Cooling fans are unsung heroes in countless applications, silently working to prevent costly damage from overheating. From keeping our computers running smoothly to maintaining optimal temperatures in industrial machinery, their function is critical for performance and longevity.

This guide will demystify the mechanics behind these essential devices. We’ll explore the fundamental principles of how cooling fans work, examining the key components and processes that allow them to efficiently dissipate heat and ensure stable operation in various environments.

What are Cooling Fans?

Recommended Cooling Fan

-

FF202 Cooling fan and filter

-

FF109 IP54/55 Electric Cabinet Ventilation Cooling Fan with Filter

-

FK5523 Cooling fan and filter

-

FK5527 Cabinet filter cooling fan electrical control cabinet

-

LK3243 Industrial Electrical Cabinet Cooling Fan

-

LK6621 Rittal cabinet cooling fan and filter

-

LK6623 Axial fan, cabinet cooling fan

-

LK6627 Cooling Fan and Filter

Cooling fans are essential electromechanical devices designed to manage and dissipate heat by actively moving air. They consist of a motor-driven impeller or blades that generate airflow, drawing hot air away from heat-generating components or areas and replacing it with cooler ambient air.

This continuous air movement is crucial for maintaining optimal operating temperatures in a vast array of systems, from preventing electronic components in computers and industrial machinery from overheating to improving air circulation and comfort in enclosed spaces.

By ensuring that critical components remain within their safe temperature limits, cooling fans play a vital role in enhancing performance, extending lifespan, and preventing damage to various types of equipment.

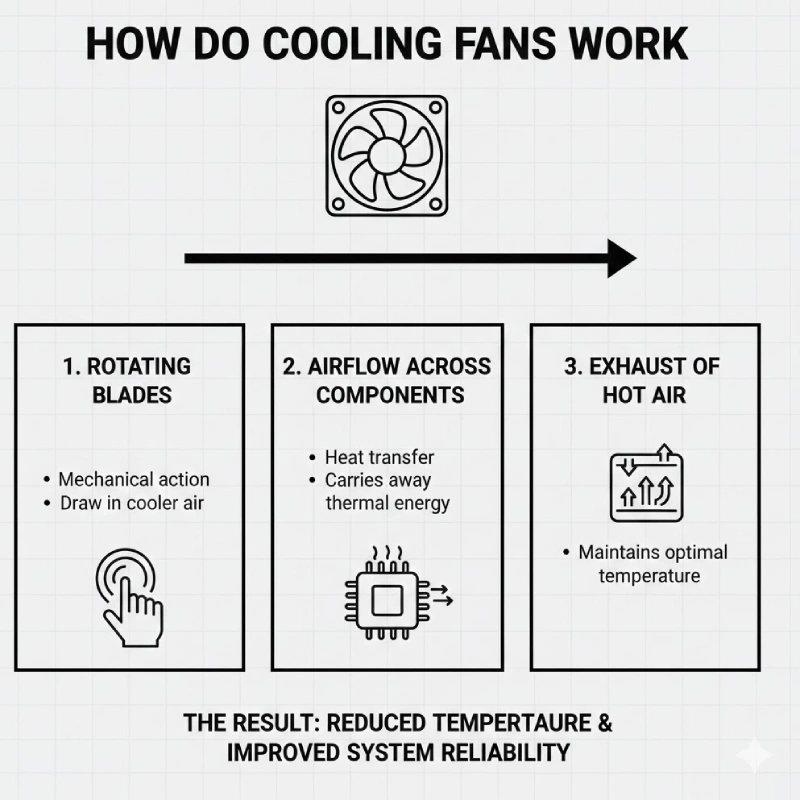

How Do Cooling Fans Work?

Cooling fans operate on a fundamental principle of thermodynamics: heat transfer through convection. At their core, a cooling fan consists of rotating blades, known as an impeller, driven by an electric motor. As the blades spin, they create a pressure differential, drawing cooler air from one side and expelling warmer air from the other. This forced movement of air directly facilitates the transfer of heat away from hot surfaces or confined spaces.

This process involves several key mechanisms:

- Convection: The primary mode of operation. As the fan moves air across a hot surface (like a heat sink or electronic component), the moving air absorbs heat from the surface and then carries that heat away, effectively cooling the component.

- Airflow Creation: The fan’s motor rotates the blades, which are specifically angled to push or pull air in a desired direction. This creates a continuous current of air, ensuring a constant supply of cooler air to the heat source and removal of warmer air.

- Heat Dissipation: By continuously replacing hot air with cooler air, the fan prevents heat from building up in a confined space (like an electrical enclosure or computer case), maintaining optimal operating temperatures for sensitive components.

The overall effectiveness of a cooling fan is determined by factors such as its airflow rate (measured in Cubic Feet per Minute or CFM), static pressure capability (how well it can move air against resistance), and its size and design, which are chosen to match the specific thermal requirements of the application.

How to Check if Cooling Fan is Working?

Testing a cooling fan is crucial to ensure optimal performance and prevent overheating. Here’s how to check if your cooling fan is working effectively:

1. Visual Inspection

Start by turning off the equipment and visually inspecting the fan. Look for any obvious signs of damage, such as:

- Cracked or broken blades: Damaged blades can unbalance the fan and reduce airflow.

- Excessive dust and debris: Accumulated dirt on blades and grilles can restrict airflow and hinder performance.

- Loose wiring or connections: Ensure all wires are securely connected to the fan and power source.

- Obstructions: Check for anything physically blocking the fan’s rotation.

2. Listen for Operation

With the equipment powered on (or the fan manually activated if possible), listen carefully to the fan. A healthy cooling fan should produce a consistent, relatively smooth hum.

- Abnormal noises: Grinding, rattling, screeching, or clicking sounds indicate potential issues with the bearings, motor, or blades hitting an obstruction.

- No sound at all: If the fan receives power but makes no sound, the motor may be faulty or seized.

3. Feel for Airflow

This is a direct test of the fan’s primary function. Place your hand near the fan’s exhaust vent (where air is pushed out) or intake vent (where air is pulled in).

- Strong, consistent airflow: This indicates the fan is moving air effectively.

- Weak or inconsistent airflow: Suggests reduced efficiency, possibly due to a failing motor, clogged filter, or blade obstruction.

- No airflow: The fan is likely not working at all.

4. Monitor Temperature

For a more definitive test, monitor the temperature of the components or enclosure the fan is designed to cool.

- Use temperature sensors: Many electronic devices and industrial equipment have built-in temperature sensors that can be read via software or display.

- Infrared thermometer: A non-contact infrared thermometer can quickly measure surface temperatures of components near the fan.

- Contact thermometer: For more precise readings on specific surfaces.

If temperatures are consistently higher than their normal operating range, even with the fan seemingly running, it indicates the fan is not providing adequate cooling.

5. Electrical Test (Advanced)

For a more thorough diagnosis, especially if the fan isn’t turning on, an electrical test using a multimeter is recommended.

- Check for voltage: With the fan powered on, use a multimeter to check for the correct voltage at the fan’s power input terminals. Ensure it matches the fan’s specified voltage (e.g., 12V DC, 230V AC). No voltage means a power supply issue, wiring fault, or a problem with a control module/relay upstream.

- Check for continuity/resistance: If the fan is completely dead, and you’ve confirmed power, you can test the motor’s windings for continuity. Refer to the fan’s specifications or a repair manual for expected resistance values. A lack of continuity or an open circuit indicates a faulty motor.

- Test the relay/control module: If the fan has a relay or control module, these components should also be tested to ensure they are sending power to the fan correctly.

By systematically going through these steps, you can effectively check if your cooling fan is working correctly and identify any potential issues before they lead to more significant problems.

Cooling Fans Application

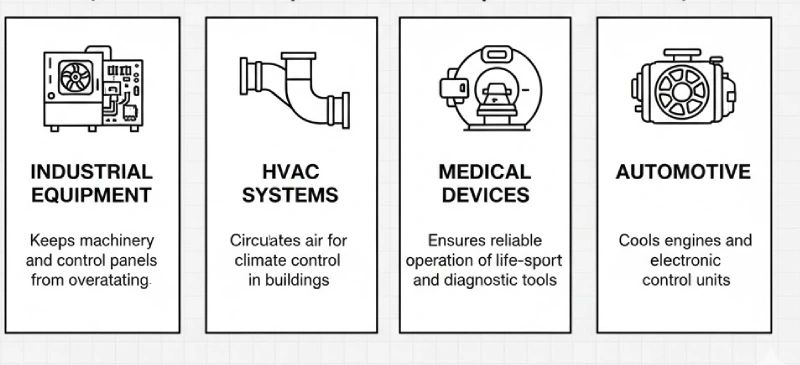

| Industry | Application | Key Requirements | Common Fan Size | Typical Airflow |

|---|---|---|---|---|

| Industrial Equipment | Control cabinets, inverters | Continuous operation, high reliability, dust resistance | 120–200 mm | 100–500 CFM |

| Electronics | Power supplies, servers | Low noise, stable airflow, compact design | 80–120 mm | 30–150 CFM |

| HVAC Systems | Air handling units, ventilation | High airflow, energy efficiency, long lifespan | 200–350 mm | 500–2000 CFM |

| Medical Devices | Diagnostic & cooling systems | Low vibration, quiet operation, precise temperature control | 60–120 mm | 20–100 CFM |

What to Do if Your Cooling Fan Isn’t Working?

If you discover that your cooling fan isn’t working, it’s crucial to address the issue promptly to prevent potential damage to the equipment it’s meant to cool. The steps you take depend on the type of fan and the system it’s part of, but generally follow a troubleshooting process.

Here’s a guide on what to do if your cooling fan isn’t working:

1. Safety First

- Disconnect Power: Before performing any inspections or repairs, always disconnect power to the equipment the fan is cooling. This is paramount to prevent electrical shock or injury.

- Allow to Cool Down: If the equipment was overheating due to the fan failure, allow it to cool down completely before handling any components.

2. Re-Check Basic Operation

- Power Supply: Double-check that the equipment itself is receiving power. Sometimes the fan issue is a symptom of a larger power problem.

- Switches/Controls: Ensure all relevant switches, circuit breakers, or controls for the fan or the system are in the “on” position.

3. Visual Inspection

- Obstructions: Look for anything physically blocking the fan blades (e.g., loose wires, debris, dust bunnies). Carefully remove any obstructions if safe to do so.

- Cleanliness: Check for excessive dust and dirt buildup on the fan blades, motor housing, and grille. A thick layer of dust can impede movement or cause overheating of the motor itself. Clean the fan thoroughly using compressed air or a soft brush.

- Physical Damage: Inspect the fan blades for any cracks, bends, or missing pieces. Check the fan housing and mounting for damage.

- Wiring: Examine all visible wiring leading to the fan. Look for frayed wires, loose connections, or signs of burning or melting.

4. Check Power Connection and Fuses

- Loose Connections: Gently wiggle the power connectors to the fan. Sometimes a loose connection is all it takes.

- Blown Fuse: If the fan is part of a system with a fuse box, check the fuse specifically designated for the cooling fan. A blown fuse indicates an overcurrent, likely due to a short circuit or a seized fan motor. Replace the fuse with one of the correct amperage.

- Circuit Breaker: If the system is on a circuit breaker, check if it has tripped. Reset the breaker.

5. Test the Fan Directly (If Applicable and Safe)

- Direct Power (Caution!): If you are comfortable and it’s safe for the fan type (e.g., a simple DC fan), you can try to provide direct power to the fan’s terminals from a known good power source (e.g., a battery of the correct voltage). If the fan spins, it indicates a problem with the original power supply, wiring, or control circuit, not the fan motor itself.

- Spin Blades Manually: With power disconnected, try to spin the fan blades manually. If they are stiff, difficult to move, or wobble excessively, the bearings may be seized or failing.

6. Diagnose Control Issues (If Present)

- Relay Test: If the fan is controlled by a relay (common in vehicles or industrial systems), test the relay’s functionality. A faulty relay might not be sending power to the fan. (Refer to “How to Test Cooling Fan Relay” for steps).

- Control Module Test: If the fan is managed by a dedicated control module, this module could be faulty. Testing these often requires specific diagnostic tools or professional help. (Refer to “How to Test Cooling Fan Control Module” for basic steps).

- Temperature Sensor: In some systems, a faulty temperature sensor might not be sending the correct signal to activate the fan.

7. Consider Replacement

- If Fan is Dead: If, after all checks, the fan still doesn’t spin, or if it makes grinding noises indicating seized bearings, the fan motor itself is likely faulty and needs replacement.

- Reduced Performance: Even if it spins, if airflow is significantly reduced or it’s making excessive noise, it’s best to replace it to ensure adequate cooling.

8. Professional Help

- If you’re unsure about any step, dealing with high voltage, or suspect a complex electrical issue (like a short in the wiring or a faulty control board), it’s always best to consult a qualified electrician or a professional technician specializing in the equipment.

Addressing a non-working cooling fan promptly is key to preventing potentially expensive damage from overheating.

Conclusion

Understanding how cooling fans work reveals their simple yet critical role in thermal management. By converting electrical energy into airflow, they efficiently dissipate heat, safeguarding components and maintaining optimal operating conditions for a vast array of systems and devices.

Proper fan selection and maintenance are key to effective heat dissipation. For robust and reliable cooling solutions, turn to Linwell Electrics. They offer a comprehensive range of wholesale cooling fans and filters, suitable for diverse industrial and commercial applications.

Investing in quality cooling fans and filters from a trusted supplier like Linwell Electrics ensures long-term protection against overheating, leading to enhanced equipment lifespan and improved operational efficiency.