You want to get Control Transformer Wiring right the first time. Safety comes first, so you need to follow proven steps and double-check every connection. Efficiency matters just as much, especially with new trends like smart transformers and advanced core materials that boost performance and save energy. Linkwell makes this job easier with high-quality, certified transformers built for modern needs. When you use trusted equipment and pay close attention to each step, you can wire your control transformer with confidence and avoid costly mistakes.

Key Takeaways

- Always prioritize safety by de-energizing your system and using proper safety gear before starting any wiring work.

- Choose certified transformers like Linkwell’s to ensure reliability and compliance with safety standards.

- Double-check all connections and specifications to avoid common mistakes that can lead to equipment failure.

- Use the right tools and materials, including insulated screwdrivers and multimeters, to ensure a smooth wiring process.

- Conduct a thorough final inspection and testing of your setup to confirm everything operates correctly before powering up.

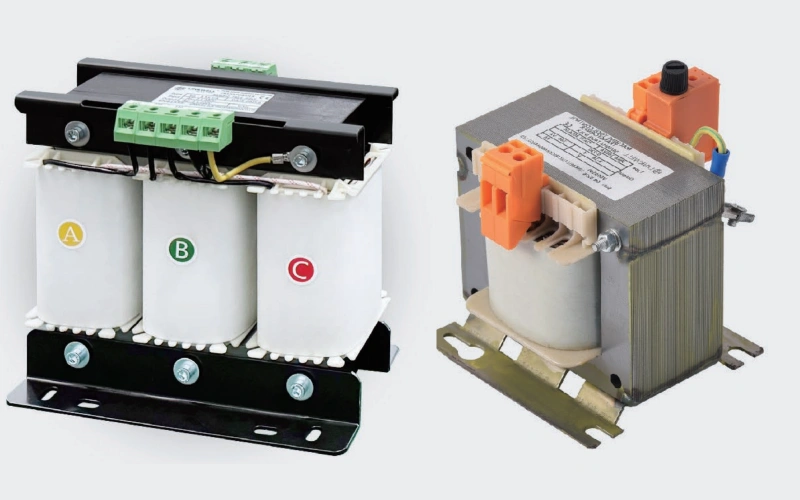

What is a Control Transformer

Principle

You might wonder how a control transformer works. It’s actually pretty simple. A control transformer takes high voltage from your main power supply and steps it down to a lower, safer voltage for control circuits. This keeps your sensitive equipment safe from power surges and voltage spikes. Most control transformers use an iron core with laminated sheets and copper or aluminum coils. These parts help the transformer handle short bursts of high current, which often happen when machines start up. You get stable voltage even if the main supply changes.

Tip: Control transformers act as isolation transformers. They keep your control circuits separate from the main power, which adds another layer of safety.

Type

You’ll find a few different types of control transformers out there. The main differences come from their construction and what they’re designed to do. Here’s a quick comparison:

| Feature | Control Transformers | Other Transformers |

|---|---|---|

| Purpose | Provide high secondary voltage stability | General power distribution |

| Voltage Rating | Typically rated for 600 volts or less | Can be rated for higher voltages |

| Inrush Current Handling | Designed to handle 3-10 times normal current | Not specifically designed for inrush |

| Construction | Iron core with laminated sheets, copper/aluminum coils | Varies by type |

Control transformers stand out because they keep voltage steady during brief overloads. You’ll see them built with strong insulation and safety certifications like UL and CE, which is important for Control Transformer Wiring in industrial settings.

Application (Electrical Control Cabinet, etc.)

You use control transformers in lots of places where stable, low-voltage power matters. Here are some common applications:

- Automation equipment and control panels

- Electrical instruments that need precise voltage for accurate readings

- Machine tool control for steady and reliable processing

- Lighting control systems for consistent illumination

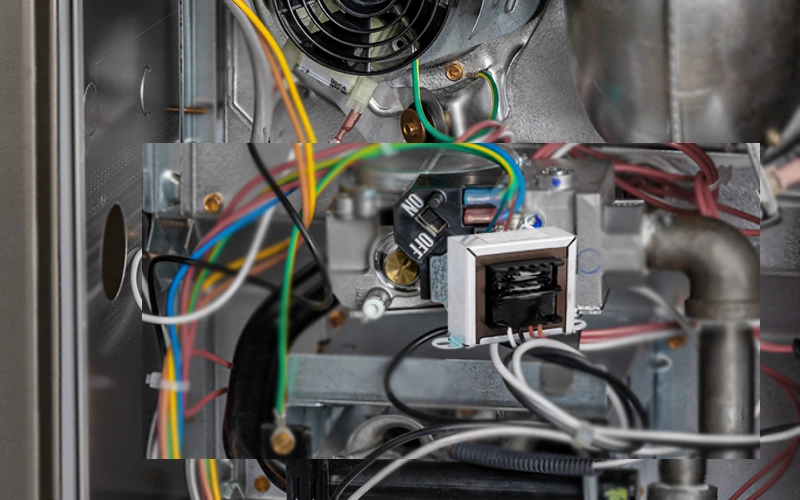

- Automated assembly lines, HVAC controllers, and renewable energy inverters

You’ll also find them in electrical control cabinets, telecom stations, and signal systems. Control transformers make sure voltage changes from the main supply don’t mess with your sensitive control circuits. That’s why they’re so important in modern industry.

| Equipment/Industry | Specific Application Scenario | Transformer Type/Role |

|---|---|---|

| Machine Tools | CNC machine tools, machining centers, milling machines, lathes, grinders. | Machine Tool Control Transformer (e.g., JBK3, JBK5 series). Provides safe low voltage (e.g., 24V, 110V) for control circuits (PLC, relays). |

| Industrial Robots/Robotic Arms | Inside the control cabinet of industrial robots. | Dedicated Transformer Unit built into the robot control cabinet. Powers the control system. |

| Industrial Automation Control Systems | Custom automation equipment, production line master control. | Stand-alone Control Power Transformer. Supplies power to PLCs, sensors, and other control components. |

| Air Compressors | Control circuits of screw-type and piston-type air compressors. | Commonly referred to as an Air Compressor Control Transformer. |

| Heavy Machinery | Punch presses, injection molding machines, crane equipment, conveyors. | Provides reliable power for motor start/stop and safety interlock circuits. High reliability required. |

| Oil & Gas / Chemical / Mining | Control circuits for pumps, compressors, and safety systems in hazardous areas. | Control Transformer with extremely high requirements for explosion-proof, corrosion resistance, and reliability. |

| HVAC Systems | Control systems for air handling units (AHUs), chillers, fan coil units. | Steps down line voltage (e.g., 480V) to 24V AC for thermostats, actuator controls, and panels. |

| Building Automation | Elevator control systems, access control, security systems, smart lighting control. | Provides isolated, stable low-voltage power for electronic control modules. |

Linkwell Control Transformer Wiring Preparation

Tools and Materials Checklist

You want to start Control Transformer Wiring with the right tools. Grab a set of insulated screwdrivers, wire strippers, and a multimeter. Non-conductive pliers help you stay safe. You also need mounting hardware, wire connectors, and a label maker for marking connections. If you use Linkwell control transformers, you get clear markings and robust terminals, which make installation easier. Always keep your safety gear close—gloves, safety glasses, and a voltage tester.

Tip: Double-check that your tools are rated for electrical work. This helps prevent accidents and keeps your wiring neat.

Reviewing Specifications and Ratings

Before you install anything, review the transformer’s specs. Look at the total capacity required for your cabinet, measured in VA or kVA. Pick a transformer with a rating equal to or higher than your needs. Make sure the input (primary) and output (secondary) voltages match your control circuit. If your cabinet might move between locations, consider a multi-tap or adjustable voltage model from Linkwell. Their transformers come with UL, CE, and ISO9001 certifications, so you know you’re getting safe and reliable equipment.

| Certification | Purpose |

|---|---|

| UL | Ensures safety and reliability in industrial use |

| CE | Confirms compliance with European standards |

| ISO9001 | Shows commitment to quality management principles |

Work Area Safety Setup

Set up your work area before you begin Control Transformer Wiring. Grounding must follow Article 250 rules, so ground one conductor of the secondary if needed. Keep at least 300mm clearance from anything that could catch fire. Use safety gear and non-conductive tools. Make sure the power is off and follow lockout/tagout procedures. You want a clean, well-lit space with no clutter.

When you look at transformer markings like H1, H2, H3, H4, X1, and X2, check the polarity and voltage ratings. Even-numbered leads (H2, H4) share the same polarity. The H winding always has more turns than the X winding, which affects voltage ratios. Correct identification keeps your wiring safe and prevents costly mistakes.

Note: Linkwell transformers offer customization, so you can match your wiring setup to your project’s needs. Their durable design means you spend less time on maintenance and more time running your system.

Step-by-Step Control Transformer Wiring Guide

Safety Precautions Before Wiring

Before you even touch a wire, you need to set up your workspace for safety. Pick a dry, well-lit spot with enough room to move around. Put up clear signage and barriers to keep others out of your work area. Always wear your safety gear—gloves, goggles, and insulated shoes. Double-check that the power is off and locked out. This step keeps you safe from accidental shocks. Make sure you have a solid ground connection at your site. These steps help you avoid accidents and keep your Control Transformer Wiring project on track.

Tip: Never skip safety checks. They protect you and your equipment.

Control Transformer Wiring in Electrical Control Cabinet

Wiring a Linkwell control transformer in an electrical control cabinet is straightforward if you follow the right steps. Here’s a simple process you can use:

- Identify Terminals and Wiring Diagram: Look for the terminal markings on your transformer. Find the wiring diagram, usually on the side or in the manual.

- Wire the Primary Side: Connect your high-voltage power source to the primary terminals (H1 and H2). Use wires that match the voltage and current requirements.

- Wire the Secondary Side: Attach the control circuit components to the secondary terminals (X1 and X2). Make sure the wires are the right size for the load.

- Grounding and Final Checks: Set up proper grounding. Double-check every connection before you turn on the power.

This method works well for Linkwell transformers because they come with clear markings and strong terminals. You get a safer and more reliable installation.

Identifying Primary and Secondary Terminals

You’ll see two sets of terminals on your transformer. The primary side usually has H1, H2, H3, and H4. This is where you connect the incoming power. The secondary side has X1 and X2, which feed your control circuits. Always check the wiring diagram to confirm which terminal does what. If your transformer has multiple taps, you might see extra markings. Take your time to match each wire to the right terminal. This step is key for safe and efficient Control Transformer Wiring.

Making Primary Connections (H1-H4)

Now you’re ready to connect the primary side. Here’s how you do it:

- Find the high-voltage windings labeled H1, H2, H3, and H4.

- For a 480V supply, jumper H2 and H3 together. Connect your 480V lines to H1 and H4.

- For a 240V supply, connect H1 to H3 and H2 to H4. This parallels the windings for lower voltage.

- If you need to test, apply 120V to the low-voltage winding with everything else disconnected. Measure the voltage across the terminals to confirm your setup.

- Adjust jumpers as needed to match your supply voltage.

Note: Always use copper conductors rated for your system’s maximum fault current. This keeps your wiring safe and up to code.

Making Secondary Connections (X1-X2)

The secondary side is where your control circuits get their power. Connect X1 and X2 to your load equipment or distribution panel. If your transformer offers dual voltage output, like 240V/120V, use the center tap as needed. Make sure your wires are tight and secure. Loose connections can cause voltage drops or even sparks. Good Control Transformer Wiring here means your equipment runs smoothly and safely.

Grounding and Neutral Bonding

Proper grounding and bonding are critical for safety. Here’s what you need to know:

- Make sure all bonding connections are mechanically strong and electrically continuous.

- Grounding sets the reference point for your system. Bonding equalizes potential around that point.

- Never bond the neutral to ground at more than one location. Doing so can create dangerous current paths.

- For separately derived systems, use a system bonding jumper at or before the first disconnect. Size this jumper based on the largest ungrounded conductor.

Pro Tip: Good grounding protects both people and equipment from electrical faults. Always follow UL and CE standards for grounding and insulation.

Final Inspection and Testing

You’re almost done, but don’t skip this last step. Inspect every connection and test the system before you power up. Here’s a checklist to guide you:

| Inspection/Test Steps | Description/Action |

|---|---|

| Verify operation of temperature gauges | Make sure gauges work as expected. |

| Check pressure relief device functionality | Test the device to confirm it operates correctly. |

| Test alarms and indicators | Ensure all alarms and indicators respond properly. |

| Inspect relays (if equipped) | Check relays for proper operation. |

| Verify tap changer controls | Make sure tap changers function as designed. |

| Check cooling control system | Test the cooling system for correct operation. |

| Test sudden pressure relay | Confirm the relay activates under sudden pressure. |

| Verify liquid level indicators | Ensure indicators show accurate levels. |

| Test fault pressure relay | Check that the relay works as intended. |

| Document all protection device tests | Keep a record of every test you perform. |

Always de-energize and lock out/tag out transformers before you inspect or test. Keep detailed records of your tests. This helps you spot problems early and keeps your Control Transformer Wiring safe for years to come.

Common Mistakes to Avoid

Here’s a quick table of mistakes people often make and how you can avoid them:

| Mistake | Description |

|---|---|

| Selecting the Wrong Transformer Rating | Always calculate your load and add a safety margin. |

| Ignoring Input Voltage and Frequency Compatibility | Double-check your supply voltage and frequency. |

| Poor Wiring and Grounding Practices | Tighten all terminals and check polarity. |

| Overlooking Ambient Conditions | Match your enclosure to the environment. |

| Replacing Without Checking Load Condition | Test for shorts or overloads before swapping transformers. |

| Using Non-Industrial-Grade Transformers | Choose certified transformers like Linkwell’s. |

| Forgetting to Verify Short-Circuit Protection | Install the right fuses or breakers on the secondary side. |

If you follow these steps and tips, you’ll have a safe, efficient, and reliable Control Transformer Wiring setup every time.

Troubleshooting and Common Mistakes

Frequent Wiring Errors

You might run into a few common mistakes when working with control transformers. Sometimes, people mix up the primary and secondary terminals. Others forget to tighten connections, which can lead to overheating or voltage drops. Using the wrong wire size causes trouble, too. If you skip grounding or bond the neutral in more than one spot, you risk safety issues. Not checking the transformer’s rating against your load can also cause problems. These errors often lead to equipment failure or unreliable performance.

Tip: Always double-check your wiring diagram and terminal markings before you start. This simple step helps you avoid most mistakes.

Troubleshooting Steps

If your transformer isn’t working right, you can follow a few steps to figure out what’s wrong. Start by looking for signs of overheating or strange smells. Check for loose wires or damaged insulation. Use a multimeter to test voltage at the terminals. If you still have issues, try these diagnostic methods:

| Diagnostic Method | Description |

|---|---|

| Exposure to excessive temperatures | High temperatures can break down insulation and oil. |

| Contamination | Moisture in the oil often causes problems. |

| Oxidation | Oxidation makes the oil decay faster. |

| Corona releases | Arcing can separate the oil and damage the transformer. |

| Furan analysis | This test predicts wear by checking the oil. |

| Static electricity | Static can harm the oil’s ability to slow arcing. |

| Partial discharge | Tests if the electrical equipment is holding up. |

| Frequency response | Finds issues with winding movement. |

| Thermal modeling | Compares expected and actual temperatures. |

| Dissolved gas | Shows if the transformer failed and why. |

| Regular inspection | Helps you spot insulation problems early. |

If you follow these steps, you can catch most issues before they get worse. Regular checks keep your Control Transformer Wiring safe and reliable.

When to Contact Linkwell Support

Sometimes, you need expert help. If you notice insulation problems or your transformer can’t handle new load demands, it’s time to reach out. Old transformers that need constant repairs are better replaced. If fixing your transformer costs more than 60% of buying a new one, replacement makes sense. Here’s a quick guide:

| Criteria for Replacement | Explanation |

|---|---|

| Safety or Reliability Is Compromised | Insulation problems make the transformer unsafe or unreliable. |

| Performance Requirements Have Changed | The transformer can’t keep up with new load demands. |

| The Transformer Is Near the End of Life | Old transformers need more repairs, so replacement saves money. |

| Repair Costs Exceed 60% of Replacement Costs | It’s smarter to buy new if repairs get too expensive. |

Note: Linkwell’s support team is available 24/7. If you’re unsure, contact them for fast, professional advice.

Conclusion

You’ve made it to the end of your control transformer wiring journey. Let’s wrap things up with a quick review. Wiring a control transformer safely and efficiently isn’t just about connecting wires. You need to follow a few key steps every time:

- De-energize your system before you start.

- Lockout and tagout the power so no one turns it on by mistake.

- Ground everything properly to keep yourself safe.

- Add fuses or breakers to protect your circuits from overloads.

- Let only qualified electricians handle the wiring.

If you stick to these steps, you’ll avoid most problems and keep your equipment running smoothly.

Choosing the right transformer matters, too. When you pick a certified product like a Linkwell control transformer, you get more than just a piece of hardware. You get peace of mind. Here’s why certified products make a difference:

| What Certified Products Offer | Why It Matters |

|---|---|

| Protect your equipment and your team | Keeps everyone safe and your system reliable |

| Meet strict standards like UL, CE, and ISO9001 | Proves quality and performance you can trust |

| Go beyond basic compliance to improve workplace safety | Means fewer surprises and less downtime |

| Boost reliability and reduce risk | Lets you focus on your work, not on repairs |

You want your control panels to work right the first time. Certified transformers help you get there.

Remember: Safety always comes first. If you ever feel unsure, reach out to a professional or contact Linkwell’s support team. They’re ready to help you 24/7. With the right tools, the right transformer, and the right steps, you can wire your control transformer safely and efficiently—every single time.

You now know how to wire a control transformer safely and efficiently. Always follow each step, use certified products like Linkwell’s, and double-check your work. If you ever feel unsure, reach out to a professional or manufacturer support. Many top companies offer expert help:

| Source | Description |

|---|---|

| Power System Protection | Specialized consulting and ongoing support for system performance. |

| Siemens Energy | Preventive maintenance and expert transformer consultation. |

| GE Vernova | Technical services, assessments, and repairs for transformers. |

Stay safe and keep your equipment running smoothly!

FAQ

How do I choose the right control transformer for my project?

You need to match the input and output voltage, power rating, and load type. Always check your system’s requirements. If you feel unsure, ask Linkwell’s support team for help.

Can I customize a Linkwell control transformer?

Yes! You can request custom voltage, power, mounting style, or enclosure. Linkwell offers flexible options to fit your unique needs. Just contact their team for details.

What should I do if my transformer gets hot?

First, turn off the power. Check for loose wires or overloads. Make sure the transformer matches your load. If the problem continues, reach out to Linkwell support.

How long does a Linkwell control transformer last?

| Typical Lifespan | Maintenance Needed |

|---|---|

| 10–15 years | Regular checks |

You can extend the life with proper installation and routine inspections.