Fan static pressure tells you how much force a fan uses to push air through obstacles like filters or tight spaces. If your electrical cabinet overheats or collects dust, you know how frustrating it gets. You want your equipment to stay cool and clean. Linkwell helps you solve these problems with reliable fan filter units and cabinet fans for industrial use. You get peace of mind and better performance.

Key Takeaways

- Fan static pressure is the force that helps a fan push air through obstacles like filters and vents. Ensure your fan has enough static pressure to keep your equipment cool.

- Regularly check your cabinet’s airflow and static pressure. This helps you spot issues before they lead to overheating or equipment failure.

- Choose the right fan based on your cabinet’s airflow needs and the resistance it faces. Higher static pressure is essential for tight spaces with filters.

- Linkwell offers reliable fan filter units and cabinet fans designed to manage static pressure effectively, ensuring better cooling and dust protection.

- Always consult the fan’s performance chart to match airflow and static pressure to your system’s requirements. This ensures optimal performance and longevity.

Fan static pressure explained

What is fan static pressure

You might wonder what fan static pressure really means. In simple terms, it’s the force your fan uses to push air through obstacles like filters, vents, or tight cabinet spaces. According to HVAC industry standards, fan static pressure is the difference between the fan’s total pressure and the velocity pressure at the discharge. You can think of it as the “push” that helps air move past anything blocking its path.

Linkwell designs its ventilation systems with static pressure in mind. When you install a fan filter unit or cabinet fan in a control panel, static pressure becomes important. If your cabinet has a filter or small exhaust holes, the fan needs enough static pressure to keep air moving and prevent overheating. Linkwell’s fans are built to deliver maximum static pressure, especially in tight or high-resistance spaces. This keeps your equipment cool and safe.

Tip: If your cabinet collects dust or gets hot, check if your fan has enough static pressure to handle the job.

How static pressure is measured

You can measure static pressure using special tools in industrial settings. These instruments help you figure out if your fan is working as it should. Here’s a quick look at how professionals measure static pressure:

| Feature | Description |

|---|---|

| Measurement Accuracy | Top transmitter accuracy for low pressure ranges in air and gas applications |

| Sensor Location | Sensors placed to sense different flow components |

| Measurement Principle | Uses the Fechheimer Pitot principle to measure total and static pressure |

| Airflow Processing | Honeycomb panels straighten air for accurate readings |

Most technicians use pressure transmitters and Pitot tubes. These tools show you how much resistance your fan faces inside a cabinet or enclosure. If you see high static pressure, your fan works harder to push air through.

Air flow vs. static pressure

You might think more airflow always means better cooling, but that’s not always true. Airflow is the amount of air your fan moves, usually measured in cubic feet per minute (CFM). Static pressure is the force that pushes this air through obstacles.

Here’s how airflow and static pressure work together:

- If your enclosure is open with no obstructions, you get maximum airflow and zero static pressure.

- If you add a small exhaust hole or a filter, airflow drops and static pressure rises.

- If your enclosure is completely closed, airflow stops and static pressure reaches its highest point.

| Scenario | Description | Air Flow | Static Pressure |

|---|---|---|---|

| 1 | Open enclosure, no obstruction | Maximum | Zero |

| 2 | Small exhaust hole or filter present | Limited | Increased |

| 3 | Completely closed enclosure | Zero | Maximum |

When you choose a fan for your cabinet, you need to balance airflow and static pressure. If you have lots of filters or tight spaces, pick a fan with higher static pressure. Linkwell’s fan filter units and cabinet fans offer different models for these needs. Larger or faster fans give you more airflow and pressure. If you run fans in parallel, you get more airflow but not more pressure. If you run fans in series, you get more pressure but not more airflow.

Note: Always check the system curve on your fan’s performance chart. It shows how airflow and static pressure change together.

You can see why static pressure matters. It helps your fan push air through filters and vents, keeping your equipment cool and dust-free. Linkwell’s products make it easy to find the right balance for your control cabinets and panels.

Why fan static pressure matters

Impact on cooling and ventilation

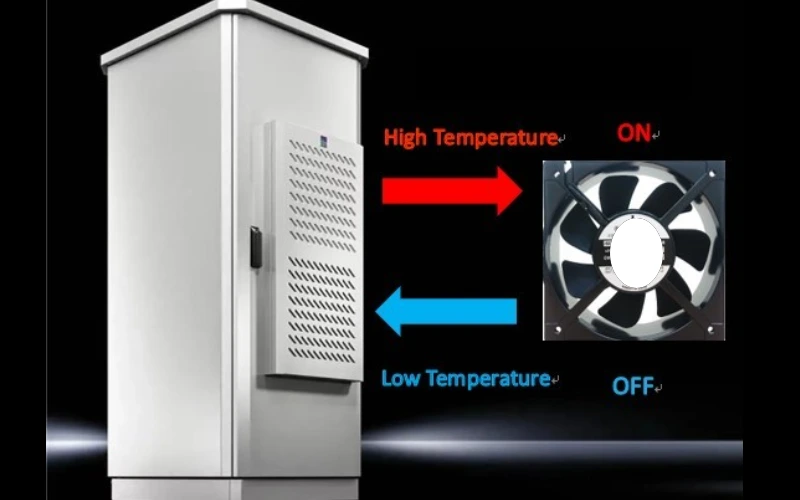

You want your electrical cabinet to stay cool and run smoothly. Fan static pressure plays a big role in making that happen. When you install a fan inside a cabinet, it faces obstacles like filters, vents, and tightly packed wires. These obstacles create resistance. The fan needs enough pressure to push air flow through and keep temperatures down.

If static pressure gets too high, air flow drops. Cooling efficiency suffers. Your equipment starts to heat up. Motors and sensitive electronics can fail early. On the other hand, low static pressure might mean leaks or not enough air flow, which also hurts cooling performance. You need the right balance. Proper static pressure keeps air moving, removes heat, and protects your components.

Tip: Regularly check your cabinet’s air flow and pressure. This helps you spot problems before they affect your equipment.

Linkwell solutions for control cabinets

Linkwell understands the challenges you face with air flow and pressure in control cabinets. Their fan filter units and cabinet fans are designed to overcome resistance and keep your system safe. Here’s how Linkwell helps you:

- Fan filter units deliver high air flow to quickly remove heat from your cabinet.

- These units provide strong static pressure to push air through filters and tight spaces.

- The EC series fans use PWM speed control. The fan automatically adjusts its RPM when temperatures rise, keeping cooling efficient.

- You get easy installation and reliable performance, even in harsh environments.

When you compare Linkwell cabinet fans to others, you see the difference in dust protection and pressure management:

| Feature | Linkwell Cabinet Fans | Competitors |

|---|---|---|

| Static Pressure Management | Effective | Varies |

| Dust Protection Rating | IP54, IP55 | Lower ratings |

| Engineered for High Volume | Yes | Not always |

| Suitable for Harsh Environments | Yes | Limited options |

Linkwell fans keep dust out and maintain strong air flow, even when your cabinet is packed with equipment. You get peace of mind knowing your system is protected.

System performance and reliability

You want your control panel to work reliably day after day. Managing static pressure is key to making that happen. Accurate measurement of duct pressure improves HVAC efficiency and boosts system reliability. If pressure gets too high, motors and blowers can fail early. Repairs get expensive. If pressure is too low, your system runs inefficiently and wears out faster.

Here’s what you need to watch for:

- High static pressure overloads motors and leads to early failure.

- Excessive pressure strains HVAC equipment and shortens fan motor life.

- Low static pressure causes inefficient operation and extra wear on components.

- Regular monitoring and adjustments based on pressure readings prevent problems and extend equipment life.

Linkwell’s fan filter units and cabinet fans help you maintain the right pressure and air flow. You get better cooling, less dust, and longer-lasting equipment. Your system stays reliable, and you avoid costly downtime.

Note: Choosing the right fan and monitoring static pressure keeps your electrical cabinets safe and your business running smoothly.

Choosing the right fan for air flow and static pressure

Selecting fans for high resistance environments

Picking the right fan for your cabinet or enclosure can feel tricky. You want to make sure your air flow stays strong, even when filters or tight spaces create resistance. Start by figuring out how much airflow your setup needs. Calculate the CFM based on your cabinet size and cooling requirements. Next, look at the pressure your system faces. If you have lots of filters or small vents, you need a fan that can push air flow through with enough pressure.

Here’s a simple checklist to help you choose:

- Figure out your airflow needs. Measure the space and decide how much cooling you want.

- Check the pressure in your system. More resistance means you need a fan with higher static pressure.

- Decide on the fan type. Axial fans work well for general air flow, while centrifugal fans handle higher pressure.

- Think about noise. Some fans run quieter than others.

- Look for energy-saving options. Efficient fans help you save on power bills.

Linkwell product options and features

Linkwell gives you plenty of choices for air flow and pressure management. Their fan filter units and cabinet fans come in different sizes and styles. You can pick the mounting style that fits your cabinet best. If you need special materials, Linkwell offers options like stainless steel or high-grade plastics. Some models include weatherproofing or climate control features for tough environments.

| Customizable Feature | Description |

|---|---|

| Size | Multiple sizes available to fit different setups. |

| Mounting Style | Various mounting options to suit installation needs. |

| Door Type | Different styles and finishes to match branding. |

| Materials | Options for special materials like stainless steel or high-grade plastics. |

| Additional Features | Options for weatherproofing, security features, or climate control. |

| Support | Expert advice and after-sales support for installation. |

You get expert support from Linkwell, so you never have to guess about air flow or pressure. Their team helps you match the right fan to your cabinet’s needs.

Comparing fan specifications

When you compare fans, focus on the specs that matter for air flow and pressure. Look at the airflow rate (CFM) to see how much air the fan moves. Check the static pressure rating to make sure the fan can handle your system’s resistance. Review the efficiency rating to keep energy costs low. Material strength matters for durability. Noise levels affect comfort and safety.

| Specification | Importance | Verification Method |

|---|---|---|

| Airflow Rate (CFM) | Ensures adequate air movement for the space | Request AMCA 210 test data |

| Static Pressure | Determines the fan’s ability to overcome system resistance | Consult manufacturer specifications |

| Efficiency Rating (FEI) | Impacts energy costs and compliance | Review manufacturer documentation |

| Material Strength | Affects durability and safety | Ask for warranty and case studies |

| Noise Levels | Important for worker safety and comfort | Check decibel ratings |

Tip: Always check the fan’s performance chart. Make sure the air flow and pressure ratings match your cabinet’s needs. Linkwell’s technical support can help you read and compare specs, so you get the best airflow and cooling for your setup.

Common mistakes with fan static pressure

Overlooking static pressure in fan selection

You might think picking a fan is as simple as matching the size or airflow. Many people make mistakes by skipping the details about pressure. Here are some common errors you should watch out for:

- You forget to calculate how much contaminated air needs to be moved. This can leave your cabinet with poor ventilation and overheating issues.

- You ignore the temperature around your cabinet. If you do not measure it, you might choose a fan that is too weak or too strong.

- You misjudge the space inside your panel. Obstructions can block airflow, making the fan less effective.

- You overlook how air moves inside the cabinet. Bad airflow patterns can create hot spots and reduce cooling.

Tip: Always check both airflow and pressure needs before you pick a fan for your cabinet.

Misreading airflow and pressure specs

It is easy to mix up airflow and pressure ratings when you look at fan specifications. If you do not match the fan’s pressure rating to your system’s resistance, you might run into trouble. Sometimes, the fan does not perform as expected. You may see poor cooling or even system failures. The problem often comes from not reading the specs carefully, not from the fan itself. Always remember that every filter, vent, or bend in your cabinet adds to the pressure the fan must overcome. If you miss this, your system can become inefficient and hard to troubleshoot.

Practical tips for choosing Linkwell fans

You can avoid most mistakes by following a few simple steps:

- Find the performance curve for the fan you want. Look for the pressure you calculated and see what airflow matches on the chart.

- Make sure the fan can move enough air at the pressure your cabinet needs. This keeps your system running smoothly.

- Try to make things easier for the fan. Shorten ducts or use bigger ones to lower resistance and improve performance.

- Focus on the basics: airflow, pressure, size, noise, and reliability. Linkwell’s team can help you compare options and pick the right fan for your setup.

Note: Linkwell offers support and guidance, so you never have to guess which fan or pressure rating is best for your cabinet.

Quick guide to checking fan static pressure

Steps to evaluate fan performance

You want your fan to keep your cabinet cool and safe. To check how well your fan works, start by looking at the total pressure rise, not just static pressure. This gives you a full picture of the energy your fan adds to the airflow. Always consider the size of the inlet and outlet areas when you compare fans. These areas affect how much static pressure your fan can handle.

Here’s a simple process you can follow:

- Measure the static pressure inside your cabinet using a differential manometer.

- Calculate the static pressure by looking at the airflow speed, duct turns, and duct length.

- Check the manufacturer’s guidelines to estimate the right static pressure for your setup.

- Compare your readings to the fan’s performance chart. Make sure the airflow matches your cooling needs.

If you see a drop in airflow, your fan might be facing too much resistance. Adjust your setup or choose a fan with higher static pressure.

Tools for comparing static pressure

You have several tools to help you compare static pressure across different fan models. Many manufacturers list static pressure ratings, making it easier to pick the right fan for your cabinet. You can use a differential manometer, like the Testo 510, to measure the pressure in your system. This tool helps you see if your fan delivers enough airflow.

Here’s a quick table of useful tools:

| Tool | What It Does |

|---|---|

| Differential Manometer | Measures static pressure in ducts |

| Manufacturer Charts | Shows airflow and pressure ratings |

| Performance Curves | Helps match airflow to system needs |

Using these tools, you can compare fans and find the best match for your airflow requirements.

Making informed decisions with Linkwell

You want to make smart choices for your cabinet cooling. Linkwell offers technical support and easy-to-read performance charts. Their team helps you match airflow and static pressure to your system’s needs. If you have questions, you can reach out for advice or troubleshooting.

When you choose a fan, look at both airflow and static pressure. Make sure the fan can push enough air through filters and vents. Linkwell’s fan filter units and cabinet fans come with clear specs, so you know exactly what you’re getting. You get reliable airflow, strong cooling, and peace of mind.

Tip: Always check your airflow and pressure readings before you install a new fan. Linkwell’s experts are ready to help you make the best choice for your project.

You now understand why fan static pressure matters for cooling and equipment reliability. When you work with hvac systems, you need to keep airflow strong and static pressure balanced. Linkwell’s fan filter units and cabinet fans help you solve hvac challenges in industrial and electrical setups. Use the tips in this blog to pick the right hvac fan for your project. Trust Linkwell’s expertise for your next hvac upgrade. The right hvac fan keeps your equipment safe and running for years.

- Choose fans with the right static pressure for your hvac needs.

- Rely on Linkwell for support and quality hvac solutions.

FAQ

What is external static pressure?

External static pressure is the resistance your fan faces from filters, vents, or ductwork outside the fan itself. You need to check this value when choosing a fan for your cabinet or HVAC system.

How do I know if my fan has enough static pressure?

You can look at the fan’s performance chart. Match your system’s resistance, including external static pressure, to the fan’s rated pressure. If the airflow drops, you may need a stronger fan.

Can I improve airflow without changing my fan?

Yes! Try cleaning filters, opening vents, or shortening ducts. These steps lower external static pressure and help your fan move air more easily.

Why does static pressure matter for electrical cabinets?

Static pressure keeps air moving through tight spaces and filters. If you ignore it, your cabinet can overheat or collect dust, which leads to equipment failure.

Where can I get help choosing the right fan?

You can contact Linkwell’s support team. They help you match airflow and static pressure to your cabinet’s needs. You get expert advice and reliable solutions.