A DIN rail provides your electrical or automation system with a reliable backbone. It is used to mount, organize, and protect vital devices inside control panels. Understanding the DIN Rail Guide: Standards and selecting the right rail ensures your setup remains safe and efficient. Explore how different choices can impact your results:

| Aspect | Impact on Safety and Efficiency |

|---|---|

| Compliance with IEC | Enhances safety and reliability through compatibility and interoperability. |

| Standardization | Allows you to mix components from various manufacturers, streamlining installation. |

| Smooth Installation | Facilitates easy upgrades without the need to disassemble everything. |

| Space Optimization | Fits into tight spaces, reducing clutter and saving valuable space. |

| Cost-effectiveness | Minimizes downtime and expenses by simplifying layouts. |

| Organized Layout | Maintains a tidy environment for safer and quicker maintenance. |

With Linkwell as your trusted global partner, you receive DIN rail solutions that adhere to international standards. Make informed choices for long-term reliability and project success.

Key Takeaways

- DIN rails are essential for organizing and securing devices in electrical panels. Choose the right type for your project to ensure safety and efficiency.

- Always check for international standards like IEC 60715 when selecting DIN rails. This ensures compatibility and reduces the risk of electrical faults.

- Consider the environment where the DIN rail will be installed. Use materials like stainless steel in harsh conditions to enhance durability.

- Plan for future upgrades by leaving space on your DIN rail. This makes it easier to add or change devices without major rework.

- Select a reliable supplier like Linkwell that offers quality products and support. This helps ensure your projects run smoothly and meet safety standards.

DIN Rail Guide: Standards and Basics

What Is a DIN Rail?

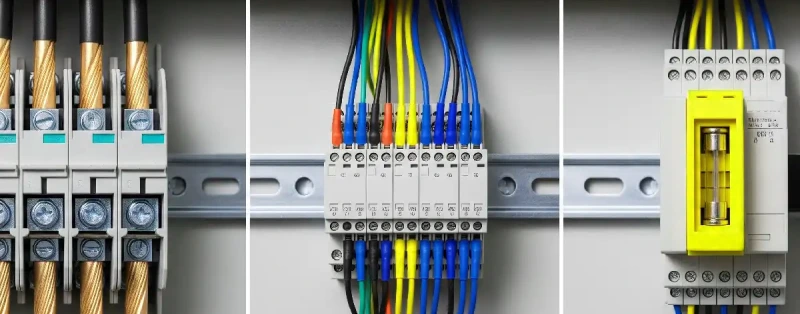

You might see the term “din rail” pop up in every electrical project. But what does it really mean? A din rail is a metal strip with precise specifications that lets you snap in circuit breakers, relays, terminal blocks, and other devices. You find these rails inside industrial control panels, energy cabinets, and even smart home setups. The rail acts as a backbone, holding everything in place and making sure your wiring stays neat.

The din rail guide: standards help you understand why this simple piece of metal matters so much. With the right specifications, you can mount devices from different brands side by side. You don’t need special brackets or tools. Just snap, lock, and you’re done.

Why DIN Rails Matter in Modern Panels

Modern electrical panels look clean and organized because of din rails. You get a system that saves space, reduces clutter, and makes upgrades easy. Here’s how different industries use din rails every day:

| Sector | Primary Functions |

|---|---|

| Industrial Automation | Mounting PLCs, I/O modules, motor controllers, relays, and sensors for organized layouts in control panels. |

| Energy Sector | Housing circuit breakers, energy meters, and control equipment in power distribution and substation panels. |

| Building Automation | Supporting controllers and sensors for HVAC, lighting, and security systems in modern buildings. |

| Telecommunications | Mounting network equipment in data centers and telecom cabinets, optimizing space with miniature din rails. |

| Transportation | Used in railway signaling and traffic control systems, enhancing reliability in critical applications. |

| Residential Applications | Providing a standardized way to mount circuit breakers and smart home devices in electrical distribution boards. |

You can see why din rails are standard in industrial cabinets. They keep everything secure, make maintenance simple, and help you expand your system without a headache.

Overview of DIN Rail Standards

You might wonder, “How do I know if my rail will fit my devices?” That’s where din rail guide: standards come in. International standards for din rails set the rules for width, height, and tolerances. These specifications make sure your components fit perfectly every time.

Here’s a quick look at the most recognized international standards for din rails:

| Standard | Description |

|---|---|

| EN 50024 | Abrogated standard for din rails, specifies tolerances and dimensions. |

| EN 50035 | Abrogated standard for G-type rails, used for heavier components. |

| EN 50022 | Specification for low voltage switchgear and control-gear, top-hat rails 35 mm wide. |

| IEC 60715 | International standard for dimensions of low-voltage switchgear and mounting on rails. |

| AS 2756.1997 | Australian standard for mounting rails for low-voltage switchgear and controlgear. |

The most important din standard today is IEC 60715. This standard covers the specifications for width, height, and even the shape of the rail. It also sets the tolerances, so you know your devices will snap on securely. EN 50022 is another key standard, especially for top-hat rails that are 35 mm wide.

Why do these standards matter? They guarantee compatibility and safety. When you follow international standards for din rails, you can:

- Mount devices from different manufacturers on the same rail.

- Align components properly, reducing wiring errors.

- Use the same rail for a variety of equipment shapes and sizes.

You get a flexible, future-proof system. You also reduce the risk of electrical faults or loose connections.

DIN Rail Standards and Compliance

Let’s talk about compliance. If you use rails that meet the right specifications, you protect your equipment and your team. Dimensional tolerances are strict for a reason. Even a small error can lead to poor connections or device failures.

Linkwell takes compliance seriously. Every din rail from Linkwell meets IEC 60715 and other international standards. You get rails with precise specifications, made from quality materials. This means your installation stays safe, reliable, and ready for the future.

Tip: Always check the specifications before you buy a din rail. Look for certifications and ask your supplier about compliance with IEC 60715 or EN 50022.

The din rail guide: standards isn’t just about rules. It’s about making your job easier and your projects safer. With the right rail, you can build panels that last for years.

DIN Rail Types and Sizes

Top Hat, C-Section, and G-Section Rails

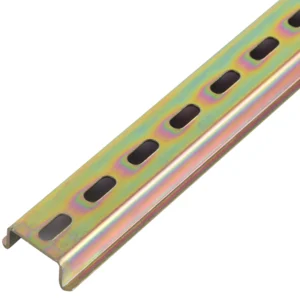

When you look at din rail types, you’ll notice three main profiles: Top Hat, C-Section, and G-Section. Each one has its own shape and purpose. The Top Hat rail, also called TS35, stands out as the most popular. You’ll find it in almost every control panel because it fits a wide range of devices, from circuit breakers to relays. The C-Section and G-Section rails work best for heavier equipment or when you need extra strength.

Here’s a quick comparison to help you spot the differences:

| Type of DIN Rail | Distinguishing Features |

|---|---|

| TS35 Rail (Top Hat) | Hat-shaped profile, versatile for many uses, perfect for circuit breakers and control devices. |

| TS32 Rail | Narrower, great for tight spaces, supports lighter components. |

| TS15 Rail (Miniature) | Smallest size, ideal for light-duty jobs like small terminal blocks and relays. |

| G-Rail | Built for heavy-duty tasks, unique shape adds strength. |

You can see why the Top Hat rail is the go-to choice for most projects. It offers flexibility and supports a wide range of components.

Common DIN Rail Sizes and Dimensions

Choosing the right size matters. Standard sizes make sure your devices fit snugly and stay secure. The most common din rail profiles come in specific widths, heights, and thicknesses. Take a look at this table for a quick guide:

| Type | Width (mm) | Height (mm) | Thickness (mm) |

|---|---|---|---|

| Top Hat | 35 | 7.5 / 15 | 1.0 – 1.5 |

| Mini | 15 | 5.5 | 1.0 |

| C Rails | 20 / 30 / 40 / 50 | 15 – 25 | N/A |

| G Rails | 32 | 15 | N/A |

Standard sizes help you design panels that are neat and safe. Thicker rails give you more strength for heavy devices. When you pick the right size, you get better compatibility, easier mounting, and a safer setup.

Tip: Always match your rail size to your device’s mounting requirements. This keeps everything secure and makes future upgrades simple.

Linkwell DIN Rail Product Range

You want options that fit your needs. Linkwell offers a full range of din rail types and sizes, so you can build panels for any job. Their rails meet international standards and come in materials like steel, aluminum, and stainless steel. You’ll find Top Hat, C-Section, and G-Section rails in their lineup, along with mini rails for compact spaces.

Linkwell’s din rail profiles support advanced features, such as pre-drilled holes for easy mounting and strong load capacity for heavy equipment. Their rails also work with a wide variety of devices, making them a smart choice for automation, utilities, and manufacturing. With Linkwell, you get reliable rails that help you organize, protect, and expand your electrical systems with confidence.

DIN Rail Materials and Features

Steel, Aluminum, and Stainless Steel Options

When you choose a din rail, you need to think about the material. The most common din rail materials are galvanized steel, aluminum, and stainless steel. Each one brings its own strengths to your project. Galvanized steel rails are strong and cost-effective. You see them in many standard control panels. Aluminum rails feel lighter and resist rust, which makes them a smart pick for humid places. Stainless steel rails shine in harsh environments. If you work near saltwater or chemicals, stainless steel gives you the best protection.

Corrosion Resistance and Durability

You want your rail to last, even when conditions get tough. The benefits of using din rails made from the right material show up in long-term reliability. Here’s how different materials stack up:

- Aluminum rails have a natural oxide layer. This layer protects against corrosion, especially in damp or humid areas.

- Anodized aluminum rails take durability up a notch. The extra coating helps them stand up to even more moisture.

- Stainless steel rails work best in extreme conditions. They handle harsh chemicals and saltwater without breaking a sweat.

- Zinc-plated steel rails offer basic corrosion resistance. They work well indoors but may not last as long as stainless or anodized aluminum in tough spots.

If you want to avoid frequent replacements, pick a rail that matches your environment.

Linkwell’s Material Advantages

Linkwell gives you options for every job. You can find rails made from galvanized steel, aluminum, or stainless steel. All rails meet strict international standards, so you get safety and peace of mind. The benefits of using din rails from Linkwell include easy installation, strong mechanical support, and reliable performance. You also get rails that resist rust and damage, which means less downtime and fewer headaches. When you choose Linkwell, you set up your system for long-term success.

How to Select the Right DIN Rail

Choosing the right din rail can make or break your project. You want a setup that fits your needs today and grows with you tomorrow. Let’s break down what you should look for when making your selection.

Application and Load Considerations

Every application has its own demands. You need to match the rail to the devices you plan to mount and the environment where you’ll install it. Think about the weight of your components, the type of enclosure, and how much space you have inside your panel. If you’re working with heavy-duty power supplies or industrial relays, you’ll want a rail that can handle the load without bending or vibrating.

Industry standards recommend that you pay close attention to the specifications of both your devices and the rail itself. The standardized design of din rails means you can trust their versatility and reliability, but you still need to check that the rail matches your electrical load and application type. For example, a control cabinet in a factory might need a robust steel rail, while a compact automation panel could use a lighter aluminum option.

Here’s a quick table to help you focus on the key factors:

| Key Factor | Description |

|---|---|

| Environmental Conditions | Consider temperature, corrosion resistance, and vibration/shock levels based on the specific application environment. |

| Space Availability | Assess the internal dimensions of the enclosure and plan the layout of components for optimal access and cooling. |

| Grounding Requirements | Determine if the DIN rail will be part of the grounding scheme and ensure proper materials and connections are used. |

| Compatibility with Enclosure | Ensure the DIN rail material is compatible with the enclosure material to prevent galvanic corrosion. |

| Specific Industry Requirements | Different industries have unique needs that influence DIN rail selection, such as hygiene standards in food processing or robustness in transportation applications. |

Tip: Always double-check the weight and mounting requirements of your devices before you pick a rail. This step helps you avoid problems down the road.

Environmental and Industry Requirements

Your environment shapes your choice. If you install a rail in a humid or corrosive area, you need materials that resist rust and damage. Stainless steel works well for outdoor or chemical-heavy locations. Aluminum offers a lightweight solution for panels in less harsh environments. If you’re building a power distribution board for a clean, dry space, galvanized steel might be all you need.

Different industries set their own standards. Food processing plants often require rails that meet strict hygiene rules. Transportation applications demand rails that can handle vibration and shock. Telecom and data enclosures need rails that support dense wiring and allow for easy upgrades. Always check the requirements for your industry before you decide.

Note: Matching the rail material to your enclosure prevents corrosion and extends the life of your system.

Compatibility and Future Expansion

You want your system to last. That means thinking about what you might add in the future. Modular and scalable electrical systems are becoming the norm. When you choose a din rail, look for options that make it easy to expand or reconfigure your panel as your needs change.

- The demand for scalable solutions is growing as electrical infrastructure expands and upgrades.

- Modular systems, like floor-mounted enclosures, give you flexibility in design and layout.

- Easy reconfiguration supports future network expansions, so you can adapt your system without big costs.

- This adaptability means your initial setup can evolve with new technology, giving you a better return on investment.

If you plan for future growth, you save time and money later. Choose a rail that lets you snap in new devices, move things around, or upgrade without tearing everything apart.

Pro Tip: Always leave a little extra space on your rail for future devices. This simple step makes upgrades much easier.

DIN Rail Costs and Pricing Factors

Material and Manufacturing Impact

When you look at the price of a din rail, the material makes a big difference. Stainless steel usually costs more than aluminum or plastic. Thicker rails use more material, so they cost more too. The way a rail is made also matters. If the manufacturer follows strict standards and uses advanced machines, the cost can go up. Some rails need to meet special compliance rules for certain applications. These extra steps add to the price but help you get a safer and more reliable product. Market trends and competition also play a role in what you pay.

Size, Customization, and Bulk Orders

Several factors can change the price you pay for a rail, especially if you need something special for your applications:

- Large orders often come with bulk discounts, so you save money when you buy more.

- Custom rails, like those with special lengths or extra holes, usually cost more because they need extra work.

- If you order through a big distributor, you might get a different price than a small business would.

- Some applications need unique solutions, such as pluggable terminal blocks, which can raise the price.

- Big industrial customers often get better pricing than smaller companies.

You might also notice that local suppliers can offer faster delivery, but overseas suppliers sometimes have lower prices. Think about your project timeline and shipping costs when you choose.

Value of Linkwell’s Cost-Effective Solutions

Linkwell helps you save money in several ways. Take a look at how their din rail solutions stand out:

| Cost-Saving Advantage | Description |

|---|---|

| Easy Installation | You can snap devices onto the rail without screws, saving time and effort. |

| Modular Design | You can add or move components without rewiring, making changes simple. |

| Compliance with Standards | Every rail meets international standards, so you avoid costly mistakes. |

| Reduced Downtime | Fast installation and maintenance mean less time with your panel offline. |

| Lower Maintenance Costs | Clear labeling and easy checks make maintenance safer and quicker. |

You get a rail that fits many applications, meets every standard, and helps you keep your project on budget. Linkwell’s focus on quality and efficiency means you spend less time worrying about costs and more time building reliable systems.

Choosing a Reliable DIN Rail Supplier

Key Qualities of a Trusted Supplier

When you pick a supplier for your din rail needs, you want more than just a catalog. You want a partner who understands your applications and delivers on every promise. Look for suppliers with strong manufacturing capabilities and a proven track record. They should offer consistent quality, fast lead times, and clear communication. Reliable suppliers provide customization options, so you get rails that fit your unique applications. Watch out for red flags like vague answers, missing documentation, or slow support. These can cause headaches down the road.

A trusted supplier will help you with technical support and flexible order sizes. They should also have experience with different industries, so they know what works best for your applications. If you see a supplier offering only generic products with no customization or support, it’s time to look elsewhere.

Evaluating Product Quality and Certifications

You want your rail to last and perform well in all applications. Certifications and quality control make a big difference here. Suppliers who follow international standards, like IEC 60715, show they care about safety and reliability. Certifications such as TUV prove that the products meet strict quality requirements. Here’s what you should expect from a top supplier:

- Certifications like TUV ensure compliance with international standards.

- High-quality materials boost reliability and efficiency.

- Manufacturing processes that follow global standards keep your applications safe.

- Willingness to provide documentation, like test certificates and compliance declarations, shows transparency.

| Evidence Type | Description |

|---|---|

| Material Traceability Documentation | Papers tracing materials back to their source |

| Test Certificates | Documentation of critical properties like corrosion resistance |

| Standards Compliance Declarations | Statements confirming adherence to IEC 60715 or regional standards |

| Quality Management Certifications | ISO 9001 certification indicates structured quality management systems |

| Environmental Compliance | RoHS and REACH compliance, indicating eco-friendly practices |

| Industry-Specific Certifications | UL Listing/Recognition for North America, CE marking for Europe, and others for specialized uses |

If a supplier can’t provide these, you might want to reconsider your choice.

Linkwell’s Global Support and Customization

You need a supplier who stands by you before, during, and after your purchase. Linkwell offers global support and customization services that make your job easier. Whether you need a single rail or thousands, Linkwell tailors solutions for your applications. Their 24/7 technical support means you always have help when you need it.

| Service Type | Description |

|---|---|

| Custom Solutions | Tailored solutions for any enclosure or device. |

| Flexible Order Sizes | Orders can range from one piece to thousands. |

| 24/7 Technical Support | Continuous support and after-sales assistance. |

Linkwell’s experience with OEMs, panel builders, and system integrators means you get expert advice for all applications. Their TUV certifications and commitment to international standards give you peace of mind. When you choose Linkwell, you get a partner who supports your success every step of the way.

Installation and Maintenance Best Practices

Step-by-Step DIN Rail Installation

Ready to tackle din rail installation? You want a safe and reliable setup. Here’s how to mount din rails the right way:

- Power Down: Turn off all power. Lock out and tag out the source. Use a multimeter to check for voltage.

- Check Compatibility: Make sure your power supply matches the load and the environment.

- Gather Tools: Get your screwdriver, wire stripper, and the correct terminal blocks.

- Review Instructions: Look at the datasheet for any special notes.

- Mount the Rail: Snap the din rail into place inside the enclosure. Make sure it’s secure.

- Install Devices: Attach your circuit breakers, relays, or terminal blocks onto the rail.

- Wire Connections: Connect input and output wires to the right terminals.

- Grounding: Ground both the power supply and the rail for safety.

- Fuse Protection: Add a fuse or breaker if needed.

- Organize Wiring: Keep wires neat and secure.

- Test Everything: Double-check connections and test the system.

Tip: Always leave some space between devices for airflow and future upgrades.

Common Mistakes to Avoid

You want your din rail installation to last. Watch out for these common mistakes:

- Using the wrong fuse rating can cause fire hazards or damage. Always match the fuse to your device.

- Choosing wires that are too thin leads to overheating. Pick the right size for your load.

- Ignoring environmental stress, like high humidity or heat, shortens equipment life.

- Messy wiring can cause short circuits or voltage drops. Route wires carefully and make precise terminations.

Note: Careful planning and neat work help you avoid costly repairs and downtime.

Maintenance and Inspection Tips

Regular installation and maintenance keep your system running smoothly. Here’s a quick table of best practices:

| Best Practice | Description |

|---|---|

| Routine Checks | Inspect for corrosion and loose parts every year or as scheduled. |

| Secure Installation | Make sure all devices stay firmly attached to the rail. |

| Material Choice | Use stainless steel rails in damp or corrosive areas for longer life. |

| Modular System | Choose modular rails for easy snap-on replacements and less downtime. |

Reminder: A clean and organized panel makes inspections faster and safer.

Understanding DIN rail standards and types helps you build safe, organized, and adaptable electrical systems. When you know what to look for in a rail and supplier, you make your projects more efficient and future-ready. Linkwell’s certified products and global support can boost your project’s success:

- Peer-reviewed certifications and ongoing support keep your installations reliable.

- Collaboration with experts ensures your system meets high standards.

Here are key takeaways for selecting and installing din rails:

| Key Consideration | Details |

|---|---|

| Environmental Conditions | Pick materials that resist temperature and corrosion. |

| Space and Layout | Plan for easy wiring and maintenance. |

| Grounding | Use proper grounding for safety. |

| Compatibility | Match rail and enclosure materials. |

| Industry Needs | Follow industry-specific practices. |

| Installation | Use correct mounting and wire management. |

| Labeling | Label components for safe maintenance. |

If you want expert advice or need a custom solution, you can contact Linkwell for help with your din projects.

FAQ

Are DIN rails universal?

You can use most devices from different brands on the same din rail. The international standards make this possible. Always check your device’s specs to be sure it fits your rail.

Can DIN rails be cut to length?

Yes, you can cut a din rail to fit your panel. Use a hacksaw or a rail cutter for a clean edge. Always smooth any sharp edges before installing.

How much weight can a DIN rail support?

A standard din rail can hold several pounds, but the exact weight depends on the rail’s material and size. Check the manufacturer’s guidelines for safe load limits.

What devices can I mount on a DIN rail?

You can mount circuit breakers, relays, terminal blocks, power supplies, and many control devices. The snap-on design makes installation quick and easy.

Do I need special tools to install a DIN rail?

You usually need only basic hand tools, like a screwdriver and a saw. Some rails snap into place, so you might not need any special tools at all.