Ensuring the safety and functionality of electrical systems hinges on proper wiring practices, and a crucial aspect of this is understanding junction box capacity. Overfilling electrical boxes can lead to hazardous conditions, including overheating and potential fires. This blog post will delve into the concept of junction box capacity, explaining what it signifies and why adhering to these limitations is paramount for any electrical installation, whether residential or commercial.

We will explore how to calculate the maximum number of wires and devices permitted within a junction box based on its size and the volume of the conductors and components. Understanding these calculations and the relevant electrical codes is essential for preventing dangerous situations and ensuring your electrical work meets safety standards.

What Is Junction Box Capacity

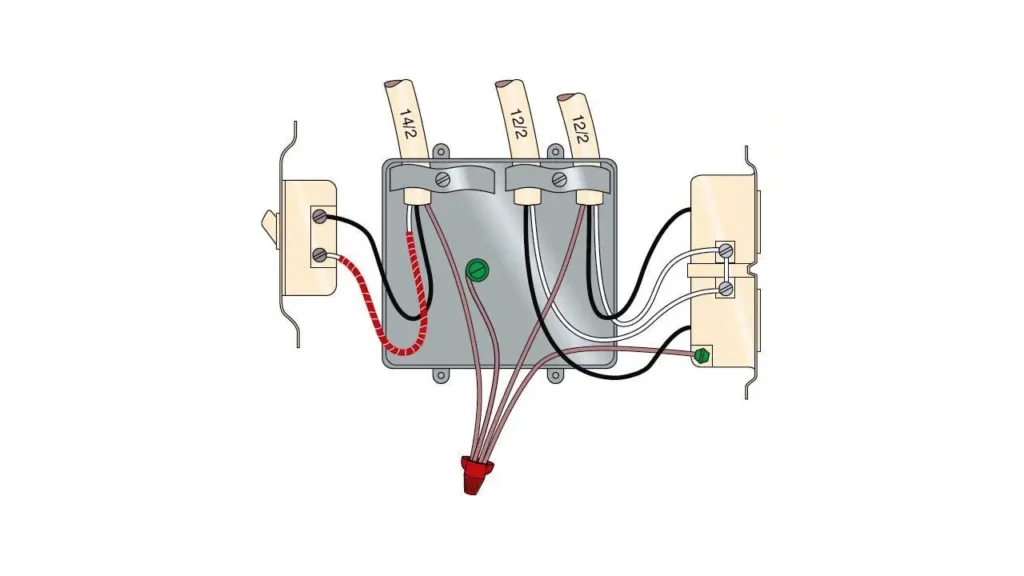

Junction box capacity refers to the maximum number and size of electrical conductors, devices (like switches or receptacles), and internal components (such as cable clamps) that can be safely contained within the enclosure. This capacity is not just about physical space; it’s a critical safety parameter defined by electrical codes like the National Electrical Code (NEC) in the United States. These codes specify fill requirements based on the box’s volume (measured in cubic inches) and the volume occupied by each element within the box.

Adhering to junction box capacity limits is essential to prevent overcrowding, which can lead to several hazardous situations. Overfilled boxes can cause excessive heat buildup due to restricted airflow, potentially damaging wire insulation and increasing the risk of short circuits and electrical fires. Furthermore, overcrowding makes it difficult to safely and effectively work within the box for maintenance or troubleshooting. Therefore, understanding and correctly calculating junction box capacity ensures a safe and reliable electrical installation that complies with regulatory standards.

Junction Box Capacity Calculator

While there isn’t a single, universal “junction box capacity calculator” in the form of a physical device, the concept refers to the methods and tools used to determine if a junction box is appropriately sized for the number and size of conductors and devices it will contain. Calculating this capacity is crucial for electrical safety and code compliance, primarily based on guidelines from the National Electrical Code (NEC). These calculations involve considering the volume of the box and the space occupied by each component inside.

To determine junction box capacity, you typically follow a set of rules and calculations outlined in the NEC. These rules account for:

- Conductor Fill: Each conductor entering, terminating, or passing through the box is counted based on its gauge size, with specific cubic inch allowances assigned to each wire size.

- Device Fill: Devices like switches and receptacles also have a volume allowance that must be factored into the total fill.

- Equipment Grounding Conductors: A specific allowance is made for grounding conductors, typically counting as one conductor based on the largest grounding wire size present.

- Internal Clamps and Fittings: Some internal components of the box, like cable clamps, also contribute to the box fill capacity.

Several online calculators and resources are available that automate these calculations based on NEC guidelines, helping electricians and DIYers determine the correct size of junction box for their specific wiring needs. These tools simplify the process of ensuring code compliance and preventing overfilled boxes.

Junction Box Capacity Calculator

How to Size a Junction Box

Properly sizing a junction box is crucial for electrical safety and code compliance. It ensures that there's enough space for all the wires and devices without overcrowding, which can lead to overheating and fire hazards. Here's a breakdown of the steps involved:

1. Determine Conductor Volume

The first step in sizing a junction box involves calculating the total volume occupied by the conductors. Each wire within the box, whether it terminates, is spliced, or passes through, must be accounted for. The National Electrical Code (NEC) provides tables that specify the volume allowance for different wire sizes (AWG). This calculation ensures that the conductors themselves have adequate space within the box.

2. Account for Devices and Fittings

In addition to the conductors, any devices located within the box, such as switches, receptacles, or other equipment, also take up space. The NEC requires that each of these devices be counted as a specific number of conductors (typically two) based on the largest conductor connected to the device. Furthermore, any internal clamps or fixture studs within the box must also be accounted for in the volume calculation.

3. Include Grounding Conductors

Grounding conductors also contribute to the overall fill of a junction box. The NEC provides specific rules for how to count grounding conductors. Generally, all grounding conductors in a box are counted as a single conductor, based on the largest grounding conductor present. However, if there are more than a certain number of grounding conductors, additional allowances may need to be made.

4. Calculate Total Volume and Select Box

Once you've determined the volume occupied by the conductors, devices, and grounding wires, you can calculate the total required volume of the junction box. The selected box must have a volume that is equal to or greater than this calculated total. Junction boxes are marked with their volume in cubic inches, making it straightforward to choose an appropriate size that meets the NEC requirements and ensures a safe installation.

Junction Box Fill Capacity

Junction box fill capacity is a critical concept in electrical work, referring to the maximum volume of conductors and devices that can be safely contained within an electrical box. Adhering to these capacity limits, primarily outlined in the National Electrical Code (NEC), is essential for preventing electrical hazards and ensuring the long-term reliability of electrical systems.

Understanding Junction Box Fill Capacity

Junction box fill capacity is the total volume of space inside an electrical box that can be occupied by wires, devices, and other components. The NEC sets limits on how much can be placed in a box to prevent overheating, short circuits, and other dangerous conditions. These regulations ensure electrical safety and proper functionality.

Factors Affecting Fill Capacity

Several factors determine the fill capacity of a junction box. These include the size and number of conductors, the presence of devices like switches and receptacles, and the volume taken up by grounding conductors. Each of these elements contributes to the overall space used within the box, and all must be carefully considered.

Calculating Fill Capacity

Calculating junction box fill capacity involves a detailed process. It begins with determining the volume of each conductor, based on its gauge (AWG) as specified by the NEC. Then, the volume occupied by devices and grounding conductors is added. The total volume of these components must not exceed the box's listed volume.

Importance of Proper Fill

Proper junction box fill is paramount for electrical safety. Overfilled boxes can lead to excessive heat buildup, increasing the risk of fire. They can also make it difficult to work on the wiring in the future. By adhering to NEC guidelines and accurately calculating fill capacity, electricians and DIYers can ensure safe and compliant installations.

Conclusion

In essence, understanding junction box capacity is paramount for safe and compliant electrical installations. Overfilling boxes can lead to overheating, damaged insulation, and potential fire hazards. Adhering to the NEC guidelines and carefully calculating box fill based on wire sizes and device counts ensures a safe and functional electrical system. Choosing the right size box for the intended number of conductors and components is a fundamental aspect of responsible electrical work.

By prioritizing proper box fill, you not only comply with electrical codes but also contribute to the longevity and reliability of your electrical installations. Avoiding overcrowded junction boxes minimizes the risk of electrical failures and ensures a safer environment for everyone. Taking the time to accurately calculate capacity is a small investment that yields significant returns in terms of safety and system integrity.

For code-compliant wholesale junction boxes in various sizes to meet your project's exact capacity requirements, look no further than Linkwell Electronics. As a leading manufacturer, we offer a comprehensive range of durable and reliable junction boxes. Contact us today to explore our wholesale options and ensure your electrical installations are safe and up to code.