Three-phase transformers are fundamental to modern electrical power systems, efficiently transmitting and distributing electricity. This ultimate guide delves into their crucial role in stepping up or stepping down voltage for industrial, commercial, and utility applications.

Understanding their construction, winding configurations (like Delta and Wye), and operational principles is key. This guide provides a comprehensive overview of how these transformers enable the reliable and economical delivery of three-phase power.

What is Three Phase Transformer

A three-phase transformer is an electrical device designed to transfer electrical energy between three circuits. Unlike a single-phase transformer which works with one alternating voltage, a three-phase transformer manages three alternating voltages that are offset in phase from one another, typically by 120 degrees. This makes them essential for high-power industrial and commercial applications where efficient generation, transmission, and distribution of electricity are required.

These transformers are constructed by using either three single-phase transformer units or a single unit with a shared core and three sets of windings (primary and secondary) for each phase. They function based on the principle of electromagnetic induction, stepping voltage up or down to match the requirements of different parts of the power grid or connected equipment.

Their ability to handle larger power capacities with greater efficiency and less conductor material compared to using three separate single-phase units makes them fundamental to modern electrical infrastructure.

How Three Phase Transformers Work

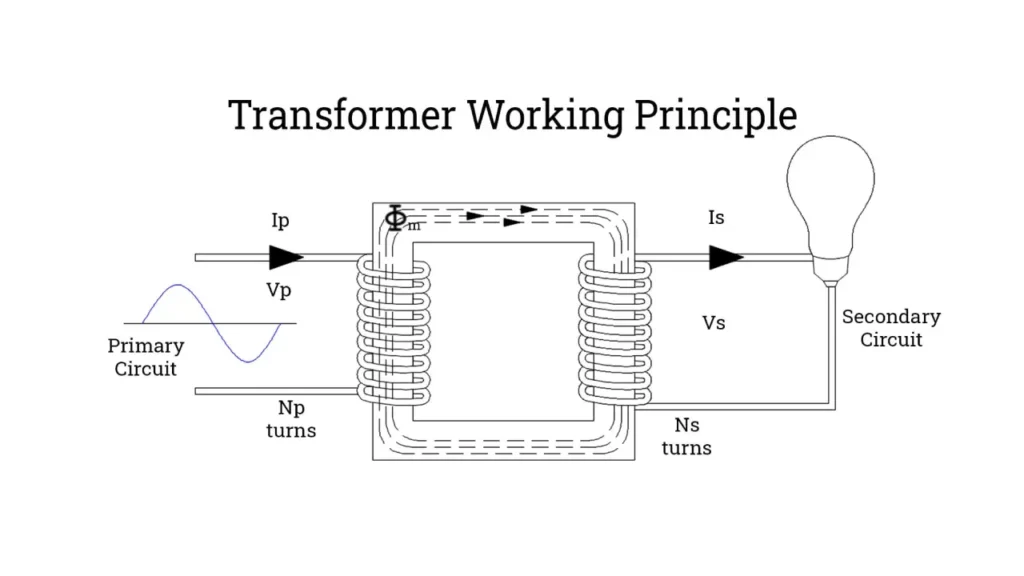

A three-phase transformer works by converting electrical power from one voltage level to another in three-phase systems. It consists of three primary windings and three secondary windings, each corresponding to a phase in the system.

Here is the working principle of three phase transformer in the following:

A three-phase transformer operates on the principle of electromagnetic induction, similar to a single-phase transformer, but extended to a three-phase system. When a three-phase AC voltage is applied to the primary windings (which are interconnected in either a delta or wye configuration), it creates three alternating magnetic fluxes within the transformer’s core, each differing in phase by 120 electrical degrees.

These changing magnetic fluxes then induce corresponding three-phase voltages in the secondary windings (also connected in either delta or wye), with the voltage transformation ratio determined by the turns ratio between the primary and secondary windings of each phase. The core is designed to handle the three simultaneous magnetic fluxes efficiently, providing a compact and effective means of transforming three-phase power.

The transformer’s core is designed to handle the magnetic flux generated by three-phase alternating current (AC), which ensures efficient power transfer with minimal loss. When three-phase power is applied to the primary windings, a magnetic field is created that induces voltage in the secondary windings, effectively stepping up or stepping down the voltage as needed.

This system helps distribute electricity in a balanced and stable manner, providing continuous power flow with minimal fluctuation. Three-phase transformers are widely used in industrial applications, power distribution, and large-scale electrical systems due to their ability to handle high power loads with efficiency.

- Utilizes three primary and three secondary windings.

- Efficiently transfers energy between different voltage levels.

- Core design reduces power losses and energy inefficiency.

- Ensures balanced and stable power distribution.

- Induces voltage in secondary windings using magnetic flux.

- Essential for large-scale power systems and industrial applications.

- Supports high power loads with minimal fluctuations.

- Common in power transmission, substations, and factories.

What is Single and Three Phase Transformer?

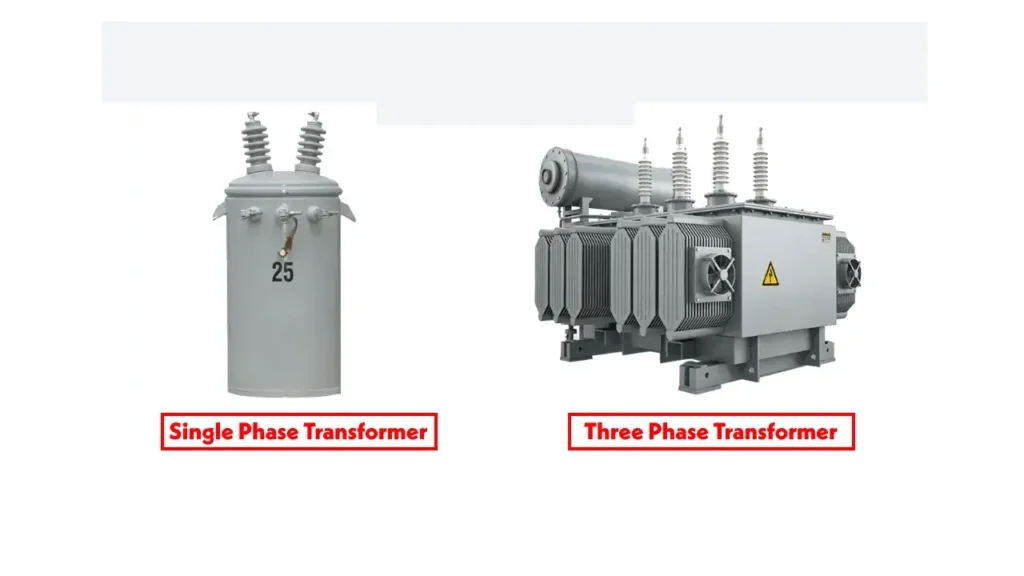

Single-phase transformers are the most common type found in residential and light commercial applications. They operate on a single alternating voltage and are used to step up or step down voltage for powering appliances, lighting, and other single-phase loads.

- Ideal for lower power requirements.

- Simpler in design and construction.

- Typically used in homes and small businesses.

Three-phase transformers, conversely, are designed for high-power industrial and commercial systems. They work with three alternating voltages, phased 120 degrees apart, enabling efficient transmission and distribution of large amounts of electrical energy to power heavy machinery, motors, and large facilities.

- Essential for high-power applications and heavy industry.

- More complex and larger than single-phase transformers.

- Provide a more stable and continuous power flow.

What is Three Phase Transformer Made of

Understanding the construction of a three-phase transformer reveals how it efficiently manages high-power electricity. These complex devices are built from a combination of carefully selected materials and parts, each playing a crucial role in their operation.

A three-phase transformer is primarily constructed from several key components:

- Core: Typically made of laminated silicon steel to reduce eddy currents and hysteresis losses, providing a path for the magnetic flux.

- Windings: Composed of conductive material, usually copper or aluminum, insulated and wound around the core. There are primary windings (connected to the input voltage) and secondary windings (where the output voltage is induced) for each of the three phases.

- Insulation: Various materials like paper, varnish, and oil (in oil-filled types) are used to electrically isolate the windings from each other and from the core, preventing short circuits.

- Tank and Bushings: For larger, oil-filled transformers, a steel tank houses the core and coils, filled with insulating oil. Bushings are insulated terminals that allow electrical connections to the windings from outside the tank.

- Cooling System: Depending on the size and type, transformers may have cooling fins, radiators, fans, or pumps to dissipate the heat generated by losses.

Types of Three Phase Transformer

Understanding the various types of three-phase transformers is key to selecting the right one for a specific application. These transformers differ in their construction and insulation methods, impacting their use cases.

Three Phase Core Type Transformer

In a three-phase core type transformer, the magnetic core has three limbs, and each limb contains both the primary and secondary windings for one phase. The limbs are connected at the top and bottom by yokes. This construction allows the magnetic flux of the three phases to share common return paths through the outer limbs, making it a common and relatively straightforward design for medium to high voltage applications.

Three Phase Dry Type Transformer

Three-phase dry type transformers do not use liquid like oil for cooling and insulation. Instead, the windings are insulated using solid materials such as resin or varnish, and cooling is achieved through natural convection or forced air. They are typically used in indoor environments or where fire safety is a critical concern, such as in buildings, hospitals, and substations, as they pose less environmental risk and are fire-resistant.

Three Phase Shell Type Transformer

The three-phase shell type transformer has a core that surrounds most of the windings. The windings are placed on the central limb, and the core provides a protective shell around them. This construction offers better mechanical protection for the windings and superior cooling characteristics due to the larger surface area of the core exposed to the cooling medium. Shell type transformers are often favored for their robustness and efficiency in certain power applications.

Three-Phase Transformer Constitution

The constitution of a three-phase transformer involves several key components working together to facilitate the transformation of three-phase electrical power. At its heart is the magnetic core, typically made of laminated steel, which provides the path for magnetic flux. Wound around this core are the primary and secondary coils for each of the three phases, usually made of copper or aluminum. These elements are carefully insulated to prevent electrical breakdown.

- Magnetic Core: Provides a low-reluctance path for the magnetic flux.

- Windings: Insulated conductors where voltage transformation occurs (primary and secondary coils for each phase).

- Insulation: Materials separating windings from each other and the core to prevent short circuits.

- Tank and Bushings (for liquid-filled types): Housing for the core and coils, and terminals for external connections.

- Cooling System: Mechanisms (like fins, radiators, or fans) to manage heat generated during operation.

Voltage and Current Characteristics of Three-Phase Transformer

Understanding the voltage and current characteristics of three-phase transformers is crucial, dictated significantly by whether the windings are connected in a Star (Wye) or Delta configuration.

These connections determine the relationship between the voltage and current measured across a single winding (phase values) and those measured between the lines connected to the transformer (line values). Distinguishing between phase and line parameters is paramount for correct system design and operation.

The choice between Star and Delta connections has a direct impact on the voltage and current levels available from the transformer. In a Star connection, the line voltage is 3 times the phase voltage, while the line current equals the phase current.

Conversely, in a Delta connection, the line voltage equals the phase voltage, but the line current is 3 times the phase current. These fundamental relationships, along with the transformer’s turns ratio, are essential for sizing the transformer and ensuring compatibility with the connected load.

- Phase values are measured across a single winding or component.

- Line values are measured between two lines or terminals.

- Star and Delta connections define the relationships between phase and line voltages and currents.

- Turns ratio is also a critical parameter for determining voltage transformation.

Table: 3-phase voltage and current characteristics

| Connection | Phase voltage | Line voltage | Phase current | Line current |

| Star | VP=VL/3 | VL=3 | IP=IL | IL=IP |

| Delta | VP=VL | VL=VP | IP=IL/3 | IL=3 |

- VL: line-to-line voltage (line voltage)

- VP: phase-to-neutral voltage (phase voltage)

- IL: line current

- IP: phase current

Three Phase Transformer Applications

Three-phase transformers are indispensable in modern electrical infrastructure due to their efficiency in handling large power loads. They are predominantly used in applications requiring significant power, facilitating the transmission and distribution of electricity from power generation plants to industrial and large commercial consumers. Their ability to step voltage up for long-distance transmission, minimizing losses, and then step it back down for utilization makes them fundamental to the power grid.

- Power generation stations (stepping up voltage for transmission)

- High-voltage transmission substations (stepping voltage up or down)

- Industrial facilities (supplying power for heavy machinery and motors)

- Large commercial buildings (providing power for HVAC, lighting, and equipment)

- Utility distribution networks (stepping down voltage for local distribution)

- Electrified railway systems

- Large data centers

How to Choose Three Phase Transformers

Choosing the right three-phase transformer involves carefully evaluating the specific requirements of the application to ensure safe and efficient operation. The first critical step is determining the necessary power capacity, typically measured in kVA (kilo-volt-amperes), which must exceed the total expected load.

Equally important are the primary and secondary voltage requirements, defining the transformer’s step-up or step-down function to match the source and load voltages. Understanding the nature of the load, such as motor loads or lighting, also influences the selection.

Beyond basic capacity and voltage, several other factors influence the choice. The required winding configuration (Delta-Delta, Delta-Star, Star-Delta, or Star-Star) is vital as it impacts voltage and current relationships and grounding options.

The insulation and cooling method, such as dry-type for indoor or sensitive locations or liquid-filled for outdoor or high-capacity needs, must suit the installation environment and safety regulations. Finally, considering factors like efficiency, impedance, size constraints, and adherence to industry standards ensures optimal performance and longevity.

- Determine the required power capacity (kVA).

- Specify primary and secondary voltage ratings.

- Consider the type and characteristics of the load.

- Select the appropriate winding connection (Star or Delta).

- Choose the suitable insulation and cooling method (dry or liquid-filled).

- Account for environmental conditions and installation space.

- Check for relevant industry standards and certifications.

Conclusion

Three-phase transformers are vital components in electrical systems, enabling efficient power distribution for industrial and commercial applications. They reliably step voltage up or down, handling larger power loads than single-phase alternatives.

Understanding their function and types is crucial for various electrical projects. Their robust nature ensures stable and consistent power transfer.

For those requiring these essential units in bulk, you can get wholesale three-phase transformers from Linkwell Electrics, a reliable supplier in the market.