Energy storage cabinets |

| Enclosure Air Conditioners | Maintain stable operating temperatures for sensitive equipment | Industrial automation, telecom |

| Thermostats | Regulate temperature to enhance safety and efficiency | Various applications |

| Heaters | Provide warmth to prevent equipment failure in cold environments | Energy storage, outdoor use |

| Control Transformers | Ensure precise voltage regulation for sensitive devices | Telecom, industrial automation |

| Wiring Ducts | Organize and protect cabling in control cabinets | Smart grids, substations |

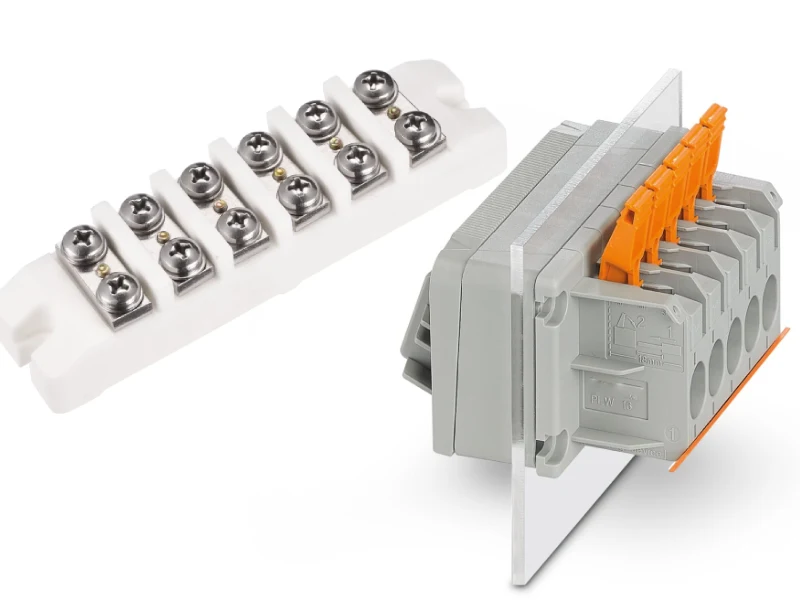

| Modular Terminal Blocks | Streamline battery management systems | Energy storage systems |

| Anti-arc Terminal Blocks | Reduce short-circuit risks in electrical installations | Critical infrastructure projects |

| Shockproof Terminal Blocks | Ensure safety in EV charging stations | Electric vehicle infrastructure |

| Waterproof Ventilation Fans | Protect against outdoor weather fluctuations | EV charging stations |

| Surge-protected Control Transformers | Safeguard against electrical surges in critical applications | EV charging stations |

You get reliable products that help your electrical control cabinet stay safe, organized, and efficient. Linkwell supports you with solutions that match your needs, whether you work in energy, telecom, or manufacturing.

Key Control Cabinet Components

When you open an electrical control panel, you see a mix of devices working together. Each part has a job, and together they keep your system safe, organized, and running smoothly. Let’s break down the main control cabinet components you’ll find inside.

Power Distribution and Protection

You start with power distribution and protection. These control cabinet components make sure electricity flows safely and reliably. Here’s a quick look at what you’ll find:

- Main Breaker: This acts as the main switch. You use it to cut off all power during maintenance or emergencies. It protects your system from overloads.

- Bus Bars: These distribute power to different devices. They handle high currents and prevent overheating.

- Branch Circuit Breakers: Each one protects a specific part of your system. If something goes wrong, only that section shuts down.

- Neutral and Ground Bars: These provide safe paths for electrical current. They help prevent shocks and electrical hazards.

- Surge Protection Devices: You rely on these to guard sensitive equipment from voltage spikes.

- Panel Enclosure: This keeps all the electrical control panel components safe from dust, moisture, and accidental contact.

Tip: Linkwell’s electrical control panels come with certified breakers, surge protectors, and robust enclosures. You get reliable power distribution and protection for any application.

Control Core and Automation

The control core is the “brain” of your system. These control cabinet components handle all the logic and automation control.

- Programmable Logic Controllers (PLCs): You use PLCs to process inputs from sensors and send commands to other devices. They make automation easy and reliable.

- Sensors: These monitor things like temperature, pressure, or speed. They send real-time data to your PLC.

- Human-Machine Interface (HMI): This is your touchscreen or display. You use it to check status, set parameters, and view alarms.

- Industrial Computers: For complex tasks, you might use an industrial PC for advanced data processing.

You’ll find that Linkwell’s electrical control panels support a wide range of PLCs and HMIs, making automation control simple and efficient.

Actuation and Switching Devices

You need actuation and switching devices to control motors, pumps, and other loads. These control cabinet components respond quickly to commands from your PLC.

| Type of Device | Typical Response Time |

|---|---|

| Mechanical Limit Switches | Milliseconds |

| Magnetic Limit Switches | Microseconds |

| Optical Limit Switches | Nanoseconds |

- Contactors: You use these to switch high-power loads like motor drives. They handle frequent on/off cycles.

- Relays: These act as electrically controlled switches. You use them for signal conversion and isolation.

- Soft Starters & Variable Frequency Drives (VFDs): These help you start motors smoothly and control their speed. VFDs are essential for energy savings and precise process control.

Linkwell’s electrical control panels are designed to integrate seamlessly with contactors, relays, and motor drives, giving you reliable switching and actuation.

Wiring and Connection Elements

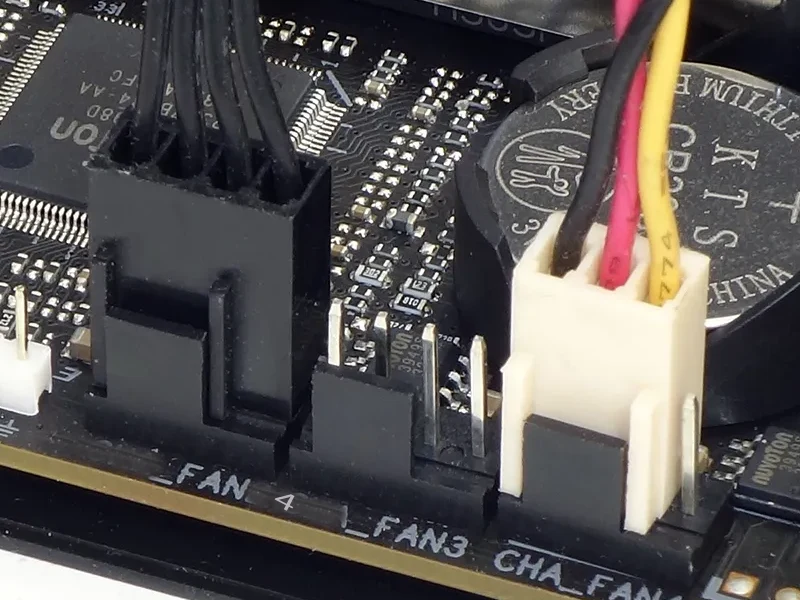

Wiring and connection elements form the “nervous system” of your control cabinet. You need these control cabinet components to connect everything neatly and safely.

- Terminal Block: This is where you connect wires from inside and outside the cabinet. It makes installation and troubleshooting much easier.

- Cables: You use different colors and sizes to organize power and signal wires.

- Wire Ducts: These keep your cables tidy, improve airflow, and make your cabinet look professional.

Note: Linkwell offers modular terminal blocks and cable management solutions that help you build organized, easy-to-maintain electrical control panels.

Measurement and Signal Conditioning

Accurate measurement and signal conditioning are key for reliable automation. These control cabinet components help you get clean, accurate data.

- Use universal signal conditioners to convert and isolate signals from sensors.

- Proper grounding and shielding reduce electrical noise.

- Isolate signals to prevent interference and keep your measurements accurate.

- Monitor noise with a portable oscilloscope.

- Regularly calibrate your system to ensure everything works as expected.

You’ll often see current transformers, voltage meters, and signal isolators inside electrical control panels. These devices help you monitor and control your process with confidence.

Enclosure and Environmental Management

The enclosure and environmental management systems protect your investment. These control cabinet components keep everything running at the right temperature and humidity.

- Enclosure: Shields your equipment from dust, water, and impacts.

- Cabinet Air Conditioner: Keeps the inside cool, even in hot or humid environments. Overheating can cause failures and expensive downtime.

- Cabinet Fan: Moves air and helps prevent hot spots.

- Heaters and Thermostats: Stop condensation and keep things dry in cold weather.

- Enclosure Light: Makes it easy for you to see inside during maintenance.

Did you know? Nearly 40% of data center failures come from cooling problems. Linkwell’s cabinet air conditioners and fans help you avoid costly outages by keeping your control cabinet components at the right temperature.

Here’s a table to help you see how industry standards group the primary components of a control panel:

| Component Category | Description |

|---|---|

| Enclosures | Protects internal components from environmental factors like dust and moisture. |

| Power Supply Units | Converts AC power to DC, ensuring stable operation of control components. |

| Main Disconnect Switches | Safely isolates the panel from power during maintenance or emergencies. |

| Circuit Breakers and Fuses | Provides overcurrent protection to prevent damage from short circuits or overloads. |

| Contactors and Relays | Switches high-power loads and handles lower-power signal switching for automation. |

| Programmable Logic Controllers | Acts as the control center, executing logic and managing inputs/outputs for automation tasks. |

| Terminal Blocks and Wiring | Organizes wiring and provides secure connection points, improving safety and compliance. |

When you choose Linkwell, you get all these control cabinet components in one place. You can trust their electrical control panels, cabinet air conditioners, enclosure lights, and cabinet fans to keep your system safe, organized, and efficient.

Functions of Industrial Control Panel Components

Power Supply and Circuit Breakers

You rely on the power supply and circuit breakers to keep your industrial control panel safe and running. The power supply converts incoming AC power to the DC voltage your devices need. Circuit breakers act as your first line of defense. They detect electrical faults, like overcurrent or ground faults, and shut off power to prevent fires or equipment damage. You can trust these safety components to protect your investment and keep your team safe.

- Power supply units and circuit breakers detect anomalies in electrical flow.

- Circuit breakers interrupt the current to prevent damage and hazards.

- They can identify ground faults, which pose risks of electric shock.

- When a ground fault is detected, the circuit breaker automatically shuts off power.

- Power circuit breakers protect against overcurrent and short circuits, preventing potential fires and equipment damage.

Did you know? Some circuit breakers can fail as high as 60%, so choosing reliable brands like Linkwell helps you avoid costly downtime.

PLCs, HMIs, and Automation Devices

Inside your industrial control panel, PLCs, HMIs, and automation devices work together to make automation possible. The PLC acts as the brain, processing input signals and sending commands to actuators. The HMI gives you a visual interface to monitor operations, adjust settings, and respond to alarms. When you use these devices together, you get real-time control and data acquisition.

| Component | Role in Advanced Process Control |

|---|---|

| PLC | Controls machinery, processes input signals, and sends output signals to actuators. Enables real-time management and data acquisition. |

| HMI | Provides an interface for operators to interact with the system, adjust parameters, and monitor operations visually. |

| SCADA | Centralizes data from multiple PLCs, enabling real-time monitoring, data analysis, and decision-making support. |

Linkwell’s automation solutions offer flexible installation, energy efficiency, and safety certifications, making your industrial control panel smarter and more reliable.

Contactors, Relays, and Motor Drives

You use contactors, relays, and motor drives to control heavy machinery and motors in your industrial control panel. Contactors switch high-power circuits, while relays manage multiple circuits with one signal. Motor drives, like VFDs and soft starters, let you adjust motor speed and torque for better efficiency.

| Component | Role in Industrial Machinery |

|---|---|

| Electrical Relays | Control circuits by opening and closing them based on electrical signals, allowing multiple circuits to be managed with one signal. |

| Motor Starters | Safely start and stop motors, providing low voltage and overcurrent protection to prevent damage during overload. |

| Electrical Contactors | Switch electrical power on and off, handling high power loads and enabling lower current to control higher power circuits. |

You should always check for normal wear, electrical issues, and environmental exposure to keep these safety components working at their best.

Terminal Blocks, Wire Ducts, and Cable Management

Terminal blocks, wire ducts, and cable management systems keep your industrial control panel organized and safe. Terminal blocks serve as connection points for input and output signals, reducing wiring errors. Wire ducts route and protect cables, preventing tangling and short circuits.

- Wire duct improves the neatness and safety of control cabinet design.

- Terminal blocks simplify circuit layout and enhance safety, especially in systems with frequent I/O changes.

- Proper cable management prevents hazards and makes maintenance easier.

Follow standards for wire size, spacing, routing, and labeling to keep your industrial control panel efficient and easy to troubleshoot.

Cooling, fan Lighting, and Environmental Controls

Cooling fans, enclosure lights, and environmental controls help maintain the right conditions inside your industrial control panel. Fans remove hot air and bring in cooler air, preventing overheating. Enclosure lights make it easy to see during maintenance. Environmental controls, like thermostats and heaters, manage humidity and temperature.

| Aspect | Description |

|---|---|

| Temperature Regulation | Regulates internal temperature to prevent damage to sensitive electrical equipment. |

| Visibility Enhancement | Industrial LED lights illuminate work areas, improving visibility in extreme conditions. |

| Humidity Management | Controls internal conditions to eliminate risks of condensation and overheating. |

Linkwell’s cabinet air conditioners, fans, and enclosure lights help you keep your industrial control panel running smoothly, even in tough environments.

How Control Panel Components Work Together

System Integration and Safety

When you build a control cabinet, you want every part to work together smoothly. Each component has a job, but real power comes from smart integration. You start by choosing safe, compliant parts. This step keeps your system up to code and protects everyone who works with it.

Here’s a quick look at what matters most for safety and compliance:

| Component | Importance |

|---|---|

| Electrical safety | Protects you from shock and fire hazards. |

| Component selection | Makes sure only safe, certified parts go into your cabinet. |

| Wiring methods | Uses best practices to prevent failures and keep things running smoothly. |

| Short-circuit rating | Sets safe limits to avoid dangerous situations. |

You can boost safety by thinking ahead. Early integration in your design phase helps you spot hazards before they become problems. A good risk assessment lets you plan for every “what if.” When you use a layered safety approach, you cover risks at every level. Some systems even use dynamic safety zones that adjust as your equipment runs, so you stay safe without slowing down.

Want to make your work easier? Standardizing your cabinet layout and using clear labels can save you time and reduce mistakes. When you follow standards like UL 508 or DIN EN 60352-2, you get reliable connections and fewer errors.

Efficiency and Reliability with Linkwell Solutions

You want your control cabinet to run efficiently and last for years. Linkwell helps you reach that goal with smart features and reliable products. Their solutions stand out because they offer patented designs, quick installation, and advanced ventilation. You get high protection ratings and lots of customization options, so your cabinet fits your needs exactly.

Check out how Linkwell compares to typical industry solutions:

| Feature | Linkwell Solutions | Industry Averages |

|---|---|---|

| Patented Designs | Yes | No |

| Quick Installation | Yes | Varies |

| Advanced Ventilation | Yes | Limited |

| Certifications | UL, CE, ROHS | Varies |

| Customization Options | High | Limited |

| Protection Ratings | High | Varies |

| Smart Airflow | Yes | Limited |

With Linkwell, you get more than just parts. You get a system that performs at its best, extends the life of your equipment, and helps you avoid costly downtime. This is especially important if you work in tough environments or need your system to run 24/7. When you choose Linkwell, you set yourself up for success—every component works together for safety, efficiency, and peace of mind.

You see how each control cabinet component plays a key role in keeping your system safe, organized, and efficient. When you choose Linkwell, you get products that meet top certifications:

| Certification | Description |

|---|---|

| UL | Safety tested by Underwriters Laboratories. |

| CE | Meets EU safety standards. |

| CCC | Certified for use in China. |

| ROHS | Environmentally safe materials. |

You save money over time with fewer repairs and better uptime.

- Lower energy use

- Longer equipment life

- Less downtime

If you want a reliable, cost-effective solution, Linkwell helps you build a smarter control cabinet.

FAQ

What is the most important component in a control cabinet?

You need every part to work together, but the main breaker stands out. It protects your whole system from overloads and short circuits. Without it, you risk equipment damage and safety hazards.

How do I choose the right cooling solution for my cabinet?

You should check your cabinet size, heat load, and environment. For hot or dusty areas, use a cabinet air conditioner. For lighter loads, a cabinet fan works well.

Tip: Linkwell offers both options for different needs.

Can I customize my control cabinet with Linkwell?

Absolutely! You can request custom sizes, labels, voltage options, and even smart monitoring features.

- Choose your layout

- Add your branding

- Select special functions

How often should I maintain my control cabinet?

You should inspect your cabinet every six months. Look for dust, loose wires, or overheating. Clean filters and check for signs of wear.

Regular checks help you avoid unexpected downtime.

Are Linkwell products certified for global use?

Yes! Linkwell products carry UL, CE, and ROHS certifications.

| Certification | Region |

|---|---|

| UL | North America |

| CE | Europe |

| ROHS | Global |