You might wonder what makes an air conditioner compressor so important in keeping your electrical cabinets safe and cool. The compressor acts as the heart of your cooling system, moving refrigerant and helping remove heat from sensitive equipment. In industrial settings, using a reliable compressor in cabinet air conditioners keeps electronics running smoothly and prevents costly downtime. Many modern compressors use variable-speed technology and smart controls, which means they adjust their power to match your cabinet’s needs. This helps save energy, lowers costs, and keeps temperatures steady.

Key Takeaways

- The air conditioner compressor is essential for cooling. It pumps refrigerant to remove heat from electrical cabinets, keeping sensitive equipment safe.

- Regular maintenance of your compressor is crucial. Schedule inspections and clean filters to prevent breakdowns and extend the lifespan of your cooling system.

- Choosing a reliable cabinet air conditioner with a high-quality compressor can save energy and reduce costs. Look for models with smart controls and energy-efficient features.

- Watch for signs of compressor issues, like strange noises or weak airflow. Early detection can prevent costly repairs and ensure your equipment stays cool.

- Linkwell cabinet air conditioners are designed for tough environments. They offer durability, energy savings, and effective cooling for industrial applications.

Air Conditioner Compressor Basics

What Is an Air Conditioner Compressor

You might hear the term “air conditioner compressor” and wonder what it actually does inside your electrical cabinet cooling system. The compressor acts as the heart of the system, pumping refrigerant through a closed loop of coils. When you switch on your cabinet air conditioner, the compressor starts working right away. It takes in refrigerant as a low-pressure gas and compresses it, which increases both its pressure and temperature. This process is essential because it allows the refrigerant to move through the system and carry heat away from sensitive electronics.

If you look at the inside of a cabinet air conditioner, you’ll find the compressor working alongside other parts like fans and filters. The compressor’s job is to keep the refrigerant moving so heat can be transferred out of the cabinet. Without a working compressor, your electrical components could overheat and fail. That’s why manufacturers like Linkwell design their air conditioning compressors for durability and high performance, especially in harsh industrial environments.

Tip: Choosing a cabinet air conditioner with a reliable compressor helps protect your equipment and keeps your operations running smoothly.

Air Conditioning Compressor Function

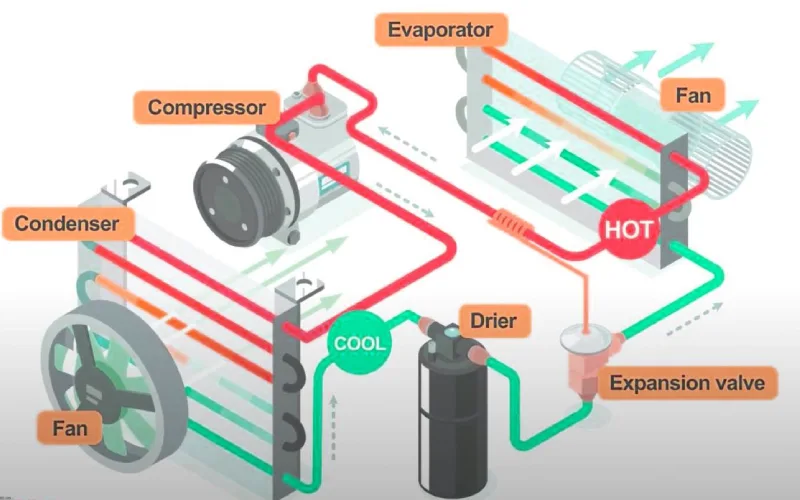

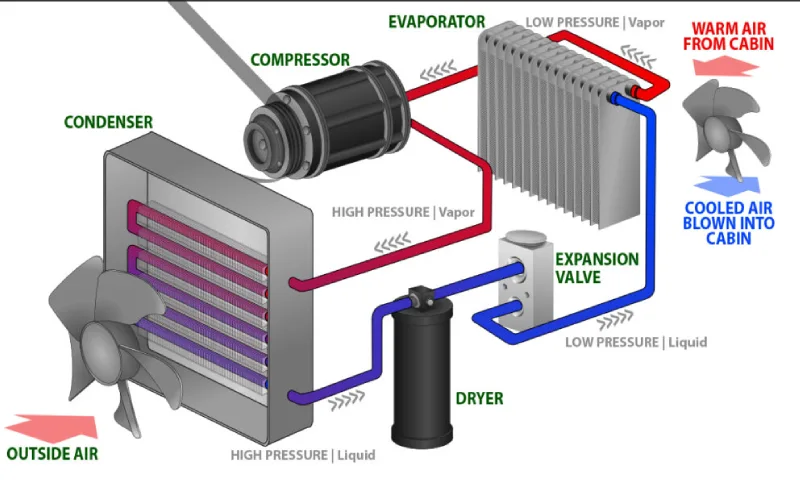

Let’s break down how the air conditioning compressor works in your cabinet cooling system. You’ll see that its main function is to compress and circulate refrigerant, which is the special fluid that absorbs and releases heat.

Here’s what happens step by step:

- The compressor pulls in refrigerant as a low-pressure vapor from the evaporator coil inside the cabinet.

- It compresses the refrigerant, raising its pressure and temperature.

- The hot, high-pressure refrigerant moves to the condenser coil, where it releases heat to the outside air.

- After cooling down, the refrigerant returns to the evaporator coil to absorb more heat from inside the cabinet.

This cycle repeats as long as your cabinet air conditioner is running. The compressor makes sure the refrigerant keeps moving, so heat gets pulled out of the cabinet and expelled outside. This process keeps your electronics safe and helps control humidity inside the enclosure.

Here’s a quick look at how different refrigerants affect performance in cabinet air conditioners:

| Refrigerant | Cooling Capacity | Energy Efficiency | GWP | ODP |

|---|---|---|---|---|

| R134a | High | Moderate | High | Low |

| R152a | Higher | High | Low | Low |

| R1234yf | Moderate | High | Low | Low |

| R600a | High | Higher | Low | Low |

| R290 | High | Higher | Low | Low |

| R32 | Moderate | High | Low | Low |

| R410a | Moderate | Moderate | High | Low |

| R454b | Moderate | High | Low | Low |

| R446a | Moderate | Highest | Low | Low |

You’ll notice that Linkwell cabinet air conditioners use advanced compressors and energy-efficient refrigerants to deliver reliable cooling performance. These systems are built for tough environments, like manufacturing plants and telecom stations, where overheating can cause major problems.

- Linkwell designs and manufactures custom air conditioning systems for industrial applications.

- Their products are engineered for durability and high performance in harsh environments.

- They cater to various industries including manufacturing, telecommunications, and oil and gas.

- Linkwell provides end-to-end solutions including engineering, prototyping, testing, and global shipping.

- They offer full-service support including pre-sales consultation and after-sales technical service.

When you choose a Linkwell cabinet air conditioner, you get a compressor that’s built to last and a system that keeps your electrical cabinets cool, safe, and efficient.

How Does It Work

Cooling Cycle Steps

You might wonder, “how does it work” when you switch on your cabinet air conditioner. The cooling process starts with the compressor and follows a series of steps that keep your electrical components safe. Here’s a simple breakdown of the cooling cycle steps:

- Compression

The compressor pulls in refrigerant as a low-pressure vapor from the evaporator inside the cabinet. It compresses this vapor, turning it into a high-pressure, high-temperature gas. This step is the driving force behind the entire process. - Condensing

The hot, pressurized refrigerant moves to the condenser coil. Here, it releases heat to the outside air and changes from a gas to a liquid. This process helps remove unwanted heat from your cabinet. - Thermal Expansion Valve (TXV)

The liquid refrigerant passes through the expansion valve. The valve drops the pressure and controls the flow into the evaporator. This process prepares the refrigerant for the next stage. - Cooling in the Evaporator

The refrigerant enters the evaporator coil inside the cabinet. It absorbs heat from the electrical components and vaporizes back into a low-pressure gas. The process repeats as the compressor draws in the vapor again.

This cooling process keeps your cabinet at a safe temperature. The compressor makes sure the refrigerant keeps moving, so heat gets pulled out and expelled. You get reliable cooling for your sensitive electronics.

Tip: If you notice your cabinet air conditioner running longer than usual, it might mean the cooling process is not working efficiently. Regular maintenance helps keep the process smooth.

Compressor Role in Heat Transfer

The compressor does more than just move refrigerant. It plays a key role in the heat transfer process inside your cabinet air conditioner. Here’s how the process works:

- The compressor increases the pressure and temperature of the refrigerant. This process allows the refrigerant to absorb more heat from inside the cabinet.

- The high-pressure refrigerant travels to the condenser. Here, the process of heat transfer happens through conduction and convection. The refrigerant releases heat to the outside air.

- The process continues as the refrigerant moves through the expansion valve and evaporator. Changes in pressure affect the boiling point of the refrigerant, so it can absorb heat from your electronics and release it outside.

- The compressor keeps the process going, making sure the refrigerant circulates and the cooling process never stops.

Heat transfer is essential for maintaining the right temperature in your cabinet. The compressor’s process ensures your equipment stays cool, even in tough industrial environments.

Note: A well-functioning compressor means efficient heat transfer and a stable cooling process. If you ever hear strange noises or see temperature spikes, it’s time to check the compressor and the cooling process.

HVAC Compressor Types and Components

Main Parts

When you look inside an hvac compressor for a cabinet air conditioner, you will find several important parts working together. Each part has a specific job to keep your cooling system running smoothly. Here’s a quick table to help you understand what each component does:

| Component | Function |

|---|---|

| Motor | Powers the compressor, turning electrical energy into mechanical energy. |

| Compressor Housing | Protects and supports all internal parts. |

| Pistons or Rotors | Compresses the refrigerant, raising its pressure and temperature. |

| Intake Valves | Lets low-pressure refrigerant enter the compressor. |

| Discharge Valves | Releases high-pressure gas into the condenser. |

| Sensors and Controls | Keeps everything running safely and efficiently. |

You want your hvac compressor to last. Compressors made from tough materials can handle harsh environments, like dusty factories or outdoor telecom boxes. High-quality compressors break down less often, so you spend less time and money on repairs.

Common Types

You will find several types of hvac compressors used in electrical cabinet air conditioners. Each type works a little differently, but all help keep your equipment cool and safe.

- Reciprocating Compressor: Uses a piston and cylinder to compress refrigerant. Great for many applications.

- Rotary Compressor: Has fewer moving parts and runs quietly. Works well in places where you need less noise.

- Scroll Compressor: Uses two spiral-shaped scrolls to compress refrigerant smoothly and efficiently.

- Brushless DC (BLDC) Compressor: Offers high energy efficiency and precise speed control.

Here’s a table showing which types you’ll often see in Linkwell cabinet air conditioners:

| Compressor Type | Description |

|---|---|

| Scroll | Commonly used for efficient cooling |

| Rotary | Known for compact size and reliability |

| Reciprocating | Traditional type, effective for various needs |

| Brushless DC (BLDC) | Standard for energy efficiency in modern units |

Linkwell Cabinet Air Conditioner Features

When you choose a Linkwell cabinet air conditioner, you get more than just a reliable hvac compressor. You also enjoy smart features and energy savings:

- Inverter technology can cut energy use by up to 40%. The hvac compressor changes speed to match your cooling needs, so you save power and money.

- You get real-time monitoring with LED digital displays. You can check temperature, humidity, and system status at a glance.

- The system supports remote monitoring and control. You can set schedules, receive alarms, and even connect to building management systems.

- Linkwell units use adaptive cooling algorithms. This means your equipment always stays at the right temperature, even if conditions change.

- The compressors are built for tough environments. Durable materials help them last longer and perform better, even in extreme conditions.

Tip: Linkwell cabinet air conditioners offer smart controls, energy efficiency, and strong performance. You protect your electronics and lower your operating costs at the same time.

Issues and Maintenance

Signs of Problems

You want your electrical cabinet to stay cool and safe, but sometimes the hvac compressor can run into trouble. Watch for these common signs that your compressor might need attention:

- Weird sounds, like loud banging or rattling, can mean the hvac compressor is struggling.

- Leaks around the unit often point to refrigerant escaping from the compressor.

- High electric bills may show your hvac compressor is working too hard or not running efficiently.

- Weak airflow from the cabinet air conditioner can signal a failing hvac compressor.

- Warm air inside the cabinet instead of cool air means the hvac compressor or refrigerant might be the issue.

- If the condenser unit feels too hot, the hvac compressor could be overheating.

If you notice any of these problems, you should reach out to a professional. Quick action can prevent bigger issues and keep your equipment running smoothly.

Maintenance Tips

Taking care of your hvac compressor helps you avoid costly repairs and downtime. Here are some easy ways to keep your cabinet air conditioner in top shape:

- Schedule regular professional maintenance twice a year for your hvac compressor.

- Clean and inspect condenser and evaporator coils to keep the hvac compressor working efficiently.

- Check and maintain refrigerant levels so your hvac compressor can deliver proper cooling.

- Replace air filters often to optimize airflow and protect the hvac compressor.

Regular upkeep, like cleaning filters, can stop unexpected failures and expensive repairs. You boost the performance and lifespan of your hvac compressor when you follow these steps. Linkwell cabinet air conditioners are designed for easy maintenance, so you spend less time worrying and more time focusing on your work.

Tip: A clean hvac compressor runs better and lasts longer. Make maintenance part of your routine.

Lifespan and Replacement

You might wonder how long your hvac compressor will last. Most compressors in cabinet air conditioners work well for 12 to 15 years. With good care, some hvac compressors can last even longer.

If your hvac compressor fails, you have a few options:

- If your compressor is still under warranty, you can replace just the compressor.

- If your cabinet air conditioner is older than 10-15 years, replacing the whole unit may save you money in the long run.

- If only the outdoor unit is having trouble and the indoor unit is still new, you can replace just the outdoor part.

Choosing the right solution depends on your system’s age and condition. Linkwell offers reliable support to help you decide what’s best for your cabinet cooling needs.

Note: Regular maintenance extends the life of your hvac compressor and keeps your cabinet air conditioner working efficiently.

You rely on your cabinet air conditioner’s compressor to keep your electronics cool and safe. Regular maintenance helps you avoid breakdowns and saves money over time. Check out how reliability and upkeep make a difference:

| Feature | Benefit |

|---|---|

| Reliable Compressor | Better cooling, lower bills, safer gear |

| Regular Maintenance | Fewer repairs, longer lifespan |

If you spot issues, reach out to a professional. For tough industrial jobs, Linkwell Cabinet Air Conditioners deliver energy savings and durability you can trust.

FAQ

How do I know if my cabinet air conditioner compressor is failing?

You might hear strange noises, notice weak cooling, or see higher energy bills. If your cabinet feels warm inside or the compressor runs nonstop, it’s time to call a technician.

Can I replace just the compressor in my cabinet air conditioner?

Yes, you can replace only the compressor if the rest of your unit works well. If your system is old or has other issues, you might want to upgrade the whole cabinet air conditioner.

How often should I clean or check my cabinet air conditioner compressor?

You should check and clean your compressor at least twice a year. Regular filter cleaning and coil inspection help your system run smoothly and last longer.

What makes Linkwell cabinet air conditioners a good choice?

Linkwell units use energy-efficient compressors, smart controls, and tough materials. You get reliable cooling, easy maintenance, and strong protection for your sensitive electronics.

Do Linkwell cabinet air conditioners work outdoors?

Yes! Many Linkwell models have IP54 or IP65 ratings. You can use them in dusty, humid, or outdoor environments without worry.