As a technical team with 20 years of industry experience and manufacturers, we can teach you everything you need to find the control transformer you need.

A control transformer is a specialized type of transformer designed to provide a stable and regulated voltage to control circuits in industrial machinery and electrical systems. Unlike power transformers that handle large amounts of power, control transformers typically operate at lower power levels.

This guide will delve into the intricacies of control transformers, exploring their purpose, construction, key specifications, selection criteria, and common applications.

What is a Control Transformer

A control transformer is a specialized type of transformer designed to provide a stable and reduced voltage to control circuits within industrial and machinery equipment. Unlike power transformers that handle large amounts of energy for distribution, control transformers typically have lower kVA ratings and prioritize voltage regulation under varying load conditions.

Their primary function is to step down higher voltage levels to safer, more manageable voltages, commonly 120V or 24V, required for the reliable operation of control components like relays, contactors, timers, and sensors.

These transformers are engineered with features that make them well-suited for control applications. They are often designed to handle the high inrush currents that occur when inductive loads are initially energized, preventing voltage dips that could disrupt the control system’s operation. Their robust construction ensures reliable performance in demanding industrial environments, contributing to the overall efficiency and safety of automated processes and machinery.

Control Transformer Construction

The construction of a control transformer prioritizes durability and efficient operation. High-conductivity materials like copper or aluminum are used for the primary and secondary windings to minimize resistive losses. These windings are meticulously insulated with robust materials to prevent short circuits and ensure electrical integrity. The number of turns in each winding is precisely determined to achieve the desired voltage transformation ratio for the control circuit.

The magnetic core, a crucial component, is typically built from stacked laminations of high-grade electrical steel. This laminated structure is essential for reducing energy losses caused by:

- Eddy currents: Circulating currents induced in the core material by the changing magnetic field.

- Hysteresis: Energy loss due to the realignment of magnetic domains within the core material as the magnetic field alternates.

Finally, the entire assembly of windings and core is housed within a protective enclosure, often made of steel. This enclosure provides:

- Mechanical protection: Shielding the internal components from physical damage.

- Environmental protection: Guarding against dust, moisture, and other contaminants that could compromise performance.

- Electrical safety: Providing an additional layer of insulation and preventing accidental contact with live parts.

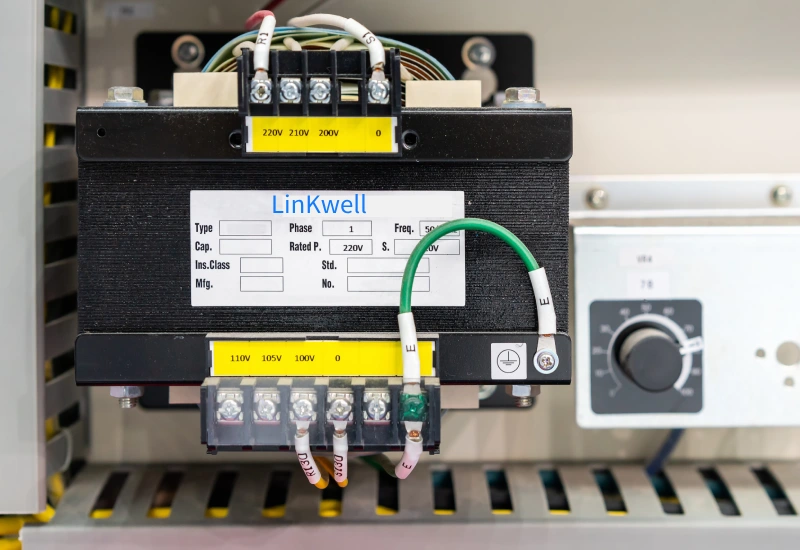

Key Components of a Control Transformer

Control transformers are indispensable devices in numerous electrical systems, particularly within industrial and automation sectors. Their primary function is to provide stable and appropriately scaled voltage levels necessary for operating control circuits, relays, contactors, and other auxiliary equipment.

Let’s delve into the essential building blocks that enable these crucial transformations.

Primary Winding: This is the coil of wire connected to the incoming AC power source. Its purpose is to receive the input voltage and create a magnetic field within the transformer’s core. The number of turns in the primary winding dictates the relationship between the input voltage and the magnetic flux.

Secondary Winding(s): These are one or more coils of wire that are magnetically linked to the primary winding through the core. The changing magnetic field generated by the primary winding induces a voltage in the secondary winding(s). The number of turns in each secondary winding determines the output voltage for that specific winding. Control transformers often have multiple secondary windings to provide different voltage levels for various control circuits.

Core: This is typically made of laminated silicon steel. The core serves as a path of low magnetic reluctance, efficiently channeling the magnetic flux created by the primary winding to the secondary winding(s). Lamination is crucial to minimize energy losses due to eddy currents. The size and material of the core influence the transformer’s power handling capacity and efficiency.

Insulation: Various types of insulation are used throughout the transformer to prevent short circuits between the windings and between the windings and the core. This includes enamel coatings on the wires, insulating paper or tape between layers of windings, and insulating materials separating the windings from the core and the transformer’s enclosure. Proper insulation is vital for the transformer’s safety and longevity.

Terminals or Lead Wires: These are the connection points that allow for the input power to be connected to the primary winding and the output voltage(s) to be accessed from the secondary winding(s). Terminals can be screw-type, quick-connect, or lead wires depending on the application and the transformer’s design. They must be appropriately sized to handle the expected current.

Enclosure (Optional but Common): Many control transformers are housed in a protective enclosure. This enclosure provides physical protection to the internal components from dust, moisture, and accidental contact. It also often includes mounting provisions for easy installation. The enclosure’s design and material depend on the intended environment of the transformer.

Mounting Provisions: Control transformers usually have features like mounting feet, holes, or DIN rail clips to facilitate secure and stable installation within control panels or equipment.

Grounding Provision: A grounding terminal or lug is typically provided for safety. Connecting the transformer’s frame or enclosure to ground helps to prevent electrical shock hazards.

These components work together to efficiently step down (or sometimes step up) the incoming voltage to the levels required for various control circuits, ensuring the safe and reliable operation of industrial and automation systems.

What Does a Control Transformer Do

Control transformers play a vital role in ensuring the safe and reliable operation of industrial and commercial machinery. They act as voltage regulators specifically tailored for control circuits, providing the necessary power for a multitude of essential functions.

Let’s delve into the specifics of what these crucial control transformers accomplish.

Voltage Step-Down for Control Circuits

The primary function of a control transformer is to reduce a higher voltage, typically the main supply voltage, to a lower, safer voltage level suitable for control circuits. These circuits power components like relays, contactors, solenoids, and pilot lights, which generally operate at lower voltages such as 120V or 24V AC.

By stepping down the voltage, the control transformer protects these sensitive components from damage and ensures the safety of personnel interacting with the control system. This regulated lower voltage provides a stable and consistent power supply, crucial for the reliable performance of the automated processes and machinery they govern.

Isolation of Control Circuits

Beyond voltage reduction, control transformers also provide electrical isolation between the primary power source and the secondary control circuit. This isolation is a critical safety feature, preventing faults or surges in the main power supply from directly impacting the control system and potentially causing damage or hazards.

The physical separation of the windings within the transformer ensures that there is no direct electrical connection, enhancing the overall safety and reliability of the control system. This isolation also helps to minimize electrical noise and interference, contributing to more stable and accurate control signal transmission.

Handling Inrush Current

Control circuits often involve inductive loads, such as motor starters and solenoids, which draw a significantly higher current when initially energized – this is known as inrush current. Control transformers are specifically designed to handle these temporary surges in current without experiencing a significant voltage drop.

Their impedance characteristics are carefully engineered to maintain a relatively stable output voltage even during these demanding periods. This capability is essential for ensuring the reliable starting and operation of inductive components within the control system, preventing nuisance tripping of protective devices and ensuring smooth, uninterrupted operation of the machinery.

How Does a Control Transformer Work

Control transformers function based on the fundamental principles of electromagnetic induction. They utilize two sets of wire coils, the primary and secondary windings, wound around a common magnetic core. When an alternating current passes through the primary winding, it generates a fluctuating magnetic field within the core. This changing magnetic field then cuts across the secondary winding, inducing an alternating voltage within it.

The key to voltage transformation lies in the ratio of the number of turns in each winding. To achieve a step-down in voltage for control circuits:

- The primary winding has a larger number of turns.

- The secondary winding has a smaller number of turns.

This difference in turns ratio dictates the voltage output of the secondary winding. The alternating current in the secondary winding then powers the connected control devices, ensuring their safe and reliable operation at the reduced voltage level.

Types of Control Transformers

Recommended products

Control transformers are essential components in various electrical systems, providing the necessary voltage levels for control circuits. While their primary function remains consistent, they come in different configurations tailored to specific application needs.

Understanding these variations allows for optimal selection and performance within diverse industrial and automation settings. Here are some common types of control transformers:

Standard Control Transformers

These are the most common type, designed for general-purpose applications where a specific voltage reduction or step-up is required for control circuits. They typically feature a single primary winding and one or more secondary windings to provide the necessary voltage outputs. Standard control transformers are widely used in machine tools, HVAC systems, and general industrial control panels to power relays, contactors, timers, and other control devices.

Buck-Boost Transformers

Buck-boost transformers are single-winding transformers that can be connected in various configurations to slightly raise or lower the incoming line voltage. They are a cost-effective solution for applications where the required voltage adjustment is relatively small, typically within a few percentage points. These transformers are often used to compensate for voltage drops in long cable runs or to match equipment voltage requirements to the available power supply.

Autotransformers

Autotransformers have a single winding with a tap point, which serves as a common connection for both the primary and secondary circuits. This design makes them smaller, lighter, and more efficient than two-winding transformers for applications where the voltage ratio is close to 1:1. However, they do not provide electrical isolation between the primary and secondary circuits, which is a critical safety consideration in some applications.

Encapsulated Control Transformers

These transformers have their core and windings completely sealed in a resin or epoxy material. This encapsulation provides excellent protection against moisture, dust, and other environmental contaminants, making them suitable for harsh industrial environments. Encapsulated transformers also offer enhanced vibration and shock resistance, contributing to increased reliability and lifespan in demanding applications.

Low Profile Control Transformers

As the name suggests, these transformers are designed with a compact, low-height profile, making them ideal for installations with limited space. They often maintain similar electrical characteristics to standard control transformers but with a more space-efficient physical design. Low-profile transformers are commonly used in densely packed control panels and electronic equipment where minimizing component height is crucial.

Low Voltage Transformer

We manufacture low voltage transformers designed to step down standard electrical voltage to safer, usable levels for industrial, commercial, and residential applications. Our transformers ensure stable power supply, protecting connected equipment from overload or voltage fluctuations.

Key Advantages

- Reliable Performance: We ensure consistent voltage output, reducing the risk of equipment damage and improving operational efficiency.

- Durable Construction: We use high-quality materials and advanced insulation techniques, extending the transformer’s lifespan even under harsh conditions.

- Safety & Compliance: We produce transformers that meet international safety standards, providing protection for both equipment and personnel.

Applications

We supply low voltage transformers for control panels, lighting systems, machinery, renewable energy systems, and other electrical devices requiring safe voltage conversion.

Industrial Control Transformer

An industrial control transformer provides stable low-voltage power for control circuits in machinery and automation systems. It ensures safe operation, reduces electrical noise, and protects sensitive equipment. With durable design and reliable performance, it is widely used in manufacturing plants, assembly lines, and industrial applications.

3-Phase Control Transformer

A 3-phase control transformer is designed to step down high-voltage three-phase input into stable low-voltage power for industrial control devices. It supports heavy-duty applications, improves efficiency, and guarantees balanced load performance. Commonly used in factories, automation systems, and equipment requiring consistent three-phase power distribution.

Single-Phase Control Transformer

A single-phase control transformer delivers dependable low-voltage power for control panels, lighting, and machinery requiring single-phase input. It provides safe isolation, reduces equipment failure, and enhances energy efficiency. Ideal for small industrial machines, HVAC systems, and electrical cabinets needing consistent and cost-effective power conversion.

Furnace Control Transformer

A furnace control transformer powers control circuits in heating furnaces and metallurgical equipment. It withstands high temperatures and heavy electrical loads, ensuring stable voltage output. With durable insulation and robust design, it improves safety, extends equipment lifespan, and guarantees reliable furnace performance in industrial environments.

Isolation Control Transformer

An isolation control transformer separates the primary circuit from the secondary, enhancing operator safety and reducing electrical noise. It provides clean, stable power for sensitive control equipment. Commonly used in automation, medical, and communication systems where voltage stability and protection against disturbances are critical.

Purpose of Control Transformer

The purpose of a standard control transformer is to provide a safe and reliable lower voltage for control circuits, stepping down higher distribution voltages to levels suitable for operating relays, contactors, and other control devices. This ensures the protection of sensitive components and the safety of personnel interacting with the control system.

The purpose of a standard control transformer is to:

- Step Down Voltage: Reduce higher voltage levels (e.g., 240V, 480V) to lower, safer operating voltages (e.g., 24V, 120V) required by control components.

- Provide Electrical Isolation: Offer galvanic isolation between the high-voltage power source and the low-voltage control circuit, enhancing safety and preventing fault propagation.

- Ensure Stable Voltage: Deliver a relatively stable output voltage to the control circuit, minimizing the impact of fluctuations in the primary power supply.

- Facilitate Circuit Protection: Allow for the implementation of overcurrent protection (fuses or circuit breakers) on both the primary and secondary sides, safeguarding the transformer and connected devices.

- Adapt to Different Voltage Systems: Enable the use of control components designed for specific lower voltages in systems with higher available power.

Control Transformer Benefits

Control transformers offer several key advantages that make them essential components in numerous electrical systems. Their primary benefit lies in providing a stable and reliable low-voltage power source specifically tailored for control circuits.

This ensures the consistent and accurate operation of connected devices, minimizing downtime and maximizing the efficiency of automated processes. Furthermore, the electrical isolation they provide enhances safety by preventing high-voltage faults from propagating into the control system, protecting both equipment and personnel.

Beyond reliable operation and safety, control transformers offer additional significant benefits:

- Voltage Regulation: They are designed to maintain a relatively stable output voltage even under fluctuating load conditions, crucial for the consistent performance of sensitive control components.

- Inrush Current Handling: Their robust design allows them to withstand the temporary high current surges associated with energizing inductive loads without significant voltage drops.

- Noise Reduction: The isolation provided by the transformer can help to filter out electrical noise and interference from the main power supply, leading to cleaner and more reliable control signals.

- Equipment Protection: By stepping down the voltage to the required level, they protect control devices from overvoltage damage, extending their lifespan and reducing replacement costs.

Control Transformer Applications

Control transformers find widespread use across various sectors due to their ability to provide stable, isolated low-voltage power for control systems. Their reliability and safety features make them indispensable in numerous applications where precise operation is critical.

- Industrial Machinery: In manufacturing and processing plants, control transformers power the intricate control circuits of automated machinery like robotic arms, packaging equipment, and machine tools. They ensure the reliable functioning of sensors, actuators, and programmable logic controllers (PLCs) that govern these complex systems.

- Heating, Ventilation, and Air Conditioning (HVAC) Systems: Control transformers are vital components in both residential and commercial HVAC systems. They supply the necessary voltage for thermostats, dampers, fans, and control valves, enabling accurate temperature and airflow management for energy efficiency and comfort.

- Motor Control Centers (MCCs): As the central hub for controlling industrial motors, MCCs heavily rely on control transformers. These transformers provide the specific voltage requirements for motor starters, overload relays, and other protective devices, ensuring the safe and efficient operation of motors driving pumps, compressors, and conveyors.

- Lighting Control Systems: From large commercial buildings to entertainment venues, control transformers play a crucial role in lighting control. They enable precise dimming, switching, and automated lighting sequences for energy savings, ambiance control, and safety.

Control Transformers in Renewable Energy Systems

Control transformers play a vital, though often unseen, role in the effective operation of renewable energy systems like solar and wind power. Within these green energy installations, control transformers are not directly involved in the high-power conversion sent to the grid. Instead, they are essential for providing stable, lower-voltage power to the various control circuits, monitoring systems, and auxiliary equipment that ensure the overall system functions safely and efficiently.

In solar energy systems, control transformers step down the AC voltage to supply power to inverters, data acquisition systems, tracking mechanisms for solar panels, and communication networks.

Similarly, in wind energy systems, they provide the necessary voltage for turbine control units, pitch and yaw mechanisms, safety systems, and meteorological monitoring equipment. The reliability of these control transformers directly impacts the uptime and performance of the entire renewable energy plant, ensuring consistent energy generation and grid stability.

Design Considerations for Control Transformers

When selecting and implementing control transformers, several critical design considerations come into play to ensure optimal performance, reliability, and safety within the intended application. These factors range from the electrical requirements of the control circuits to the environmental conditions where the transformer will operate. Thoughtful consideration of these aspects will lead to a robust and efficient control system.

Key design considerations include:

- Voltage Requirements: Precisely determine the input voltage available and the required output voltage(s) for all connected control devices. Account for potential voltage fluctuations in the supply.

- VA Rating (Volt-Ampere): Calculate the total apparent power demand of all connected loads. Select a transformer with a VA rating that meets or slightly exceeds this demand to prevent overheating and ensure reliable operation.

- Isolation: Determine if electrical isolation between the primary and secondary circuits is necessary for safety and to prevent ground loops. Standard two-winding transformers provide isolation, while autotransformers do not.

- Environmental Conditions: Consider the operating temperature, humidity levels, presence of dust, corrosive substances, and potential for vibration or shock. Choose a transformer with appropriate environmental protection (e.g., encapsulated designs for harsh environments).

- Mounting Requirements: Determine the available space and preferred mounting method (e.g., foot mounting, DIN rail mounting). Select a transformer with compatible mounting provisions.

- Safety Standards and Certifications: Ensure the chosen transformer meets relevant safety standards (e.g., UL, CSA, CE) for the intended application and region.

- Efficiency: While often secondary to reliability in control circuits, consider the transformer’s efficiency, especially for larger installations, to minimize energy losses and heat generation.

- Inrush Current: Be aware of the inrush current characteristics of the connected loads, particularly inductive loads like motors and solenoids. Select a transformer that can handle these transient currents without excessive voltage drop.

FAQ

What is the difference between a control transformer and a power transformer?

A power transformer is designed to transfer high-voltage electricity across grids and systems, while a control transformer is specifically for powering control circuits. Control transformers handle short-term overloads better and provide consistent low-voltage output. This stability protects relays, contactors, and other sensitive equipment, making them more reliable for machinery.

How do I choose the right control transformer size?

To select the correct size, check the total VA (volt-ampere) rating of your control circuit devices. Always choose a transformer with at least 20–30% higher capacity than your load. This prevents overheating, extends service life, and ensures reliable performance under fluctuating industrial conditions.

What industries use control transformers the most?

Control transformers are widely used in manufacturing plants, HVAC systems, telecom cabinets, automation systems, furnaces, and power distribution cabinets. Any industry where machines run on control circuits needs them. They protect sensitive equipment and reduce costly downtime caused by overheating or unstable voltage.

What is the lifespan of a control transformer?

A quality control transformer can last 10–20 years, depending on operating conditions. Factors like overload, poor ventilation, and high humidity can shorten its life. Choosing certified products and proper installation ensures maximum durability and long-term cost savings for industrial buyers.

Can control transformers be customized?

Yes, as manufacturers, we provide custom control transformers with specific voltage, frequency, and capacity requirements. Custom options include different insulation levels, compact designs, and temperature-resistant materials. This ensures better compatibility with your machines and increases reliability in demanding environments.

How does Linkwellelectrics support wholesale buyers of control transformers?

At Linkwellelectrics, we provide bulk supply, OEM customization, and fast delivery for control transformers. Our products meet industry certifications, and we offer technical support to help distributors, resellers, and large factories maximize efficiency and reduce downtime. Contact us today for wholesale inquiries and quotes.

Conclusion

A control transformer is a specialized transformer designed to provide stable and reliable voltage to control circuits in industrial and machinery applications. These transformers ensure the proper operation of critical components like contactors, relays, and solenoids by stepping down higher voltages to safer, usable levels. Their robust design and ability to handle inrush currents make them indispensable for automation and control systems.

For businesses seeking to source these essential components, Linkwell Electrics stands out as a potential wholesale supplier. They offer a range of control transformers suitable for various industrial needs. Sourcing from a reputable wholesaler like Linkwell Electrics can ensure competitive pricing and a consistent supply of quality control transformers for your operational requirements.

Therefore, understanding the function of a control transformer is crucial for maintaining efficient industrial operations, and businesses can explore wholesale options from suppliers such as Linkwell Electrics to meet their specific voltage control needs effectively.