When tackling electrical wiring projects, understanding the nuances between conduit boxes and junction boxes is essential for safety and code compliance. While both serve as protective enclosures for wire connections, their primary functions and design characteristics differ significantly. Choosing the right type depends heavily on the specific wiring method and installation requirements of your project.

Conduit boxes are specifically designed to terminate and support electrical conduits, providing a secure pathway for wires. Junction boxes, on the other hand, are more general-purpose enclosures used to house wire splices and connections, often without direct conduit attachments. Recognizing these distinctions will ensure you select the appropriate box for a safe and efficient electrical system.

What Is a Conduit Box

A conduit box is a robust enclosure designed to protect electrical wiring and provide a termination point for electrical conduits. Unlike junction boxes, which primarily serve as connection points for wires, conduit boxes are built to withstand physical damage and environmental factors, offering a secure pathway for conductors. They come in various shapes and sizes, often featuring threaded hubs or knockouts for easy conduit attachment, ensuring a continuous, protected raceway for electrical wiring in diverse applications.

What Is a Junction Box

A junction box is an electrical enclosure designed to house and protect wire connections, providing a safe and organized point where multiple electrical circuits meet and are joined together.

Typically made of metal or plastic, it serves to contain wire splices, protect them from environmental factors and physical damage, and prevent accidental contact, thereby ensuring electrical safety and code compliance. Junction boxes are essential components in any electrical wiring system, facilitating the distribution and control of electrical power throughout a building or structure.

Conduit Box vs Junction Box

Understanding the distinctions between conduit boxes and junction boxes is fundamental for anyone involved in electrical work. While both are integral components of electrical systems, they serve different primary purposes and possess unique characteristics. This comparison will delve into their definitions, functions, materials and construction, and common applications to clarify their roles.

Here are the differences between conduit and junction boxes in the following:

Definition and Primary Purpose

Conduit boxes are robust enclosures specifically designed to terminate and provide access to electrical wiring within a conduit system. Their main purpose is to offer mechanical protection to the enclosed wires and to facilitate the connection of conduit runs, ensuring a continuous, protected pathway for electrical conductors. These junction boxes often feature threaded hubs or knockouts that allow for secure attachment of conduits, safeguarding the wiring from physical damage, moisture, and other environmental hazards.

Junction boxes, in contrast, are primarily intended as connection points for electrical wires. Their main function is to provide a safe and organized enclosure for wire splices and terminations, allowing multiple circuits to be joined or branched. These boxes protect the electrical connections from accidental contact, dust, and moisture, ensuring electrical safety and preventing potential hazards. They come in various shapes and sizes and are typically used to facilitate the distribution of power to different parts of an electrical system.

Materials and Construction

Conduit junction boxes are typically constructed from durable materials such as steel, aluminum, or rigid PVC to provide significant mechanical protection to the enclosed wiring. Their construction often involves robust designs with threaded entries or knockouts to create a secure and watertight connection with conduits. The focus is on durability and the ability to withstand harsh environments, ensuring the longevity and integrity of the wiring system.

Junction junction boxes are also made from metal (steel, aluminum) or plastic, but their construction emphasizes ease of access for wiring and connection. They often feature removable covers secured with screws, allowing for inspection, maintenance, and modifications to the wire connections inside. While they offer protection to the splices, their primary design consideration is facilitating electrical connections rather than providing extensive mechanical protection for long runs of wiring.

Common Applications

Conduit junction boxes are commonly used in industrial, commercial, and outdoor applications where wiring needs significant physical protection. They are essential in exposed locations, damp or wet environments, and areas where wires might be subject to mechanical stress or damage. Examples include factories, construction sites, and outdoor lighting installations, where conduits and conduit boxes ensure the safety and reliability of the electrical system.

Junction junction boxes are widely used in residential, commercial, and industrial buildings to facilitate the distribution of power to various outlets, lights, and appliances. They are typically found concealed within walls or ceilings, providing a safe enclosure for wire connections at branching points in the electrical circuit. They are crucial for wiring devices and ensuring that all electrical connections are properly contained and protected according to electrical codes.

| Feature | Conduit Box | Junction Box |

| Primary Purpose | Protect wiring within a conduit system | House and protect wire connections (splices) |

| Mechanical Protection | High, designed for durability and protection | Moderate, primarily protects connections |

| Conduit Connection | Features threaded hubs or knockouts for conduit | May have knockouts for conduit entry, but not primary |

| Wire Connection | Provides termination point for wires in conduit | Primary function is to house wire connections |

| Materials | Steel, aluminum, rigid PVC (durable) | Metal (steel, aluminum), plastic |

| Access | Primarily for conduit termination and access | Removable cover for easy access to wiring |

| Common Applications | Industrial, commercial, outdoor, exposed wiring | Residential, commercial, concealed wiring |

How to Connect Conduit to a Junction Box

Connecting conduit to a junction box is a fundamental skill in electrical work, ensuring a secure and protected pathway for wiring. Proper connection is crucial for safety and code compliance, preventing damage to conductors and ensuring a reliable electrical system.

This guide outlines the essential steps to effectively join conduit to a junction box, creating a continuous and protected raceway for your electrical wiring.

Gather Necessary Tools and Materials

Before starting, ensure you have the correct type and size of conduit and fittings for your project. You’ll also need appropriate tools, such as a conduit cutter or hacksaw, a reamer to smooth cut edges, measuring tape, a screwdriver or wrench to tighten connectors, and possibly a fish tape for pulling wires later. Having all the necessary materials and tools readily available will streamline the connection process and ensure a professional result.

Step 1. Prepare the Conduit End

Begin by accurately measuring and cutting the conduit to the required length, ensuring it will reach the junction box entry point with a slight allowance. After cutting, it’s essential to ream the inside edges of the conduit end to remove any sharp burrs or ridges.

These sharp edges can damage wire insulation as it’s pulled through later. A smooth conduit end will facilitate easier and safer wire installation.

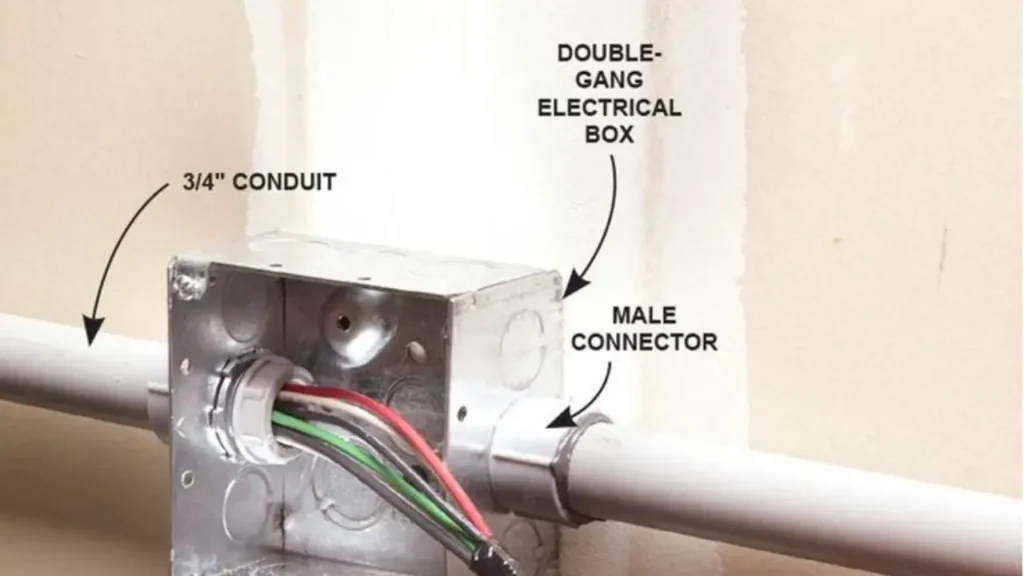

Step 2. Select and Install the Correct Connector

Choose a conduit connector that is appropriate for the type and size of conduit you are using and the knockout size on the junction box. Common types include set-screw connectors, compression connectors, and threaded connectors.

Insert the connector into the corresponding knockout on the junction box and secure it tightly using the locknut provided, ensuring a solid mechanical connection. The connector will serve as the interface between the conduit and the box.

Step 3. Attach the Conduit to the Connector

Slide the prepared end of the conduit into the installed connector on the junction box. For set-screw connectors, tighten the setscrews firmly onto the conduit to secure it in place.

For compression connectors, tighten the compression nut to create a tight seal. If using threaded conduit and connectors, screw the conduit firmly into the threaded hub of the connector. The connection should be snug and mechanically sound to ensure the conduit remains securely attached to the junction box.

Step 4. Secure and Inspect the Connection

Once the conduit is attached, give it a gentle tug to ensure it is firmly held by the connector and cannot be easily dislodged. Inspect the connection to make sure there are no gaps or loose parts.

A secure connection is vital for maintaining the physical protection of the wiring and ensuring the integrity of the electrical system. This final check confirms that the conduit is properly connected to the junction box, ready for wires to be pulled through.

How Many Conduits in a Junction Box

The number of conduits that can enter a junction box isn’t strictly limited by a specific count but rather by the physical size and available knockouts of the box, as well as the need to maintain adequate space for wiring and connections within.

Electrical codes, such as the National Electrical Code (NEC) in the United States, focus on the fill capacity of the box, which dictates the maximum number and size of conductors, devices, and fittings allowed within it. Therefore, a junction box can accommodate multiple conduits as long as the resulting fill doesn’t exceed the box’s cubic inch capacity.

Physical Knockout Limitations:

Junction boxes come with a certain number and size of knockouts, which are pre-punched holes designed for conduit or cable entry. The number of conduits you can physically attach is limited by the number and size of these knockouts. While it’s sometimes possible to create additional openings, doing so must be done carefully and in compliance with local codes to maintain the junction box’s integrity. You need to ensure that each conduit entering the box can be securely fastened with an appropriate connector.

Box Fill Capacity:

The most critical factor determining how many conduits can effectively be used with a junction box is the box’s internal volume and the space required for the conductors entering through those conduits, as well as any devices or splices within the box. Each conductor, cable clamp, and device contributes to the box fill.

Electrical codes provide specific calculations based on wire gauge and the size of devices to ensure that the box isn’t overcrowded, which could lead to overheating or difficulty in making safe connections. Therefore, even if a box has multiple knockouts available, the number of conduits used must be considered in relation to the overall fill capacity requirements.

How to Choose the Conduit and Junction Box

When selecting the appropriate conduit and junction box for an electrical installation, several critical factors must be carefully considered to ensure safety, functionality, and code compliance. The environment where the installation will be located, the type and number of conductors to be run, and the specific requirements of the application all play a significant role in the selection process. Taking these aspects into account from the outset will help prevent issues during installation and ensure a reliable electrical system.

Environmental Conditions:

The environment where the conduit and junction box will be installed is a primary consideration. For outdoor or wet locations, weatherproof or watertight boxes and conduit fittings are essential to prevent moisture ingress and corrosion.

In areas prone to physical damage, such as industrial settings, rigid metal conduit (RMC) and robust metal boxes offer superior protection. For corrosive environments, PVC conduit and non-metallic boxes might be a better choice. Understanding the environmental stressors will guide the selection of appropriate materials and ratings.

Conductor Type and Fill Capacity:

The type and number of conductors you plan to run will dictate the required size of both the conduit and the junction box. Electrical codes specify the maximum percentage of conduit fill allowed based on the number and size of conductors to ensure proper heat dissipation and ease of pulling wires.

Similarly, junction boxes have a specific cubic inch capacity that determines the maximum number and size of conductors, connectors, and devices they can safely accommodate. Careful calculation of conductor fill for both the conduit and the box is crucial for code compliance and system safety.

Application Requirements:

The specific application of the electrical system will also influence the choice of conduit and junction box.

For instance, residential wiring might utilize electrical metallic tubing (EMT) and standard metallic or non-metallic junction boxes, while commercial or industrial applications may require more robust solutions like intermediate metal conduit (IMC) or RMC and larger, more durable junction boxes. Additionally, specific applications might necessitate specialized boxes, such as those designed for ceiling fans or multi-gang setups. Considering the intended use ensures that the chosen components meet the functional demands of the system.

Code Compliance:

Adherence to local and national electrical codes is paramount when selecting conduit and junction boxes. Codes like the National Electrical Code (NEC) in the United States provide detailed regulations on the types of materials, installation methods, and fill capacities allowed for different applications. Ensuring that the chosen conduit and junction boxes are UL-listed or meet other relevant safety standards and that the installation complies with all applicable code requirements is essential for safety and legal compliance.

Conclusion

While both conduit and junction boxes serve crucial roles in electrical systems, their primary functions and designs differ significantly. Conduit boxes act as protective raceways for wiring, offering mechanical protection and routing pathways. Junction boxes, on the other hand, serve as connection points for multiple wires, ensuring safe and organized electrical circuits. Understanding these distinctions is vital for proper electrical installations and maintenance.

For projects requiring reliable and high-quality junction boxes, look no further. We offer a comprehensive range of wholesale junction boxes designed to meet diverse electrical needs. Our durable and code-compliant boxes ensure safe and organized wiring connections for residential, commercial, and industrial applications.

Partner with us for your wholesale junction box requirements and benefit from our competitive pricing and extensive selection. We are committed to providing the electrical components you need to complete your projects efficiently and effectively. Contact us today to explore our offerings and secure your supply of quality junction boxes.