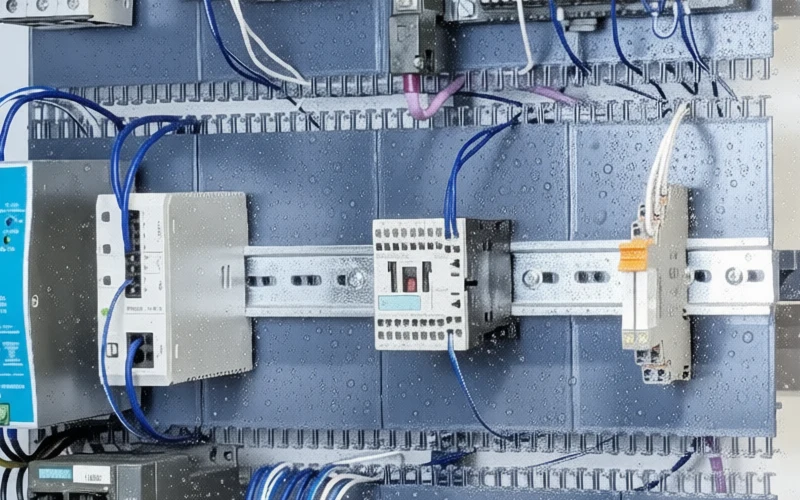

You want your electrical enclosure to run smoothly every day. When you ignore why you should use heating/cooling in electrical enclosures, you risk condensation, overheating, and unexpected downtime. These problems can lead to damaged equipment and even fire hazards. Here are some common safety risks you face:

- Overheated electrical panels often cause equipment failure and fire.

- Hot wires and cords can trigger electrical fires.

- Poor insulation or damaged wires may result in short circuits.

Heating and cooling solutions keep your enclosures at optimal operating conditions. By understanding why you should use heating/cooling in electrical enclosures, you save money, boost safety, and improve reliability. Linkwell offers specialized heating and cooling options for every need.

Key Takeaways

- Control the temperature inside your electrical enclosure to prevent overheating and equipment failure.

- Use heating and cooling systems to protect sensitive electronics from moisture and corrosion.

- Regularly check your enclosure’s temperature and humidity to avoid costly repairs.

- Choose energy-efficient cooling solutions to save on power bills and reduce maintenance costs.

- Select the right Linkwell products based on your environment to ensure optimal performance and safety.

Why You Should Use Heating/Cooling in Electrical Enclosures

You might wonder why you should use heating/cooling in electrical enclosures. The answer is simple: you want your equipment to last, stay safe, and work without interruptions. When you control the temperature inside your electrical enclosure, you protect sensitive electronics from damage and keep your operations running smoothly. Linkwell offers a full range of solutions for enclosure thermal management, so you can always find the right fit for your needs.

Preventing Equipment Failure

If you ignore why you should use heating/cooling in electrical enclosures, you risk costly breakdowns. Power electronics have strict temperature limits. Summer heat can push your enclosure past those limits. Here’s what industry experts say are the main reasons to use heating and cooling:

- Control maximum enclosure temperature.

- Keep out dirt and debris.

- Prevent entry of corrosive vapors.

- Prevent water entry.

- Extend component life.

- Prevent malfunction due to overheating.

- Remove excessive heat.

When you use proper thermal management, you keep your electrical enclosure within safe temperature ranges. Excessive heat can speed up insulation aging, cause your equipment to lose precision, and lead to premature failure. By maintaining optimal temperatures, you avoid expensive repairs and keep your systems reliable.

Ensuring System Safety

Safety should always come first. Overheating inside electrical enclosures can lead to fires or explosions. Every 10°C rise above the rated temperature can cut the life expectancy of your components in half. Heating and cooling systems help you manage these risks. You get better reliability, fewer dangerous incidents, and lower maintenance costs. Installing a climate control system is often more affordable than replacing damaged equipment. Linkwell’s certified products give you peace of mind, knowing your enclosures stay safe and your operations stay on track.

Tip: Regularly check your enclosure’s temperature and humidity. A small investment in heating or cooling can save you from big problems down the road.

Condensation Protection in Electrical Enclosures

Condensation sneaks up on you inside an electrical enclosure. When warm air meets a cold surface, moisture forms and settles on your electronics. This can lead to corrosion, short circuits, and even total equipment failure. You want to keep your electrical enclosure dry and safe, so you need smart thermal management and temperature control.

Linkwell Enclosure Heater Solutions

Linkwell offers enclosure heating solutions that tackle condensation head-on. Their enclosure heaters maintain a steady temperature inside your enclosure, keeping surfaces above the dew point. This stops moisture from forming and protects your sensitive electronics. You get reliable temperature control with built-in thermostats, so the heater only runs when needed. Linkwell enclosure heaters come with certifications like UL, CE, and IEC/EN 60079, giving you confidence in their safety and performance.

| Certification | Description |

|---|---|

| UL/cUL | Safety standards for electrical devices |

| CE | European conformity marking for safety |

| IEC/EN 60079 | Standards for explosion-proof variants |

You can choose from different power ratings and mounting styles to fit your enclosure. The IP65 full-seal design keeps dust and water out, making these heaters perfect for harsh environments. You get peace of mind knowing your electrical enclosure is protected against condensation and freezing.

Moisture and Corrosion Prevention

Moisture inside electrical enclosures causes big problems. Condensation leads to corrosion, which can seize moving parts and damage electronic components. Temperature control and thermal management are your best defense. Here’s what you can do:

- Use proper ventilation to keep air moving and balance humidity.

- Select materials with low thermal conductivity for better insulation.

- Install enclosure heating to maintain stable internal temperatures.

- Seal and insulate your enclosure to block moisture.

- Schedule regular maintenance to catch condensation early.

When you prevent condensation, you stop corrosion before it starts. You protect your equipment, extend its lifespan, and avoid costly repairs. Linkwell’s thermal management solutions make it easy for you to keep your electrical enclosure safe and dry.

Enclosure Cooling for Overheating Prevention

When you pack more electronics into a small space, heat builds up fast. This is a big reason why enclosure cooling is so important. If you let the temperature rise inside your electrical enclosure, you risk equipment failure, shutdowns, and even fire. The trend toward smaller, more complex panels means less airflow and more heat. You need cooling systems that can handle this challenge and prevent malfunction due to overheating.

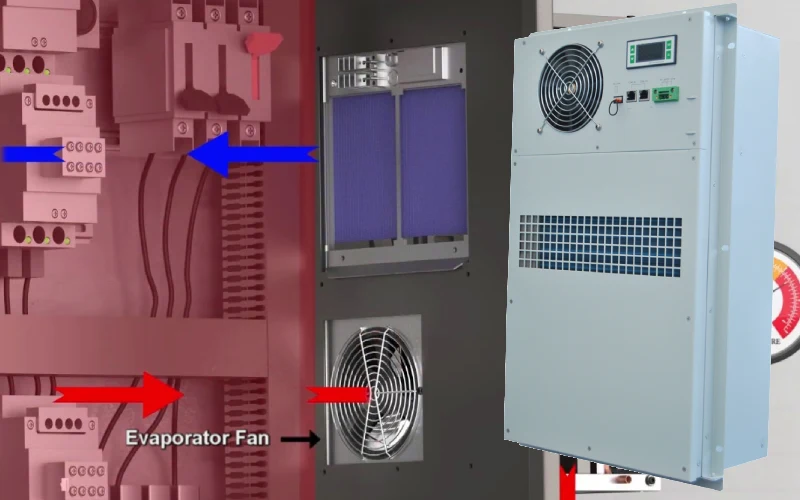

Cabinet Air Conditioner Benefits

Cabinet air conditioners give you powerful enclosure cooling. These cooling systems work by removing heat from inside the enclosure and keeping your sensitive electronics at a safe temperature. Every 18°F rise in temperature can cut the reliability of your components in half. That’s why you want to use cooling systems that keep things steady.

Here’s a quick look at what cabinet air conditioners can do for you:

| Benefit | Description |

|---|---|

| Improved Equipment Lifespan | Proper cooling prevents overheating and extends the life of your equipment. |

| Energy Efficiency | The right system ensures optimal energy use, reducing operational costs. |

| Enhanced Performance | Maintaining the correct temperature ensures your equipment operates at peak efficiency. |

| Reduced Downtime | Reliable cooling minimizes the risk of equipment failure and costly downtime. |

Linkwell’s enclosure cooling systems use inverter technology and smart controls. You get energy-efficient cooling that adapts to changing conditions. These cooling systems help you remove excessive heat, so your equipment runs longer and better.

Electrical Enclosure Fan Applications

Fans are another great way to boost enclosure cooling. These cooling systems use forced convection to move air and cool your electronics. Fans are easy to install and fit into almost any enclosure design. They take up little space and cost less than other cooling solutions.

| Benefit/Mechanism | Description |

|---|---|

| Forced Convection | Fans create airflow that enhances heat transfer, making cooling more efficient than passive methods. |

| Cost-Effectiveness | Fans are cheaper to install and operate compared to refrigeration or liquid cooling systems. |

| Enhanced Integration | Fans can be easily fitted into various enclosure designs, providing flexibility in cooling solutions. |

| Compact Design | Fans require less space than liquid cooling systems, making them ideal for tight spaces. |

You can use enclosure cooling fans with thermostats for smart thermal management. This setup keeps your electrical enclosure at the right temperature and protects your equipment from enclosure overheating. When you combine heating and cooling systems, you get the best protection for your enclosures. Linkwell offers a full range of cooling systems, so you always have the right tool for the job. With effective cooling, you improve performance, reduce downtime, and keep your operations running smoothly.

Extending Electrical Enclosure Lifespan

Reducing Thermal Stress

You want your electrical enclosure to last as long as possible. When you set up a solid thermal management plan, you protect your equipment from the damage caused by temperature swings. Heat and cold both put stress on sensitive parts. If you let temperatures rise or fall too much, you speed up wear and tear. That means more breakdowns and more time spent fixing things.

A good thermal management plan helps you avoid these problems. Here’s how it works for you:

- Effective thermal management plan prevents overheating, so your components don’t wear out as fast.

- Fewer temperature spikes mean your system shuts down less often.

- When you have fewer failures, you don’t need to inspect or repair your enclosure as much.

You can use enclosure heating in cold environments to keep everything running smoothly. In hot spots, cooling systems keep things from getting too warm. With the right thermal management plan, you extend component life and keep your electrical enclosure working longer.

Linkwell Product Durability

You want products that stand up to tough conditions. Linkwell designs every enclosure solution to meet strict durability standards. Their products go through testing based on IEC 60529, which checks how well enclosures keep out dust and water. You can trust these ratings:

| Rating | Description | Application |

|---|---|---|

| IP55 | Protects against dust and low-pressure water jets | General use |

| IP65 | Protects against dust and water from a nozzle | Harsh environments |

Linkwell products meet these standards, so you know your electrical enclosure is safe in demanding settings. When you use a Linkwell solution as part of your thermal management plan, you get long-lasting protection. You spend less time on maintenance and more time focusing on your work. A strong thermal management plan, with the right heating and cooling, keeps your enclosures reliable for years.

Tip: Review your thermal management plan every season. Small changes can make a big difference in the life of your equipment.

Improving Reliability and Uptime

You want your electrical enclosure to work every day without surprises. Reliable cooling systems and heating solutions help you avoid sudden breakdowns and keep your operations running. When you use Linkwell’s thermal management products, you get the support you need for mission-critical tasks.

Minimizing Downtime

Downtime can cost you thousands of dollars every minute. Factories often face over a hundred unexpected shutdowns each year, with losses reaching millions. You can prevent these costly interruptions by using cooling systems that keep your enclosures at the right temperature. Early detection of overheating motors and failing parts lets you fix problems before they stop your work. Infrared thermography helps you spot thermal issues quickly, so you can take action and avoid shutdowns.

Linkwell’s solutions make your job easier. Here’s how their products help you minimize downtime:

| Feature | Benefit |

|---|---|

| Modular terminal blocks | Streamlines battery management systems (BMS) |

| Customizable transformers | Enables precise voltage regulation |

| Compact ventilation fans | Prevents overheating in confined energy storage cabinets |

| Organized cable management | Enhances airflow, facilitates faster troubleshooting, and extends equipment life |

You get better airflow, faster troubleshooting, and a safer workspace. These features prevent downtime and make future upgrades easier.

Note: Manufacturers who use predictive maintenance see a big boost in reliability. You can shift from reacting to problems to preventing them.

Stable Performance in Harsh Environments

Your equipment faces tough conditions every day. Extreme heat, cold, dust, and moisture can threaten safety and reliability. Linkwell’s cooling systems and heating solutions keep your electrical enclosure stable, even in harsh environments.

| Thermal Management Solution | Application in Harsh Environments |

|---|---|

| Enclosure heaters | Prevent condensation and maintain minimum operating temperature in cold environments |

| Filter fans | Provide cooling for moderate heat loads in hot environments |

| Enclosure air conditioners | Address demanding cooling requirements in high-heat scenarios |

| Vortex coolers | Offer spot cooling for specific components |

| Ventilation systems | Manage humidity and air exchange effectively |

You can select enclosures with the right IP or NEMA ratings to handle environmental challenges. Materials like stainless steel or strong non-metallic options resist corrosion. Seals and gaskets block moisture, dust, and harmful agents. These steps help you maintain safety and keep your equipment performing at its best.

Linkwell’s cooling systems and heating solutions give you the reliability you need. You get stable performance, longer equipment life, and peace of mind knowing your operations are protected.

Enhancing Safety in Electrical Enclosures

You want your workspace to be safe. When you manage the temperature inside your electrical enclosure, you lower the risk of fire and explosion. Heating and cooling systems do more than just keep things comfortable—they protect your equipment and everyone around it.

Fire and Explosion Risk Reduction

Heat can build up fast inside enclosures. If you ignore it, wires may overheat, insulation can break down, and sparks might fly. That’s when fires or explosions happen. You can stop these dangers by using smart thermal management.

Here’s how heating and cooling systems help you:

- They keep the temperature steady, so parts don’t get too hot.

- Closed-loop cooling blocks outside air, dust, and gases from getting in.

- Condensate management keeps things dry, so water doesn’t cause shorts or corrosion.

- Strong materials like stainless steel resist rust and damage.

Take a look at some key safety factors:

| Key Factor | Description |

|---|---|

| NEC Classifications | Systems meet hazardous location rules for safe operation. |

| Certifications | UL 60079-1, UL 60079-7, and UL 60079-31 help prevent fire and explosion. |

| Material | Stainless steel keeps enclosures strong and rust-free. |

| Ingress Protection | IP67 and IP68 ratings keep out water and dust. |

| Control Mechanisms | Sunshades, breathers, drains, heaters, and dehumidifiers manage conditions. |

When you use these features, you get improved safety and peace of mind.

Compliance with Safety Standards

You want to know your equipment meets the highest safety standards. Linkwell designs products to pass strict tests and earn top certifications. These certifications prove your enclosures are safe and reliable.

| Certification | Description |

|---|---|

| UL | Ensures safety and performance. |

| cUL | Meets Canadian safety rules. |

| CE | Shows compliance with European safety standards. |

| ISO9001 | Guarantees quality management. |

| NEMA Ratings | Rates enclosures for electrical safety. |

| UL 508A | Covers industrial control panels. |

| NFPA 70 | Follows the National Electrical Code. |

| IEC 61439 | Sets standards for low-voltage switchgear and controlgear. |

You can trust Linkwell’s heating and cooling solutions to keep your electrical enclosure safe. These certifications mean your equipment is ready for tough jobs and harsh environments.

Tip: Always check for safety certifications before you install new equipment. Certified products help you avoid accidents and keep your team safe.

Cost Savings with Efficient Enclosure Cooling

Lower Maintenance Costs

You want to save money on your electrical enclosure. Efficient cooling systems help you do just that. When you use proper thermal management, you prevent overheating and keep your equipment running smoothly. This means you spend less time and money on repairs. You also avoid replacing expensive parts that fail because of heat or condensation.

Here’s how efficient cooling systems lower your maintenance costs:

- They stop overheating, which keeps your electrical enclosure reliable.

- You avoid frequent repairs or replacements since your equipment stays within safe temperature limits.

- Good thermal management during the design phase helps you prevent condensation and other costly problems.

You get more uptime and fewer headaches. Your team can focus on important work instead of fixing broken equipment. Over time, these savings really add up.

Energy-Efficient Linkwell Solutions

You want your cooling systems to work hard without wasting energy. Linkwell’s cooling solutions use advanced technology to help you save on power bills. Their cooling systems feature inverter compressors and EC fans that adjust to real-time needs. These smart systems only use the power you need, when you need it.

Let’s look at some energy-saving features you get with Linkwell electrical enclosure cooling:

- Inverter compressors and EC fans that match cooling output to your enclosure’s needs.

- Smart sensors and controls that automatically adjust power usage.

- Compact cooling units designed to cut down on energy waste.

- LED lighting and motion sensors that help reduce power use.

- Energy management systems that keep your overall power usage low.

You can see big savings with the right cooling systems. For example, cold aisle containment can reduce cooling-related energy costs by up to 30%. Hot aisle containment can save even more—up to 40%. In large factories, every kilowatt saved means more power for your machines and less money spent on utilities.

When you choose Linkwell’s cooling solutions, you get reliable performance, lower maintenance costs, and real energy savings. You protect your enclosures and your budget at the same time.

Choosing the Right Linkwell Solution

Assessing Environment and Application

You want the best results from your electrical enclosure, so picking the right heating or cooling product matters. Start by looking at your environment. Is your enclosure indoors or outdoors? Does it face dust, moisture, or extreme temperatures? These details help you decide what features you need.

Environmental assessment plays a big role in your choice. You need to check airflow, heat load, and how much cooling or heating your system needs. Good air circulation keeps your equipment safe and running longer. If you skip this step, you might face thermal stress or even equipment failure.

Here’s a simple checklist to help you choose the right Linkwell solution:

- Figure out the heat load inside your enclosure.

- Pick energy-efficient air conditioners with smart controls.

- Make sure your enclosure meets the right NEMA or IP rating for your location.

- Plan for easy access to filters and controls for quick maintenance.

- Keep intake and exhaust areas clear for steady airflow.

- Use condensate removal systems to stop water buildup.

- Clean filters often, especially if your site is dusty.

Tip: Take time to review your enclosure’s needs before you buy. A little planning now saves you trouble later.

Customization and Support

Every project is different. That’s why Linkwell gives you plenty of ways to customize your solution. You can pick the size, power rating, voltage, and mounting style that fit your setup. Want extra safety features or a special design? Linkwell can help with that too.

You also get strong support from Linkwell’s team. They offer layout advice, help with installation, and even run thermal simulations to make sure your system works right. If you need fast delivery or technical documents, they have you covered. Here’s a quick look at what you get:

| Customization Options | Support Services |

|---|---|

| Tailored design choices | Layout optimization |

| Size, power, voltage choices | Installation guidance |

| Mounting type | Thermal simulation |

| Safety features | Compliance consulting |

| Flexible designs | Technical documentation |

| Competitive pricing | Remote setup advice |

| Fast lead times | Prompt delivery and service |

You can trust Linkwell to help you find the perfect fit for your enclosures. Their certified products and expert support make your job easier from start to finish.

You want your electrical enclosure to work safely and efficiently. Here are seven key reasons to use heating and cooling:

- Control temperature

- Keep out dirt and debris

- Block corrosive vapors

- Prevent water entry

- Extend component life

- Avoid overheating

- Remove excess heat

Electrical enclosures protect your equipment from hazards and keep your operations reliable.

Take time to review your needs. Linkwell offers certified solutions and expert advice for tailored thermal management. Reach out for support and product recommendations.

FAQ

How do I know if my enclosure needs heating or cooling?

You should check for temperature swings, condensation, or frequent equipment failures. If you see moisture or feel heat inside, it’s time to add heating or cooling.

Can I install Linkwell products myself?

Most Linkwell products come with easy-to-follow instructions. You can handle basic installations, but you should call a qualified electrician for wiring or complex setups.

What certifications do Linkwell heating and cooling products have?

Linkwell products carry UL, CE, and RoHS certifications. These prove the products meet international safety and quality standards.

How often should I clean or replace filters in my enclosure cooling system?

You should inspect filters monthly. Replace them every 3–6 months, especially if your site is dusty or humid. Clean filters help your co