If you’re curious about how to cut DIN rail for your next project, the process depends on your tools, skill level, and the specific type of rail you’re working with. Quality is key, so selecting a reliable brand like Linkwell ensures your job is both smoother and safer. When it comes to how to cut DIN rail, some people use hand tools, while others opt for machines. Choosing the right cutting method helps you achieve a clean cut and keeps your project running efficiently.

Key Takeaways

- Choose the right cutting method for your DIN rail project. Hand tools work well for small jobs, while machines excel in speed and precision for larger tasks.

- Always prioritize safety when cutting DIN rail. Wear protective gear like gloves and safety glasses, and keep your workspace organized.

- Use high-quality DIN rails, like those from Linkwell, for smoother cuts and better results. Their rails are designed to minimize bending and splintering.

- Follow a clear step-by-step process for cutting DIN rail, whether by hand or machine. This ensures clean, professional results every time.

- Consider Linkwell’s cut-to-length services for convenience. You can get DIN rails delivered in the exact size you need, saving time and reducing waste.

How to Cut Din Rail: Manual Methods

When you want to tackle a project by hand, knowing how to cut din rail the right way makes all the difference. The quality of your DIN rail matters, too. Linkwell’s rails use corrosion-resistant materials and meet IEC 60715 standards, so you get a smooth, safe cut every time. High-quality rails from Linkwell won’t bend or splinter, which means less effort and a cleaner finish.

Tools Needed for Hand Cutting

You have several options for cutting DIN rail by hand. Each tool has its own strengths and weaknesses. Here’s a quick comparison to help you choose the best fit for your job:

| Tool Type | Advantages | Disadvantages |

|---|---|---|

| Manual Ratcheting Cutters | High precision, low physical effort, clean cuts, compact size | Slightly higher initial cost, limited to specific rail widths unless adjustable |

| Scissor-Type Hand Cutters | Affordable, lightweight, easy to carry | Require significant hand strength, may produce uneven cuts over time, wear faster |

| Adjustable Multi-Rail Cutters | Versatile across projects, future-proof for varied job types | More complex setup, potentially bulkier |

| Powered Cutters | Extremely fast, consistent in high-volume settings | Expensive, not practical for fieldwork, require power source |

If you’re working with Linkwell’s DIN rails, you’ll find that manual ratcheting cutters or adjustable multi-rail cutters work especially well. These tools handle the sturdy, standardized profiles with ease.

Safety Tips for Manual Cutting

Cutting DIN rail by hand is straightforward, but safety should always come first. Here are some best practices to keep you safe:

- Wear personal protective equipment like safety glasses and gloves. This protects you from flying metal bits.

- Keep your workspace clean and organized. A tidy area helps prevent slips and trips.

- Clamp your DIN rail securely before you start cutting. This keeps the rail steady and your hands safe.

- Stay aware of your surroundings. Watch out for other people and potential hazards.

- Use spark-resistant tools if you’re working near flammable materials.

Tip: Always double-check your tool’s condition before starting. Sharp, well-maintained blades make cutting easier and safer.

Step-by-Step: Cutting Din Rail by Hand

Ready to get started? Here’s how to cut din rail by hand for a clean, professional result:

- Measure and Mark

Use a tape measure to find your desired length. Mark the spot clearly with a permanent marker or scribe. - Secure the Rail

Place the DIN rail in a sturdy vise or clamp. Make sure it’s tight so the rail won’t move while you cut. - Choose Your Tool

Pick the right cutter for your rail type. Manual ratcheting cutters work great for most Linkwell rails. If you have a different profile, check your tool’s compatibility. - Align the Blade

Line up the blade with your mark. Double-check your measurement before you cut. - Cut the Rail

Apply steady pressure and squeeze the handles. Let the tool do the work. For thicker rails, you might need to use a ratcheting motion. - Smooth the Edges

After cutting, use a metal file to remove any sharp burrs. This step keeps your installation safe and professional. - Inspect Your Work

Check the cut for straightness and smoothness. Linkwell’s DIN rails make this easy because of their consistent quality.

If you follow these steps, you’ll get a precise cut every time. High-quality rails from Linkwell help you avoid jagged edges and wasted material, so your project looks sharp and stays safe.

How to Cut Din Rail: Machine Methods

When you want speed, precision, and a professional finish, machine cutting is the way to go. Many panel builders and electricians choose this method, especially when working with high-quality DIN rail from Linkwell. Our rails are designed to fit all standard machine cutters, so you get a clean cut every time—no matter the project size.

Types of Cutting Machines

You have several options when it comes to machine cutting. The most common machines for DIN rail include:

| Machine Type | Cutting Mechanism | Best For |

|---|---|---|

| Dedicated DIN Rail Cutter | Guillotine or scissor action | Fast, precise, burr-free cuts |

| Chop Saw | Abrasive or toothed blade | Cutting multiple rails quickly |

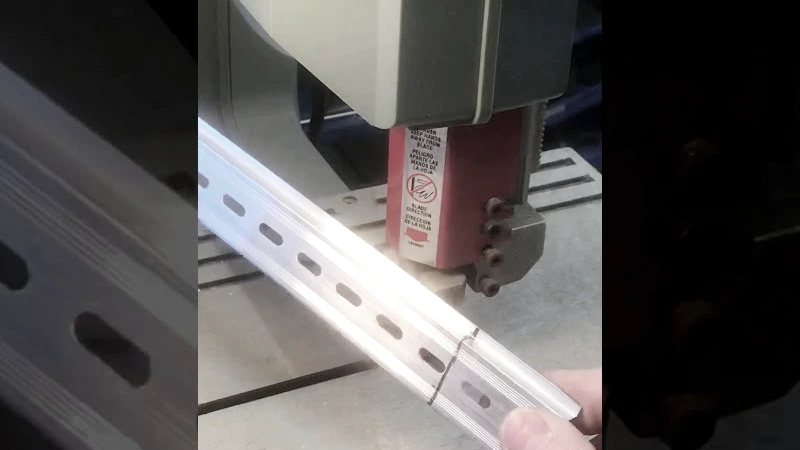

| Band Saw | Continuous loop blade | Long, straight cuts, versatility |

Dedicated DIN rail cutters use a guillotine or scissor-like action. You just pull the lever, and the blade slices through the rail with almost no effort. Chop saws and band saws use high-speed blades to cut through metal. These machines work well for bulk jobs or when you need to cut different rail profiles.

Linkwell’s DIN rails are compatible with all these machines. The rails’ consistent thickness and sturdy materials mean you get reliable results, whether you use a manual guillotine cutter or a powered saw.

Tip: If you work in a busy shop or handle lots of rails, investing in a dedicated DIN rail cutter can save you time and reduce waste.

Using a Chop Saw or Band Saw

Chop saws and band saws are popular in workshops. They handle tough jobs and make quick work of even the thickest rails. Here’s what you need to know:

- Chop Saw: This tool uses a circular blade to slice through metal. You lower the blade onto the rail, making a fast, straight cut. Chop saws are great for cutting several rails at once.

- Band Saw: This machine uses a continuous blade that moves in a loop. You feed the rail into the blade for a smooth, controlled cut. Band saws are perfect for longer rails or when you want extra precision.

Both machines work well with Linkwell’s DIN rails. The rails’ corrosion-resistant finish and uniform shape help you get a smooth edge with less filing afterward.

Safety First: Always wear safety glasses and gloves. Secure the rail firmly before cutting. Keep your hands clear of the blade, and never rush the process.

Step-by-Step: Machine Cutting Process

If you want to know how to cut din rail with a machine, follow these steps for a clean, accurate result:

- Mount the Cutter or Set Up the Saw

Attach your DIN rail cutter to a solid workbench. If you use a chop saw or band saw, make sure it sits on a stable surface. - Install Accessories

Add the handle, measuring guide, or any other attachments your machine needs. This helps you measure and cut the rail to the exact length. - Set the Cutting Length

Adjust the measuring guide to your desired length. Double-check your measurement for accuracy. - Insert the DIN Rail

Slide the rail into the machine’s slot or clamp it in place. Make sure it sits flush against the guide stop. - Secure the Rail

Lower the guide wall or clamp to hold the rail steady. This step keeps your cut straight and your hands safe. - Make the Cut

Pull the lever on a dedicated cutter in one smooth motion. For a chop saw or band saw, lower or feed the blade through the rail slowly and steadily. - Remove and Inspect

Lift the guide wall or unclamp the rail. Take out the freshly cut piece and check the edge. Use a metal file to smooth any burrs if needed.

Note: Linkwell’s DIN rails are designed for easy, burr-free cutting. You’ll spend less time filing and more time finishing your project.

Knowing how to cut din rail with a machine gives you a big advantage. You get fast, repeatable results and a professional look every time. With Linkwell’s rails, you can trust that every cut will be clean and precise, whether you use a guillotine cutter, chop saw, or band saw.

Comparing Manual vs. Machine Cutting

When you need to decide between manual and machine cutting for your DIN rail, it helps to look at what matters most for your project. Let’s break it down so you can pick the best method for your needs.

Speed and Efficiency

Manual cutting works well for small jobs or quick fixes. You can grab your hand tool and get started right away. If you only need a few pieces, this method saves time on setup. Machine cutting shines when you have a lot of rails to cut. You can line up several rails and slice through them in seconds. Shops and busy installers often choose machines because they boost productivity and keep projects on track.

If you want to save even more time, Linkwell offers cut-to-length DIN rail services. You get rails delivered to your exact size, ready to install.

Precision and Finish

Hand tools give you good control, especially if you use quality cutters and rails. You can make careful cuts and check each piece as you go. Sometimes, you might need to file the edges for a smooth finish. Machines, on the other hand, deliver consistent, straight cuts every time. You get a professional look with less effort. Linkwell’s DIN rails work perfectly with both methods, thanks to their sturdy build and smooth surface.

| Method | Precision | Finish |

|---|---|---|

| Manual | Good | May need filing |

| Machine | Excellent | Clean, smooth |

Cost and Accessibility

Manual cutting tools cost less and fit in any toolbox. You don’t need much space or power. This makes them great for fieldwork or small shops. Machine cutters cost more upfront, but they pay off if you cut rails often. They also need a dedicated workspace. If you want to skip the hassle, Linkwell’s customization services let you order rails in any length or profile. You get exactly what you need, with no waste.

Not sure which method fits your project? If you’re working on a large panel build or need perfect cuts every time, machine cutting or Linkwell’s custom services are your best bet. For quick jobs or repairs, manual tools do the trick.

Choosing the Right Linkwell Din Rail

Types of Din Rail Offered by Linkwell

When you choose Linkwell, you get access to a full range of DIN rail options for any project. Each type has its own strengths, so you can find the perfect fit for your needs. Here’s a quick look at what you can pick from:

- Top Hat Rails (TS35): These are 35mm wide and work well for most modern devices. You’ll see them in many control panels.

- Mini Top Hat Rails (TS15): At just 15mm wide, these rails fit into tight spaces and hold smaller components.

- C Rails: With a width of 32mm, C rails are built for heavier equipment and offer strong support.

- G Rails (TS32): Also 32mm wide, G rails give extra support for heavy-duty parts and demanding setups.

You can compare the main types in this table:

| Type of DIN Rail | Width (mm) | Depth (mm) | Main Use |

|---|---|---|---|

| Top Hat (TS35) | 35 | 7.5 / 15 | Versatile, fits most components |

| Mini Top Hat (TS15) | 15 | 5.5 | Compact, for small devices |

| C Rail | 32 | N/A | Supports heavier equipment |

| G Rail (TS32) | 32 | N/A | Heavy-duty support |

Linkwell’s DIN rails meet international safety standards and work with major brands. You get rails that are strong, corrosion-resistant, and easy to install. This means you can trust them in any environment, from factories to outdoor panels.

Selecting the Best Rail for Your Project

Picking the right DIN rail is about more than just size. You want to match the rail to your application, the weight of your devices, and even your preferred cutting method. Some rails are easier to cut by hand, while others work best with machines.

“Choosing the right DIN rail channel begins with understanding the application, load requirements, and compatibility with other terminal blocks accessories.”

Here are some things to think about:

- Material: Choose steel, aluminum, or copper based on how tough your environment is and how much durability you need.

- Profile type: Pick Top Hat, C-Rail, G-Rail, or Miniature DIN Rail depending on your space and the devices you plan to mount.

- Load capacity: Make sure your rail can handle the weight of all your components.

- Mounting method: Decide if you need screws or snap-on brackets for a secure fit.

- Environment: Go for corrosion-resistant rails if you’re working in harsh or outdoor conditions.

| Factor | Consideration |

|---|---|

| Mounting Method | Screws or snap-on brackets for secure fit |

| Rail Type | Match to device requirements (e.g., Top Hat) |

| Load Capacity | Check static vs. dynamic load |

| Environment | Use corrosion-resistant materials if needed |

Linkwell’s DIN rails help you organize your wiring, keep your panel safe, and make future upgrades easy. You can add, remove, or move components without hassle. If you ever need help choosing, Linkwell’s team is ready to support you with expert advice and custom solutions.

Conclusion

You now have a clear path for cutting DIN rail, whether you prefer hand tools or machine methods. Both approaches have their place. Manual cutting works well for quick jobs or when you need flexibility on-site. Machine cutting gives you speed and precision, especially if you handle large projects or want a professional finish every time.

When you choose Linkwell DIN rail, you set yourself up for success. Our rails meet international standards and work with all common cutting tools. You get consistent quality, so your cuts stay clean and your installations look sharp. If you ever feel unsure about which method to use, just think about your project size, your available tools, and how much time you want to spend.

Safety always comes first. Wear your gloves and safety glasses. Double-check your measurements before you cut. Take a moment to file any sharp edges for a smooth, safe result.

Here’s a quick recap to help you decide:

| Project Size | Best Cutting Method | Linkwell Advantage |

|---|---|---|

| Small/Field Work | Manual Tools | Easy to cut, reliable quality |

| Large/Workshop | Machine Cutters | Fast, precise, less waste |

| Custom Orders | Linkwell Cut-to-Length | Ready-to-install, zero hassle |

If you want to skip the cutting altogether, Linkwell offers cut-to-length and custom DIN rail services. You get exactly what you need, delivered fast, with support from a team that knows DIN rail inside and out.

Ready to upgrade your next project? Visit Linkwell’s website or reach out for expert advice. With Linkwell, you get more than just DIN rail—you get a partner who cares about your success.

You now know the key differences between manual and machine cutting. Manual tools work well for quick jobs or fieldwork. Machines give you speed and perfect cuts for bigger projects. Always wear safety gear and double-check your work. If you need help, Linkwell offers expert support and a wide range of DIN rail options. Check out this quick guide to Linkwell’s support:

| Aspect | Details and Selection Criteria |

|---|---|

| Types Available | DIN Rail Distribution Blocks (by current, voltage, connection type) |

| Current Ratings | Up to 310A |

| Voltage Range | 12V, 48V, 600V |

| Connection Types | Screw, Push-in, Spring-clamp |

| Housing Material | Flame-retardant polyamide |

| Certifications | UL, CE, RoHS |

| Customization | Labeling, colors, OEM branding |

| Selection Criteria | Match current/voltage to load; pick connection type; check safety |

Let Linkwell help you get the right DIN rail for your next project.

FAQ

How do I know which DIN rail type fits my project?

You can match your device size and weight to the rail profile. Top Hat rails work for most panels. C and G rails support heavier equipment. If you need help, Linkwell’s team can guide you to the best choice.

Can I cut Linkwell DIN rails with any hand tool?

Yes, you can use most standard hand tools like ratcheting cutters or hacksaws. Linkwell DIN rails have consistent thickness and strong materials, so you get a smooth cut with the right tool.

Do I need special safety gear when cutting DIN rail?

Absolutely! Always wear safety glasses and gloves. Metal bits can fly when you cut. A secure workspace keeps you safe. Safety comes first, whether you use hand tools or machines.

What if I want custom-length DIN rails?

No problem! Linkwell offers cut-to-length services. You can order rails in any size you need. This saves you time and gives you a perfect fit for your project.

Are Linkwell DIN rails compatible with other brands’ components?

Yes, Linkwell DIN rails follow international standards. You can mount devices from many brands on them. This makes your panel flexible and future-proof.