Rotary cam switches give you reliable, precise control over machinery in industrial electrical systems. You use rotary cam switches to help keep your equipment running smoothly and safely. These devices prevent accidents by stopping uncontrolled movement, overtravel, and failure of emergency shutdowns.

- Uncontrolled movement can damage machines.

- Overtravel may injure operators.

- Emergency shutdown failures can escalate hazards.

If you want to ensure operational continuity and safety, rotary cam switches are essential. For proven quality and support, you can count on Linkwell, a trusted name in industrial electrical components. This guide to rotary cam switches will help you understand their importance in your operations.

Key Takeaways

- Rotary cam switches provide precise, reliable control for industrial machines, improving safety and preventing damage.

- These switches come in many types and positions, allowing you to customize control for different circuits and functions.

- Choose rotary cam switches with the right current, voltage, and material ratings to ensure long-lasting performance.

- Regular inspection and proper installation keep rotary cam switches safe and extend their service life.

- Linkwell offers high-quality rotary cam switches with expert support, helping you find the best solution for your needs.

Rotary Cam Switches Overview

What is a Cam Rotary Switch

When you step into an industrial control room, you often see rotary cam switches on panels and machines. These switches stand out because they offer more than just simple on-off control. Rotary cam switches give you the power to manage complex circuits with a single turn. You can find them in many forms, such as a 3 phase rotary cam switch, 3 position rotary cam switch, 4 position rotary cam switch, or even an 8 position rotary cam switch. Each type lets you select different functions or operations.

Here’s what makes rotary cam switches unique:

- Multi-pole and multi-position configurations let you control several circuits at once.

- You can choose from a wide range of positions, from 2 up to 12, which is more than most toggle or rocker switches.

- Rotary cam switches use different contact materials to handle various current and resistance needs.

- They come in several mounting styles, like panel mounting or PCB mounting, so you can fit them almost anywhere.

- These switches handle a broad range of current ratings, including rotary cam switch 25a models for heavy-duty jobs.

- Built for durability, rotary cam switches last through at least 10,000 cycles, making them reliable for daily use.

- Their design supports advanced switching functions, such as make-before-break or break-before-make, which you won’t find in simpler switches.

Tip: If you need a rotary lamp switch replacement or want to upgrade your control system, rotary cam switches offer flexibility and long-term value.

How Rotary Cam Switches Work

Rotary cam switches use a rotating cam inside the switch body. When you turn the handle, the rotating cam moves and actuates electrical contacts in a set sequence. This action lets you control different circuits or machine functions with precision. For example, you can use a cam switch to start or stop a motor, change its direction, or select different speeds.

Here’s how rotary cam switches operate in your control system:

- The rotating cam moves contacts to open or close circuits as you turn the switch.

- You can control multiple operations, like switching between machine modes or selecting power sources.

- Rotary cam switches are common in control panels, where you need reliable and repeatable switching.

- These switches support both simple and complex tasks, from basic kill switches to advanced automation.

- With a cam rotary design, you get precise, repeatable actions every time you use the switch.

If you need to handle more advanced switching, such as in smart factories or IoT applications, rotary cam switches adapt easily. Their robust construction and flexible design make them a top choice for demanding environments. Whether you need a switch cam for a small machine or a rotary cam switch 25a for heavy equipment, you’ll find a solution that fits your needs.

Advantages of Using Rotary Cam Switches

Durability and Reliability

When you choose rotary cam switches for your industrial setup, you get devices built to last. These switches often reach a rated lifespan of about 10,000 electrical cycles and 20,000 mechanical cycles under normal use. If you follow proper maintenance and stick to the recommended usage ratings, you can extend their life even further. That means less downtime and fewer replacements for your equipment.

What makes rotary cam switches so tough? Take a look at their construction:

- High-quality, abrasion-resistant conductive materials like copper alloys for the cams help reduce electrical resistance and boost durability.

- The cams sit on a rotating shaft, which allows for multiple switching positions and supports frequent operation.

- The robust build lets these switches work reliably in harsh environments and handle frequent switching.

- You get multiple installation options, and these switches meet international quality and safety standards like ISO9001, CE, CB, and TUV.

You can trust rotary cam switches to keep your operations running smoothly, even in demanding conditions.

Flexibility and Customization

One of the biggest advantages of using rotary cam switches is their flexibility. You can customize them to fit your exact control needs. Here’s how they adapt to your requirements:

- Modular design lets you tailor the switch for specific control functions.

- You can pick from different types, such as multi-position, changeover, motor control, and timer switches.

- Manufacturers offer adjustable switches with customizable pole configurations, switching sequences, and contact materials.

- You can choose mounting types that fit your setup, like panel-mounted or base-mounted.

- Contact materials such as silver alloy improve durability and conductivity.

Rotary cam switches support a wide range of control functions, from startup sequences to speed adjustments. Their user-friendly design makes installation and operation simple, so you can integrate them into complex systems with ease.

Linkwell Quality and Support

When you work with Linkwell, you get more than just reliable rotary cam switches. You get a partner committed to sustainable quality and rapid delivery. Linkwell stands out by offering 24/7 support, so you always have help when you need it. The company’s dedication to international standards and customer satisfaction means you can trust their switches to perform in any industrial environment.

Tip: If you want peace of mind and long-term value, choose rotary cam switches from a provider like Linkwell. Their support and quality make all the difference.

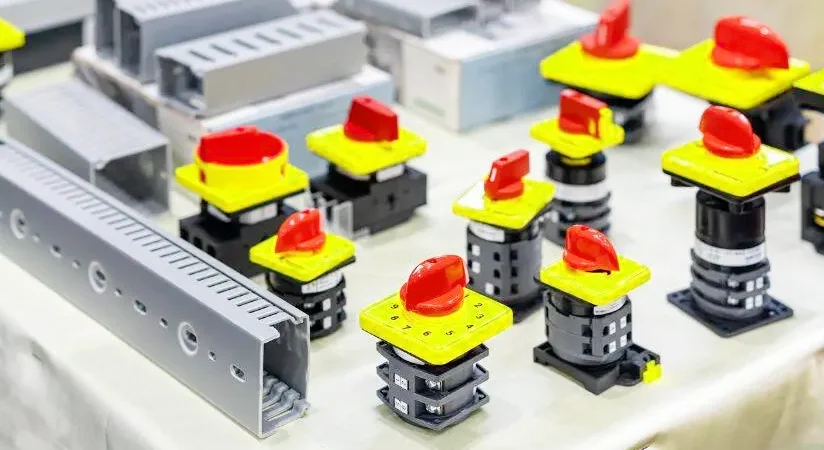

Types of Rotary Cam Switches

When you look at industrial control panels, you’ll notice that not all rotary cam switches are the same. You have several types of rotary cam switches to choose from, each designed for specific control tasks. Understanding the main types of rotary cam switches helps you pick the right one for your application. Let’s break down the most common types and see where you might use them.

On-Off Switches

On-off rotary cam switches are the simplest and most familiar. You use these switches to connect or disconnect a circuit manually. They work great when you need to start or stop equipment, especially if you don’t need to switch often. You’ll find on-off rotary cam switches in places like:

- Direct control of three-phase asynchronous motors

- Primary command control panels

- Circuit measurement setups

- Speed adjustment for electrical circuits

- Welding machines and testing equipment

These switches handle infrequent manual operations but deliver reliable performance every time. You can trust them for basic circuit control, especially when safety and compliance matter. Linkwell offers on-off rotary cam switches that meet international standards, so you get peace of mind and long-lasting service.

Tip: If you need a simple solution for starting or stopping a machine, an on-off rotary cam switch is your go-to choice.

Changeover Switches

Changeover rotary cam switches step up the game. You use these switches when you need to switch between two or more power sources or circuits. Imagine you have a backup generator and want to switch from the main power supply to the generator during an outage. That’s where changeover rotary cam switches shine.

These switches feature a rotating cam mechanism that moves contacts in a precise sequence. You get clear position indexing, so you always know which source is active. The robust design, often with copper and silver alloy contacts, ensures durability and reliable conductivity. Changeover rotary cam switches also include mechanical interlocks and arc extinguishing features for safe operation.

You’ll see these switches in:

- Power switching for multi-source systems

- Motor speed control

- Control circuit applications in factories

- Safe manual transfer between power supplies

Linkwell’s range includes changeover rotary cam switches built for demanding environments. You get reliable switching, clear position feedback, and the confidence that your system will run smoothly.

Multi-Position Switches

Multi-position rotary cam switches give you more flexibility. You can select from several positions, not just on or off. This type is perfect when you need to control multiple functions or select different operating modes. The number of positions and contacts can vary, so you can tailor the switch to your needs.

Common uses for multi-position rotary cam switches include:

- Selecting different speeds for motors

- Switching between machine modes

- Controlling multiple circuits from a single switch

- Adjusting settings in automation systems

You’ll find single-pole, double-pole, and multi-position rotary cam switches in the market. Some are electrical, while others are mechanical. The variety lets you match the switch to your exact requirements. Linkwell supports a wide range of multi-position rotary cam switches, so you can always find the right fit for your control panel.

Note: Always check the number of positions and contacts before choosing a multi-position rotary cam switch. This ensures you get the control options you need.

Step Switches

Step rotary cam switches are the specialists in sequential control. You use these switches when you want to move through a series of steps, one at a time, based on specific signals. The rotating cam advances only when it receives an acknowledgment, making it ideal for automated processes.

Step rotary cam switches excel in:

- Machine tool control

- Automated process loops

- Motor positioning

- Counting, timing, and programming tasks

In these applications, the switch cam moves through positions triggered by relay signals or limit switches. This setup gives you precise, step-by-step control over complex operations. Linkwell’s step rotary cam switches are built for reliability and accuracy, helping you manage even the most demanding sequential tasks.

| Type of Rotary Cam Switch | Typical Use Case | Linkwell Support |

|---|---|---|

| On-Off | Manual circuit control, motor start/stop | Yes |

| Changeover | Power source switching, motor control | Yes |

| Multi-Position | Mode selection, multi-circuit control | Yes |

| Step | Sequential process control | Yes |

You have many types of rotary cam switches at your disposal. Each type offers unique features and benefits. Whether you need a simple on-off function or advanced sequential control, Linkwell has a rotary cam switch to match your needs. Always consider the number of positions and contacts required for your application. This ensures you get the right performance and flexibility for your industrial setup.

Selection Criteria

Choosing the right rotary cam switches for your setup can make a big difference in safety and performance. You want to match the switch to your system’s needs, so let’s break down the key features to consider.

Ratings and Specifications

When you select rotary cam switches, always check the current and voltage ratings first. These ratings tell you how much power the switch can handle without overheating or failing. Here are the key features to consider:

- Current rating: Make sure the switch can handle the maximum current your system uses.

- Voltage rating: Pick a switch that matches or exceeds your system’s voltage.

- Number of positions and contacts: Decide how many functions or circuits you need to control.

- Contact configuration: Look at how the contacts are arranged for your application.

- Power requirements: Check if you need AC or DC operation.

If you work with motors or lamps, remember to consider inrush currents. These spikes can be much higher than normal running current. Always choose rotary cam switches that meet or exceed your system’s current and voltage ratings for safe, reliable operation.

Material and Construction

The materials used in rotary cam switches affect how long they last and how well they perform. Here’s a quick look at what matters:

| Material Type | Examples | Why It Matters |

|---|---|---|

| Contact Materials | Silver, Copper, Brass, Alloys | Good conductivity, resists wear and corrosion |

| Insulation Materials | Thermoset plastics, composites | High thermal stability, strong electrical isolation |

Silver contacts give you excellent conductivity and resist oxidation, but alloys can boost durability. For insulation, thermoset plastics and composites help the switch stand up to heat and tough environments. Picking the right materials means your rotary cam switches will last longer and work better.

Installation and Ease of Use

You want rotary cam switches that are easy to install and operate. Look for these features:

- Clear tactile feedback at each position, so you know exactly what you’re selecting.

- Standard mounting sizes, like 22.5mm central fixing, for quick panel installation.

- Finger-proof screw terminals to keep wiring safe and simple.

- Legend plates for clear labeling, which helps prevent mistakes.

A user-friendly design makes setup faster and reduces errors. When you focus on ease of installation and use, you save time and keep your system running smoothly.

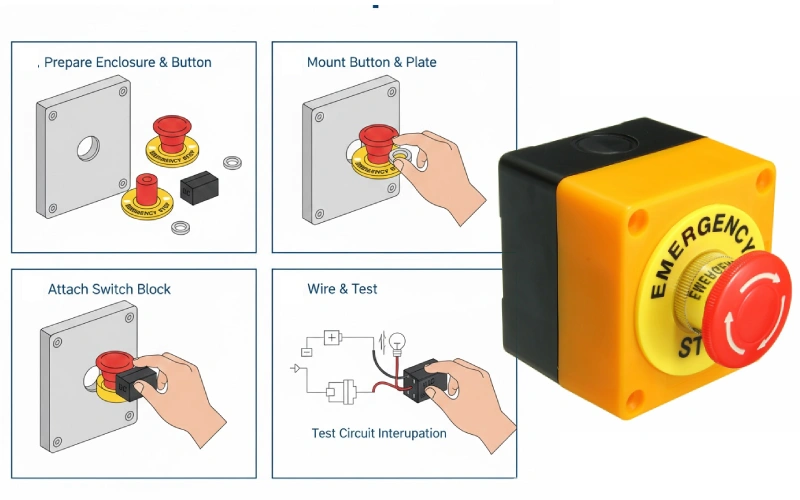

Linkwell Push Button Switch Integration

Rotary cam switches work even better when you pair them with the right accessories. Linkwell’s push button switch is a great example. You can use these push buttons for start and stop commands, giving you instant manual control over your equipment. They fit easily into your control panels and offer customization options like color, illumination, and labeling. By combining rotary cam switches with Linkwell push button switches, you create a safer, more responsive control system that fits your exact needs.

Tip: Always match your rotary cam switches and push button switches to your application’s ratings and requirements. This ensures safe, efficient, and reliable operation every time.

Applications of Rotary Cam Switches

Manufacturing and Automation

You see rotary cam switches everywhere in manufacturing and automation. These switches help you control machines, assembly lines, and packaging equipment. You can use them to start and stop motors, change directions, or switch between machine modes. Their rugged design lets them handle harsh environments, frequent switching, and vibration. You can program a rotating cam to activate or deactivate parts at specific times, which boosts productivity and quality. Here’s how you might use them:

- Control motors for starting, stopping, and reversing.

- Switch between different operating modes on control panels.

- Manage operations like cutting, welding, or packaging.

- Select power sources or backup systems for power distribution.

You find cam switches in industries like material handling, food processing, and textiles. Their easy installation and long service life make them a cost-effective choice for industrial control.

Energy and Power

You rely on rotary cam switches in energy and power distribution systems. These switches control generators, manage load distribution, and let you switch smoothly between main and backup power. This is critical in places like hospitals and data centers, where you need a stable energy supply. You can use a switch cam as the main power switch in electrical panels, giving you selective control over circuits or equipment. Their robust build and precise control keep your power systems safe and reliable.

Marine and Aerospace

You need rotary cam switches that can handle tough conditions in marine and aerospace environments. Manufacturers design these switches for ruggedness, precision, and wide temperature ranges. They seal them against dust, moisture, and chemicals, so you get reliable performance even in harsh conditions. You find them in ship control panels, aircraft systems, and defense equipment. These switches meet strict international standards and pass tests for vibration, shock, and endurance.

Linkwell in Industrial Solutions

Linkwell brings decades of experience to the applications of rotary cam switches. You see Linkwell products in control panels, energy systems, and automation lines worldwide. Major companies trust Linkwell for reliable cam rotary solutions that meet international standards. You can integrate Linkwell’s rotary cam switches with push button switches for even greater control and safety. If you need a custom solution, Linkwell offers support and fast delivery to keep your projects on track.

Table: Where You’ll Find Rotary Cam Switches

| Sector | Typical Applications |

|---|---|

| Industrial Equipment | Machinery, control systems, automation |

| Energy & Power | Power panels, generators, backup switching |

| Marine & Aerospace | Ship controls, aircraft, defense systems |

| Automotive | Vehicle controls, testing equipment |

| Consumer Electronics | Home appliances, telecom equipment |

You can count on rotary cam switches for reliable, flexible control in every industry.

Maintenance Tips

Keeping your rotary cam switches in top shape helps you avoid downtime and keeps your operations safe. Let’s look at some practical maintenance and safety tips you can use every day.

Load Ratings and Safety

You want your rotary cam switches to last and work safely. Always check the load and voltage ratings before installation. Using a switch outside its rated limits can cause overheating or even failure. Here’s a quick table to help you pick the right switch for your needs:

| Series / Product Range | Load Rating (Primary Current) | Voltage Rating | Notes |

|---|---|---|---|

| ROTACAM | 0.4 A – 6 A | 5 V – 600 V | Heavy-duty, IP66 protection |

| General Cam Switches | 10 A – 1200 A | Up to 690 V | Motor, main, control, instrument use |

| P0-PX-C0-CX-G series | 12 A – 200 A | 1 V – 600 V | High durability and safety |

| VN series | 25 A – 250 A | 220 V – 690 V | Wide range, manual operation |

| T series | 16 A – 315 A (up to 1200 A) | 500 V, 690 V | Multiple mounting options |

Tip: Stick to the recommended ratings to prevent overheating and extend the life of your rotary cam switches.

Professional Installation

| Category | Key Installation Requirements |

|---|---|

| Safety Precautions | – Disconnect power before work – Use proper PPE – Never modify certified switches |

| Component Selection | – Match voltage/current ratings – Choose correct IP rating – Use relays for high-power loads |

| Installation | – Secure mounting with proper alignment – Follow manufacturer wiring diagrams – Use mechanical stops |

| Wiring Best Practices | – Shielded cables with strain relief – Proper grounding – Tighten all terminals securely |

| Protection | – Install fuses/circuit breakers – Use certified equipment in hazardous zones |

| Documentation & Compliance | – Label all components clearly – Maintain updated documentation – Comply with IEC/OSHA standards |

| Verification | – Test operation after installation – Schedule regular inspections |

Following these maintenance and safety tips helps you avoid common issues like loose connections or electrical faults.

Regular Inspection

You should inspect your rotary cam switches at least twice a year. Look for signs of wear, dirt, or loose terminals. Clean the contacts with compressed air or a soft brush. Make sure everything is dry before you put the switch back together. Regular checks help you catch problems early and keep your switches running smoothly.

Common issues include:

- Wear and tear on components

- Dirt or debris buildup

- Overheating from overloaded circuits

- Electrical faults from contamination

- Installation mistakes

Regular maintenance and safety tips keep your rotary cam switches reliable and safe for years to come.

Choosing the right rotary cam switches keeps your equipment running safely and efficiently. When you pick high-quality rotary cam switches, you get long-lasting reliability, fewer breakdowns, and easy integration into your systems. You also enjoy better safety features and lower maintenance costs. If you want a partner who understands your needs, Linkwell offers expert support and custom solutions. Reach out to Linkwell for advice and products that help your business succeed.

FAQ

What is a rotary cam switch and how does it work?

You use a rotary cam switch to control circuits by turning a handle. The rotating cam inside moves contacts in a set sequence. This lets you manage multiple functions, like a 3 phase rotary cam switch or a 4 position rotary cam switch.

Where can I use a rotary cam switch in my facility?

You can install rotary cam switches in control panels, machinery, and power distribution boards. They work well for kill switches, cam switches, and even as a rotary lamp switch replacement. You get flexibility for automation, energy, and marine applications.

How do I choose the right rotary cam switch for my needs?

First, check your current and voltage requirements. Decide if you need a 3 position rotary cam switch, 8 position rotary cam switch, or a rotary cam switch 25a. Look for durable materials and easy installation. You can always ask Linkwell for help.

Can I use rotary cam switches with push buttons?

Yes! You can pair a rotary cam switch with a push button for better control. Use the push button for start/stop and the cam rotary for mode selection. This combo boosts safety and makes your system more responsive.

What maintenance do rotary cam switches need?

You should inspect your switch cam twice a year. Clean contacts, check for loose wires, and test operation. Regular care keeps your cam switch reliable and extends its life. Always follow safety guidelines during maintenance.

Conclusion

Choosing the right rotary cam switch helps you keep your equipment safe and efficient. You get reliable performance, easy integration, and long service life. If you want expert advice or custom solutions, Linkwell stands ready to support your industrial needs.