Choosing the right electrical control panel keeps things safe and working well. The table below shows the most common types and what they are used for:

| Electrical Control Panel Type | Description | Primary Applications |

|---|---|---|

| Power Control Center (PCC Panel) | Holds switchgear, breakers, and busbars to control power. | Used for power distribution in factories and big buildings. |

| Motor Control Center (MCC Panel) | Controls many motors with safety devices and starters. | Runs motors in factories and processing plants. |

| Automation Panel (SCADA PLC Panel) | Uses PLCs to help with automation and monitoring. | Controls automated processes in many industries. |

| Intelligent MCC Panel | Gives advanced motor control with real-time monitoring. | Used for flexible, low voltage motor control. |

Picking the right panel stops dangers and helps things work better. Important things to think about are what the panel does, if it meets rules, and if it is checked often. Choosing the right Types of Control Panel in Electrical keeps people safe, stops long breaks, and saves money.

Key Takeaways

- Different electrical control panels do special jobs. Some help with power distribution. Some control motors. Others help with automation.

- Picking the right panel makes things safer. It also saves energy. It helps systems work well.

- Panels need to follow safety rules. They must be put in the right way. This keeps people and equipment safe.

- Checking and fixing panels often stops problems. It also helps panels last longer.

- Custom panels are made for special needs. They are good for dangerous or tricky places.

Electrical Control Panel Basics

What Is an Electrical Control Panel

An electrical control panel is the main place for handling electricity in a building. It sends power to different circuits and keeps things safe by controlling how electricity moves. The panel stops wires and equipment from getting too much power or breaking. Inside, there is a controller that watches the system and changes power when needed. Many new panels have special features like real-time checks and automatic shut-off. These features make things safer and help everything work better. The controller helps workers keep control over hard jobs, so the system is easy to use and works well.

Note: An electrical control panel does more than send out power. It also keeps people and equipment safe by finding problems and turning off circuits if needed.

Key Components

Each electrical control panel has important parts that work together for safety and good performance. The controller is like the brain. It takes in information and tells other parts what to do. Here are the main parts you will find in most panels:

- Main circuit breaker: Turns off the system if there is a problem and controls the main power.

- Surge arrester: Protects the panel from sudden high voltage.

- Branch circuit breaker: Stops each circuit from getting too much power.

- Transformer or power supply: Lowers voltage for control devices.

- Terminal blocks: Keep power organized and safe.

- Programmable logic controller (PLC): Runs and controls factory processes.

- Relays and contactors: Turn power on or off for devices and motors.

- Network switch: Helps the controller talk to other equipment.

- Human-machine interface (HMI): Lets workers see and control the system.

- Push buttons and pilot lights: Give manual control and show system status.

| Component | Essential Function |

|---|---|

| Main Circuit Breaker | Stops too much power and short circuits; lets you turn off the system for safety or repairs. |

| Surge Arrestors | Send extra current to the ground to protect from high voltage. |

| Transformers | Change voltage levels so equipment can work safely. |

| Relays | Open or close circuits to help with automation and keep things separate. |

| Programmable Logic Controller (PLC) | Runs hard tasks and controls how things work. |

| Human Machine Interface (HMI) | Gives a screen for workers to use and control the system. |

| Terminal Blocks | Hold and organize wires to keep things working well. |

New electrical control panels use smart technology like AI to find problems fast. They also use IoT to watch the system and smart breakers to keep things safe. These tools help the controller spot trouble early, stop long breaks, and make things safer. Good panels are built carefully and tested to meet world rules, so they last a long time and protect well.

Types of Electrical Control Panels

Power Control Center (PCC) Panels

A power control center is the main spot for sending out electricity in big places. This kind of electrical control panel holds switchgear, circuit breakers, and busbars. The controller inside helps move power safely and keeps things working well. You will see PCC panels in factories, big office buildings, and power plants.

Key safety standards for these panels are:

- IEC 61439-1 & 2

- IS 8623

- UL 508A

- IEEE C37.20.1

- CE Marking

- CSA Certification

- CPRI Certification

PCC panels need special certification for short circuit ratings, like 65kA/1 second. They also need protection levels from IP42 to IP55. These certifications show the panel meets safety rules and works well.

Tip: Make sure there is enough space, good cable management, clear labels, and correct grounding for PCC panels to work right.

Main applications:

- Power for factories

- Big office buildings

- Utility substations

Motor Control Center (MCC) Panels

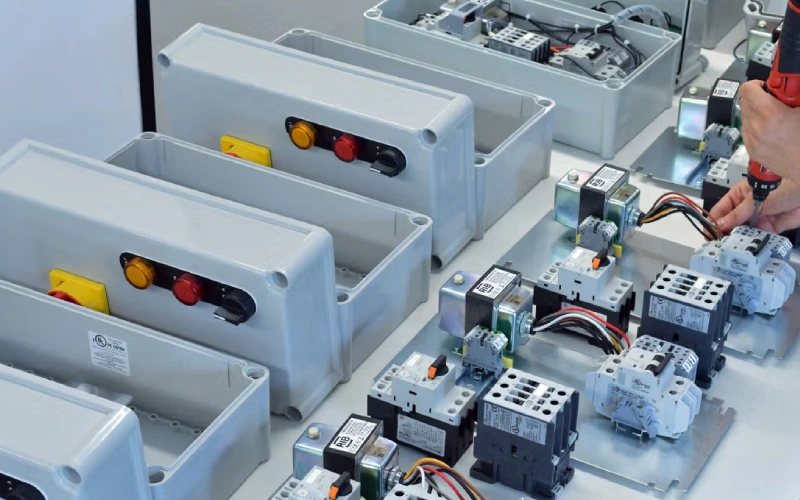

Motor control centers help control many motors in one place. They are important in factories and places where things are made. Each MCC panel has starters, overload relays, and a controller to run the motors. This setup makes fixing things easier and helps everything work better.

Benefits of MCC panels:

- Easy to use and fix

- Safer by lowering electrical dangers

- Saves energy with variable frequency drives (VFDs)

- Finds problems fast, so less downtime

- Can be made bigger later

| Industry Sector | Common Uses of MCC Panels | Reasons for Use |

|---|---|---|

| Manufacturing Plants | Runs conveyor belts, robots, and lines | Makes motors work better, keeps things safe, stops failures |

| Oil & Gas Facilities | Runs pumps, compressors, and drills | Keeps things safe, controls motors in one place, less downtime |

| Food Processing Units | Runs mixers, grinders, and coolers | Saves energy, keeps things safe |

| Pharmaceutical Production | Runs machines for making medicine | Helps with automation, keeps things working right |

| Large Buildings & Malls | Runs lights, HVAC, and escalators | Controls many systems, makes fixing things easier |

| Data Centers | Keeps power for servers and cooling | Makes systems work better, helps important equipment |

| Hospitals & Healthcare | Runs emergency power, air, and medical tools | Very important for safety, keeps things running |

| Power Plants & Utilities | Runs substations, transformers, and green energy systems | Controls motors well, helps with automation, saves energy |

MCC panels are very important for motor controller jobs, especially where automation is needed.

Automation, PLC, and SCADA Panels

Automation panels, like PLC control panels and SCADA systems, help run modern factories. A PLC control panel uses a programmable logic controller to make quick choices using sensor data. The controller runs devices and keeps track of simple data.

SCADA panels do more. They collect data from PLCs and other devices, look at the data, and show it to workers on screens. This helps people watch, report, and make things work better.

Main applications:

- Automated factory lines

- Water cleaning plants

- Building control systems

- Energy management

Automation panels help things run smoother and make work easier in many places.

Main Breaker and Main Lug Panels

Main breaker panels and main lug panels are two types of electrical panels used in homes, offices, and factories.

Main breaker panel:

- Has a main breaker to stop too much power

- Lets you turn off all power for safety

- Is the main panel in most buildings

Main lug panel:

- Does not have a main breaker inside

- Needs another breaker before it for safety

- Used as a subpanel or extra power spot

Note: Main breaker panels are easier for meeting rules that need a main shut-off. Main lug panels are smaller and cheaper but need another shut-off.

Typical applications:

- Main breaker panels: Main power for homes, offices, and factories

- Main lug panels: Extra panels in big buildings or for special systems

Sub-Panels and Transfer Switch Panels

Sub-panels and transfer switch panels help share power and keep things running.

| Panel Type | Common Scenarios of Use | Main Benefits |

|---|---|---|

| Sub-Panels | Home add-ons, parts of stores, far-away work areas | Shares power well, gives local control, easy to add more |

| Transfer Switch Panels | Homes with lots of outages, hospitals, important places | Keeps power on, safe, switches power during outages |

Sub-panels help share power and let you control things close by. Transfer switch panels switch between normal and backup power, so things keep working and stay safe.

VFD, APFC, and AMF Panels

VFD, APFC, and AMF panels help save energy and keep power good.

VFD panels use a controller to change how fast motors go. This saves power and helps things work better. APFC panels make power use better and cut down on wasted energy. AMF panels switch to backup power when the main power goes out, so things keep running.

Main applications:

- Heating and cooling systems

- Pump stations

- Factory automation

- Saving energy in big buildings

These electrical control panels help things work well and keep power strong in tough places.

Virtual and Remote Panels

Virtual and remote panels are new and use digital screens instead of real panels. These panels let people watch and control systems from anywhere using the internet.

Advantages:

- Saves money and needs less equipment

- Can be used from anywhere

- Shows what is happening right now

Limitations:

- Needs good internet and tech to work

- Less face-to-face checking

Virtual panels are good when you need to control things from far away or want to save money. Real panels are still needed for hands-on work and safety.

Custom and Special Purpose Panels

Custom control panels are made for special jobs that normal panels cannot do. These panels might have special controllers, ways to talk to other machines, or tough cases for hard places.

| Panel Type | Examples / Applications | Unique Requirements Addressed |

|---|---|---|

| Lighting Control Panels | Stadiums, airports, big storage places | Timers, smart controls, built for inside or outside |

| Test Panels | Motor tests, training, software checks | Many power sources, strong cases, HMI, digital and analog controls |

| Conveyor Panels | Car making, mining, mail sorting | PLC, HMI, VFD drives, cameras, barcode readers |

| Food & Beverage Panels | Controls for liquids, powders, and gases | Batch programs, HMI screens |

| SCADA Panels | Data collection for servers | Rack mount, backup power, network switches, fixing tools |

| Custom Control Panels | Explosion proof, NEMA cases | Tough for the environment, special certificates, custom looks |

| Wastewater Removal Panels | Pumps and checks for farms, water plants | Remote checks, warning systems, solar power options |

Custom control panels are used in dangerous places, small spaces, and places with strict rules. They help with temperature control, motor control, and work with other automation systems.

Types of Control Panel in Electrical Applications

Industrial Uses

Industrial control panels are very important in factories and plants. They help run machines and keep workers safe. The main types are Motor Control Centers, PLC panels, and Variable Frequency Drive panels. Motor Control Centers can run many motors at the same time. PLC panels help machines work by themselves and watch equipment. Variable Frequency Drive panels save energy by changing how fast motors go. Custom panels mix different tools for special jobs.

| Control Panel Type | Main Function | Typical Industrial Applications |

|---|---|---|

| MCCs | Central motor control | Making things, food factories |

| PLC Panels | Automation and process control | Biotech, energy plants |

| VFD Panels | Motor speed and energy management | HVAC, water cleaning |

| Custom Panels | Special safety and integration | Old machines, unique jobs |

Industrial panels are not the same as commercial ones. They use higher voltage and have more safety rules. These panels must follow standards like UL 508A and NEMA.

Commercial and Building Uses

Commercial control panels help with lights, air, and safety in buildings. The main types are main breaker panels, sub-panels, and HMI panels. These panels use less voltage than industrial ones. They focus on comfort and safety in buildings. Commercial panels use simple automation and fewer safety parts.

- Main breaker panels: Give power to the whole building.

- Sub-panels: Send power to certain areas or systems.

- HMI panels: Let workers watch and control building systems.

Commercial panels must follow local rules and be easy to fix. They do not need advanced automation or strong protection like industrial panels.

Infrastructure and Utilities

Infrastructure and utility panels must be strong and easy to grow. The main types are distributed I/O systems, custom panels, and Variable Frequency Drive panels. These panels control power for water plants and transport. They handle big loads and let people watch from far away.

Tip: Distributed I/O panels use less wire and work better in big places.

Infrastructure panels mix automation, safety, and watching to keep things running well.

Hazardous and Specialized Environments

Hazardous panels keep people and equipment safe in dangerous places. The main types are explosion-proof panels and panels with special covers. These panels use strong materials to stop sparks and fires.

| Hazardous Zone | Panel Needs | Example Uses |

|---|---|---|

| Zone 0 | Safe design, far from people | Oil plants, chemical plants |

| Zone 1 | Strong covers, air systems | Grain, medicine factories |

| Zone 2 | Standard strong covers | Paint shops, storage |

Special panels use steel or fiberglass to stop rust. They may have heaters or coolers for hot or cold places. These panels must meet tough safety and strength rules.

Choosing the Right Panel

Assessing Needs

Picking the right electrical control panel means knowing what you need. Engineers look at a few things. They figure out how much power is needed. They check if voltage needs to change and if circuits need protection. The enclosure must be the right size and type. It should protect against water or chemicals. The control parts should match how hard the job is. Some jobs need simple relays. Others need advanced PLCs. Operator interfaces are important too. These can be pushbuttons, lights, or HMIs. Engineers also think about the total cost. This includes putting it in, fixing it, and any time it might stop working.

Tip: Tell the supplier what you need clearly. This helps avoid mistakes that cost money.

Safety and Standards

Safety is very important when picking a panel. Panels must follow rules to keep people safe and follow the law. The table below shows some important standards:

| Standard | Description |

|---|---|

| IEC 60439-1 | Tells how to design and test low-voltage switchgear and control gear. |

| UL 508A | U.S. safety rule for industrial control panels. |

| CSA C22.2 No. 14 | Canadian safety rule for industrial control panels. |

| NFPA 79 | U.S. rule for electrical equipment in machines. |

| IEC 61508 | World rule for safe control systems. |

Panels with good safety parts, like circuit breakers and surge protectors, help stop dangers. They also make the system work better.

Installation and Environment

Where you put the panel matters a lot. The place changes what kind of enclosure you need. Electronics need to be safe from dust, water, and heat or cold. If the panel is inside, a simple box may be enough. If it is outside or in a tough place, it needs a stronger box. NEMA Type 4 or 4X enclosures are good for these places. Dangerous areas need explosion-proof boxes. Putting the panel in right and sealing it keeps it safe. Keeping the inside cool or warm helps the panel work well.

Maintenance and Upgrades

Checking panels often keeps them working longer. Good habits include regular checks and watching the temperature. Labeling all the parts makes fixing things easier. Use good wires and make sure they are tight. Write down all the work done on the panel. Upgrading panels helps with new needs. You may need an upgrade if there are many overloads, more power is needed, or safety parts are old. An expert should check the panel to make sure it follows new rules and works with new tech.

Picking the right Types of Control Panel in Electrical keeps people safe and helps things work well. Each panel has its own job, like sending out power or helping machines run by themselves. You need to think about what your project needs, where the panel will go, and what rules you must follow. Experts say panels should be easy to use, simple to fix, and tested before use. For hard projects, check rules like IEC 61439, UL 60947-4-1, and NEC Article 409. Always read the instructions and ask an expert if you are not sure. If you have questions, look at the FAQ section for helpful answers.

FAQ

What is the main difference between PCC and MCC panels?

PCC panels send power to big areas. MCC panels help run and protect many motors. PCC panels care about power moving safely. MCC panels care about motors working right and staying safe.

How often should electrical control panels get inspected?

Experts say to check panels every six months. Regular checks help find loose wires, dust, or hot spots. Finding problems early stops failures and keeps things safe.

Can one panel type work for all applications?

No one panel works for everything. Each type of control panel in electrical systems has its own job. Picking the right panel depends on what you need, how much power, and safety rules.

What standards must electrical control panels meet?

Panels must follow rules like IEC 61439, UL 508A, and NFPA 79. These rules help keep people safe and make sure panels work well and follow the law.

Are custom panels necessary for hazardous environments?

Yes. Dangerous places need custom panels with special covers. These panels stop sparks and help prevent fires or explosions. Always use certified panels in risky places.

Conclusion

Picking the right Types of Control Panel in Electrical keeps people safe and things working well. Each panel type does a special job, like sending out power or helping machines run. Checking panels often and following rules keeps systems working right. For hard jobs, ask experts for help. Knowing these basics helps people choose well and keep things safe.