When you ask, “What is a PTC?” in electrical engineering, you’re referring to a Positive Temperature Coefficient thermistor. This small but powerful device is essential for circuit protection. As the temperature goes up, the resistance of a PTC increases, making it ideal for safety and self-regulation in electrical systems. Industries worldwide depend on PTCs, and the global market for these thermistors reached approximately USD 620 million in 2023. With demand continuing to rise, it’s clear that PTCs play a crucial role in today’s modern electrical infrastructure.

PTC Key Takeaways

- PTC thermistors increase resistance as temperature rises, acting as a safety switch to protect circuits from overheating.

- These devices are essential in various industries, including automotive and healthcare, for reliable overcurrent protection.

- Ceramic PTC thermistors offer fast response and stability, while polymer PTC thermistors are cost-effective for simpler applications.

- Using PTC thermistors can reduce maintenance costs since they reset automatically after an overload, unlike traditional fuses.

- Incorporating PTC heaters in industrial settings enhances energy efficiency and protects sensitive electronics from temperature fluctuations.

What is a PTC

PTC Meaning

If you’ve ever wondered what is a ptc, you’re not alone. In electrical engineering, a PTC stands for Positive Temperature Coefficient thermistor. You’ll find these small components in all sorts of devices, from industrial machines to everyday electronics. When you look at a PTC, you see a device that changes its resistance as the temperature rises. This unique property makes it a go-to choice for protecting circuits and regulating heat.

Let’s break down what makes a PTC special. The term “positive temperature coefficient” means the resistance of the material goes up as the temperature increases. You can think of it as a built-in safety switch. When things get too hot, the PTC steps in and limits the current, keeping your equipment safe.

You might be curious about what materials make up a PTC thermistor. Here are the most common ones:

- Ceramic PTC thermistors use doped barium titanate, which combines barium carbonate and titanium dioxide. This material reacts to temperature changes in a way that’s perfect for circuit protection.

- Polymeric PTC thermistors contain conductive particles, like carbon, inside a polymer matrix. These offer a cost-effective alternative and work well in many applications.

- Barium titanate (BaTiO₃) is the core material for ceramic PTC thermistors. It’s known for its reliable temperature-resistance characteristics.

You’ll see PTC thermistors in many industries. Here’s a quick look at where they show up:

| Sector | Description |

|---|---|

| Manufacturing | Uses PTC thermistors for overcurrent protection in automated equipment. |

| Automotive | Relies on PTC thermistors in hybrid and electric vehicles to prevent electrical failures. |

| Consumer Electronics | Enhances safety and reliability in complex devices with PTC thermistors. |

| Healthcare | Integrates PTC thermistors in medical devices for critical safety and reliability. |

Positive Temperature Coefficient Explained

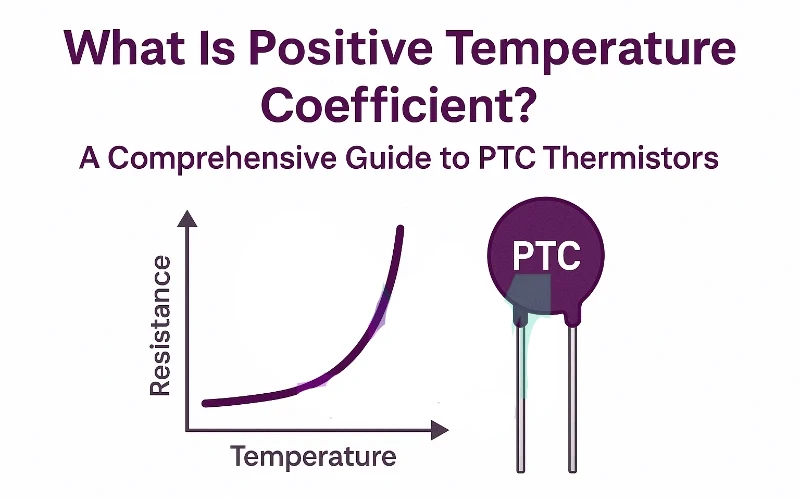

So, what is a ptc effect, and why does it matter? When you hear “positive temperature coefficient,” you’re talking about a material that increases its resistance as it gets hotter. This isn’t just a gradual change. The resistance of a PTC thermistor starts off low and steady. As the temperature climbs, it drops a little at first. Once it hits a certain point—called the Curie temperature—the resistance shoots up fast. This sharp jump acts like a fuse, stopping current flow and protecting your system.

Here’s how it works inside the material. As the temperature rises, the crystal lattice vibrates more. These vibrations scatter electrons, making it harder for them to move. That’s why the resistance goes up. When the temperature reaches the Curie point, the material goes through a phase change. This transition causes a dramatic increase in resistivity, almost like flipping a switch.

You can picture the resistance-temperature curve for a standard PTC thermistor like this:

- There’s a small region where resistance drops slightly (NTC region).

- After the switching point, resistance rises sharply within just a few degrees.

- The curve looks almost vertical after the Curie point, showing how quickly the PTC reacts.

This positive temperature coefficient effect is crucial for safety. It lets the PTC act as a self-regulating device. If your equipment gets too hot, the PTC increases resistance and cuts off the current. You get protection without needing extra fuses or switches.

Tip: If you’re designing a system that needs automatic protection from overheating, a PTC thermistor is a smart choice. You get reliability and peace of mind, especially in critical applications.

How PTCs Work

Self-Regulation Principle

When you use a ptc thermistor in your circuit, you get a built-in safety feature. This device knows how to protect itself and your equipment. Here’s how the self-regulation principle works:

- The ptc thermistor automatically limits current flow if there is too much current.

- When the current goes above a safe level, the resistance of the thermistor rises quickly. This action protects your circuit from damage and stops overheating.

- PTC heating elements show a sharp change in resistance at a certain temperature. Below this point, they let current flow and produce heat. Above it, they almost stop the current, so the temperature stays steady.

- Even if the voltage or heat load changes, the ptc keeps the temperature consistent. You do not need to worry about sudden spikes or drops.

Tip: You can think of a ptc thermistor as a smart guard for your electronics. It steps in when things get too hot and keeps everything running safely.

Curie Temperature

The Curie temperature is a key part of how ptc thermistors work. When the temperature is below this point, the resistance stays low and steady. As the temperature gets close to the Curie temperature, something special happens inside the thermistor. The ceramic material changes its crystal structure. This change makes it harder for electricity to move through, so the resistance jumps up fast.

This sudden rise in resistance is what gives the ptc its self-regulating power. When the temperature goes past the Curie point, the thermistor almost stops the current. This feature helps prevent overheating and keeps your devices safe. The Curie temperature marks the spot where the ptc switches from letting current flow to blocking it, making it perfect for overcurrent protection and temperature sensing.

PTC Thermistor Types

When you look at ptc thermistors, you’ll notice two main types: ceramic and polymer. Each type has its own strengths and fits different jobs. Let’s break down what makes them unique.

Ceramic PTC Thermistor

Ceramic ptc thermistors use a special material called doped barium titanate. You’ll see these thermistors in places where you need fast and reliable protection. The resistance in a ceramic ptc thermistor jumps sharply at a certain temperature. This feature helps you keep your devices safe from overheating or electrical surges.

Here’s a quick look at the key characteristics and typical uses:

| Key Characteristics | Typical Applications |

|---|---|

| Resistance-Temperature Curve | Temperature Monitoring |

| Switching Temperature (T$_s$) | Thermal Protection |

| Doped Barium Titanate (BaTiO$_3$) | Overcurrent Protection |

| Sharp increase in resistance at T$_s$ | Use in Consumer Electronics and Automotive |

You’ll find ceramic ptc thermistors in cars, home electronics, and even industrial machines. They work well for temperature monitoring and overcurrent protection. If you need a thermistor that reacts quickly and stays stable, ceramic is a solid choice.

Note: Ceramic ptc thermistors often have smaller case sizes because of their multilayered design. This makes them easy to fit into tight spaces.

Polymer PTC Thermistor

Polymer ptc thermistors use a mix of conductive particles inside a polymer base. These thermistors are great for simple overcurrent and temperature sensing tasks. You might pick a polymer ptc thermistor if you want something cost-effective and easy to use.

Let’s compare polymer and ceramic ptc thermistors:

| Feature | Polymer PTC Thermistors | Ceramic PTC Thermistors |

|---|---|---|

| Applications | Overcurrent and temperature sensing only | Overcurrent, temperature sensing, and specific applications like degaussing and inrush current limiting |

| Size | Larger physical case sizes due to surface area reliance | Smaller case sizes due to multilayered designs |

| Stability | Less stable over time | More stable over time |

| Cost | Generally less expensive | Generally more expensive |

| Performance | Performance is proportional to surface area | Stable performance across various applications |

Polymer ptc thermistors usually cost less, but they can be bigger and less stable over time. You’ll see them in basic circuit protection and temperature sensing. If you want a budget-friendly solution for simple jobs, polymer ptc thermistors work well.

Tip: Choose ceramic ptc thermistors for high-stability and tight spaces. Go with polymer ptc thermistors when you need a low-cost option for less demanding tasks.

PTC vs NTC Thermistors

Key Differences

You might wonder how PTC and NTC thermistors really compare. The main difference comes down to how their resistance changes with temperature. PTC thermistors increase resistance as they get hotter. NTC thermistors do the opposite—their resistance drops when the temperature rises. This simple difference leads to very different uses in your circuits.

Here’s a quick table to help you see the contrast:

| Feature | NTC Thermistor | PTC Thermistor |

|---|---|---|

| Resistance vs Temp | Decreases as temperature increases | Increases as temperature increases |

| Primary Function | Temperature sensing, inrush limiting | Current protection, self-regulating |

| Response Time | Fast | Moderate to slow |

| Typical Applications | Power supplies, battery packs, sensors | Fuses, motors, heaters |

| Recovery Behavior | Passive, requires cool-down | Automatic reset after overload |

You can see that NTC thermistors work best when you need quick temperature sensing or to limit inrush current. PTC thermistors shine when you want automatic protection and self-regulation.

Tip: If you need a device that resets itself after an overload, a ptc thermistor is your best friend.

Applications Comparison

You will find that each type of thermistor fits certain jobs better. NTC thermistors often show up in power supplies, battery packs, and temperature sensors. They react quickly and help manage sudden surges of current.

PTC thermistors, on the other hand, are perfect for safety and protection. You’ll see them in:

- Overcurrent protection in safety devices

- Motor starting devices

- Temperature-controlled switches

- Overtemperature protection

- Automated heating elements in consumer electronics

A ptc thermistor increases its resistance as it heats up, which helps limit current and prevent overheating. This makes it ideal for rechargeable batteries and motor protection. It also works well in self-regulating heaters, where you want stable temperatures and energy efficiency.

Note: When you want to keep your equipment safe from overheating or electrical faults, PTC thermistors offer a reliable and automatic solution.

PTC Heaters and Industrial Applications

Linkwell Enclosure Heater

When you need to protect sensitive electronics in control cabinets or telecom racks, Linkwell Enclosure Heaters step up to the job. These ptc heaters use self-regulating technology to keep the temperature inside your enclosure just right. You do not have to worry about overheating or wasted energy. The ptc heaters only turn on when needed, so you save power and keep your equipment safe.

Here’s a quick look at how Linkwell Enclosure Heaters work for you:

| Feature | Benefit for You |

|---|---|

| Self-regulating ptc heaters | Prevent overheating and maintain stable temps |

| Activates only when needed | Saves energy and reduces operational costs |

| Durable aluminum housing | Resists corrosion and lasts longer |

| IP65 full-seal design | Keeps out dust and water in harsh environments |

You can count on these ptc heaters to deliver reliable performance in tough industrial settings.

Linkwell Thermostats

Linkwell Thermostats work hand-in-hand with ptc heaters to give you precise temperature control. You get to set the exact temperature you want inside your cabinet or enclosure. The thermostat switches the ptc heaters on or off, depending on the conditions. This combo keeps your electronics safe from both heat and cold.

You will find these thermostats easy to install and compatible with most industrial enclosures. They help you avoid condensation, prevent freezing, and extend the life of your equipment. When you pair Linkwell Thermostats with ptc heaters, you get a smart, energy-saving solution for your control panels.

Benefits in Industrial Settings

You might wonder why so many industries choose ptc heaters. Here are some key reasons:

- ptc heaters adjust their energy use based on the temperature around them, which means you save energy over time.

- These heaters warm up quickly and then use less power to keep things steady, so you get fast results and lower bills.

- ptc heaters have a simple design with no moving parts, so they last longer and need less maintenance.

- The self-regulating feature of ptc heaters keeps them from getting too hot, which protects your equipment and reduces fire risks.

- ptc heaters resist damage from water, chemicals, and corrosion, making them perfect for harsh industrial environments.

- You can use ptc heaters in many places, like industrial ovens, dryers, mold heating, and fluid heating systems.

With ptc heaters from Linkwell, you get peace of mind. Your sensitive electronics stay safe, your energy costs drop, and your equipment lasts longer.

PTC Advantages

Safety and Reliability

When you want to keep your electrical systems safe, you can count on PTC thermistors. These devices meet strict safety standards, so you know they are built for tough jobs. Here’s a quick look at the certifications you might see:

| Certification/Standard | Description |

|---|---|

| RoHS | Compliant with RoHS regulations |

| IEC 60738-1 | Meets certification requirements of IEC 60738-1 |

| IEC 60730-1 | Meets certification requirements of IEC 60730-1 |

| AEC-Q200 rev. D | Qualified according to AEC-Q200 rev. D standards |

| UL1434 | UL certified under standard UL1434 |

You get more than just a certified part. PTC thermistors offer real reliability. They last a long time and protect your equipment again and again. Unlike traditional fuses, which you have to replace after they blow, a PTC thermistor resets itself. For example, in a lithium battery pack, a PTC resettable fuse tripped only twice in two weeks and reset in just 30 seconds. That means less downtime and fewer headaches for you.

| Feature | Description |

|---|---|

| Longevity | Designed for repeated use, reducing maintenance costs |

| Reliability | Consistent over-current protection for sensitive components |

| Efficiency | Self-resetting, so you spend less time fixing and more time working |

Tip: If you want a system that keeps running without constant repairs, choose a PTC thermistor for your protection needs.

Energy Efficiency

You probably want to save energy and lower your bills. PTC heating elements help you do just that. These heaters control their own temperature, so they only use the electricity they need. You don’t have to worry about wasted power or overheating.

- PTC heating elements automatically adjust to the right temperature, which means less energy use.

- They use less electricity than traditional heaters, so you see lower costs on your energy bill.

- The self-regulating feature makes sure you never use more power than necessary.

PTC thermistors also help you cut down on maintenance costs. They keep your machines from overheating and help cooling systems work better. This means your equipment lasts longer and you spend less on repairs.

Note: As industries look for compact and effective protection, PTC thermistors stand out. They boost safety, cut costs, and help you meet new safety rules.

You now know what is a ptc and why it matters in electrical engineering. Check out this quick table to recap the essentials:

| Key Point | Description |

|---|---|

| Definition | PTC thermistors increase resistance as temperature rises. |

| Principle | Made from ceramic, resistance jumps at a critical temperature. |

| Advantages | Stable, compact, fast response, cost-effective, no calibration needed. |

PTC technology keeps your systems safe and efficient. You see more industries using ptc solutions like Linkwell’s enclosure heaters and thermostats to protect equipment and boost reliability.

- Automation and energy efficiency drive adoption.

- Companies invest in smarter designs and better collaboration.

If you want reliable performance, consider what is a ptc for your next project.

FAQ

What does PTC stand for in electrical engineering?

PTC means Positive Temperature Coefficient. You see this term when talking about thermistors that increase resistance as temperature rises. These devices help protect your circuits and keep your equipment safe.

How does a PTC thermistor protect my electronics?

A PTC thermistor acts like a smart fuse. When things get too hot, it increases resistance and limits current. You avoid overheating and keep your devices running smoothly.

Where can I use PTC heaters?

You can use PTC heaters in control cabinets, telecom racks, and industrial enclosures. They work well for keeping electronics dry, preventing condensation, and maintaining stable temperatures.

What is the Curie temperature in a PTC thermistor?

The Curie temperature is the point where the thermistor’s resistance jumps up quickly. You get automatic protection because the device almost stops current flow when it gets too hot.

Do I need a thermostat with my PTC heater?

Yes, pairing a thermostat with your PTC heater gives you precise temperature control. You set the temperature you want, and the system keeps your equipment safe and energy-efficient.