You need reliable transformers in your control cabinets to keep your operations smooth and safe. The right transformers help you manage voltage, protect equipment, and keep everything running efficiently. In 2026, you will see new standards and smarter technology in industrial settings. Linkwell stands out as a global leader, offering control cabinet transformers that meet strict safety and quality standards.

The demand for these transformers keeps rising, with the global market expected to grow at a CAGR of 14.5% from 2026 to 2033. If you want to understand the Difference Between Step Up and Down Transformer, you should know how they shape the future of control cabinets. Transformers give your system the power to adapt, protect, and perform.

Key Takeaways

- Step-up transformers increase voltage for specialized equipment, ensuring proper operation in control cabinets.

- Step-down transformers reduce high voltage to safe levels, protecting sensitive devices from damage.

- Linkwell transformers offer certified quality and durability, meeting global safety standards for reliable performance.

- Using the right transformers enhances energy efficiency, leading to significant cost savings over time.

- Smart technology integration in transformers allows for real-time monitoring, improving system reliability and safety.

Step-Up and Step-Down Transformers in Control Cabinets

What Are Step-Up Transformers

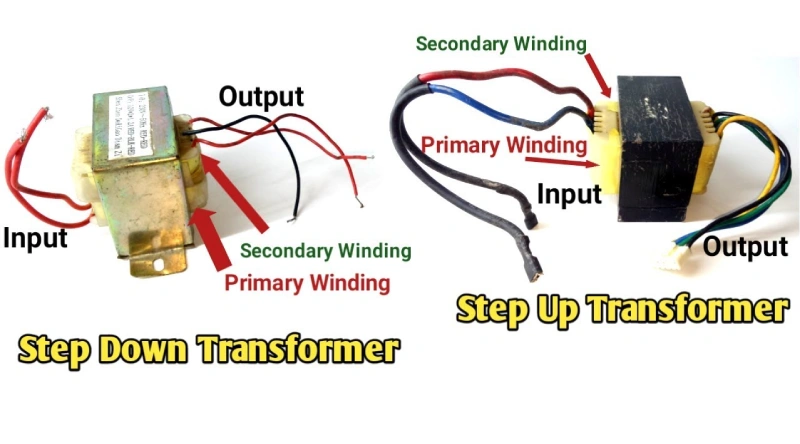

You might wonder why step-up transformers matter in your control cabinets. These transformers take the voltage from your power source and increase it to a higher level. You see this when you need to power devices that require more voltage than your main supply provides. Step-up transformers have fewer windings on the primary side and more on the secondary side. This design lets you boost voltage safely and efficiently. In control cabinets, step-up transformers help you run specialized equipment or connect to systems that need higher voltage for proper operation. You can count on them to deliver stable power, which keeps your electrical systems running smoothly.

What Are Step-Down Transformers

Step-down transformers do the opposite job. They take high voltage and reduce it to a safer, usable level for your devices. Most of your control cabinets need step-down transformers because many components can’t handle high voltage directly. These transformers protect your equipment from overload and damage. They also make sure your devices get the right voltage every time. Linkwell’s step down transformer stands out for its compact design, heat-resistant copper windings, and reliable performance. You can use these transformers in telecom racks, industrial control panels, and other power systems where safety and efficiency matter most.

Role in Transmission and Industrial Applications

Transformers play a huge role in transmission and industrial settings. In your control cabinets, step-up transformers help you connect to high-voltage transmission lines or specialized machinery. Step-down transformers make sure the voltage drops to a safe level before reaching sensitive devices. This process prevents equipment damage and keeps your operations safe. You need both types of transformers for smooth power distribution systems in modern factories, telecom stations, and automation setups. Linkwell’s control transformer products give you the flexibility to customize voltage, frequency, and power levels for any application. With certified safety and energy efficiency, these transformers support stable operation in all your electrical systems.

Tip: Custom step-up and step-down transformers are essential for safe voltage conversion. They prevent catastrophic incidents and keep your equipment running without interruption.

You can trust transformers to handle voltage changes, protect your gear, and keep your power systems future-ready.

Difference Between Step Up and Down Transformer

Key Features and Functions

You might wonder what sets step-up transformers apart from step-down transformers in your control cabinets. The difference between step up and down transformer comes down to how each one handles voltage and current. Step-up transformers take a lower voltage and boost it to a higher level. You use them when your equipment needs more voltage than your main supply gives. Step-down transformers do the opposite. They take a high voltage and bring it down to a safer, usable level for your devices.

Let’s break down the technical side. Here’s a simple table to help you see the functional differences:

| Specification | Step-Up Transformers | Step-Down Transformers |

|---|---|---|

| Voltage | Low input voltage, high output voltage | High input voltage, low output voltage |

| Winding | Secondary winding has high voltage | Primary winding has high voltage |

| Current | Low current on the secondary winding | High current on the secondary winding |

| Rating of Output Voltage | 11000 volts or above | 110v, 24v, 20v, 10v, etc. |

You can see that step-up transformers are all about increasing voltage for special applications, while step-down transformers focus on making power safe for your control circuits. Both types play a big role in transmission inside your control cabinets. They help you manage energy flow and keep your systems running smoothly.

Application Scenarios in Control Cabinets

You use step-up transformers in control cabinets when you need to power devices that require higher voltage. For example, you might have sensors, actuators, or communication modules that need more voltage than your main supply. These transformers help you connect to transmission lines or specialized equipment that operates at a higher voltage.

Step-down transformers are more common in control cabinets. You rely on them to protect sensitive devices like relays, timers, and PLCs. They make sure your equipment gets the right voltage, which prevents overload and damage. You see them in telecom racks, automation panels, and industrial control systems. Step-down transformers also help you meet safety standards by lowering voltage before it reaches your devices.

Both types of transformers support reliable transmission and energy management in your control cabinets. You can customize them for different voltage levels, frequencies, and power needs. This flexibility lets you design control cabinets that fit your exact requirements.

Linkwell Product Advantages

When you choose Linkwell transformers for your control cabinets, you get more than just basic voltage conversion. You get products built for reliability, safety, and long-term performance. Here’s what makes Linkwell stand out:

- Military-grade insulation materials give you a lifespan of over 20 years.

- Fully automated production means you get consistent quality every time, with a product consistency rate above 98%.

- You can request custom designs for voltage levels, pin layouts, and special applications.

- Linkwell transformers come with global certifications like UL, CE, RoHS, and GB/T 19212.1.

- You benefit from a low defect rate—just one in a thousand, much lower than the international average.

- An in-house R&D team helps you create solutions tailored to your control cabinet needs.

You also need to know about the latest certification requirements. By September 1, 2026, all step-up and step-down transformers for control cabinets must have BIS certification under the new Omnibus Technical Regulation. This rule boosts safety, performance, and reliability for critical energy infrastructure. Linkwell already meets or exceeds these standards, so you can trust their transformers in your projects.

Tip: Always check for certifications like UL, CE, and BIS when you pick transformers for your control cabinets. Certified products keep your systems safe and compliant with future regulations.

The difference between step up and down transformer matters for every control cabinet. You need the right type for each application, and you want a partner who delivers quality and support. Linkwell gives you both, making your control cabinets ready for the future.

Benefits of Using Step-Down Transformers

Voltage Regulation and Equipment Protection

You want your control cabinets to run safely and smoothly. Step-down transformers help you achieve that by providing reliable voltage regulation. They take high voltage levels and reduce them to the right amount for your sensitive equipment. This process protects your devices from overload and damage. You get a stable power supply, which means fewer interruptions and longer equipment life.

Here’s how step-down transformers boost safety in your control cabinets:

- Fault protection features like fuses and breakers limit energy surges and prevent overheating.

- Pressure relief systems safely release built-up pressure, stopping explosions before they start.

- Only trained personnel can access the cabinet, thanks to authorized access controls and safety signage.

- Tamper-resistant designs and fault protection keep public areas safe.

You can trust these transformers to keep your control panels secure and your team protected.

Energy Efficiency and Cost Savings

Step-down transformers don’t just keep your equipment safe—they also help you save money. By lowering voltage levels, they support efficient power distribution and reduce wasted energy. You get the efficient transfer of power your system needs. Over five years, high-efficiency transformers can save you between $4,000 and $8,000 per MVA rating in energy loss. You see a return on investment in as little as three years. That means more money stays in your budget for upgrades or new projects.

Linkwell’s Step Down Transformer Features

If you’re looking for step-down transformers designed for control cabinets, Linkwell has you covered. Their transformers offer:

- Stable, isolated power for equipment protection.

- Robust construction and excellent voltage regulation.

- Compact design that fits easily inside control panels.

- Protective metal enclosures and integrated safety features.

- Certifications like UL5085, CE, RoHS, CCC, and ISO9001 for international compliance.

Here’s a quick look at the certifications:

| Certification | Description |

|---|---|

| UL | Essential for safety approval in the U.S. |

| CE | Mandatory for compliance in the EU. |

| ISO 9001:2015 | Recognized for quality management systems. |

With Linkwell’s step-down transformers, you get peace of mind, reliable performance, and products that meet global standards. You make your control cabinets ready for the future.

Future Trends for Control Cabinets in 2026

Evolving Standards and Smart Integration

You’re going to see big changes in control cabinets as new standards roll out. Regulations now push for higher transmission efficiency and safer operation. You need to meet global standards like IEC 60076, DOE 2016, and GB 1094, which focus on energy savings and environmental safety. These rules shape how you select transformers for your cabinets. You’ll notice more smart technology in your systems. Control transformers now come with sensors and IoT features. You can monitor temperature, voltage, and load status in real time. This helps you predict problems and manage transmission more effectively. Smart integration means your control cabinets work better with long-distance transmission networks, boosting transmission efficiency and reliability.

Note: Smart transformers let you track performance and spot issues before they cause downtime. You get safer, more efficient transmission every day.

Innovations in Control Transformers

Manufacturers keep pushing the limits with new designs. You’ll find advanced core materials like nanocrystalline steel, which cut down on energy loss and improve transmission efficiency. Precise winding techniques help you get better inductance control. IoT integration lets you check your transformer’s health from anywhere. Here’s a quick look at what’s new:

| Innovation Type | Description |

|---|---|

| Advanced Core Materials | Nanocrystalline steel for lower loss and better transmission efficiency |

| IoT Integration | Real-time monitoring for predictive maintenance |

| Energy Efficiency | Optimized winding for improved transmission efficiency |

| Manufacturing Techniques | Enhanced winding for better transmission efficiency |

You get more reliable transmission and less wasted energy. These innovations make your control cabinets ready for the future.

Linkwell’s Commitment to Quality and Support

You want a partner who stands by you as standards change. Linkwell tests every transformer with voltage ratio checks, insulation resistance, and load loss assessments. Only units that pass strict tests get shipped. You get a quality control seal for peace of mind. Linkwell also offers lifetime technical support, wiring diagrams, and installation help. If you need a custom solution for transmission efficiency or long-distance transmission, Linkwell can design it for you. Their after-sales team helps you minimize downtime and keep your control cabinets running smoothly.

Tip: Choose Linkwell for transformers that meet future standards and give you reliable transmission efficiency.

Conclusion

You’ve seen how step-up and step-down transformers shape the future of control cabinets. These devices give you the power to manage voltage, protect your equipment, and keep your operations running smoothly. When you use the right transformer, you make your control cabinet safer, more efficient, and ready for new technology in 2026.

Let’s recap the key reasons you need these transformers:

- Safety: You lower the risk of overloads and electrical faults. Your sensitive devices get the right voltage every time.

- Efficiency: You cut down on wasted energy and save money on power bills. Your system runs better and lasts longer.

- Reliability: You avoid downtime and keep your production lines moving. Your control cabinets stay future-ready.

Always check for certifications like UL, CE, and ISO9001 when you choose transformers. Certified products help you meet global standards and keep your systems safe.

Here’s a quick table to help you remember what makes Linkwell stand out:

| Feature | Benefit for You |

|---|---|

| Customization Options | Fit any cabinet or application |

| Global Certifications | Meet safety and quality rules |

| Fast Delivery | Get products when you need them |

| Expert Support | Solve problems quickly |

You want a partner who understands your needs. Linkwell gives you high-quality transformers, expert advice, and support whenever you need it. You can trust their products to help you upgrade or design control cabinets that meet the latest standards.

Ready to future-proof your control cabinets? Visit Linkwell’s website or reach out for a custom solution. You’ll see how easy it is to build safer, smarter, and more efficient systems for 2026 and beyond.

You need step-up and step-down transformers in your control cabinets to keep everything safe, efficient, and ready for the future. Here’s what matters most:

- Step-down transformers lower voltage for control circuits and electronics.

- Step-up transformers boost voltage for special industrial equipment.

- Linkwell gives you certified quality, durable designs, and fast delivery trusted worldwide.

| Factor | Why It Matters for 2026 |

|---|---|

| Compliance with standards | Keeps your system safe and reliable |

| Load requirements | Matches your power needs |

| Future capacity planning | Prepares you for growth |

Choose Linkwell to upgrade your control cabinets and meet tomorrow’s standards with confidence.

FAQ

What is the main job of a transformer in a control cabinet?

You use a transformer in your control cabinet to change voltage levels. This keeps your equipment safe and helps everything run smoothly. It also protects sensitive devices from power surges.

How do I choose the right transformer for my control cabinet?

You should check your input and output voltage needs, power rating, and the type of equipment you want to protect. If you feel unsure, ask a supplier like Linkwell for help.

Can I customize a transformer for my specific application?

Yes! You can request custom voltage, frequency, or size. Linkwell offers many options to fit your unique control cabinet setup.

How do I know if my transformer meets safety standards?

Look for certifications like UL, CE, or ISO9001 on your transformer. These marks show that your product meets strict safety and quality rules.