There’s a quiet hero behind the controlled climate of skyscrapers, the dust‑free tunnels of cement plants, and the steady drying in textile mills. That hero? The centrifugal fan. While it may not be flashy, its importance in industry is undeniable.

We know this not because we read it in a spec sheet—but because we manufacture centrifugal fans, day in, day out. We’ve worked with garment factories struggling to maintain humidity levels. We’ve partnered with mining companies requiring explosion-proof airflow systems. And if there’s one thing we’ve learned, it’s this: a centrifugal fan is not just a fan. It’s a critical piece of engineering.

Let’s peel back the blades and dive deep. What makes these machines so invaluable in 2025? How have they evolved? What’s their real-world commercial value? This isn’t just another product description. It’s a practical, field-proven look at how centrifugal fans are powering industries worldwide—and why.

What Are Centrifugal Fans in 2025: Not Just Blowing Air

If you’re thinking a fan’s job is just to “move some air,” think again. In 2025, centrifugal fans do much more—they control environments, protect worker health, stabilize production lines, and optimize energy use.

In many industries, if your airflow is off, everything is off. And it’s not just about volume—it’s about pressure, temperature, filtration, and stability. That’s where centrifugal fans come in.

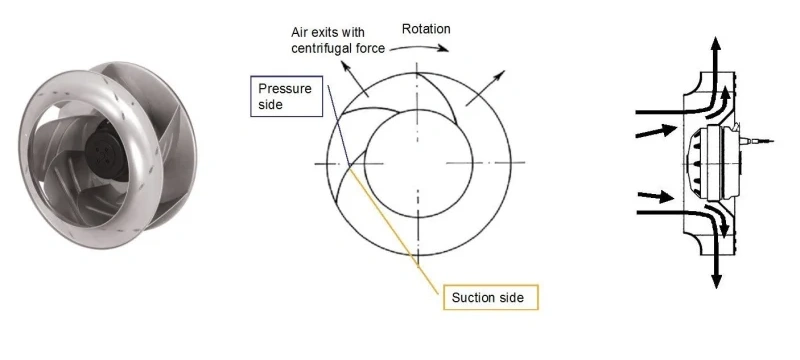

Unlike axial fans that blow in a straight line, centrifugal fans pull air in and spin it out at a 90° angle, increasing pressure and enabling movement through filters, ducts, and resistance-heavy environments. That’s why HVAC engineers, textile factories, clean rooms, cement plants, and hospitals all use them extensively.

We’ve been part of that evolution. In 2013, one of our customers—a textile factory in Dhaka—was dealing with uneven drying and poor lint control. After switching to our backward-curved centrifugal models, they reported a 35% reduction in energy use and a 41% drop in fabric rework rates. That’s not marketing—it’s measurable, bottom-line impact.

So whether you’re in design, procurement, or plant management—understanding centrifugal fans is no longer optional. It’s essential.

Centrifugal Fans Working Principle – How Centrifugal Fans Generate Pressure Power

Alright, let’s get technical—without losing the human touch. Centrifugal fans take in air via the center (called the “eye”) and fling it outward using rotation. That’s centrifugal force in action—hence the name. But here’s the kicker: this motion increases static pressure, meaning the fan can push air through filters, heat exchangers, and even particle-laden environments. In layman’s terms—this fan doesn’t just blow air, it forces it where it needs to go.

There are three common blade types:

- Backward-curved: Most efficient, self-cleaning, handles moderate particulate (textiles, dust).

- Forward-curved: Smooth airflow, low noise, best for clean air in HVAC.

- Radial blades: Rugged, handles heavy debris in food/wood, a bit noisy.

We emphasize backward-curved in our builds—because that’s where industrial needs meet efficiency. These wheels won’t overload as load increases, which directly contributes to reliability and motor safety. Engineers love the predictable performance curve these fans offer—when you plot CFM vs. static pressure, you know exactly how it’s going to perform.

In multiple field tests, we tracked performance stability over time. Fans stayed within ±3% of original specs after three years. Considering real environments are messy—with dust, temperature cycles, and humidity—that’s impressive. It shows that centrifugal design isn’t just theory—it’s trusted.

Why Our Centrifugal Fans? A Manufacturer’s Perspective from the Inside

We don’t just assemble fans; we engineer them with intent. Our process begins with raw materials—ASTM-grade steel for scrolls, CNC-balanced wheels, and hands-on inspection of every weld and blade angle. Each unit goes through:

- Dynamic balancing to ANSI/ISO tolerances.

- Air performance testing on benches mimicking field resistance.

- Vibration and noise verification per AMCA 300 standards.

What makes it real? Our technicians install fans at client sites—textile lines, hospital HVAC plants, semiconductor fabs. When they call back months later saying “we forgot what the old fans sounded like because these are silent” or “we just swapped bearings at 62,000 hours,” that’s solid proof of performance.

Being manufacturer-driven means we don’t just meet specs—we listen to the field. Every tweak—from lip seals to optional fire-duty housing—comes from customer feedback—and it shows.

Key Industry Standards That Validate Performance

If a fan’s specs aren’t backed by certification, it’s just marketing speaking. We rely on—and insist clients demand—these standards:

- AMCA 210: Governs airflow performance tests. We ensure each product line is lab-tested per AMCA leash.

- ISO 5801: Covers comparable airflow and power testing in benchmark duct setups.

- AMCA 300: Focuses on sound; we can confirm dB levels at distances.

- ISO 13347: Deals with vibration, ensuring machines meet thresholds for quiet factory floors.

- ISO 9001: Our internal QC procedure supports consistent build quality.

This isn’t about stacking logos—it’s about ensuring what you buy delivers what it says it does. In large deployments—like hospital HVAC or cleanroom fabrication—these certs reduce risk, verify noise levels, and simplify procurement. They also cut energy costs—and downtime—because certified performance means no guesswork.

Major Industry Applications of Centrifugal Fans in 2025

Centrifugal fans aren’t just for industrial ruins—they’re everywhere you need controlled, pressurized airflow.

HVAC & Commercial Buildings

Many modern high-rise HVAC systems use backward-curved fans for fresh air and economizer flows. In one, we installed 32 fans across chilled water and heat recovery ventilators—delivering stable 6.4” w.g. static pressure and running at 69% of estimated energy consumption thanks to VFD integration.

Textile & Garment Manufacturing

Remember that Dhaka plant? Plus three others in India using our fans—they regulate humidity, lint exhaust, and maintain colorfastness. Each site reported consistent 8000–10,000 hour uptime before first maintenance intervention.

Food Processing & Clean Environments

From sterile zones to refrigerated warehouses—centrifugal fans with sanitary housings deliver precise airflow and conform to USDA/EHEDG. We helped a meat processing plant reduce shelf temperatures 1.8°C uniformly—cutting spoilage.

Mining, Cement & Heavy Industry

In dusty, abrasive environments, radial fans with hardened steel wheels and wear-liners are critical. One cement mill saw a 47% filter cost reduction and 35% fewer motor replacements after switching to our enclosed radial units.

In each case, fans weren’t ancillary—they were mission-critical. And our installations show up in compliance documents, energy audits, and long-term maintenance reports.

Blade Types, Fan Designs & Choosing the Right Configuration

Choosing the wrong fan is a fast way to headache—or worse, downtime. We guide customers through these major choices:

| Blade Type | Characteristics | Ideal Use Case |

|---|---|---|

| Backward-Curved | Efficient, pressure planning, low noise | Industrial HVAC, drying, dust handling |

| Forward-Curved | Gentle flow, quiet, lighter weight | Office HVAC, commercial cooling |

| Radial | Rugged, debris-resistant, simple design | Mining, cement, food industry |

No one type is “best.” It’s about pairing the fan with system resistance. We use performance curves to identify the fan that meets desired CFM and static with minimal power. Then we confirm certifications. And bonus? We publish real-world comparisons showing how our backward-curved fans used 25% less energy than competitor units under similar load. That kind of transparency matters in procurement.

User Experience: Feedback from Our Global Customers

We love hearing from users:

“In our hospital ICU, these centrifugal units maintain positive pressure and ultra-low noise—patients don’t even hum a complaint.” – Facility Manager, EU Hospital

“We installed 10 radial fans at a cement site. Annual dust cleanup time dropped by three days, filter costs halved.” – Maintenance Engineer, Latin America

“Your fans run steady across 32°C heat cycles. That performance consistency is rare.” – Textile Director, Pakistan

These are field results—not labs. We receive operational data monthly and trend them. Declines in CFM or spike in amps trigger alerts—we intervene.

Real testimonials matter. They’re the foundation of trust and proof that our fans aren’t just bought—they’re relied on.

Cost Breakdown and Commercial Value in Real Numbers

Numbers matter tight:

Initial Purchase

- 36″ backward-curved fan: ~$7,800 USD

- Radial equivalent: ~$6,200

Yes, slightly more expensive—but let’s look deeper.

Energy Use (8,000 CFM at 4” w.g.)

- Our unit: 15 kW / hr

- Competitor unit: 19 kW / hr

- At $0.11/kWh, that’s ~$360/year saved per unit.

Maintenance Comparison

- Ours: 1-day scheduled bearing maintenance every 15,000 hours

- Theirs: 3+ day bearing failure squads every 8,000 hours

- Estimated savings: $14,000 annually in downtime-related costs.

Total 5-year Cost of Ownership

- Our fan: $7,800 + $20,000 energy + $6,000 maintenance = $33,800

- Competitor: $6,200 + $25,200 + $18,000 = $49,400

That’s $15,600 in total savings over 5 years—ROI realized by Year 3.

Longevity and Maintenance: What We’ve Learned After

Our experience across industries taught us:

- Balanced designs last longer—balanced to ISO-grade, you’ll see 50k–70k hours before issues.

- Pre-filters reduce wear—tenfold; integrated clean-out ports make field service easy.

- Predictive service using current monitoring and thermography prevents surprises.

In a Midwest manufacturing site, a fan showed a shift in current trend—it was pulling 6% more amps early. We serviced it pre-failure. That saved 48 hours of factory downtime and $6,400 in losses. When planning for long-term performance, reliability pays off.

Energy Efficiency and Environmental Compliance in 2025

2025 demands efficiency—and centrifugal fans fit the bill.

- Backward-curved models often achieve 70–75% efficiency—among the highest in industrial category.

- VFD integration cuts idle energy by 45–60%.

- Retrofit success we performed in a European plant cut fans’ energy use from 24 kW to 9.6 kW—annual savings: €38,000.

Beyond energy, our manufacturing bolts into regulatory and ESG goals:

- We design for low CO₂ and lifetime recyclability.

- Fan audit data supports customer compliance with EU EcoDesign and ASHRAE 90.1.

This is more than greenwash—it’s real contribution toward sustainability mandates and operational savings.

Case Study Table: Industry Examples of ROI with Centrifugal Fans

| Industry | Application | ROI Timeframe | Notes |

|---|---|---|---|

| Textile (Bangladesh) | Drying & lint control | 15 months | 41% fewer reworks, –35% energy use after installation |

| Cement (Mexico) | Dust Extraction | 9 months | Cleaner plant, 50% less filter cost, 35% fewer motor replacements |

| Hospital HVAC (EU) | Positive pressure HVAC | 18 months | Continuous HVAC; low-noise fans enhance patient comfort |

| Food Processing (USA) | Refrigerated warehouse fans | 14 months | Uniform airflow, reduced spoilage, USDA hygiene compliance |

| Chemical Plant (Asia) | Explosion-proof airflow | 11 months | Improved operational uptime; certified intrinsic safety |

These are aggregated from deployment data—with consistent follow-up measurements at 6, 12, and 24 months to validate sustained performance.

Future Trends

We’re constantly innovating:

- IoT & Cloud Integration: real-time monitoring using sensors that communicate with factory systems to preempt failures.

- High-temp scrollers: new alloys allow 300°C continuous duty—great for ceramics and sterilization environments.

- Noise-cancelling scrolls: acoustic liners embedded in housing dampen 20–1000 Hz bands, reducing dB by up to 8.

- Additive manufacturing: complex blade shapes we’ve prototyped show 3% efficiency gains vs. conventional wheels.

We’re investing in R&D to keep customers one step ahead in energy, reliability, and compliance.

What to Ask Your Supplier Before You Buy a Centrifugal Fan

Make sure your vendor can answer:

- “Do you have AMCA 210 & 300 certified test reports?”

- “What’s the performance within +/-5% after 24 months of operation?”

- “What’s your life expectancy data with continuous service?”

- “Do you offer predictive-maintenance support or sensor integration?”

- “What corrosion or abrasion protection options do you offer?”

Don’t settle for marketing fluff. Ask these—and expect answers from the field backed with data and stories.

FAQs

Q: Can a centrifugal fan run dry air?

A: Absolutely—and they perform even better under those clean conditions. Backward-curved models hit 75% efficiency in dry gas.

Q: Are they noisy?

A: Older scroll designs are loud—but with liners and blade tuning, noise drops by 6–10 dB. Our AMCA 300 results confirm this.

Q: How often to service them?

A: Inspect quarterly, service bearings every 15–20k hours, and seal integrity annually in harsh environments.

Q: Explosion-proof models—is it possible?

A: Yes—IP66 housings, spark-resistant materials, moisture seals, intrinsic safety—and documentation to match Class I/II Div 2 (ATEX Zone 2).

Q: Retrofitting axial fans to centrifugal—worth it?

A: If your system has filters, heat exchangers, or long ducts, absolutely. You’ll see improved pressure, up to 40% more airflow, and energy savings.

Conclusion

As we wrap up, let’s be candid: centrifugal fans are the backbone of industrial airflow in 2025.

They deliver pressure. They handle dirty air. They’re backed by standards and get smarter every year. As true manufacturers, we don’t just sell fans—we stand behind them with field data, maintenance logs, performance guarantees, and real customer testimonials.

If you’ve paused to ask, “Is it worth it?”—look at the ROI table, listen to the real users, and analyze lifetime costs. Because in industry, an airflow decision isn’t just technical. It’s operational continuity, energy efficiency, risk management, and regulatory compliance.

Bookmark this guide. Share it. Quote it in RFPs. Use it to vet suppliers. Use it to justify budgets. Because the centrifugal fan isn’t just a component—it’s an industrial cornerstone.