A marshalling cabinet acts as the central hub for organizing field wiring in industrial automation. It connects sensors, transmitters, and other field devices to the control system, making the wiring process much simpler. The main purpose of a marshalling cabinet is to provide a safe and organized space for managing all these connections. Here’s why plants rely on them:

| Benefit | Description |

|---|---|

| Organized Wiring | They organize and protect field wiring, which boosts system reliability. |

| Faster Installation | They reduce installation time by centralizing connections. |

| Enhanced Safety | They enhance safety by securing electrical connections. |

| Easier Maintenance | They simplify maintenance with easier access to wires and parts. |

| Protection from Damage | They protect wiring and control components from damage, improving reliability. |

When someone asks, “What is Marshalling Cabinet?”, they’re really asking how to make industrial automation systems safer, easier to maintain, and more reliable.

Key Takeaways

- A marshalling cabinet organizes and protects wiring between field devices and control systems, making complex automation easier to manage.

- It improves safety by isolating electrical signals and including protective devices like fuses and surge protectors.

- The cabinet simplifies maintenance with clear labeling, easy access, and flexible wiring options that support future upgrades.

- Marshalling cabinets reduce installation time and costs by centralizing connections and preventing wiring errors.

- Choosing the right type of marshalling cabinet helps meet specific industrial needs, enhancing system reliability and safety.

What is Marshalling Cabinet

Definition

When someone asks, “what is marshalling cabinet,” they want to know about a key piece of equipment in any industrial process control system. A marshalling cabinet, sometimes called a marshalling panel, acts as a central point where all the wiring from field devices—like sensors, transmitters, and actuators—comes together. This cabinet sits between the field junction boxes and the main control system, such as a DCS (Distributed Control System) or PLC (Programmable Logic Controller).

The marshalling cabinet does more than just collect wires. It organizes, protects, and manages every signal that travels between the field and the control room. Inside, you’ll find terminal blocks, surge protection devices, power distribution units, and sometimes even signal conditioning modules. These components help group and route signals, making the system easier to maintain and troubleshoot.

Note: Industry standards, like those from ISA and IEC, guide the installation and wiring of marshalling cabinets. These standards ensure that every wire is labeled, sized, and terminated correctly, which keeps the system safe and easy to manage.

A marshalling cabinet also separates different types of signals—such as analog input, analog output, digital input, and digital output—onto dedicated boards. This separation prevents confusion and reduces the risk of wiring errors. In large plants, this organization becomes critical for keeping the industrial process control system running smoothly.

Interface Role

The marshalling cabinet plays a vital role as the interface between field devices and the control system. Think of it as a translator and traffic controller for electrical signals. Here’s how it works in a typical automation setup:

- Field devices send signals to local junction boxes.

- These signals travel through multi-core cables to the marshalling cabinet.

- The marshalling cabinet receives, organizes, and sometimes conditions these signals.

- It then routes the signals to the correct I/O cards in the control system cabinet.

This process ensures that every signal from the field reaches the right spot in the control system. The marshalling panel also allows for cross-wiring, which means technicians can match field wires to the correct I/O channels, even if the numbers don’t line up perfectly. This flexibility helps avoid the classic “rat’s nest” of tangled wires and makes future changes much easier.

Here’s a quick comparison to show how a marshalling cabinet differs from a simple junction box:

| Functionality Aspect | Marshalling Cabinet | Junction Box |

|---|---|---|

| Role | Routes and organizes signals between field devices and control systems, ensuring correct I/O assignment. | Collects and consolidates field device wiring for cable management. |

| Signal Management | Supports cross-wiring, signal conditioning, and proper allocation to I/O modules. | Provides direct connections without internal signal redirection. |

| Components | Includes terminal blocks, IS barriers, surge protection, power distribution, and cross-wiring terminals. | Contains basic terminal blocks for wire termination only. |

| Complexity | More complex, handling multiple I/O types and system integration needs. | Simpler, mainly a wiring consolidation point. |

| Application | Suitable for large industrial plants requiring structured signal routing. | Suitable for smaller setups with basic wiring needs. |

A marshalling cabinet in an industrial process control system also improves safety and reliability. It isolates the control system from field wiring, which protects sensitive electronics from electrical faults or surges. The cabinet often includes diagnostic features, like LED indicators, that help technicians spot problems quickly.

Marshalling panels make it possible to adapt to changes in the plant without major rewiring. For example, if a new sensor needs to connect to the control system, technicians can add it to the marshalling cabinet and cross-wire it to the right I/O channel. This flexibility saves time and reduces the risk of mistakes.

Purpose of Marshalling Cabinets

Signal Organization

The main purpose of a marshalling cabinet centers on organizing the many i/o signals that come from field devices. In a busy industrial plant, hundreds or even thousands of wires arrive from sensors, switches, and transmitters. Without improved organization, these wires could quickly become tangled and confusing. A marshalling cabinet brings order to this chaos by grouping i/o signals and routing them to the right place in the control system.

Manufacturers use different methods to make this process easier. Some, like Emerson, use hardware modules called Charms. Each Charm connects to a field device and sends data over Ethernet, so technicians can route signals without moving wires. Others, such as Honeywell and Foxboro, use software-configurable modules. These let users set up any channel for any type of signal—analog, digital, or even HART—right from a computer. This flexibility means the cabinet can handle changes or upgrades without a lot of rewiring.

Phoenix Contact takes a hardware approach with compact terminal blocks. These blocks mount on rails inside the cabinet and keep wires neat and easy to find. They also include test points, so technicians can check signals quickly. This setup saves space and makes future maintenance much simpler.

When a plant uses advanced terminal blocks with push-in connections, wiring becomes faster and more reliable. Color-coded and multi-tier blocks help prevent mistakes and make troubleshooting easier. These features lead to improved organization, which is one of the key applications of a marshalling cabinet.

Organized wiring does more than just look tidy. It helps the control system run smoothly, reduces errors, and makes it easier to add new devices later. By keeping everything labeled and grouped, the marshalling cabinet supports efficient maintenance and future expansion.

System Protection

A marshalling cabinet does more than organize signals; it also protects the automation system. Industrial environments can be harsh, with dust, moisture, and even the risk of explosions. The cabinet’s durable enclosure shields sensitive electronics from these dangers. This protection is another one of the key applications of a marshalling cabinet.

Inside the cabinet, fuses and circuit breakers guard against electrical overloads. Signal isolators and conditioners prevent interference and boost weak signals, making sure the control system receives accurate data. Some cabinets even have mounts that protect against earthquakes or heavy vibrations.

- Cabinets use wiring ducts to keep cables safe from physical damage.

- Explosion-resistant designs keep workers and equipment safe in hazardous areas.

- Proper grounding and termination of spare wires prevent shocks and sparks.

- Modular enclosures with partitions separate high-voltage and low-voltage sections, reducing the risk of electrical faults.

Marshalling cabinets also help with enhanced safety by supporting lock-out-tag-out procedures. This means workers can safely disconnect power before doing maintenance. The cabinet’s design follows strict industry standards, which ensures safety and reliability for everyone on site.

By acting as a barrier between field wiring and the control system, the marshalling cabinet helps prevent electrical faults. It keeps high and low voltage equipment apart, isolates faults, and makes sure only trained personnel can access energized parts. This level of protection is essential for any automation project.

In summary, the purpose of marshalling cabinets is to provide both organization and protection. They keep signals clear and safe, which helps the entire automation system work better and last longer.

Functions

A marshalling cabinet performs several important functions in industrial automation. These functions help organize, protect, and manage the flow of i/o signals between field devices and the control system. Let’s look at each main function and see how it supports simplified maintenance and system reliability.

Signal Termination

Signal termination is the first step in the grouping of i/o. The marshalling cabinet sorts incoming signals by type, such as analog or digital, and connects them to the right terminal blocks. The process usually follows these steps:

- Sort field signals by type at the marshalling level.

- Process signals through an interface level.

- Wire signals from the interface to specific input/output cards on the control system.

- Use Termination Carriers for quick, error-free connections.

- Take advantage of plug-and-play wiring for compact and reliable terminations.

This method keeps wiring neat and organized. Proper signal termination also uses Field Termination Assemblies to make sure each signal is easy to find and maintain. When signals are terminated correctly, the system runs more reliably and technicians can spot problems faster.

Tip: Regular checks for loose wires and damaged cables help prevent faults and keep the control system running smoothly.

Cross-Wiring

The cross wiring function is what makes the marshalling cabinet so flexible. Field cables often carry more signals than a single I/O card can handle. Cross-wiring splits and routes these signals to the right cards. For example, a cable with 20 signals might need to connect to two different cards. The marshalling cabinet handles this by matching each signal to its correct spot.

Cross-wiring also separates mixed signal types, like analog and digital, onto dedicated boards. This makes troubleshooting much easier. If a problem comes up, technicians can quickly trace the signal path. The cross wiring function also allows for changes in the system without major rewiring, which supports simplified maintenance and flexible upgrades.

Isolation

Isolation is another key function of the marshalling cabinet. It protects sensitive equipment from electrical surges, noise, and faults. The cabinet uses barriers and isolators to keep dangerous voltages away from the control system. Surge Protection Devices inside the cabinet shield digital and control circuits from spikes caused by lightning or faults.

Marshalling cabinets also use special grounding techniques. Instrument Earth bars are kept separate from Safety Earth bars to prevent electrical noise. This setup keeps signals clean and protects both equipment and people. By providing strong isolation, the marshalling cabinet boosts safety and helps the automation system last longer.

Note: Isolation not only protects devices but also makes it safer for technicians to work on the system during maintenance.

The functions of a marshalling cabinet—signal termination, cross-wiring, and isolation—work together to organize signals, protect equipment, and make maintenance easier. These features help keep industrial automation systems safe, reliable, and easy to manage.

Operation

Signal Flow

The working principle of a marshalling cabinet starts with the field devices. These devices, like sensors and transmitters, send signals through branch cables to field junction boxes. The signals from several junction boxes then travel together in a larger cable called the incoming field cable. This cable brings all the signals to the marshalling cabinet.

Here’s how the signal flow works step by step:

- Field transmitters connect to field junction boxes using branch cables.

- Signals from many junction boxes combine into multi-conductor main cables.

- The main cables, also known as homerun cables, terminate at the marshalling cabinet.

- Inside the marshalling cabinet, signals are sorted and routed to the right places.

- The cabinet sends each signal to the correct analog input or output card in the control system.

- Analog input cards change the 4-20mA signals from the field into digital codes.

- The processor card reads these digital signals and runs the programmed instructions.

- The processed data travels to the workstation, often over Ethernet, for display and monitoring.

This organized flow helps achieve reduced installation time and makes troubleshooting much easier. The working principle of a marshalling cabinet ensures that every signal reaches its destination without confusion or error.

A well-designed marshalling cabinet keeps the signal flow clear and reliable, which is vital for any automation project.

Maintenance

Maintenance of a marshalling cabinet is straightforward when the wiring stays organized. Technicians can quickly find and test any connection because each wire is labeled and grouped by type. This setup means less time spent searching for problems and more time fixing them.

Routine checks help spot loose wires or damaged cables before they cause trouble. Many cabinets include test points and LED indicators, so technicians can see if a signal is present or if a fuse has blown. These features make it easy to keep the system running smoothly.

When changes happen in the plant, such as adding a new sensor, the marshalling cabinet allows for quick updates. Technicians can connect the new device to the cabinet and route its signal to the right spot in the control system. This flexibility supports safe and efficient maintenance.

Regular maintenance not only keeps the system reliable but also extends the life of the equipment.

Marshalling Cabinets Components and Types

Main Components

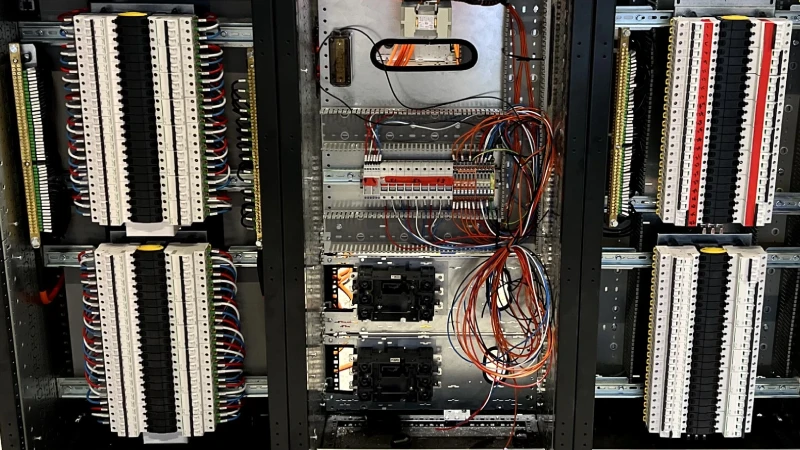

Every marshalling cabinet comes packed with important parts that keep automation systems running smoothly. When someone looks inside, they will see the major components of a marshalling cabinet arranged in a neat and logical way. Here are some of the most common items found inside:

- Terminal blocks for connecting and organizing wires

- Field Terminal Assemblies (FTA) that link field wiring to the control system

- Power distribution units for both AC and DC supplies

- Signal conditioners that turn raw sensor signals into usable data

- Protective devices like fuses, circuit breakers, and MCBs to guard against electrical faults

- Grounding and earthing strips to keep everything safe

- Fans and thermostats for temperature control

- Alarm wiring for monitoring cabinet conditions

- Utility power sockets and color-coded internal wiring for easy identification

- Name plates that show cabinet identification and specifications

These major components of a marshalling cabinet work together to support both instrumentation and control system needs. They help organize signals, protect equipment, and make sure everything runs safely.

Tip: Good labeling and color coding inside the cabinet make maintenance much easier for technicians.

Types

Different industries need different solutions, so there are several types of marshalling cabinets available. Each type fits a specific need, from basic wiring to advanced safety or space-saving designs. The table below shows how each type matches up with its main use:

| Type of Marshalling Cabinet | Industrial Automation Need Catered To |

|---|---|

| General Purpose | Broad applications with basic components for connecting and organizing field instrumentation signals. |

| Intrinsically Safe | Hazardous locations requiring isolation and limitation of electrical energy to prevent ignition of flammable materials. |

| Seismic | Areas prone to earthquakes, with seismic isolation mounts to protect cabinet and contents during seismic events. |

| Explosion-Proof (Ex-proof) | Explosive environments like oil and gas facilities, preventing explosions inside the cabinet. |

| Compact | Space-limited areas such as offshore platforms or mobile equipment, emphasizing small size and lightweight design. |

| Modular | Applications needing expansion and customization over time, with easily addable/removable components. |

| Remote | Remote or difficult-to-access locations, featuring remote monitoring, control, and environmental protection. |

| Intelligent | Integration of advanced electronics and communication interfaces for enhanced control, monitoring, and diagnostics. |

General purpose marshalling cabinets work well for most plants. Intrinsically safe marshalling cabinets are a must in places where flammable gases or dust could be a problem. The types of marshalling cabinets keep growing as technology advances, so there is always a solution for every automation challenge.

Note: Choosing the right type of marshalling cabinet can improve safety, save space, and make future upgrades easier.

Benefits and Disadvantages

Advantages

Marshalling cabinets bring several advantages to automation projects, especially in large-scale plants. They help organize complex wiring, making it easier for technicians to manage and maintain the system. Many companies have seen big cost savings by using these cabinets. For example:

- Southern States cut construction and wiring costs by 40% compared to older methods. They could also make late changes without going over budget.

- Kuwait Oil Company reduced the size of their cabinets and cross-wiring, which saved both money and time. This setup also made it easier to expand in the future.

- Seplat Petroleum swapped out hundreds of cables for just a few fiber optic lines, saving $1.4 million and lowering project risks.

- Samsung Biologics and Mahou-San Miguel both shortened project schedules and reduced labor by standardizing their wiring and using smarter cabinet designs.

These advantages show that marshalling cabinets can lower installation costs, speed up commissioning, and support future upgrades. They also help keep wiring neat, which makes troubleshooting and maintenance much simpler. Many plants choose marshalling cabinets for their flexibility and ability to handle changes without major rewiring.

Tip: Organized wiring not only saves money but also helps prevent mistakes during installation and maintenance.

Drawbacks

Despite their many advantages, marshalling cabinets do have some disadvantages. Traditional designs often require each cabinet to be custom-built, which can lead to hundreds of unique cabinets in a single facility. When engineers need to add or change a device, they might have to update many drawings and make changes across several cabinets. This process can slow down projects and increase costs.

Some common disadvantages include:

- Complex wiring methods that make installation and changes harder.

- Extra cabinet space needed, which takes up valuable room in control areas.

- Higher costs for installation, maintenance, and documentation.

- Delays caused by late changes or the need to rewire for new devices.

Here’s a quick comparison between traditional marshalling cabinets and newer remote I/O solutions:

| Aspect | Marshalling Cabinets (Traditional) | Remote I/O with Universal Channel Technology |

|---|---|---|

| Wiring Complexity | Complex, often needs rewiring for changes | Simple, modules near field devices, less wiring |

| Cabinet Space & Footprint | Needs more space in control rooms | Smaller footprint, fewer cabinets |

| Installation & Maintenance | Higher costs and more labor | Lower costs, easier changes |

| Flexibility & Adaptability | Hard to adapt to late changes | Easy software-based updates |

| Project Schedule & Risk | Delays from late changes and shipping risks | Faster schedules, less risk |

| Lifecycle Benefits | More space needed, harder to upgrade | Better use of space, easier migrations |

| Cost | Higher initial and ongoing costs | Up to 33% savings on installation |

Many companies now look for alternatives that offer the same advantages but with fewer disadvantages. Newer technologies help reduce wiring, save space, and make future changes much easier.

A marshalling cabinet stands out as the backbone of organized automation. It streamlines connections between field devices and control systems, making complex wiring much easier to manage. By consolidating signals and following strict industry standards like UL 508A, it boosts safety and keeps systems reliable in industries such as oil and gas or water treatment. Plants choose marshalling cabinets when they need:

- Efficient signal management

- Enhanced safety and compliance

- Reliable performance in demanding environments

For any project with lots of field wiring, a marshalling cabinet helps keep everything running smoothly and safely.

FAQ

What is the main difference between a marshalling cabinet and a control panel?

A marshalling cabinet organizes and routes field wiring. A control panel houses the main control equipment, like PLCs or DCS. The marshalling cabinet acts as the middleman, while the control panel does the actual controlling.

Can marshalling cabinets handle both analog and digital signals?

Yes, marshalling cabinets can manage both analog and digital signals. They separate and organize each type on dedicated terminal blocks. This setup helps technicians find and troubleshoot signals quickly.

Why do large plants need marshalling cabinets?

Large plants use marshalling cabinets to keep wiring organized and safe. With hundreds of devices, things can get messy fast. Marshalling cabinets make maintenance easier and help prevent wiring mistakes.

How often should technicians inspect a marshalling cabinet?

Technicians should check marshalling cabinets during regular maintenance cycles, usually every 6 to 12 months. They look for loose wires, damaged cables, and signs of overheating.

Are there any safety features inside a marshalling cabinet?

Marshalling cabinets include safety features like fuses, circuit breakers, and grounding strips. Some even have surge protectors and isolators. These features protect both equipment and people from electrical hazards.