Let’s be honest. In the world of electrical infrastructure, switchboard cooling often gets overlooked. Yet it’s one of those silent guardians that determines whether your equipment quietly hums for a decade—or fails spectacularly when you need it most. As a leading manufacturer of switchboard cooling systems, we’ve seen it all: from tiny control cabinets in dusty workshops to towering industrial boards handling brutal ambient conditions. And let us tell you—nothing kills uptime faster than unmanaged heat.

Switchboard Cooling

Switchboard cooling is essential for protecting electrical components from heat damage. Effective cooling ensures reliable operation, extends equipment lifespan, and supports safety in industrial and commercial environments.

Cooling isn’t a luxury. It’s a necessity. According to IEC 61439 standards for low-voltage switchgear assemblies, ambient temperature is one of the most critical parameters affecting the thermal stability and lifespan of internal components. The failure rate of electronic components doubles with every 10°C increase in temperature beyond the recommended range. That’s not a theory. It’s physics.

In this article, we’re not just going to throw cooling methods at you. We’re going to break it down, real talk—what works, where it works, why it works, and how to make the smartest choice whether you’re a panel builder, electrical engineer, contractor, or wholesaler.

Passive Ventilation: The Simplicity that Still Surprises

Sometimes, less is more. That’s the spirit behind passive ventilation. It doesn’t involve any motors, thermostat sensors, or refrigerants—just the age-old principle that hot air rises and cold air sinks. By installing louvres on the sides or doors of your cabinet, you let nature do the work. When designed properly, passive systems create a chimney-like airflow that draws in cooler air from the bottom and pushes hot air out the top.

So when does passive ventilation make sense?

- Low internal heat loads: Think control panels with minimal power electronics or infrequently operating systems.

- Moderate ambient conditions: Locations that don’t swing wildly between freezing and sweltering temperatures.

- Cost-conscious installs: Where budget is tight but reliability can’t be compromised.

One of our long-term wholesale partners in Queensland, Australia, who deals primarily with solar battery enclosures, swears by passive ventilation for outdoor cabinets under shade. He told us:

“Your passive kits are so easy to install and last forever. Haven’t had a single call-back in three years.”

But here’s the truth: passive cooling has limits. Without proper protective hoods, your IP rating maxes out at IP54. With a hood, you can stretch it to IP56—but you’re still depending on stable temperatures. If your internal components generate more heat than nature can evacuate, you’ll hit a thermal ceiling fast.

Our advice? Don’t overestimate passive cooling. It’s a great solution when used strategically, not universally.

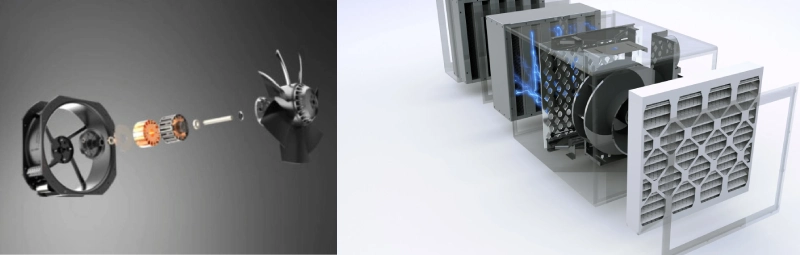

Forced Ventilation Switchboard Fan : The Goldilocks Zone for Moderate to High Heat Loads

When natural airflow just isn’t cutting it, the next logical step is forced ventilation—aka, using switchboard fan. It’s a solid middle ground: more effective than passive systems but not as complex or costly as air conditioning.

Our in-house testing lab shows that a well-placed exhaust fan can lower internal cabinet temperatures by 10°C to 15°C, especially when paired with inlet filters. The basic idea is to push hot air out and pull cooler air in, creating a continuous exchange.

You can operate the fans:

- Continuously for critical applications that can’t risk overheating.

- Thermally triggered, using thermostats or sensors for energy efficiency.

- Digitally controlled, if you want full automation tied to your PLC system.

However, don’t forget the IP rating game. Without a protective hood, externally mounted fans typically peak at IP54. Add a hood, and you can hit IP56, which meets many industrial and commercial enclosure standards.

A mining contractor in Western Australia told us:

“We’ve switched entirely to your IP56 fan kits for all our MCC panels. The dust protection and heat performance are way better than our old models.”

That’s the thing about forced ventilation: it works, and it works well, but only if you size it correctly and keep it clean. Dust buildup can turn a high-performance fan into a weak breeze in just months. We always advise routine inspection every 3–6 months.

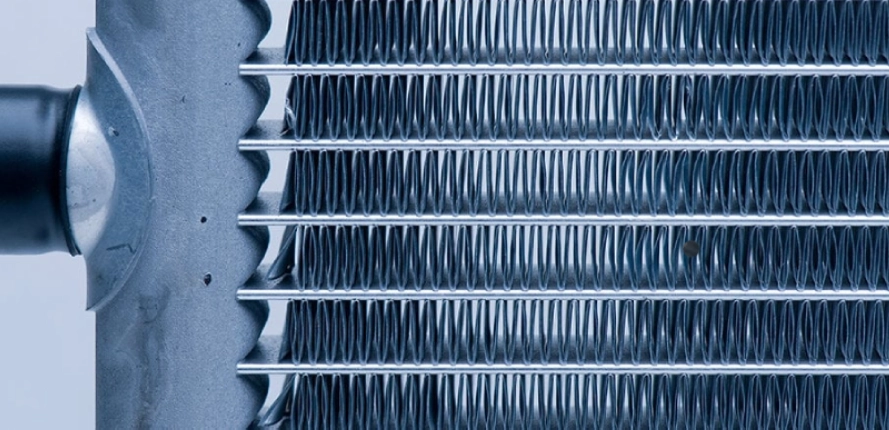

Heat Exchangers: Precision Cooling for Stable, Dusty, or Moist Environments

When your environment is dusty, wet, or both—but you still need active cooling—a heat exchanger is often the smart choice. This system doesn’t let inside and outside air mingle. Instead, it uses a closed-loop system with a thermal medium (either air-to-air or air-to-liquid) to move heat out of the cabinet without exposing sensitive internals to contaminants.

Here’s where heat exchangers really shine:

- IP55 protection or higher.

- Ideal for chemical plants, food manufacturing, and outdoor enclosures.

- Low maintenance: minimal moving parts mean fewer failure points.

An air-to-air exchanger, for example, uses aluminum fins to absorb and dissipate heat efficiently. If you’re looking at heat-sensitive gear like VFDs, PLCs, or embedded systems, this is a reliable way to stay cool without inviting moisture or particles into the party.

We’ve had clients in pharmaceutical production rave about how our sealed heat exchangers cut their enclosure downtime by over 70%, mainly because they no longer had to worry about water vapor corroding sensitive connections.

Just remember: heat exchangers aren’t meant for extreme heat loads or volatile ambient temps. They balance thermal performance with environmental isolation. And that’s the sweet spot for many industries.

Air Conditioning: When Only High-Powered Cooling Will Do

Sometimes, the only thing standing between a fried circuit and flawless operation is a dedicated air conditioner. For those high-density switchboards in industrial plants, server rooms, or remote mining sites, air conditioning is not optional—it’s mission-critical.

Our compressor-based AC units are engineered to cope with Australia’s harshest conditions, with models rated for ambient temps up to 60°C. The internal refrigerant system circulates coolant through evaporator coils, sucking heat from inside and releasing it outside—completely sealed and IP55 rated.

Why choose air conditioning?

- Handles high and fluctuating heat loads.

- Excellent for high-humidity or corrosive atmospheres.

- Delivers tight thermal control, down to ±1°C accuracy.

Of course, this level of performance comes with higher upfront and operational costs. Installation needs to be precise—incorrect placement can disrupt airflow, and refrigerant lines must be sealed to perfection. But the payoff in reliability and component lifespan is often well worth it.

One of our gold-tier distributors recently equipped an oil refinery project in the Northern Territory with our compact AC models. Post-installation review?

“The units run flawlessly, even in 48°C ambient. Zero failures in 14 months. Clients are thrilled.”

That’s the kind of reliability you get when you stop treating cooling as an afterthought and start making it a design pillar.

FAQ

What is the best cooling solution for switchboards in hot and humid environments?

In regions with high heat and humidity, air conditioning is typically the best solution. It ensures sealed enclosure integrity, maintains stable internal temperatures, and prevents condensation. For areas with frequent temperature fluctuations, adding anti-condensation heaters provides further protection against moisture-related failures.

How do I choose between passive and forced ventilation?

Choose passive ventilation if your switchboard has a low internal heat load and is located in a moderate climate. If heat buildup is more significant or ambient conditions vary, go with forced ventilation using fans. This offers better heat dissipation while remaining cost-effective.

Can I install a heat exchanger outdoors?

Yes—but you must choose a model with an IP55 or higher rating and ensure it’s installed with proper weatherproofing. Heat exchangers are excellent for sealed environments where you need to avoid dust, gas, or moisture infiltration while still managing heat.

How often should cooling equipment be maintained?

Fans and filters: Every 3–6 months for cleaning and inspection.

Heat exchangers: Yearly checks, unless in highly contaminated environments.

Air conditioners: Professional servicing every 6–12 months, especially before summer.

Regular maintenance ensures optimal performance and avoids unexpected breakdowns.

Conclusion

Whether you’re dealing with mild ambient conditions or extreme industrial environments, the right cooling method makes all the difference. Passive ventilation works beautifully in low-heat, cost-sensitive scenarios. Forced ventilation offers active control for moderate thermal demands. Heat exchangers keep enclosures sealed and safe in harsh conditions. And air conditioning provides top-tier performance when the stakes—and the temperatures—are high. Don’t overlook anti-condensation heaters either—they’re your best defense against moisture and corrosion, especially in variable climates.

As a switchboard fan manufacturer with years of field-proven experience, we’ve helped thousands of clients—from small OEMs to major industrial contractors—optimize their switchboard cooling strategies. The results speak for themselves: longer component lifespans, fewer failures, happier clients, and greater ROI.

Ready to find the perfect cooling solution for your next project? Talk to our team of experts today. We don’t just manufacture systems—we help you build smarter, safer, and more resilient infrastructure.