A control cabinet heater keeps control panels safe from water and heat. Many factories have problems like water leaks or electrical issues. A control cabinet heater stops these problems and helps protect the electrical cabinet. Companies that use these heaters have fewer breakdowns and their equipment lasts longer. Every system needs to work well and be reliable.

Control Cabinet Heater for Temperature Stability

Maintain a Stable Equipment Temperature

A control cabinet heater helps keep the inside temperature steady. If the temperature changes too fast, parts can break or stop working. Heaters make sure the air inside stays warm and even. This stops cold spots and keeps everything the same temperature.

Researchers say steady temperatures protect equipment. A study in Nature Communications shows that special materials and heaters can keep containers at a steady temperature. These systems use smart designs and careful control to stop big heat changes. The same idea works in control cabinets. Using a control cabinet heater helps companies avoid sudden temperature changes that can hurt equipment.

Many heaters have fans or blowers to move warm air around. This helps all parts get the same heat. Some heaters use thermostats or sensors. These tools turn the heater on or off to keep the temperature right. When the temperature stays steady, there is less risk of damage from heat or cold.

Extend The Service Life of Components

Steady temperatures help electrical parts last longer. If parts get too hot or cold, they wear out faster. A control cabinet heater keeps the temperature safe for these parts. This means wires, circuit boards, and connectors do not get stressed by changing temperatures.

Experts found that good heating systems use special controls to keep the temperature steady. Devices like thermostats and sensors watch the temperature and change the heater as needed. This careful control stops parts from getting too hot or cold. Because of this, the equipment inside the cabinet works better and lasts longer.

Longer equipment life saves money and time. Companies do not need to replace parts as much. They also avoid expensive repairs and downtime. By using a control cabinet heater, they protect their investment and keep their systems working well.

Benefits of Control Cabinet Heater

Preventing Downtime

Electrical failures can stop machines and cause expensive delays. Control cabinet heaters help machines keep working by stopping moisture and big temperature changes. When the heater keeps the cabinet warm and dry, water cannot collect on wires or metal parts. This stops rust and corrosion, which can cause short circuits or broken connections.

Many companies use heaters with thermostats or hygrostats built in. These devices turn the heater on or off by themselves. They keep the air inside the cabinet at a safe level. Workers do not have to check the cabinet all the time. The system protects itself, even if the weather changes fast.

Some heaters, like resistance heaters and PTC ceramic heaters, work in different ways to keep the temperature steady. Resistance heaters give simple, steady heat. PTC ceramic heaters change their heat as needed, saving energy and stopping overheating. Both types help stop downtime by keeping the cabinet safe for sensitive electronics.

Reliable Performance

A control cabinet heater helps machines work well in many ways. It keeps the temperature and humidity steady, which protects important parts from damage. Heaters with smart features, like thermostats and automatic controls, make sure the cabinet stays safe without extra work.

- Heaters keep the temperature steady and stop condensation.

- They protect electrical parts from cold and wet air.

- Automatic controls keep the cabinet safe for sensitive equipment.

- Easy setup and strong connections make things safer and more reliable.

Companies like LINKWELL and STEGO make heaters for tough places. Their heaters work well in very cold or very wet areas. For example, the STEGO CS 032 heater series keeps cabinets safe from -45°C to +70°C and humidity up to 90%. These heaters help stop problems and keep systems working well.

When companies use a control cabinet heater, their machines work better. Machines last longer and do not stop as often. This means less time fixing things and more time with machines working right.

Safety Benefits

Enclosure heaters protect more than just equipment. They also help keep workers safe. These heaters lower the chance of problems in electrical panels. Here are some ways they help:

- Heaters with thermostats keep the temperature steady. This stops moisture from breaking insulation and causing short circuits.

- Good insulation and steady heat keep wires safe from hot or cold. This keeps the insulation strong.

- Workers are safer because the risk of shocks or fires goes down.

- The chance of fire or explosion is lower when heaters stop water and cold from hurting insulation.

Enclosure heaters are important for keeping equipment and people safe. They help stop accidents and keep the workplace running smoothly.

Fewer Repairs

Enclosure heaters keep panels dry and warm. Dry panels stop wires and metal from rusting. This means workers fix fewer problems. Companies see that panels with heaters need less care. Heaters stop water from getting inside the cabinet. They also keep the temperature steady, so parts do not break.

A steady place helps all parts last longer. Workers do not need to change wires or boards as much. This saves time and keeps machines working. Many factories use enclosure heaters to stop surprise breakdowns. When equipment works well, workers can do other jobs.

Cost Savings

Needing less maintenance saves companies real money. When repairs are rare, companies spend less on parts and work. A study by Lawrence Berkeley National Laboratory found electric heat pumps, like enclosure heaters, cut maintenance costs by about 30% compared to gas furnaces. This shows electric heating systems help save money.

Another case study looked at Cambridge S-Series enclosure heaters. After using these heaters, the company saw costs drop from $1.12 to $0.65 per square foot. Over 20 years, this saved up to $1.54 million. The savings came from fewer repairs and long-lasting heaters.

Enclosure heaters help companies save money over time. They protect equipment and lower repair needs. Companies using these heaters see fewer problems and more savings each year.

Electric Enclosure Heater in Harsh Environments

Cold and Humid Conditions

Factories and outdoor areas can get very cold and wet. This kind of weather can hurt electrical panels and slow down jobs. An electric enclosure heater keeps the cabinet warm and dry inside. This stops water from getting on wires and metal parts. If it gets colder than 20°F, pipes and equipment might freeze and break. Heaters help keep the temperature steady and stop freezing.

- Pipes can freeze and burst if it is under 20°F.

- Heating systems keep equipment and materials safe from freezing.

- Some things, like adhesives, need to be warmer than 50°F to work right.

- Cold and wet air makes paint and drywall dry slower, but heaters help keep the air dry.

- The right temperature and humidity stop water damage and help work go faster.

Heaters also stop water drops from forming inside the cabinet. Warm air touching a cold surface can make water appear. This water can cause rust or electrical problems. Heaters keep the air inside warm, so this does not happen. This helps machines last longer and work better.

Outdoor Applications

Outdoor electrical panels have to deal with dust, rain, and big changes in temperature. Companies use special designs so heaters work well outside. Stainless steel hinges and latches help stop rust. Good gaskets, like silicone, keep water and dust out. Coatings that stop rust protect cooling parts from bad weather.

Manufacturers test heaters in hard conditions. Some heaters go through an 8-hour dust test with powder. Then, they are put under water for one hour at two meters deep. After these tests, workers check if dust or water got inside. They turn the heaters on to see if they still work. These tests show heaters can handle tough outdoor jobs.

Heaters that meet NEMA, UL, and CSA ratings give extra safety. These standards show the heater can work in tough outdoor places. With these features, companies keep their electrical panels safe and working, even in very harsh places.

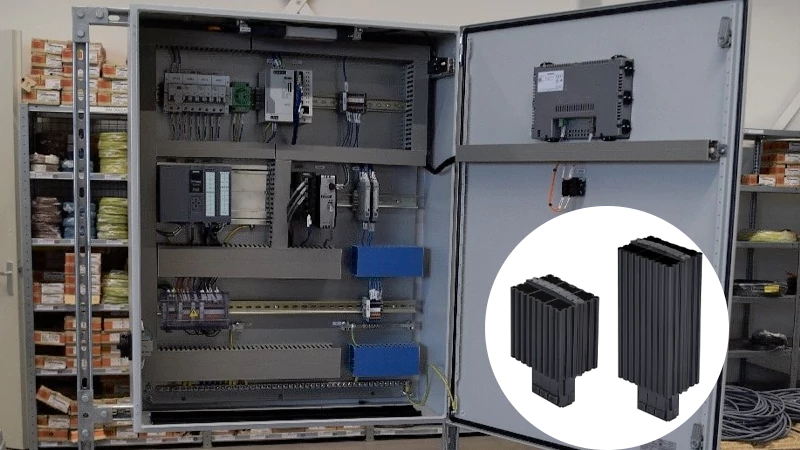

Product Features

The LinkWell LK Series Fan Heater is small and strong. It helps keep control cabinets warm and dry inside. This stops water drops and frost from forming on parts. The built-in fan spreads warm air everywhere. This helps all the parts work better and last longer.

The LK Series has many good features:

- Small size fits in tight spots in panels.

- Clip fixing makes it quick and easy to install.

- No maintenance means you save time and work.

- Long life gives steady performance every year.

Installation and Maintenance

It is easy to install the LK Series Fan Heater. The clip fixing system lets workers attach it to a rail fast. You do not need special tools. The small shape helps it fit in small or crowded spaces.

You do not need to do maintenance on this heater. It is made with strong materials that last a long time. The fan and heater work together to keep air moving and the temperature steady. Workers do not have to check or change parts often. This saves time and lowers the chance of surprise problems.

Why Choose LinkWell

Many companies pick LinkWell heaters because they are high-quality and reliable. The LK Series Fan Heater works in factories and stores. It keeps panels safe from water, frost, and fast temperature changes.

LinkWell makes products for places where you need things to work well and not break. The LK Series helps stop downtime and expensive repairs. It also protects against freezing in tough places. This makes it a smart choice for anyone who wants to keep electrical systems safe and working.

A control cabinet heater helps keep electrical cabinets safe by stopping water drops from forming and keeping panels dry. Almost 70% of panel problems happen because of condensation, but enclosure heaters help stop this and keep equipment safe even when it is very hot or cold.

- Heaters keep the temperature and humidity steady, so there is less rust, corrosion, and fewer short circuits.

- Real-life examples show heaters work well from -34°C to 49°C.

FAQs

What does a control cabinet heater do?

A control cabinet heater keeps the inside of an electrical panel warm and dry. This stops water drops from forming and protects wires and parts from damage.

Why is condensation bad for electrical panels?

Condensation can cause rust and short circuits. Wet parts may stop working or break. Keeping panels dry helps equipment last longer and work safely.

How does the LinkWell LK Series Fan Heater help in cold weather?

The LK Series Fan Heater keeps the air inside the panel warm. This stops frost and freezing. It helps machines work well even when it is very cold outside.

Is the LK Series Fan Heater hard to install?

No, the LK Series Fan Heater uses a clip fixing system. Workers can install it quickly without special tools. The small size fits in tight spaces.

Does the LK Series Fan Heater need maintenance?

The LK Series Fan Heater does not need regular maintenance. It has a strong design and lasts a long time. This saves time and lowers repair costs.