Welcome to our exploration of control transformers versus power transformers, two essential components in electrical systems but with distinct purposes and designs. While both transform voltage levels, their applications and operational characteristics differ significantly. Understanding these differences is crucial for selecting the right transformer for specific needs, ensuring efficiency and safety.

In this blog, we’ll delve into the key distinctions between control and power transformers, examining their primary functions, design features, power handling capabilities, and typical applications. By highlighting these differences, we aim to provide a clear understanding of when to use each type of transformer in various electrical systems.

What is a Control Transformer

A control transformer is a specialized type of isolation transformer designed to provide a stable and reduced voltage to control circuits, typically found in industrial and commercial applications across the United States.

It steps down higher voltages (like 240V or 480V) to lower, safer voltages (often 24V or 120V) needed to power relays, contactors, timers, and other control components, ensuring the reliable and safe operation of machinery and automated systems.

Recommended products

What is a Power Transformer

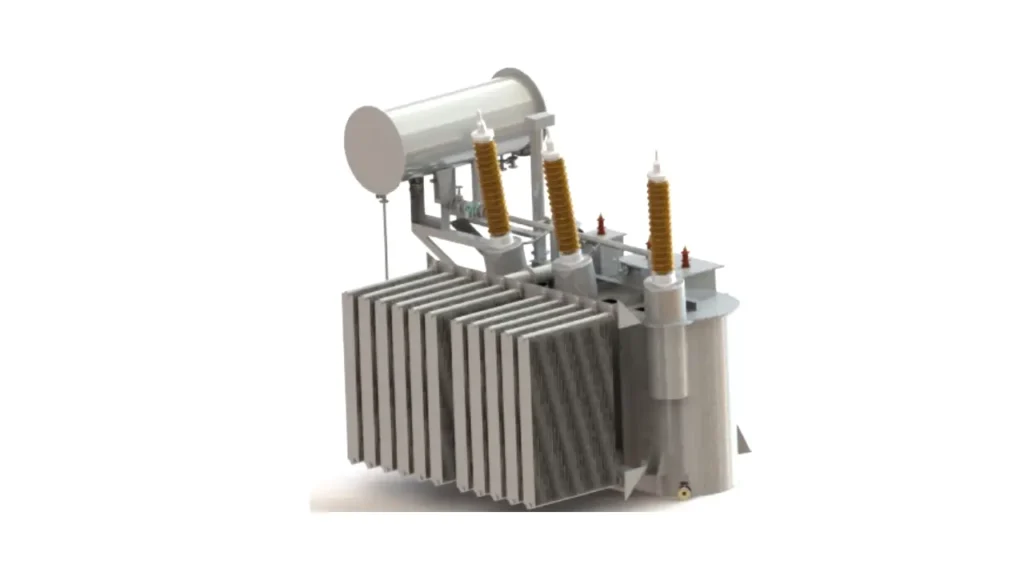

A power transformer is an electrical device designed for efficient transmission and distribution of electrical energy between different voltage levels in a power system.

Operating on the principle of electromagnetic induction, it typically handles high voltage and power (kVA or MVA) and is crucial for stepping up voltage for long-distance transmission to minimize losses, and stepping it down at substations for distribution to industrial, commercial, and residential consumers.

Control Transformer vs Power Transformer

Control transformers and power transformers are both essential electrical devices that utilize electromagnetic induction to transfer energy between circuits. However, they are designed for distinctly different purposes and thus exhibit key differences in their characteristics, applications, and priorities. Understanding these distinctions is crucial for selecting the appropriate transformer for a specific task.

Purpose and Application

Control transformers are primarily designed to provide a stable, lower voltage supply for control circuits in industrial and commercial equipment. Their main role is to step down higher distribution voltages (e.g., 240V, 480V) to the lower voltage levels (e.g., 24V, 120V) required by control components such as relays, contactors, timers, and PLCs. These transformers often prioritize high isolation to protect sensitive control electronics and personnel from high-voltage faults. They are integral to ensuring the safe and reliable operation of automated systems and machinery.

Power transformers, on the other hand, are designed for the efficient transmission and distribution of bulk electrical power across a power grid. They operate at much higher voltage and power levels (kVA to MVA) and are used to step up voltage at generating stations for long-distance transmission (minimizing losses) and then step it down at substations for distribution to various end-users, including industrial, commercial, and residential consumers. Efficiency and the ability to handle large amounts of power are the primary design considerations for power transformers.

Voltage and VA Rating

Control transformers typically have relatively low VA ratings, ranging from a few VA up to around 5 kVA, although some specialized units can go higher. Their primary and secondary voltage ratings are usually within the range of standard industrial and commercial voltages, such as 240V, 480V on the primary side and 24V, 120V on the secondary side. The focus is on providing the specific voltage needed for control devices with sufficient capacity for their operation, including handling inrush currents.

Power transformers are characterized by significantly higher VA or kVA ratings, often ranging from tens of kVA to hundreds of MVA. They handle a much wider range of voltages, from several kilovolts at distribution levels to hundreds of kilovolts for transmission. The design emphasizes efficient voltage transformation across these high levels to facilitate the bulk transfer of electrical energy with minimal losses over long distances.

Isolation and Construction

Control transformers often feature robust electrical isolation between the primary and secondary windings. This isolation is crucial for safety, preventing high-voltage faults from reaching the low-voltage control circuits and protecting operators and sensitive equipment. They may employ specific winding configurations or shielding techniques to enhance this isolation. Their construction is typically compact and designed for mounting within control panels or machinery enclosures.

While power transformers also provide electrical isolation, the focus is more on efficient energy transfer at high power levels. Their construction is often more elaborate, especially for larger units, involving features like oil or other liquid coolants, sophisticated insulation systems, and robust mechanical structures to withstand the stresses of high voltage and current. The physical size of power transformers is generally much larger than that of control transformers due to the higher power handling requirements.

| Feature | Control Transformer | Power Transformer |

| Primary Purpose | Powering control circuits at lower voltages | Efficient transmission and distribution of bulk power |

| VA Rating | Typically low (few VA to ~5 kVA) | Typically high (tens of kVA to hundreds of MVA) |

| Voltage Levels | Lower industrial/commercial voltages (e.g., 24V-480V) | High to very high voltages (kV range) |

| Isolation | Often high priority for safety of control circuits | Important, but efficiency is a primary focus |

| Construction | Compact, often for panel mounting | Large, often with cooling systems |

| Applications | Industrial machinery, automation systems, HVAC controls | Power generation, substations, distribution networks |

How to Choose Control Transformer and Power Transformer

When choosing between a control transformer and a power transformer, several key factors come into play, primarily centered around the intended application and the specific electrical requirements of the system. Carefully evaluating these aspects will ensure you select the most appropriate and efficient transformer for your needs.

Here are crucial considerations for choosing between a control transformer and a power transformer:

Load Requirements:

- Control Transformer: Determine the total volt-amperes (VA) needed by all control devices (relays, contactors, sensors) that will operate simultaneously. Account for the inrush current of inductive loads and apply a safety factor (typically 20-25%).

- Power Transformer: Calculate the total power (kVA or MVA) required by the connected loads, considering the type of load (resistive, inductive, capacitive) and any potential for future expansion. Efficiency at the expected load levels is a significant factor.

Voltage Transformation Ratio:

- Control Transformer: Select a transformer with a primary voltage rating that matches the available power supply and a secondary voltage rating that meets the specific voltage requirements of the control circuit (e.g., stepping down 480V to 120V or 24V).

- Power Transformer: Choose a transformer with the appropriate voltage transformation ratio to step up voltage for transmission (e.g., kV to hundreds of kV) or step down voltage for distribution (e.g., high kV to lower kV or down to utilization voltages like 480V, 208V, or 120V).

Conclusion

In summary, control transformers and power transformers serve distinct purposes within electrical systems. Control transformers prioritize voltage step-down for control circuits and often feature higher isolation capabilities, while power transformers focus on efficient power distribution at higher voltage and kVA levels. Understanding these fundamental differences in design and application is crucial for selecting the appropriate transformer for a given task.

Key distinctions lie in their VA ratings, voltage handling capabilities, isolation requirements, and typical applications. Control transformers are integral for ensuring the safe and reliable operation of control components, whereas power transformers are vital for the bulk transfer of electrical energy. For top-rated control transformers tailored to your needs, explore the offerings at Linkwell Electrics.

Choosing the right transformer type is essential for system efficiency and safety. Linkwell Electrics provides a range of high-quality control transformers designed for various industrial and commercial applications. Contact us today to find the ideal control transformer solution for your specific requirements.