Understanding the distinctions between cable trays and raceways is crucial for effective cable management. While both serve to support and organize cables, their design, application, and level of protection offered vary significantly, influencing their suitability for different environments.

This guide will delve into the core differences between cable trays and raceways, exploring their respective advantages and ideal use cases. Choosing the right solution ensures optimal cable performance, safety, and long-term reliability for your infrastructure.

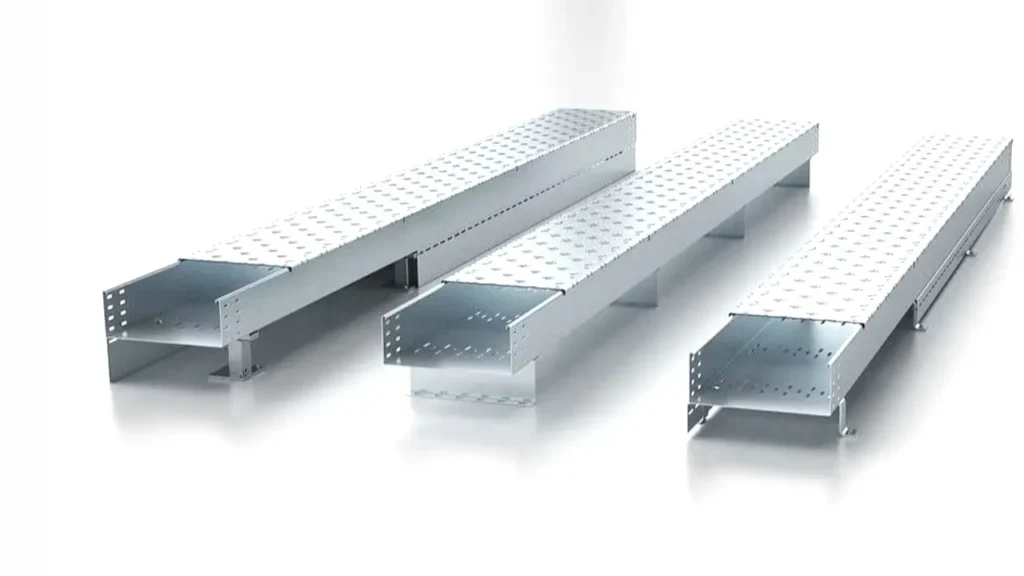

What is a Cable Tray?

A cable tray is a rigid structural system used in the electrical wiring of buildings and other structures to support and organize insulated electrical cables for power distribution, control, and communication. Unlike raceways that completely enclose cables, cable trays provide an open, accessible pathway, resembling a “bridge” for wires.

This design offers advantages such as easier installation, maintenance, and modification of wiring systems, as new cables can simply be laid into the tray rather than pulled through a conduit. Cable trays come in various types, including ladder, solid-bottom, perforated, wire mesh, and channel, and are made from materials like galvanized steel, stainless steel, aluminum, or fiberglass, chosen based on the specific application and environmental conditions.

What is a Cable Raceway?

A cable raceway is a specialized channel or enclosure designed to meticulously organize, protect, and discreetly conceal electrical wiring, data cables, and power cords. Typically fabricated from materials like plastic (such as PVC), metal, or even fiberglass, these systems offer a neat and secure solution for managing cables within residential, commercial, and industrial settings.

Their primary functions include preventing unsightly tangles, eliminating tripping hazards, safeguarding cables from physical damage, dust, and moisture, and contributing to a more professional and aesthetically pleasing environment.

Available in diverse shapes, sizes, and installation configurations—ranging from simple adhesive-backed surface mounts to robust corner ducts—cable raceways provide a highly versatile and efficient means to manage a wide array of cabling requirements.

Cable Tray vs Raceway

Cable trays are indispensable in modern electrical infrastructure, providing crucial support and organization for a wide array of cables. They offer a flexible and efficient alternative to traditional conduit systems.

Types of Cable Trays

Ladder type cable trays consist of two longitudinal side rails connected by individual rungs, resembling a ladder. This design allows for maximum ventilation, which is crucial for dissipating heat from cables, especially in high-current applications. The open design also makes it very easy to drop cables in and out at any point along the tray, facilitating quick installations, modifications, and maintenance.

Solid bottom cable trays, also known as trough trays, feature a continuous bottom surface with no perforations or rungs. This design offers the best protection for cables against dust, dirt, and moisture accumulation, making them suitable for sensitive environments or where cables need to be shielded from external elements. However, the lack of ventilation means they are less ideal for applications with high heat dissipation requirements, as heat can become trapped within the tray.

Materials

Galvanized steel is a widely used material for cable trays due to its excellent strength and corrosion resistance. The galvanization process involves coating the steel with a layer of zinc, which acts as a sacrificial barrier against rust. This makes galvanized steel trays suitable for both indoor and outdoor applications, providing a durable and cost-effective solution for many industrial and commercial settings.

Stainless steel cable trays offer superior corrosion resistance, particularly in harsh environments involving chemicals, saltwater, or extreme temperatures. While more expensive than galvanized steel, their longevity and ability to withstand aggressive conditions make them a preferred choice for specialized applications such as food processing plants, marine environments, and chemical facilities. They are also aesthetically pleasing, making them suitable for visible installations.

Load Capacity

The load capacity of a cable tray refers to the maximum weight of cables it can safely support over a given span. This is a critical design consideration, as exceeding the load capacity can lead to structural failure, posing safety hazards and damaging cables. Proper calculation of cable weight, including future expansion, is essential to ensure the longevity and reliability of the cable tray system.

Factors influencing load capacity include the tray’s material, its cross-sectional area, and the support span lengths. Engineers must carefully consider these variables, often referring to industry standards and manufacturer specifications, to select a tray system that can adequately handle the anticipated cable weight and dynamic loads, such as those from maintenance activities.

Installation and Accessibility

Cable tray installation involves mounting the trays to ceilings, walls, or other structures using various support methods like trapeze hangers, brackets, or central support systems. Proper installation ensures the stability and safety of the cable management system. The open design of many cable tray types significantly simplifies the process of laying cables, reducing installation time and labor costs compared to pulling cables through conduits.

The accessibility offered by cable trays is a major advantage for maintenance and future modifications. Technicians can easily inspect, add, or remove cables without disrupting the entire system. This flexibility is particularly beneficial in dynamic environments where wiring changes are frequent, allowing for quick adaptations to evolving power and data requirements.

Ventilation

Ventilation in cable trays is crucial for managing heat generated by electrical currents flowing through cables. Adequate airflow prevents heat buildup, which can degrade cable insulation over time and reduce the lifespan of the cables. Ladder and perforated cable trays are designed with open structures to maximize air circulation, promoting efficient heat dissipation, particularly important for power cables carrying significant loads.

In contrast, solid bottom trays offer minimal ventilation, making them less suitable for applications where heat is a major concern. When using solid bottom trays for heat-generating cables, it’s often necessary to derate the cables (reduce their current carrying capacity) or implement additional cooling measures to prevent overheating. Proper ventilation selection is a key factor in ensuring the long-term performance and safety of the electrical system.

| Feature | Ladder Type Cable Tray | Solid Bottom Cable Tray |

| Primary Advantage | Excellent ventilation, easy cable access/modification | Best cable protection from dust/moisture |

| Ventilation | High | Low |

| Cable Protection | Moderate (open design) | High (enclosed bottom) |

| Installation Flexibility | High (cables can be dropped in anywhere) | Moderate (cables must be pulled through) |

| Heat Dissipation | Very Good | Poor (can trap heat) |

How to Choose Cable Tray and Raceway

Selecting the appropriate cable management system, whether a cable tray or a raceway, depends heavily on the specific application requirements, environmental conditions, and future expandability needs. It is crucial to assess factors like the volume and type of cables, the level of protection required, and the available space to make an informed decision that optimizes both performance and cost-effectiveness for the electrical infrastructure.

Careful consideration of the environmental factors, such as the presence of dust, moisture, or corrosive agents, is also paramount in choosing the right material and type of enclosure for long-term reliability.

Cable Type and Quantity:

- Cable Tray: Ideal for a large number of power and control cables, especially when future expansion or frequent modifications are anticipated. Its open design simplifies adding or removing cables.

- Raceway: Better suited for a limited number of sensitive data or communication cables, offering superior protection against external interference and physical damage, ensuring signal integrity.

Environmental Conditions:

- Cable Tray: Appropriate for indoor and outdoor use, with material selection (e.g., galvanized, stainless steel) crucial for resisting corrosion in various environments, including industrial settings.

- Raceway: Preferred in environments where cables require maximum protection from dust, moisture, or chemical exposure, often sealed to prevent ingress, safeguarding critical wiring.

Protection Requirements:

- Cable Tray: Provides physical support and organization but offers less protection against impact or electromagnetic interference. Additional covers can be added for some shielding.

- Raceway: Offers excellent mechanical protection and can be specified with shielding capabilities against electromagnetic interference, vital for sensitive electronic circuits.

Ventilation and Heat Dissipation:

- Cable Tray: Designs like ladder or perforated trays promote excellent airflow, crucial for dissipating heat from power cables, preventing overheating and extending cable lifespan effectively.

- Raceway: Enclosed nature can trap heat; therefore, careful consideration of cable fill ratios and potential for heat buildup is necessary, sometimes requiring derating of cables.

Installation and Maintenance:

- Cable Tray: Generally easier and faster to install, especially for large cable runs, and provides straightforward access for future maintenance, inspections, and modifications without major disruptions.

- Raceway: Installation can be more labor-intensive due to the need to pull cables through, and accessing cables for maintenance or changes requires opening the raceway, potentially taking more time.

Cost Considerations:

- Cable Tray: Often more cost-effective for large-scale installations due to simpler design and quicker installation times, leading to lower labor costs per linear foot.

- Raceway: Can be more expensive per linear foot due to material costs and more intricate installation procedures, but the added protection can justify the investment for critical applications.

Conclusion

Choosing between cable trays and raceways boils down to the specific demands of your project. Cable trays excel in high-capacity, flexible routing with easy access for changes, making them perfect for industrial and data center environments where adaptability is key.

Conversely, cable raceways offer enclosed protection and a more aesthetically pleasing solution, ideal for environments where safety from physical contact, dust, and a clean appearance are paramount, such as offices and residential settings.

For all your cable management needs, including high-quality wholesale cable raceways, consider Linkwell Electrics. They provide reliable solutions to ensure your electrical infrastructure is organized, safe, and efficient.