Cable management is crucial in any electrical installation, ensuring safety, organization, and efficient maintenance. Two primary systems, cable trunks and cable trays, fulfill this role but differ significantly in design and application. Understanding these distinctions is vital for selecting the appropriate solution for a given project.

While both cable trunks and cable trays aim to support and protect electrical wiring, their fundamental structures dictate their suitability for various environments. Cable trunks provide an enclosed, often sealed pathway, offering maximum protection, whereas cable trays feature an open design that prioritizes ventilation and easy access. This core difference impacts everything from installation to the type of cables they can safely manage.

What Is Cable Trunking?

Recommended Cable Trunking

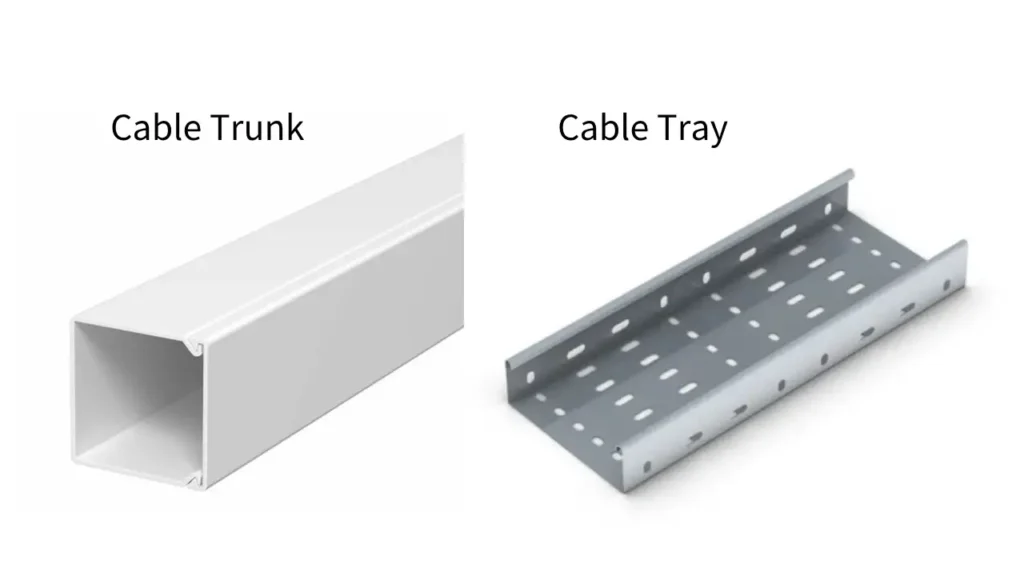

Cable trunking is an enclosed conduit system designed to house, protect, and organize electrical cables and wires within a building or structure.

Typically rectangular or square in cross-section and made from materials like uPVC or metal, it provides a safe and tidy pathway for wiring, preventing tangles, protecting cables from damage, and improving the overall aesthetic of an installation. Its primary function is to manage and conceal wiring, ensuring safety and ease of maintenance in various environments, from residential to industrial.

Cable Trunk Uses

Cable trunking serves a wide array of practical applications, primarily centered on creating organized, protected, and accessible pathways for electrical and data cables. It is a versatile solution employed in various environments to enhance safety, improve aesthetics, and facilitate efficient maintenance of wiring infrastructure.

Key uses of cable trunking include:

- Residential Buildings: For concealing and protecting wiring for lighting, power outlets, and entertainment systems, ensuring a neat and safe environment. This includes skirting trunking or dado trunking that blends with interior design.

- Commercial Offices: Managing power, data, and communication cables for workstations, servers, and telecommunication equipment, promoting a professional and organized workspace. Compartmentalized trunking is often used to segregate different cable types.

- Industrial Facilities: Providing robust protection for power and control cables in factories, warehouses, and manufacturing plants, shielding them from physical damage, dust, and harsh environmental conditions.

- Healthcare Facilities: Routing critical power and communication cables in hospitals and clinics, where hygiene, safety, and easy access for maintenance are paramount.

- Educational Institutions: Organizing network and power cables in classrooms, laboratories, and administrative areas, supporting IT infrastructure and maintaining a tidy learning environment.

- Retail Spaces: Discreetly managing wiring for lighting, POS systems, and security cameras, contributing to a clean and appealing store layout.

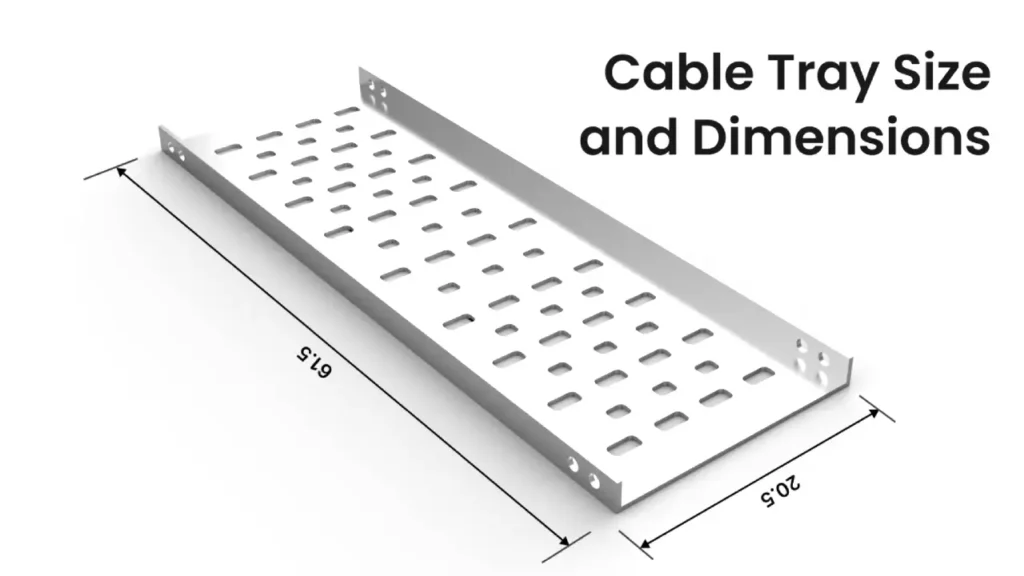

What is a Cable Tray?

A cable tray is an open support system used in electrical wiring of buildings and industrial facilities to support and organize insulated electrical cables for power distribution, control, and communication.

Unlike enclosed trunking, cable trays have a U-shaped, ladder-like, or perforated design, which allows for excellent ventilation, preventing heat buildup in large cable bundles. This open structure also provides easy access for installing, modifying, or repairing cables, making it a highly versatile and cost-effective solution for managing extensive and evolving cabling infrastructure.

Cable Tray Uses

Cable trays are widely utilized in various industries and settings for supporting and organizing electrical cables. Their open design and robust construction make them ideal for applications requiring efficient cable management, heat dissipation, and easy accessibility for maintenance and future modifications.

Key uses include:

- Industrial Facilities: Factories, manufacturing plants, and processing facilities use cable trays to route large volumes of power, control, and instrumentation cables for machinery and production lines.

- Data Centers: Essential for managing dense networks of data and power cables, cable trays facilitate airflow to prevent overheating of sensitive equipment and allow for quick upgrades.

- Commercial Buildings: Offices, hospitals, schools, and shopping centers use cable trays for organized routing of electrical power, lighting, communication, and security system cables, often in suspended ceiling spaces.

- Power Generation and Distribution: In power plants and substations, cable trays are crucial for managing high-voltage cables, ensuring safety, and efficient power transmission.

- Outdoor and Harsh Environments: Galvanized steel, aluminum, or fiberglass cable trays are employed outdoors or in corrosive environments where their durability and resistance to elements are beneficial.

- Telecommunications: Cable trays support extensive networks of fiber optic and copper communication cables in central offices, server rooms, and large communication hubs.

Cable Trunk vs Cable Tray

Cable trunks and cable trays both manage electrical cables, but they are fundamentally different in design and application. Understanding these distinctions is crucial for selecting the appropriate cable management system for any given project.

Design and Structure

Cable trunking is an enclosed system, typically featuring a solid base and a removable lid, creating a fully contained channel for cables. This design prioritizes the complete encapsulation of wiring, offering a high degree of protection from external elements and providing a very neat, discreet appearance.

In contrast, a cable tray is an open support system, resembling a ladder or a perforated trough, designed to support cables without fully enclosing them. This open structure is crucial for ventilation and allows for easier addition or removal of cables compared to the enclosed nature of trunking.

Cable Protection

Cable trunking offers superior protection against physical damage, dust, moisture, and accidental contact with live wires due to its enclosed structure. This makes it a preferred choice in environments where cables are vulnerable or where aesthetic considerations demand that wiring remain unseen and untouched.

Cable trays provide good mechanical support for cables but offer less protection against environmental factors like dust or moisture. Their primary role is to bear the weight of cables and route them efficiently, especially in areas where cables are less exposed to direct physical harm.

Ventilation and Heat Dissipation

One of the most significant differences lies in ventilation. Cable trays, with their open design, allow for excellent airflow around cables, facilitating heat dissipation. This is vital for managing large bundles of power cables that generate considerable heat, preventing overheating and ensuring cable longevity.

Cable trunking, being an enclosed system, can trap heat, which might be a concern for high-density or high-current cable runs. While some trunking designs incorporate ventilation slots, they generally do not match the airflow capabilities of open cable trays, making them less suitable for applications prone to significant heat buildup.

Installation Environment

Cable trunking is often chosen for indoor, visible areas such as offices, commercial spaces, and residential buildings where aesthetics are important, and where cables need to be hidden and protected from casual interaction. It is also used in light industrial settings for organized and protected low-voltage wiring.

Cable trays are typically found in industrial environments, data centers, power plants, and large commercial facilities. Their robust construction and ability to handle heavy cable loads make them ideal for infrastructure where extensive and potentially high-voltage cabling needs to be routed, often in overhead or less aesthetically critical areas.

Accessibility and Future Expansion

Cable trays offer superior accessibility for maintenance, additions, or reconfigurations of cables. Their open design allows technicians to easily lay new cables or access existing ones without dismantling the entire system, which is a major advantage in dynamic environments where cabling needs frequent changes.

While cable trunking with removable lids allows for access, adding or removing cables can be more time-consuming and labor-intensive due to the confined space and the need to open and re-secure covers along the route. This can limit its flexibility in situations requiring frequent modifications.

| Aspect | Cable Tray | Cable Trunking |

| Design and Structure | Open, U-shaped, ladder-like, or perforated | Enclosed, box-like with solid base and removable lid |

| Cable Protection | Moderate; primarily for support; less against dust/moisture | High; excellent against dust, moisture, physical impact |

| Ventilation | Excellent; allows superior heat dissipation | Limited; can trap heat (unless specifically ventilated) |

| Installation Environment | Industrial, data centers, outdoor, heavy-duty | Residential, commercial, light industrial, visible indoor areas |

| Accessibility & Expansion | Easy for additions/modifications; flexible | Moderate; requires lid removal; less straightforward for changes |

| Primary Function | Support and route large volumes of cables with good airflow and access | Protect and conceal cables, providing a neat and safe enclosed pathway |

How to Choose Cable Trunk and Cable Tray

Choosing between cable trunking and cable trays requires a careful assessment of the specific needs of your electrical installation. Consider the environmental conditions, the types and volume of cables, and the desired level of protection and accessibility. A thoughtful decision ensures optimal performance, safety, and cost-effectiveness for your cabling infrastructure.

Key considerations for selection include:

- Environmental Conditions: For environments with high dust, moisture, or potential for physical impact, cable trunking is generally preferred due to its enclosed design, offering superior protection against external elements. Conversely, outdoor or industrial settings exposed to harsh conditions often benefit from the robust construction of metal cable trays.

- Cable Type and Volume: If you are managing a large volume of power cables that generate significant heat, cable trays are the better choice. Their open design facilitates excellent ventilation, preventing overheating and ensuring the longevity of the cables. For smaller bundles of control or data cables, especially where aesthetics are important, trunking often suffices.

- Protection Requirements: When maximum protection from physical damage, tampering, or contaminants is paramount, such as in public areas or sensitive environments, cable trunking provides a secure, enclosed pathway. If the primary concern is mechanical support for heavy cable loads in less exposed areas, cable trays are highly effective.

- Accessibility and Future Expansion: For installations where frequent additions, modifications, or maintenance of cables are anticipated, the open design of cable trays offers significantly easier access and flexibility. Cable trunking, while accessible, can be more time-consuming for reconfigurations due to its enclosed nature and lid removal.

- Aesthetics and Space Constraints: In visible areas like offices, retail spaces, or homes, cable trunking provides a neat, discreet, and aesthetically pleasing solution by concealing wiring. Cable trays, being more industrial in appearance, are typically used in less visible areas such as ceilings, basements, or dedicated electrical rooms.

- Cost and Installation: Consider the overall cost, including material and labor. For extensive runs with numerous cables, cable trays can sometimes be more cost-effective and quicker to install. Trunking might involve more precise cutting and fitting, potentially increasing labor, but offers specific benefits that justify the cost in certain applications.

Conclusion

Both cable trunks and cable trays are essential for cable management, but they cater to distinct needs. Cable trunks offer complete enclosure, providing superior protection from dust, moisture, and impact, ideal for environments prioritizing aesthetics and maximum cable safeguarding. Conversely, cable trays are open structures, excelling in ventilation and accessibility, making them perfect for large cable volumes in industrial settings where heat dissipation is critical.

The choice between a cable trunk and a cable tray ultimately depends on the specific application’s requirements. Consider the environment, the level of cable protection needed, heat dissipation demands, and future accessibility. For robust protection and a neat finish, trunking is often preferred; for high-volume, accessible, and well-ventilated cable routing, trays are the better solution.

For those seeking quality cable management solutions, you can acquire wholesale cable trunking systems from Inkwell Electrics, ensuring reliable and efficient electrical installations.