Resistive heaters use a special resistor to make heat from electricity. When electricity moves through a resistive material, tiny particles hit each other and make heat. These heaters can warm the air or send heat to things using infrared energy. You can find resistive heaters in many electric devices at home and in factories. The way these heaters work makes them dependable and simple to control.

What Are Resistive Heaters

- Resistive heaters make heat when electricity goes through special materials that do not let electricity pass easily. This process changes almost all the power into heat very well.

- There are many kinds of resistive heaters. Some are wire coil, strip, cartridge, and flexible heaters. Each type works for different heating jobs at home or in factories.

- Materials like Nichrome and Kanthal are used in resistive heating parts. These materials do not rust and can handle very high heat.

- Resistive heaters give quick and steady heat. They are easy to control and do not need much care. This makes them good for homes and factories.

- Resistive heaters work well, but they can use more electricity than heat pumps. If electricity costs a lot, using them may make your bills higher.

Resistive Heating Science

Joule Heating Principle

When you use a resistive heater, you depend on the Joule heating principle. This idea shows how electric current makes heat as it moves through a conductor. Inside the resistive material, electrons move and hit atoms. These hits make the atoms shake more, which creates heat. If you send more current, you get more heat. Scientists use a simple formula for this:

Power (P) = Current squared (I²) × Resistance (R)

This formula means the heat made depends on the current and resistance. In resistive heating, you can change the heat by changing the current or resistance. Things like electric kettles, space heaters, and light bulb filaments use this process to make heat. You get steady and direct heating because all the electric energy becomes heat.

Ohmic Heating Explained

Ohmic heating sends electric current right through the thing you want to heat. The material’s own resistance makes heat inside it. You see this in some food factories, where food heats up fast and evenly. Ohmic heating is not like old ways, which heat from the outside with a hot surface or steam.

Here’s a table to help you compare ohmic heating with traditional electrical heating:

| Feature | Ohmic Heating | Traditional Electrical Heating (e.g., Boilers) |

|---|---|---|

| Mechanism | Electric current goes through the material, making heat inside by electrical resistance (Joule heating). | Heat made outside by resistive parts or burning; heat moves to the material through exchangers. |

| Heating Speed | Fast, instant heating with no wait time. | Slower heating because heat must move through exchangers. |

| Energy Efficiency | Up to 6% more efficient; saves energy by not losing heat in exchangers. | Less efficient because of heat loss in exchangers and scaling. |

| Maintenance | Stops scaling and rust, so less fixing is needed. | Needs more cleaning and part changes because of scaling and rust. |

| Temperature Control | Exact and steady temperature control with no big changes. | Not as exact, can get too hot or heat unevenly. |

| Operational Costs | Lower energy and fixing costs. | Uses more energy and costs more to fix. |

With ohmic heating, you get quick, even heating and better temperature control. You also save energy because you do not lose heat in extra parts. This makes ohmic heating a good choice for some factories.

Electrical Resistance Heating

Electrical resistance heating is the main way most resistive heaters work. When electric current goes through a resistive element, the resistance turns all the power into heat. This process is almost 100% efficient at the device level. Here is how it works:

- You send electric current through a resistive material.

- The resistance causes electrons to hit other particles, which makes heat.

- The power you use (P = I²R) becomes heat, with almost no loss.

- The heat moves to the air or things around the heater by conduction, convection, or radiation.

- You can pick the resistance of the heating part to control the heat and power.

Because resistive heating changes almost all the electric power into heat, you get very high efficiency. For example, a resistor and a lamp with the same resistance use the same power, but the resistor turns almost all of it into heat, while the lamp loses a little as light. This is why electric resistance heating is used a lot for home and factory heating.

Note: Resistive heating is not the same as induction heating. In induction heating, you use electromagnetic fields to make heat inside the object, often without touching it. Induction heating is better for some jobs, like metal hardening or induction cooktops, because it loses less heat. But resistive heating is easier and works well for many daily uses.

Types of Resistive Heaters

Resistive heaters come in many shapes and sizes. You pick the type based on what you need to heat and how much power you want. Some heaters work better for certain jobs than others. Here are some common types you might see:

Wire and Coil Heaters

Wire and coil heaters use a special wire called nichrome to make heat. These heaters are found in homes and factories. The wire can be shaped into coils, spirals, or stars. This helps the heater fit in small spaces or wrap around pipes. Open coil heaters heat up fast but are less safe. Closed coil heaters have a cover to keep you safe. You find these heaters in ovens, water tanks, and HVAC systems. They are also used in machines that mold plastic. They heat up quickly when you change the power and last a long time.

Tip: Coil heaters bend easily and work at high heat, so they are good for many jobs.

Strip and Band Heaters

Strip heaters are flat and thin. You put them on surfaces to heat things like cabinets or molds. Band heaters wrap around barrels or pipes to give even heat. Both types use resistive parts and can get very hot. You see strip and band heaters in factories for molding plastic, making food, and chemical work. They let you control the temperature well and help keep products good by holding steady heat.

- Benefits include:

- Even heat everywhere

- Quick to react when you change power

- Simple to put in and fix

Cartridge Heaters

Cartridge heaters look like metal sticks. You put them into holes to heat things from the inside. These heaters have a wire inside, packed with insulation, and covered in metal. You find cartridge heaters in plastic molding, packaging, food machines, and even planes for de-icing. They give lots of heat in a small space and get hot fast. You can pick different sizes and power for your needs.

Flexible Heaters

Flexible heaters can bend and twist to fit odd shapes or curves. They have thin resistive parts between layers like silicone rubber or polyimide. You use flexible heaters for strange shapes or tight spaces. These heaters are used in medical tools, planes, cars, and electronics. They heat up fast, spread heat evenly, and work in tough places. Flexible heaters are light and easy to put in.

Note: Flexible heaters are great when stiff heaters will not fit or when you need fast, even heat.

Resistive Heating Elements

Common Materials

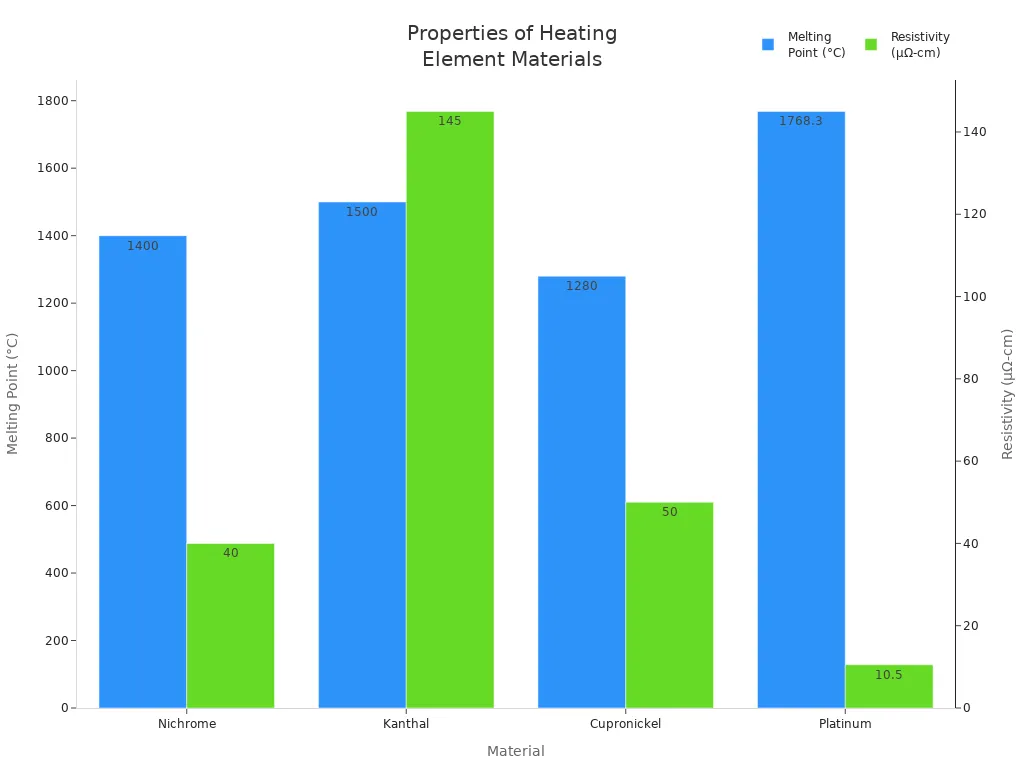

When you look at resistive heating elements, you see a few main materials. Nichrome is used the most. It has about 80% nickel and 20% chromium. This mix makes a layer that stops rust. It helps the element last longer. Kanthal is another top choice. It is made from iron, chromium, and aluminum. Kanthal works at higher heat and fights rust better than Nichrome. But Kanthal can break more easily. Cupronickel is a mix of copper and nickel. It is used for jobs that need less heat. Platinum is rare and costs a lot. You find it in special furnaces that get very hot because it can handle extreme heat.

Here is a table that lists the main materials for resistive heating elements:

| Material | Composition Highlights | Melting Point (°C) | Resistivity (µΩ-cm) |

|---|---|---|---|

| Nichrome | ~80% Nickel, 20% Chromium | 1400 | 40 |

| Kanthal | ~72% Iron, 22% Chromium, 5.8% Aluminum | 1500 | 145 |

| Cupronickel | ~75% Copper, 23% Nickel | 1280 | 50 |

| Platinum | Pure element (Pt) | 1768.3 | 10.5 |

You can see these materials have high melting points and good resistivity. This makes them great for resistive heating elements that must work safely at high heat.

Material Selection Reasons

You must pick the right material for resistive heating elements for many reasons. The main questions are: What are you heating? How hot do you need it? What power do you have? Engineers check the resistivity, melting point, and how well the material fights rust. Nichrome is strong and does not rust, so it is good for home appliances. Kanthal is better for big furnaces that need more heat and longer life.

Other things matter too:

- Some alloys last longer because they make a strong oxide layer.

- Where you use the element changes your choice. In air, you need good rust resistance. In a vacuum, you might use molybdenum or tungsten.

- Cost and how easy it is to get the material are important. Nichrome and Kanthal are common in factories because they are cheap and easy to find.

- The heater’s shape and size also matter. Flexible heaters need thin, bendy materials. Cartridge heaters need strong, thick wires.

Tip: To help your resistive heating elements last longer, keep them clean and do not let them get too hot or cold too fast. Kanthal can last up to four times longer than Nichrome in tough places.

The right material helps your resistive heating elements work better, last longer, and use less energy. If you choose well, your resistive heating system will be safer and more reliable.

Resistive Heaters Applications

Home Uses

Resistive heaters are used in many places at home. The most common one is the electric space heater. These heaters warm up rooms fast and safely. You also find them in water heaters, ovens, and stovetops. Many families use electric space heaters for extra warmth in winter. Storage tank water heaters use resistive elements to heat water for showers and cleaning.

Here are some facts about how homes use resistive heaters:

- About 36% of U.S. homes use electricity to heat their space.

- Around 46% use electricity for their main water heater.

- Nearly 57% cook with electricity, and many stoves use resistive heating.

- Storage tank heaters are the most common electric water heater.

Resistive heaters help keep you comfortable every day. They keep your home warm and your water hot. These devices give quick and steady heat. But resistive heaters can break down over time. The main problems are thermal aging, mechanical stress, and insulation breakdown. You can help your heater last longer by letting it warm up slowly and keeping it clean.

Industrial Uses

Factories and big buildings use resistive heaters for many jobs. They are used in steel and metal work to heat furnaces and treat metals. Cement, lime, and pulp factories use electric kilns for high heat jobs. Manufacturing plants use resistive heaters for drying, curing, and heat treating products. Car makers use them for engine preheating and defrosting. Food and drink companies keep products at the right temperature during processing and packaging. Hospitals use resistive heaters in medical devices and sterilizers. Chemical and drug factories control temperatures in reactors and storage tanks.

Resistive heaters help with thermal remediation in many ways. They are used in vapor extraction wells and other thermal remediation tools. Industrial resistive heaters can have power from less than 1 kW to over 100 kW. Most factories use heaters between 1 and 10 kW, but some need much more.

Here is a table showing how resistive heaters help with process control and product quality:

| Feature/Benefit | Description/Impact |

|---|---|

| Temperature Control Accuracy | Keeps heat within ±1°F for exact process control. |

| Zone Heating | Lets you set different heat levels for different parts of a product. |

| Response Time | Reaches set heat in under 30 seconds for quick changes. |

| Heat Transfer Efficiency | Up to 95% efficiency for fast, even heating. |

| Energy Consumption Reduction | Uses 20-40% less energy, saving money and resources. |

| Production Time Reduction | Cuts production time by up to 30%. |

| Durability and Reliability | Lowers maintenance needs and keeps output quality steady. |

To keep your resistive heaters working well, check them often. Make sure they have good airflow and follow cleaning tips from the maker. Regular care helps stop problems and keeps heating safe and reliable.

Advantages and Limitations

Benefits

Resistive heating has some clear good points for homes and work. These heaters change almost all the electricity they use into heat. This means you get heat right where you want it. The heater does not waste power inside itself.

Here are some main benefits of resistive heating:

- You can put in resistive heaters fast and with little trouble. You do not need to add ducts or special air systems.

- Infrared resistive heaters can lower your heating bills by 30-50% compared to old systems.

- You get steady heat and easy controls. You can pick the power level you want.

- These heaters need little care. Many have long warranties, so you save on repairs.

- You can use resistive heating in many places, from small rooms to big factories.

- There are no moving parts or tricky systems. This makes the heaters last longer.

Note: Resistive heaters are 100% efficient at the device. But some power is lost when electricity comes from the power plant to your home. This means the total energy efficiency is less than the device number.

Drawbacks

You should also know the limits of resistive heating. The heater uses all the power it gets, but making and sending electricity wastes energy. Power plants, especially those using fossil fuels, lose energy when making power. Power lines also lose some power as electricity travels far.

Here are some drawbacks to think about:

- Resistive heating uses more power than heat pumps for the same heat. Heat pumps can give two to four times more heat for each unit of power.

- If you use resistive heaters where electricity costs a lot, your bills can get high.

- Indirect resistance heating can take a long time to warm up. This can slow your work or comfort.

- Direct resistance heating only works with things that conduct electricity.

- You cannot always control the power level easily with direct resistance heating.

- Using resistive heating where electricity comes from fossil fuels can raise your carbon footprint.

| Comparison | Resistive Heating | Heat Pumps | Gas Heating |

|---|---|---|---|

| Power Use | High | Low | Medium |

| Energy Efficiency | 100% at device | 200-400% (COP) | 90-98% on-site |

| Maintenance | Low | Medium | Medium |

| Environmental Impact | High (if fossil) | Low | Medium |

Tip: To get the best from your resistive heating, do regular care, use smart controls, and pick the right heater for your space and power needs.

You now know that resistive heaters use electric current and special materials to make heat fast and safely. There are many types of these heaters, like ceramic, tubular, and immersion heaters. Each type is good for different jobs. The table below shows the main ideas:

| Aspect | Key Details |

|---|---|

| Science | Electric current heats resistive materials by electron collisions. |

| Materials | Nichrome, Kanthal, PTC ceramics, and metal sheaths for safety and durability. |

| Types | Ceramic, tubular, immersion, band, and cartridge heaters for different needs. |

| Applications | Home comfort, industrial heating, food processing, and more. |

| Advantages | Clean, efficient, fast heating, with safety features and easy control. |

When picking a heater, think about your room size, how much energy costs, and what safety you need. Resistive heaters can be a good choice for many uses.

FAQ

What is the main difference between resistive and induction heaters?

Resistive heaters use electric current to make heat in a wire or element. Induction heaters use magnetic fields to heat metal objects directly. You will find resistive heaters easier to use for most home and factory jobs.

Can you use resistive heaters outdoors?

You can use some resistive heaters outdoors if they have weatherproof covers. Always check the product label for outdoor use. Keep the heater dry and away from rain or snow for safety.

How do you make a resistive heater last longer?

Clean your heater often. Do not let dust or dirt build up. Let the heater warm up and cool down slowly. Avoid turning it on and off quickly. Follow the maker’s care tips.

Are resistive heaters safe for children and pets?

Resistive heaters can get very hot. Place them where children and pets cannot touch them. Use heaters with safety covers or tip-over switches. Always watch the heater when it is on.

Conclusion

Resistive heaters continue to be a trusted and widely used heating method in both residential and industrial settings. By converting electrical energy directly into heat through high-resistance materials, they deliver near 100% efficiency at the device level. From space heaters and water heaters in homes to cartridge, strip, and flexible heaters in manufacturing, resistive heaters offer fast response, precise control, simple design, and low maintenance.

While modern systems like heat pumps may offer better overall energy efficiency, resistive heaters stand out for their ease of installation, consistent performance, and immediate heat delivery. These features make them especially valuable where fast, localized heating is needed without complex infrastructure.

To get the best results, users should select the right heater type and material based on their application, environment, and power availability. When properly maintained and paired with smart controls, resistive heaters offer a safe, efficient, and cost-effective solution for a wide range of heating needs.