When you look at a/c compressor types, you’ll find five main options: reciprocating, scroll, rotary, screw, and centrifugal. Each type of air conditioning compressor brings unique benefits, from the high efficiency of scroll compressors to the rugged performance of screw compressors in industrial settings. Knowing the types of air conditioning compressor helps you match the right technology to your needs, which boosts energy efficiency and keeps operational costs down. The right types of ac compressors also improve reliability, especially when you need stable cooling for sensitive enclosures. Linkwell stands out as a trusted source for cabinet air conditioners and enclosure cooling solutions, making it easier to choose the best a/c compressors for your application.

Key Takeaways

- There are five main types of A/C compressors: reciprocating, scroll, rotary, screw, and centrifugal, each suited for different cooling needs and environments.

- Reciprocating compressors offer rugged reliability and high pressure, ideal for tough or industrial settings, while scroll compressors provide quiet, energy-efficient cooling for sensitive spaces.

- Screw compressors deliver continuous, heavy-duty cooling for large industrial applications, and rotary compressors save space and energy in smaller systems.

- Centrifugal compressors handle large-scale cooling with high efficiency and low maintenance, perfect for big factories and data centers.

- Choosing the right compressor depends on factors like enclosure size, heat load, noise level, and maintenance needs; matching these ensures better efficiency, reliability, and equipment protection.

A/C Compressor Types

When you start exploring a/c compressor types, you’ll notice five main designs. Each one works a bit differently and suits specific cooling needs. Let’s break down the types of air conditioning compressors so you can see how they work and which ones fit your application best.

Reciprocating Compressor

A reciprocating air conditioner compressor uses a piston and cylinder setup to compress refrigerant. Here’s how it works:

- The piston moves back and forth inside the cylinder, driven by a crankshaft and connecting rod.

- As the piston retreats, the suction valve opens, letting refrigerant enter.

- The piston advances, compressing refrigerant and closing the suction valve.

- When pressure builds up, the discharge valve opens, sending compressed gas to the condenser.

- This cycle repeats, delivering a steady flow of high-pressure refrigerant.

Tip: Reciprocating compressors handle dirty environments well, making them a solid choice for outdoor or industrial settings.

| Advantage | Explanation | Application Context |

|---|---|---|

| High Pressure Generation | Produces pressures up to 30,000 PSI; ideal for climate control needing 60-90 PSI | Industrial sectors, commercial air conditioning |

| Flexibility | Available in oil-free and oil-flooded types; tank or base mounted | Sensitive environments, adaptable installation |

| High Efficiency | Uses less energy during intermittent operation | HVAC, commercial systems with cycling |

| Suitable for Intermittent Use | Maintains efficiency during non-continuous operation | Intermittent duty cycles, smaller operations |

You’ll often find reciprocating ac compressors in smaller commercial systems, industrial plants, and places where high pressure and reliability matter. Linkwell’s cabinet air conditioners sometimes use this technology for rugged, reliable cooling in tough environments.

Scroll Compressor

A scroll compressor stands out for its quiet operation and energy efficiency. It uses two spiral-shaped scrolls—one fixed, one orbiting—to compress refrigerant. Here’s how they work:

- The orbiting scroll moves around the fixed scroll, trapping pockets of refrigerant and pushing them toward the center.

- This motion compresses the refrigerant smoothly, with fewer moving parts than other designs.

Scroll air conditioning compressors run quietly and need less maintenance. You’ll appreciate their compact size and reliability, especially in sensitive environments.

| Feature | Scroll Compressor | Rotary Compressor |

|---|---|---|

| Operating Mechanism | Two spiral scrolls: one fixed, one orbiting, compress air by moving pockets toward the center. | Helical screws mesh and rotate to compress air by reducing volume. |

| Design Distinction | One moving scroll orbits a fixed scroll. | Rotating screws or rollers. |

| Energy Efficiency & Operation | High efficiency, low noise, fewer moving parts. | Wide capacity range, continuous operation. |

| Applications | Quiet, reliable, oil-free, sensitive environments. | Variable capacity, high-volume applications. |

Scroll compressors work well in enclosure cooling solutions, like Linkwell’s cabinet air conditioners. They deliver high efficiency and low noise, making them perfect for medical facilities, telecom cabinets, and places where quiet operation matters.

Screw Compressor

A screw air conditioning compressor uses two interlocking helical rotors (male and female screws) to compress air continuously. Here’s a quick look at how they work:

- Air enters through a filter, removing dust and impurities.

- The rotors trap air between their lobes inside the compression chamber.

- As the rotors turn, the volume shrinks, compressing the air.

- Oil-injected models add oil to seal gaps, reduce friction, and absorb heat.

- The compressed air-oil mixture is discharged, and oil is separated and recycled.

- Continuous rotor rotation ensures a smooth, uninterrupted flow of compressed air.

Screw compressors excel in heavy-duty, industrial applications. You’ll see them in food processing, agriculture, oil and gas, and power generation. They offer reliable, continuous operation and are a popular choice for large-scale cooling systems. Linkwell’s industrial cooling solutions often feature screw compressors for robust performance in demanding environments.

Rotary Compressor

A rotary air conditioning compressor uses a roller and vane system inside a cylinder to compress refrigerant. Here’s how it works:

- The motor and compressor share a shaft inside a sealed casing.

- As the crankshaft rotates, the roller spins in an orbital path, compressing refrigerant gas.

- The vane separates high and low-pressure sides, maintaining efficient compression.

Rotary compressors are compact and efficient, making them ideal for residential air conditioning and smaller cabinet air conditioners. You’ll find them in Linkwell’s compact cooling units, where space and energy savings matter. With proper maintenance, rotary compressors can last 10 to 15 years, keeping your enclosure cool and your electronics safe.

Note: Regular maintenance—like changing filters and checking oil—helps rotary compressors run smoothly and last longer.

Centrifugal Compressor

A centrifugal air conditioning compressor uses high-speed impellers to compress refrigerant. Here’s how they work:

- Refrigerant vapor enters at low pressure and passes through inlet guide vanes.

- The impeller blades spin rapidly, pushing refrigerant outward by centrifugal force.

- The refrigerant enters a diffuser, where its velocity drops and pressure rises.

- The pressurized refrigerant collects in a volute and moves to the condenser.

Centrifugal compressors handle huge volumes of refrigerant, making them perfect for large-scale industrial cooling. They run efficiently at full load, consume less energy, and require less maintenance due to fewer moving parts. You’ll see centrifugal compressors in big factories, data centers, and power plants. Linkwell’s advanced enclosure cooling solutions can integrate centrifugal technology for maximum cooling capacity and energy savings.

Centrifugal compressors support sustainability by reducing energy losses and helping industries decarbonize.

When you compare all a/c compressor types, you’ll see each one has strengths for different jobs. Whether you need a reciprocating compressor for rugged reliability, a scroll compressor for quiet efficiency, or a centrifugal compressor for massive cooling, Linkwell offers solutions that match your needs. Understanding how they work helps you choose the right air conditioning compressor for your enclosure or industrial application.

Types of Air Conditioning Compressors in Industrial Applications

Linkwell Cabinet Air Conditioner Solutions

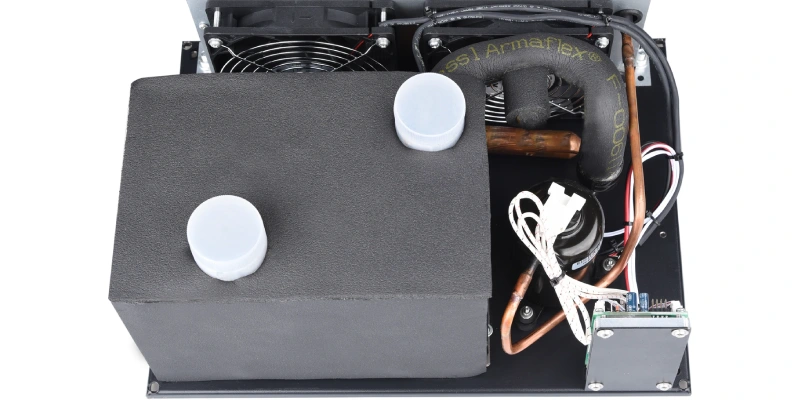

When you choose an air conditioning compressor for industrial or enclosure cooling, you want reliability, efficiency, and protection for your sensitive equipment. Industrial environments can be tough—dust, heat, humidity, and even corrosive gases can threaten your electronics. That’s why Linkwell cabinet air conditioners use advanced compressor technology to keep your enclosures safe and cool.

Linkwell integrates inverter compressors and DC compressors into their cabinet air conditioners. These technologies boost energy efficiency and deliver precise temperature control. Inverter compressors adjust their speed based on cooling demand, so you save energy and extend the life of your equipment. You also get smart digital controls and EC fans, which help you manage temperature and airflow with ease. Linkwell’s closed-loop cooling systems keep dust and moisture out, making them perfect for telecom towers, data centers, and industrial control cabinets.

Tip: Linkwell cabinet air conditioners hold UL and CE certifications, so you know you’re getting a product built for durability and safety.

Choosing the Right Compressor for Enclosures

Picking the right air conditioning compressor for your enclosure depends on several factors. You need to think about the size of your enclosure, the amount of heat your equipment generates, and the environment where you install the unit. Here’s a quick checklist to help you decide:

- Required operating pressure and airflow (CFM)

- Duty cycle and how often the compressor will run

- Maintenance needs and ease of access

- Noise level, especially in sensitive areas

- Durability and build quality for harsh environments

- Air quality requirements for sensitive electronics

- Budget and future expansion plans

Different compressor types suit different needs. For example, reciprocating compressors work well for intermittent use and rugged conditions. Rotary screw compressors handle continuous operation and high airflow. In enclosure cooling, vapor compression coolers (using a refrigeration compressor) provide sub-ambient cooling and closed-loop protection, which is ideal for harsh or dirty environments.

| Compressor Type / Cooling Technology | Cooling Mechanism | Typical Applications | Key Features |

|---|---|---|---|

| Vapor Compression Coolers | Closed-loop refrigeration cycle | Electronics enclosures, data centers | Sub-ambient cooling, protects from dust and moisture |

| Thermoelectric Coolers | Solid-state Peltier effect | Small cabinets, rail controls | Quiet, low power, no moving parts |

| Heat Sink Coolers | Air-to-air heat transfer | Indoor/outdoor enclosures | Economical, simple design |

| Heat Pipe Coolers | Evaporative fluid cycle | Compact enclosures | Compact, continuous operation |

You can trust Linkwell to match the right compressor and cooling technology to your application. Their cabinet air conditioners deliver stable temperatures, energy savings, and long-term reliability—even in the most demanding industrial settings.

How to Choose the Best Air Conditioning Compressor

Key Factors to Consider

When you start selecting the right air conditioning compressor, you want to look at more than just the price tag. Think about how your system will work day after day. Here are some important things you should check:

- System Age: If your current setup is over 10 years old, a new compressor or even a full replacement might save you money in the long run.

- Extent of Damage: Small electrical issues are often fixable, but big mechanical failures usually mean you need a new compressor.

- Budget and Warranty: Check if your warranty covers replacement. This can make a big difference in cost.

- Serviceability: Easy access for maintenance means fewer headaches and better reliability.

- Temperature and Ventilation: Make sure your compressor gets enough airflow and stays cool. Hot, stuffy spaces can shorten its life.

- Power Supply Location: Place your compressor close to the power source and where you need cooling. This cuts down on energy loss.

- Cleanliness: Dusty or dirty environments can cause overheating and damage.

- Noise and Vibration: If your equipment sits near people or sensitive electronics, quieter compressors are best.

- Preventive Maintenance: Regular cleaning and inspections help your compressor last longer and run more efficiently.

Tip: Always match the compressor’s cooling capacity to your enclosure’s heat load. Oversized or undersized units waste energy and can cause problems.

Matching Compressor Types to Your Needs

Not every compressor fits every job. You need to think about your application, environment, and how much cooling you need. Here’s a quick guide to help you decide:

| Compressor Type | Best For | Key Benefits |

|---|---|---|

| Reciprocating | Small to medium enclosures | Reliable, handles tough conditions |

| Scroll | Quiet, sensitive environments | Low noise, high efficiency |

| Rotary | Compact spaces, light loads | Space-saving, energy efficient |

| Screw | Large, industrial applications | Continuous operation, high capacity |

| Centrifugal | Massive cooling needs | Efficient at scale, low maintenance |

Variable-speed (inverter) compressors work well if your cooling demand changes throughout the day. They adjust their speed, saving energy and keeping temperatures steady. Fixed-speed compressors run at one speed, which can use more power and wear out faster.

If you need to protect sensitive electronics in harsh or outdoor environments, Linkwell’s cabinet air conditioners and outdoor enclosures are a smart choice. These systems use sealed, compressor-based cooling to keep out dust and moisture, control humidity, and maintain precise temperatures. This helps your equipment last longer and reduces downtime.

Remember: Choosing the right compressor and cooling system keeps your operations running smoothly and your electronics safe.

Choosing the right A/C compressor makes a big difference in how your system performs. Here’s a quick look at how each type stacks up:

| Type | Best For | Key Benefit |

|---|---|---|

| Reciprocating | Small systems, intermittent use | Simple, reliable |

| Scroll | Quiet, efficient cooling | Ultra-quiet, compact |

| Screw | Heavy-duty, continuous use | Long life, steady airflow |

| Rotary | Compact, light loads | Space-saving, efficient |

| Centrifugal | Large-scale cooling | High flow, low maintenance |

Need help picking the right solution? You can reach out to Linkwell for expert advice, fast quotes, and reliable cabinet air conditioners that keep your equipment safe and efficient.

FAQ

What is the main job of an A/C compressor?

You need an A/C compressor to move refrigerant through your cooling system. It raises the pressure and temperature, so the refrigerant can release heat and keep your enclosure or space cool.

How do I know which compressor type fits my enclosure?

You should check your enclosure size, heat load, and environment. If you want quiet operation, pick a scroll compressor. For tough conditions, a reciprocating or screw compressor works best.

Can I use cabinet air conditioners in outdoor settings?

Yes, you can use cabinet air conditioners outdoors. Linkwell offers models with IP54/IP65 ratings. These units protect your electronics from dust, rain, and humidity, keeping everything safe and cool.

How often should I maintain my A/C compressor?

You should clean filters and inspect your compressor every three months. In dusty places, check monthly. Regular maintenance helps your system run longer and keeps cooling performance strong.

Are these compressors used in automotive air conditioning systems?

You will find similar compressor types in automotive air conditioning systems. Scroll, rotary, and reciprocating compressors all help cool vehicles, just like they do in industrial and enclosure cooling.

Conclusion

Exploring different A/C Compressor Types—reciprocating, scroll, rotary, screw, and centrifugal—helps you choose the best solution for your cooling needs. Each type offers unique benefits, from high efficiency to rugged performance. Selecting the right compressor improves energy savings, reliability, and equipment protection.

Linkwell provides tailored cabinet air conditioners and cooling solutions, ensuring your enclosures stay safe and efficient. Contact us today for expert advice, customization, and competitive pricing.