Custom Cabinet Transformer Manufacturer in China

A Cabinet Transformer is designed to safely step voltage up or down inside control cabinets, electrical cabinets, and telecom signal cabinets. As a manufacturer, we offer stable performance, fast delivery, and technical support under our brand Linkwellelectrics. If you need reliable solutions, contact us anytime—we’re ready to support your project.

Linkwell Electrics - Your Trusted Cabinet Transformer Manufacturer from China

Certified quality supported by CE, RoHS, and IEC 61558 compliance for safety.

Low-loss core ensures high energy efficiency and reduced long-term operating cost.

Industrial-grade enclosures provide stronger protection in dusty or humid cabinet environments.

Stable voltage output supports sensitive control electronics with long service life.

Global Partnership

Cabinet Transformer Type By number of phases

Cabinet Transformers can be single-phase or three-phase, depending on the power system. Each type supports different loads and cabinet environments, making them suitable for control cabinets, telecom cabinets, and electrical distribution systems.

Single-phase Transformer

Description: Converts AC voltage for smaller loads in control cabinets and telecom cabinets.

Key Features: Compact size, low noise, simple wiring.

Applications: PLC control, sensors, lighting systems, low-power automation.

Three-phase Transformer

Description: Handles higher loads and industrial power distribution.

Key Features: Balanced power delivery, high efficiency, stable three-phase output.

Applications: Industrial cabinets, telecom stations, heavy automation systems.

Cabinet Transformer Type By winding configuration

These transformers differ by how their windings are arranged. Isolation and autotransformers offer unique advantages based on safety needs, cabinet layout, and load requirements.

Isolation Transformer

Description: Electrically isolates circuits for safety.

Key Features: Reduced interference, shock protection, stable output.

Applications: Sensitive electronics, communication cabinets, measurement devices.

Auto-transformer

Description: Uses shared winding for efficient voltage adjustment.

Key Features: Smaller size, higher efficiency, lower cost.

Applications: HVAC controls, industrial cabinets, telecom power systems.

Cabinet Transformer Type By core material

Core materials influence energy efficiency, noise level, and heat performance. Laminated cores and toroidal cores offer different benefits depending on the environment and load stability needs.

Laminated iron core Transformer

Description: Built with stacked steel laminations to reduce losses.

Key Features: Strong performance, cost-effective, stable output.

Applications: Electrical cabinets, signal cabinets, power distribution.

Toroidal core transformer

Description: Circular core offering high efficiency.

Key Features: Low noise, low EMI, compact size.

Applications: Telecom equipment, audio systems, sensitive automation.

Cabinet Transformer Type By enclosure type

Enclosures protect transformers from dust, vibration, moisture, and heat. Ventilated and encapsulated types are chosen based on the cabinet environment and reliability needs.

Ventilated Transformer

Description: Openings allow airflow for cooling.

Key Features: Lower temperature, good heat dissipation.

Applications: Indoor cabinets, automation systems, HVAC control cabinets.

Encapsulated transformer

Description: Sealed with resin for harsh environments.

Key Features: Moisture-proof, dust-proof, corrosion-resistant.

Applications: Outdoor telecom stations, dusty factories, vibration-prone cabinets.

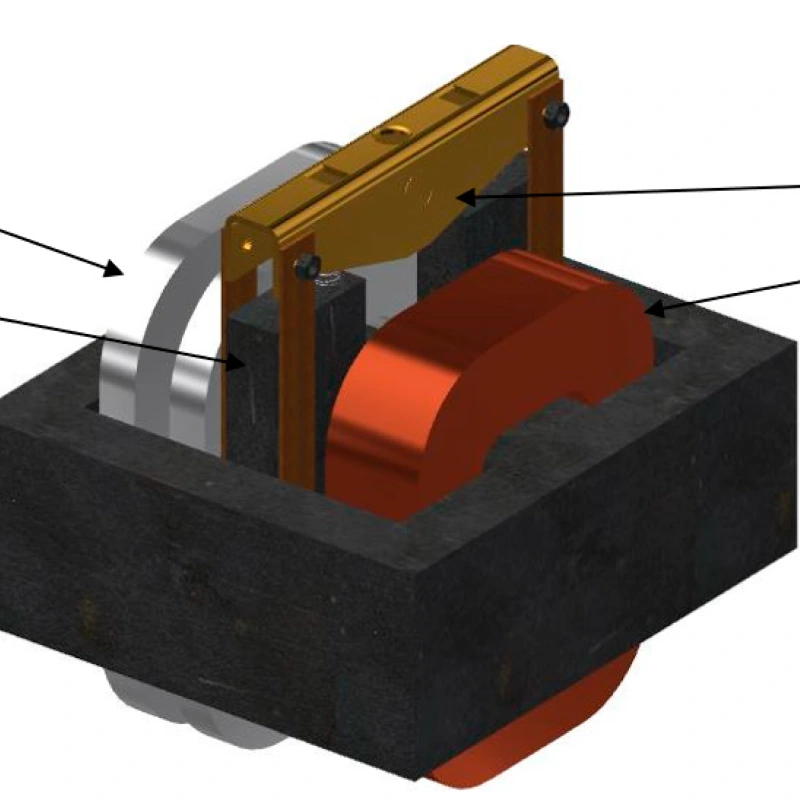

Cabinet Transformer Key Parts

Primary Winding

Types: Copper or aluminum windings depending on efficiency and cost requirements.

Performance: Provides stable input voltage conversion, helping downstream controls operate reliably.

Durability: Insulated to withstand high temperatures and fluctuating electrical loads over long durations.

Integration: Designed to fit compact cabinet spaces while maintaining easy wiring access.

Secondary Winding

Types: Multiple voltage tap options for different load applications.

Performance: Stable output protects sensitive devices like PLCs and sensors.

Durability: Thick insulation prevents short circuits even under humidity and vibration.

Integration: Compatible with various cabinet terminal blocks and wiring layouts.

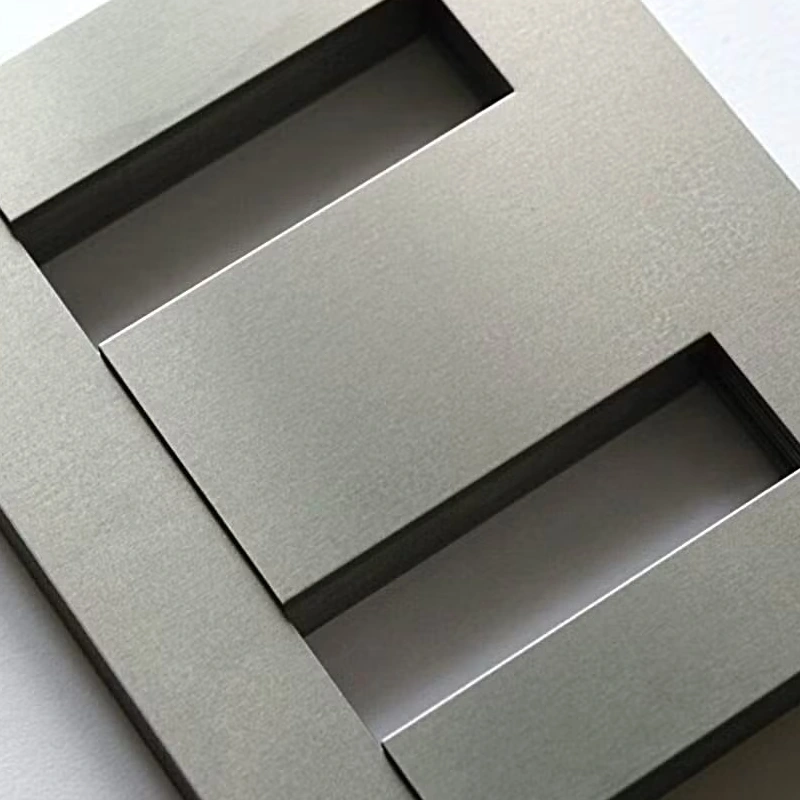

Laminated Core

Types: Laminated steel or toroidal structures tailored for low loss and stable performance in cabinet environments.

Performance: Ensures efficient magnetic flow, reducing heat buildup during long-term continuous equipment operation.

Durability: Resistant to stress and temperature changes, maintaining stable magnetics across the transformer’s lifespan.

Integration: Fits smoothly into cabinet layouts without interfering with wiring pathways or enclosure mounting.

Certificate

Application of Cabinet Transformer in Different Industries

Telecommunications

Industrial Automation

Building Management Systems

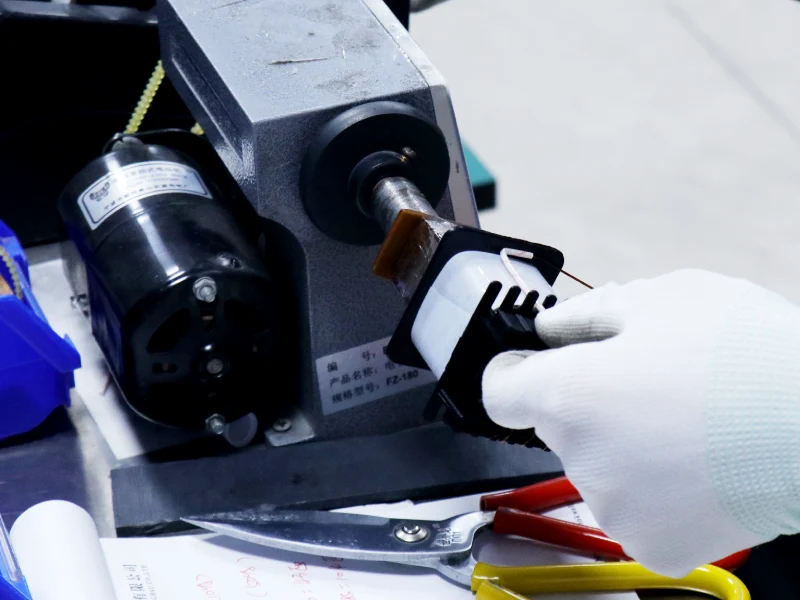

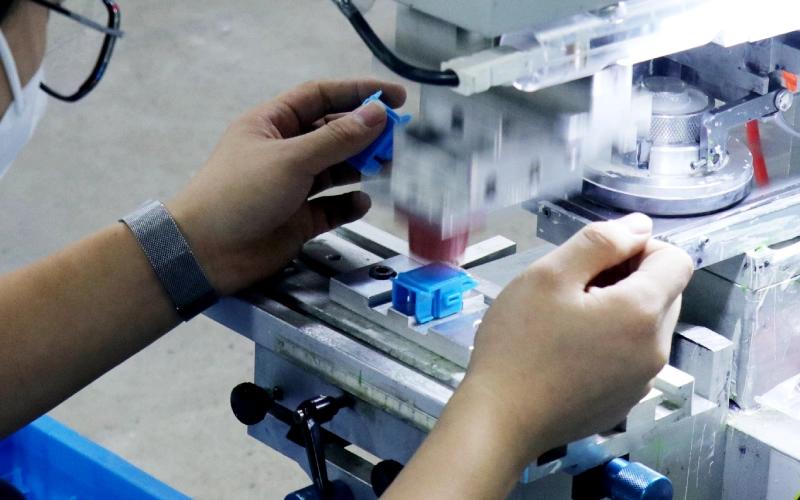

Our Factory

Choosing a Cabinet Transformer from Linkwellelectrics gives you a reliable, long-lasting solution designed for real industrial environments. We manufacture with strict quality control, ensuring stable performance for control cabinets, telecom stations, automation systems, and building equipment. As a professional factory, we support customization, OEM branding, fast delivery, and full after-sales assistance. Whether you are a wholesaler, distributor, or major brand, you gain a trustworthy partner that helps you grow your business with confidence. Our engineering team responds quickly and helps you choose the right transformer for any project. Reach out to us anytime—we are ready to support your success.

Customize Your Cabinet Transformer

Quality Performance

Stable Voltage Output: We ensure each Cabinet Transformer delivers smooth, low-noise voltage, protecting sensitive control modules and extending equipment life, which reduces your long-term maintenance cost.

Certified Manufacturing: Our production meets CE and IEC standards, giving wholesalers and distributors confidence when selling to regulated industries. Buyers benefit from fewer product returns and stronger brand reputation.

Industrial-Grade Components: We use low-loss cores and flame-retardant enclosures, ensuring dependable performance in telecom cabinets, control cabinets, and outdoor signal stations.

Durability & Reliability

High Heat Resistance: We design transformers that maintain stable performance in narrow cabinets with limited airflow, helping your equipment operate continuously without overheating.

Moisture-Resistant Enclosures: Our enclosures protect coils from humidity and dust, extending lifespan and reducing replacement frequency for buyers.

Strong Mechanical Structure: We reinforce internal windings to withstand vibration and long-term mechanical stress, ideal for telecommunication and industrial facilities.

Customization & Project Flexibility

Electrical Customization: We offer custom voltages, frequency options, tap settings, and terminal designs to fit unique cabinet layouts and load demands.

Mechanical Customization: We adjust mounting holes, enclosure size, and wiring directions, allowing faster installation and lower engineering labor costs for your customers.

Brand & Market Customization: We support OEM logos, labels, and packaging, helping distributors build their own brand identity and expand their market reach.

Supply Capacity & Business Value

Fast Lead Times: We keep core materials in stock, helping you maintain quick delivery for urgent projects and bulk orders.

Reliable Long-Term Supply: Our steady production capacity ensures continuity, ideal for distributors building multi-year supply chains.

Wholesale-Friendly Pricing: Through optimized manufacturing, we offer competitive pricing, helping you secure better profit margins in your local market.

What are the Benefits of Cabinet Transformer?

1. Safety & Isolation

Cabinet Transformers provide strong electrical isolation, protecting equipment and personnel from shocks, surges, and electrical noise. This is essential in telecom stations and automation cabinets, where sensitive electronics need clean power. Stable isolation reduces failures and extends the life of the system.

2. Reliable Voltage Stabilization

They deliver smooth, steady voltage even when the main power fluctuates. This protects PLCs, relays, controllers, and communication modules from damage. For buyers, this means fewer maintenance issues and significantly lower downtime in critical operations.

3. Long Service Life & Low Maintenance

With high-quality cores, industrial-grade insulation, and well-designed enclosures, Cabinet Transformers offer long-term durability. They require minimal maintenance, making them ideal for wholesalers and brands aiming to offer dependable, low-failure-rate components.

FAQs

What is a Cabinet Transformer used for?

A Cabinet Transformer is used to safely convert voltage levels inside electrical cabinets, control cabinets, telecom cabinets, and signal stations. It ensures stable power for PLCs, relays, sensors, controllers, and communication modules. This helps protect sensitive components from voltage fluctuations, reduces equipment failures, and improves the lifespan of the entire system.

How long does a Cabinet Transformer typically last?

Most Cabinet Transformers last 8–15 years depending on load, environment, ventilation, and enclosure type. Units installed in dry, cool cabinets usually last longer. We design ours with industrial-grade insulation and low-loss cores to extend service life, giving buyers better long-term performance and fewer replacement costs.

Are Cabinet Transformers safe for telecom and signal cabinets?

Yes. Cabinet Transformers are widely used in telecom base stations, signal cabinets, and low-voltage communication rooms. They offer stable isolated voltage, reduce interference, and provide reliable power for sensitive electronics. Our models are designed to run continuously with low electromagnetic noise to protect communication quality.

What maintenance does a Cabinet Transformer require?

Maintenance is simple: check wiring tightness, inspect for dust, verify cabinet airflow, and confirm that the temperature does not exceed recommended levels. No complicated servicing is needed. With quality materials and sealed enclosures, our transformers operate reliably with minimal intervention.

How do I choose the right Cabinet Transformer?

You should consider voltage input/output, enclosure type, available cabinet space, load type, and environmental conditions. We help customers choose the correct rating by analyzing their equipment, operating environment, and safety requirements—ensuring the right match for long-term reliability.

Can Cabinet Transformers be customized?

Yes. Custom options include voltage, tap selections, input terminals, enclosures, mounting holes, and logo branding. We support small-batch customization as well as large OEM production. Customization helps distributors stand out from competitors and secure better project opportunities.

What is your production lead time?

Standard models ship in 7–12 days. Customized designs require 12–18 days depending on complexity. For urgent orders, we can accelerate production, ensuring you stay competitive in fast-paced industry demands.