When you hear the term brushless motor meaning, think of a motor that runs without the traditional brushes found in older designs. This technology uses electronics to control the motor, which makes it more efficient and longer-lasting. In today’s world, brushless motors play a huge role in cooling systems for cabinets and industrial equipment. You’ll notice a big shift toward these motors because people want energy savings and reliable performance.

- The market for brushless motors in cabinet fans has nearly doubled over the past decade, with demand rising due to energy efficiency and sustainability.

Linkwell leads the way by offering advanced fan solutions built on this technology.

Key Takeaways

- Brushless motors use electronic controls instead of brushes, leading to smoother operation and longer lifespan.

- These motors are highly efficient, saving energy and reducing power bills by up to 30%.

- Minimal maintenance is required for brushless motors, which means less downtime and fewer repairs.

- Brushless motors operate quietly, making them ideal for sensitive environments like offices and data centers.

- Choosing brushless motors for cooling systems ensures reliable performance and consistent airflow.

Brushless Motor Meaning

What Is a Brushless Motor?

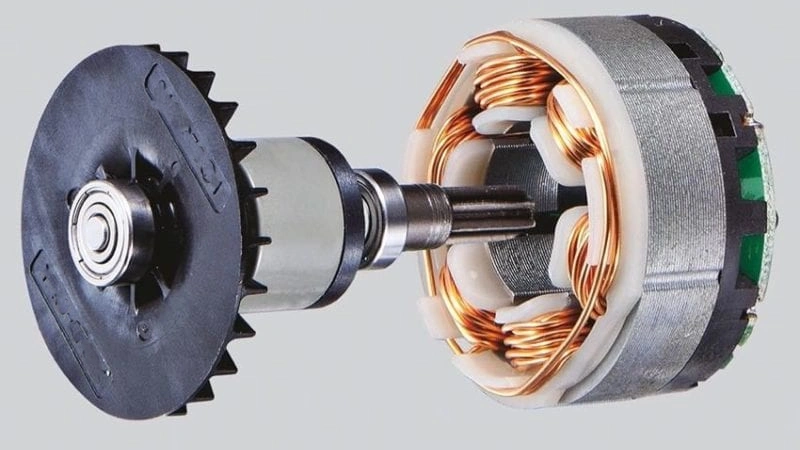

You might wonder what brushless motor meaning is all about. When you look at a brushless motor, you see a design that skips the old-school brushes and uses smart electronics instead. This change makes the motor run smoother and last longer. In simple terms, a brushless motor uses permanent magnets on the rotor and electronic controllers to manage how the motor spins. You get a motor that works with less friction, less heat, and more reliability.

Here’s a quick look at what sets brushless motors apart from other types:

| Component | Description |

|---|---|

| Absence of Brushes | Brushless motors do not use brushes, unlike brushed motors. |

| Permanent Magnets on Rotor | The rotor contains permanent magnets, which is a key feature of brushless motors. |

| Electronic Controllers | These controllers manage the commutation electronically, replacing mechanical parts. |

You’ll often hear people call these motors BLDC or electronically commutated motor. The brushless motor meaning centers on the idea of using electronics to control the motor’s movement, which boosts efficiency and cuts down on maintenance.

Key Features

Let’s talk about the features that make brushless motors stand out. You get a bunch of benefits when you choose this technology for your cooling systems or industrial equipment.

- Electronic commutation gives you precise control over speed and torque.

- Energy efficiency means you save on power bills and reduce waste.

- High power density lets you pack more performance into a smaller space.

- Minimal maintenance keeps your downtime low and your equipment running longer.

- Superior torque-to-watt and torque-to-weight ratios help you get more work done with less energy.

- Reduced acoustic noise creates a quieter environment, which is great for offices or sensitive areas.

- Exceptional reliability means you can trust your motor to keep working day after day.

You’ll notice that a brushless dc electric motor uses electronic controls and permanent magnets. This setup allows you to manage the current flow with precision, making the motor much more efficient than older brushed designs. BLDC motors also have a compact design and lighter weight, so you can fit them into tight spaces without sacrificing performance.

When you look at the brushless motor meaning, you see a focus on smarter technology, better efficiency, and longer life. You get a motor that’s built for today’s demands, whether you need it for cabinet fans, computer chassis fans, or other industrial uses.

Brushless DC Electric Motor Basics

How It Works

When you look at a brushless dc electric motor, you see a smart design that puts precision at the center of everything. Instead of using brushes, this motor relies on an electronic speed controller and sensors to manage how the motor spins. You get precision control over speed and torque, which means you can fine-tune performance for any application. The controller sends electric current to the right coils at the right time, always matching the rotor’s position. This approach gives you a level of precision that brushed motors just can’t match.

Here’s what electronic commutation brings to the table:

- Precise control of torque and speed, so you always get the performance you want.

- Efficiency and power consumption stay low, which saves you energy.

- Smooth operation and reduced noise, making your equipment quieter.

- High-speed capability, letting you run the motor faster without worrying about wear.

You’ll notice that a bldc motor can handle rapid changes in speed and direction. This makes it perfect for applications where precision and reliability matter most. The electronic speed controller works with sensors to keep everything running smoothly, so you get consistent results every time.

Construction

The construction of a brushless dc electric motor sets it apart from older designs. You’ll find permanent magnets on the rotor and a wound laminated core on the stator. The control mechanism uses magnetic sensors and a drive circuit, which gives you even more precision. Take a look at how this compares to a brushed motor:

| Motor Type | Rotor Construction | Stator Construction | Control Mechanism |

|---|---|---|---|

| Brushed DC motor | Wound laminated core | Permanent magnet | Brushes and commutator |

| Brushless DC motor | Permanent magnet | Wound laminated core | Magnetic sensor and drive circuit |

The materials used in a bldc motor make a big difference. Strong magnets, like neodymium, keep their strength for years. Durable bearings cut down on friction and wear, which means your motor lasts longer. If you use high-quality components, you get better efficiency and a longer lifespan. On the other hand, poor materials can cause early failure, so it pays to choose a motor built with precision in mind.

When you pick a brushless dc electric motor, you’re choosing a solution that delivers precision, reliability, and long-term value. You get a motor that’s ready for demanding jobs, whether you need it for cooling, automation, or any application where precision control is key.

Brushless Motors vs Brushed Motors

Main Differences

When you compare brushless motors to brushed motors, you notice some big changes right away. Brushless motors use electronic commutation, which means they do not have brushes that wear out. This design cuts down on friction and makes the motor run more efficiently. You get smoother speed control and a much longer service life. Brushed motors, on the other hand, rely on physical brushes that touch the spinning part of the motor. These brushes wear down over time, which means you need to replace them and deal with more maintenance.

You will see that brushless motors work better in demanding precision applications. They handle high speeds and quick changes without losing performance. You also get less electrical noise, which is important for sensitive equipment. In cooling fan applications, brushless motors convert more electrical energy into useful work. This means less wasted power and lower energy bills for you.

Linkwell uses brushless motors in both its Electrical Enclosure Fan and Computer Chassis Fan products. These fans deliver reliable cooling, low noise, and long-lasting performance. You can trust them for industrial settings where you need consistent airflow and minimal downtime.

Comparison Table

Here’s a quick table to help you see the differences between brushed and brushless motors:

| Aspect | Brushless Motors (BLDC) | Brushed Motors |

|---|---|---|

| Commutation | Electronic, no friction | Mechanical, brush friction |

| Efficiency | 85-90% | 75-80% |

| Speed Control | Smooth, precise, wide range | Less precise, limited range |

| Maintenance | Minimal, no brushes to replace | Frequent, brushes wear out |

| Service Life | 10,000–50,000 hours | 1,000–5,000 hours |

| Electrical Noise | Low | High |

| Cost Over 10 Years | ~30% lower total cost | Higher due to replacements |

| Suitability | Industrial, continuous use | Simple, low-demand uses |

Tip: If you want a fan that lasts longer and saves you money, go with a BLDC motor. You will spend less on maintenance and get better performance.

You can see why Linkwell chooses brushless motors for its fans. These motors give you better efficiency, less noise, and longer life. They are perfect for industrial cooling and cabinet fan systems where you need reliable, precise control.

Pros and Cons of Brushless Motors

Advantages

When you look at the strengths and weaknesses of brushless motors, the advantages really stand out. You get high efficiency and reliable performance, which makes these motors a top choice for cooling systems and industrial equipment. Here’s why you might want to choose brushless motors for your next project:

- You save energy because brushless motors don’t have friction from brushes. This means longer battery life for devices and lower power bills for you.

- The efficiency of brushless precision torque motors can go above 90%. You waste less energy, so your equipment runs cooler and lasts longer.

- Brushless motors offer high efficiency thanks to precise control of current direction. This streamlined operation keeps power consumption low.

- You get a long lifespan since there are no brushes to wear out. Less mechanical wear means fewer repairs and less downtime.

- Brushless precision torque motors deliver smooth and quiet operation. You notice less noise, which is great for offices or sensitive environments.

- Maintenance stays simple. You don’t have to worry about replacing brushes or dealing with frequent breakdowns.

- BLDC motors give you accurate control over speed and torque. This helps you fine-tune performance for different tasks.

- Brushless precision torque motors work well in industrial cooling systems. You get reliable airflow and consistent results.

If you want a motor that combines high efficiency, low maintenance, and a long lifespan, brushless motors are hard to beat.

Disadvantages

You should also consider the strengths and weaknesses of brushless motors before making a decision. Here’s a table showing some common disadvantages:

| Disadvantage | Description |

|---|---|

| Higher Initial Cost | You pay more upfront because BLDC motors need electronic controllers and precise components. |

| Complex Control Systems | These motors require advanced electronic control, which can make design and setup harder. |

| Sensitivity to Environmental Conditions | Extreme temperatures or moisture can affect performance, so you need protective measures. |

| Electromagnetic Interference (EMI) | Electronic switching may cause EMI, which can impact nearby devices unless you use shielding. |

| Maintenance of Controllers | While motors need little maintenance, controllers may need updates and regular checks. |

| Limited Speed Range | BLDC motors sometimes have a smaller speed range, which might not suit every application. |

You might notice that the initial cost is higher for brushless motors. This comes from the added electronics and materials needed for precise control. However, the high efficiency and long lifespan often make up for the extra investment over time.

Main Applications for Brushless Motors

Cabinet Fans and Enclosure Cooling

You see brushless motors everywhere in modern cooling systems. They have become the top choice for cabinet fans and enclosure cooling. Why? You get higher efficiency, less noise, and a longer lifespan compared to traditional motors. When you use a cabinet fan powered by a bldc motor, you notice the difference right away. The fan runs quietly, keeps your equipment cool, and rarely needs maintenance.

Take a look at how brushless motors stack up against traditional motors in cooling applications:

| Feature | Brushless Motors | Traditional Motors |

|---|---|---|

| Mechanical Wear and Tear | None | Present (due to brushes) |

| Efficiency | Higher (no brush losses) | Lower (brush and commutator losses) |

| Lifespan | Extended (no wear components) | Shorter (prone to early failures) |

| Noise Level | Low (minimal electrical noise) | High (electrical noise present) |

| Maintenance | Less frequent | More frequent |

| Speed Control | Precise (PWM control) | Less precise |

You get precise control over airflow and temperature, which is essential for protecting sensitive electronics inside enclosures. With less mechanical wear, your fans last longer and keep your systems running smoothly.

Linkwell Electrical Enclosure Fan

Recommended products

If you want a reliable cooling solution for your electrical cabinets, Linkwell’s Electrical Enclosure Fan stands out. This fan uses advanced brushless motors to deliver consistent airflow and efficient cooling. You benefit from a design that reduces energy use and keeps noise levels low—sometimes as quiet as 30 decibels. That means a more comfortable work environment and less distraction.

Linkwell’s fans come with certifications that prove their quality and safety:

| Certification | Description |

|---|---|

| ISO | Certified materials used in manufacturing |

| CE | Compliance with European safety standards |

| UL | Underwriters Laboratories certification for safety |

| cUL | Canadian counterpart of UL certification |

You can trust these fans in tough industrial settings. They handle high temperatures, resist dust and moisture, and work well with climate control systems. When you connect them to thermostats or hygrostats, you get automated cooling that responds to real-time conditions. This integration helps you maintain the perfect environment for your equipment, reducing the risk of overheating and costly downtime.

Tip: Linkwell’s enclosure fans require up to 80% less maintenance than traditional options, saving you time and money.

Linkwell Computer Chassis Fan

You also find brushless motors at the heart of Linkwell’s Computer Chassis Fan. These fans keep your servers, workstations, and industrial computers cool—even under heavy loads. You get powerful airflow, ultra-low noise, and energy savings of up to 55%. The advanced PWM control lets you fine-tune fan speed based on system needs, so you always get the right balance of cooling and quiet.

Linkwell’s chassis fans use industrial-grade materials and offer a long service life. You can install them easily thanks to universal mounting options. They fit perfectly into data centers, electronics manufacturing, and IT equipment assembly lines. With these fans, you protect your valuable hardware and avoid unexpected shutdowns.

Note: BLDC fans from Linkwell consume up to 50% less power than traditional fans, leading to real savings on your electricity bills.

Other Industrial Uses

Brushless motors do more than just cool cabinets and computers. You see them in many other industrial applications because of their efficiency and reliability. Here are some common uses:

- Precision devices: Hard drives, DVD players, and Blu-Ray recorders rely on brushless motors for smooth disk rotation.

- Automotive applications: Electric power steering, headlamp leveling, and door lock motors all use these motors for precise movement.

- Commercial electrical products: Laser printers, drones, and power tools benefit from the durability and control that brushless motors provide.

In industrial settings, you often find brushless motors integrated with climate control systems. These motors give you better control over airflow and temperature regulation. The main components—a rotor with permanent magnets, a stator with copper coils, and a feedback sensor—work together to deliver precise performance. This setup helps you maintain optimal climate conditions, which is crucial for sensitive equipment and processes.

When you choose brushless motors for your industrial applications, you enjoy several benefits:

- Consistent airflow for efficient ventilation.

- Minimal maintenance, with up to 80% fewer service calls.

- Noise reduction, creating a more comfortable workspace.

You also get:

| Benefit | Description |

|---|---|

| Efficiency | Consumes less energy while providing the same or greater airflow, leading to cost savings. |

| Reliability | Known for low failure rates due to the absence of brushes, crucial for minimizing downtime. |

| Reduced Maintenance | Requires less maintenance compared to traditional fans, saving time and costs in industrial settings. |

| Quiet Operation | Operates quietly, creating a comfortable work environment. |

| Long Lifespan | Longer operational lifespan reduces the need for frequent replacements. |

| Environmental Benefits | Contributes to lower energy consumption and greenhouse gas emissions. |

You see brushless motors powering the future of industrial cooling and automation. They help you save energy, reduce maintenance, and keep your operations running smoothly. Whether you need them for cabinet fans, computer chassis fans, or other precision devices, these motors deliver the performance and reliability you expect.

You now know that brushless motors bring you higher efficiency, longer life, and quieter operation. These motors cut energy use by up to 30% and last much longer than traditional designs. Linkwell’s fans use this technology to give you reliable, low-maintenance cooling for cabinets and industrial spaces.

- You save on energy bills and reduce repairs.

- Fans run quietly and need less upkeep.

- Smart controls help you manage cooling with ease.

| Advantage | Description |

|---|---|

| Higher Efficiency | Uses less energy, saves money |

| Longer Lifespan | Runs longer with fewer breakdowns |

| Eco-Friendly | Supports sustainability and lower emissions |

Choose Linkwell for cooling solutions that keep your equipment safe and your costs down.

FAQ

What makes a brushless motor different from a brushed motor?

You won’t find brushes in a brushless motor. Instead, it uses electronic controls for smoother, quieter, and more efficient operation. This design means less maintenance and a longer lifespan for your equipment.

Why should I choose a brushless motor for my cabinet fan?

You get better energy savings, less noise, and longer service life. Brushless motors also need less maintenance, so you spend less time worrying about repairs and more time focusing on your work.

How long does a brushless motor usually last?

Most brushless motors run for 10,000 to 50,000 hours. You can expect years of reliable service, especially if you keep your equipment clean and follow basic maintenance tips.

Can I use Linkwell’s brushless fans in harsh environments?

Absolutely! Linkwell’s fans come with weatherproof housing and certifications like CE and UL. You can trust them to handle dust, moisture, and high temperatures in industrial or telecom settings.