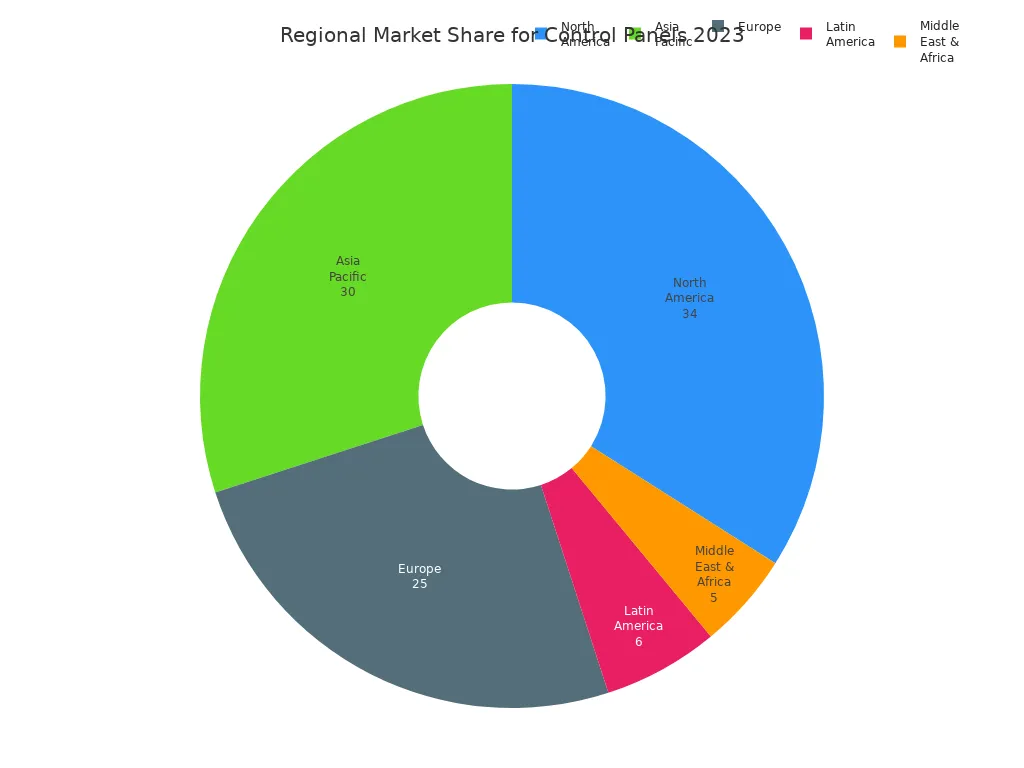

If you’ve ever wondered about the difference between a control panel and an enclosure, you’re not alone. A control panel actively manages and automates your electrical systems, while an enclosure simply protects those components from dust, moisture, and damage. Choosing the right one matters—mixing them up can lead to equipment failure or safety risks. Check out these latest market stats to see why this topic is so important:

| Metric/Aspect | Value/Detail |

|---|---|

| Market Size 2024 | USD 3.5 billion |

| Projected Market Size 2033 | USD 5.2 billion |

| Fastest Growing Region | Asia Pacific (CAGR 6.8%) |

| Largest Application Sector | Energy & Power (38% market share) |

Understanding Control Panels vs Enclosures helps you keep your operations safe and efficient. Linkewell stands out as a trusted provider for both solutions.

Key Takeaways

- Control panels actively manage and automate electrical systems, while enclosures protect these components from dust, moisture, and damage.

- Pairing the right control panel with the right enclosure improves safety, reliability, and makes maintenance easier.

- Control panels contain key parts like circuit breakers and PLCs, while enclosures provide physical protection and meet safety standards like UL and NEMA.

- Choose your solution based on the environment, safety needs, and how often you need to access the equipment.

- Linkewell offers customizable, certified control panels and enclosures that combine smart features with strong protection for various industries.

Control Panels Overview

What Is an Electrical Control Panel?

When you walk into a factory or a big commercial building, you’ll probably see a metal box on the wall filled with switches, wires, and blinking lights. That’s an electrical control panel. It acts as the brain for machines and systems, making sure everything runs smoothly and safely. You’ll find industrial control panels in places like manufacturing plants, water treatment facilities, and even in large HVAC systems. Some panels are open control panels, where the components are exposed for easy access during maintenance. Others are enclosed control panels, which keep everything protected from dust, water, and accidental contact.

Industrial control panels come in many types. Here’s a quick look at the most common ones:

| Panel Type | Description |

|---|---|

| Power Control Center (PCC) Panel | Controls power distribution for large systems, often from 440V to 800V AC. |

| Motor Control Center (MCC) Panel | Manages multiple motors with overload protection and starters. |

| Automation Panel (SCADA PLC Panel) | Uses programmable logic for efficient process control. |

| Intelligent MCC Panel | Adds smart features for centralized motor control and automation. |

You’ll also see open industrial control panels in some settings, but most industries prefer enclosed industrial control panels for better safety and reliability.

Key Components and Functions

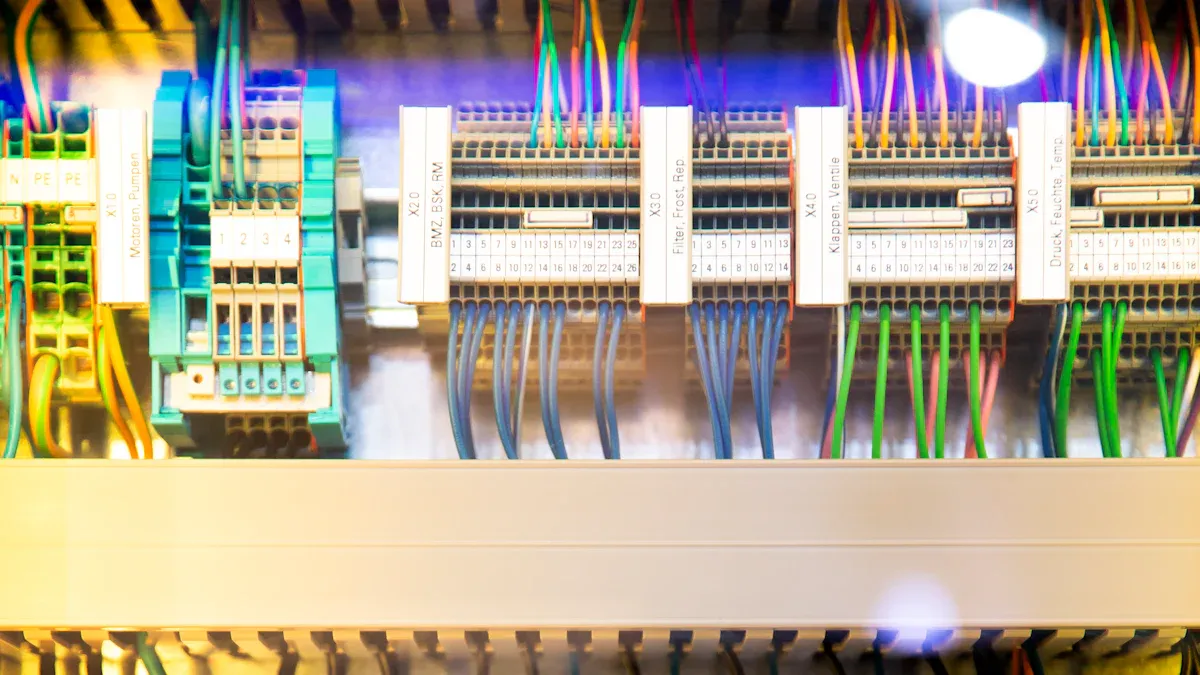

Every electrical control panel has a set of key parts that work together to keep your operations running. Here’s what you’ll usually find inside industrial control panels:

- Circuit breakers, fuses, and surge suppressors for overload protection.

- Power supplies and transformers to provide the right voltage.

- Switches, relays, and contactors to control power flow.

- Terminal blocks for neat and safe wiring.

- Enclosures and grounding panels for safety.

- Human-machine interfaces (HMI) and programmable logic controllers (PLC) for control and monitoring.

- Motor drives and variable frequency drives (VFD) to manage motor speed.

- Wire ducts and DIN rails to organize everything.

These components help industrial control panels handle tasks like switching equipment on and off, protecting against electrical faults, and providing overload protection. You’ll also find enclosed industrial control panels with extra features for harsh environments.

Linkewell Electrical Control Panel Features

If you want reliability, Linkewell’s electrical control panels stand out. They meet top industry standards like UL 508A and IEC 61439. You get enclosures rated for IP65 or higher, so your equipment stays safe from dust and water. Linkewell uses components from trusted brands like ABB, Schneider, and Siemens. Their panels support advanced features such as IoT integration and remote monitoring, making them perfect for modern automation.

“After trying three vendors, we switched to your panels. In two years, zero breakdowns. Your build quality is unmatched.” — Rahul N., HVAC Installer, Singapore

Linkewell’s enclosed industrial control panels go through strict testing and validation, including thermal imaging and 48-hour burn-in tests. You can customize your panel for any application, from open industrial control panels to enclosed industrial control panels for hazardous locations. With Linkewell, you get electrical control panels that deliver safety, efficiency, and peace of mind.

How Control Panels and Enclosures Work Together

Importance of Proper Pairing

You might think a control panel and an enclosure are just two separate things, but they actually work best as a team. When you pair the right control panel with the right enclosure, you get a safer and more reliable setup. The enclosure keeps dust, water, and curious hands away from live wires and sensitive parts. This helps prevent shocks and fires, which means you can trust your system to run smoothly.

A good match also makes your life easier during maintenance. When you open the enclosure, you find all the important parts within easy reach. This smart layout saves time and helps you spot problems before they get serious. You also get better electrical performance because the wiring and grounding stay organized and protected.

Tip: Choosing the right enclosure for your control panel helps you meet safety codes and keeps your equipment running longer, even in tough environments.

Here’s what you gain from proper pairing:

- Safety from accidental contact and electrical hazards

- Protection against dust, moisture, and harsh weather

- Easier maintenance and faster troubleshooting

- Better heat management for sensitive components

- Long-term reliability and lower repair costs

Real-World Use Cases

Let’s look at how this teamwork plays out in real life. In modern factories, smart enclosures with IoT features let you monitor equipment in real time. This means you can fix problems before they cause downtime. For example, in automotive plants, precise control panels inside sturdy enclosures have boosted production speed and cut down on wasted paint.

Solar power companies use advanced control panels in weatherproof enclosures to collect and distribute energy more efficiently. They can even predict when maintenance is needed, which keeps the power flowing and reduces outages. Water treatment plants have also seen big improvements. By automating their systems with well-designed panels and enclosures, they save energy and deliver cleaner water.

No matter the application, a well-paired control panel and enclosure make your operations safer, more efficient, and easier to manage.

Control Panels vs Enclosures

Purpose and Function

When you look at control panels vs enclosures, you see two very different roles in your electrical system. Control panels act as the “brain” of your operation. They manage, automate, and monitor everything from motors to lighting. You find them packed with switches, relays, and controllers that keep your machines running safely and efficiently. These panels can handle simple on/off tasks or run complex automation for entire factories.

On the other hand, electrical enclosures serve as the “body armor.” Their main job is to protect the sensitive parts inside—like your industrial control panels—from dust, water, heat, and accidental bumps. They don’t control or automate anything themselves. Instead, they create a safe space so your equipment can work without interruption. This is one of the key differences you need to know when choosing between control panels vs enclosures for your project.

Think of it this way: the control panel does the thinking, while the enclosure does the shielding.

Components and Safety

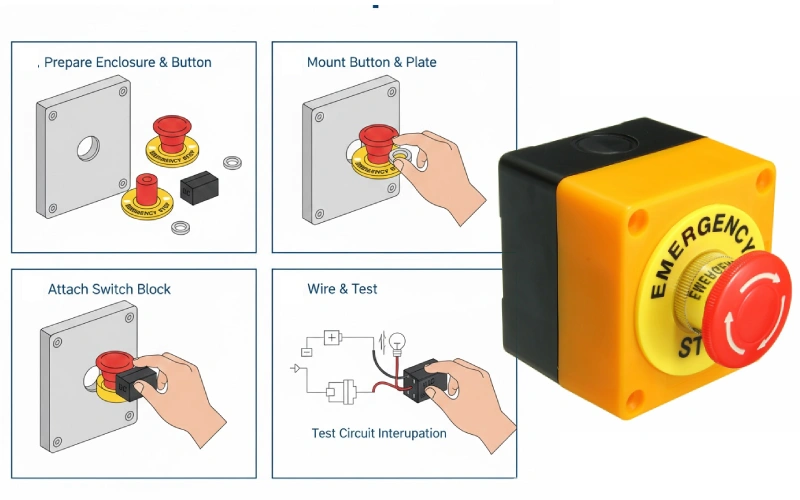

You’ll notice more key differences when you open up an industrial control panel versus an electrical enclosure. Inside a control panel, you find a busy network of components: circuit breakers, PLCs, terminal blocks, relays, and power supplies. These parts work together to control, monitor, and protect your system. Built-in safety features like overload protection and emergency shutoffs help prevent accidents and keep your operation running smoothly.

Electrical enclosures, by contrast, are usually empty when you first get them. Their main components are the physical features—like doors, locks, gaskets, and sometimes racks or shelves. The enclosure’s job is to keep out dust, moisture, and other hazards. You can customize the layout with racks or shelves to fit your equipment. The material—stainless steel, powder-coated steel, or polycarbonate—adds another layer of protection.

Safety standards matter here. Control panels must meet UL508A standards, which means they go through strict testing for electrical safety and reliability. Electrical enclosures follow UL and NEMA ratings, which tell you how well they protect against things like water and dust. The National Electrical Code (NEC) and NFPA 70 also set rules for how you install both control panels and enclosures, making sure everything is safe and up to code.

Here’s a quick look at the key differences in components and safety:

| Aspect | Electrical Control Panels | Electrical Enclosures |

|---|---|---|

| Main Role | Manage and automate electrical systems | Protect internal components from environmental hazards |

| Components | Circuit breakers, PLCs, relays, terminal blocks, HMIs | Doors, locks, gaskets, racks, shelves, cabinet frame |

| Functionality | Active control, automation, safety management | Passive protection, customizable layouts |

| Safety Features | Overload protection, emergency shutoffs, monitoring | Physical shielding, environmental protection |

| Safety Standards | UL508A, NEC, NFPA 70 | UL/NEMA ratings, NEC, NFPA 70 |

Tip: Always check the safety standards before you buy. This helps you avoid downtime and keeps your team safe.

Linkewell Product Comparison

Let’s compare two real-world examples from Linkewell to help you see the key differences between control panels vs enclosures.

- Linkewell Electrical Control Panel:

This panel acts as the command center for your machines. It comes loaded with certified components from brands like Siemens and ABB. You get features like automatic switching, temperature control, and remote monitoring. The panel meets UL508A standards and is built for harsh environments. You can customize the size, layout, and even add smart monitoring. These panels are perfect for industrial automation, manufacturing, and telecom. - Linkewell Electrical Power Distribution Box:

This is a type of electrical enclosure designed to distribute power safely across multiple circuits. It protects sensitive equipment from dust, water, and physical damage. The box uses corrosion-resistant materials and offers IP65 or IP66 ratings for tough environments. You can choose from different sizes, materials, and layouts. The distribution box includes main and branch circuit breakers, busbars, and surge protection. It’s ideal for data centers, telecom, and outdoor installations.

Here’s a side-by-side comparison to make things even clearer:

| Feature/Aspect | Linkewell Electrical Control Panel | Linkewell Electrical Power Distribution Box |

|---|---|---|

| Main Function | Active control, automation, and monitoring | Safe power distribution and environmental protection |

| Typical Components | Circuit breakers, PLCs, relays, HMIs, sensors | Busbars, circuit breakers, terminal blocks, surge protectors |

| Safety Standards | UL508A, IEC 61439, NEC, NFPA 70 | UL/NEMA ratings, IEC 61439, NEC, NFPA 70 |

| Customization | Size, layout, branding, smart features | Material, size, IP/NEMA rating, internal configuration |

| Application | Industrial automation, manufacturing, telecom | Data centers, telecom, outdoor/harsh environments |

| Maintenance | Needs regular checks for wiring and components | Occasional inspection for seals, locks, and corrosion |

When you compare control panels vs enclosures, you see that each plays a unique role. Industrial control panels give you the brains and automation, while electrical enclosures provide the muscle and protection. Choosing the right combination keeps your operation safe, efficient, and ready for anything.

Electrical Enclosures in Application

Industrial and Commercial Uses

You see electrical enclosures everywhere, even if you don’t notice them. These boxes keep your equipment safe and your operations running smoothly. In factories, electrical enclosures protect control electronics like PLCs and VFDs from dust and moisture. You’ll find them in commercial buildings, where they house distribution panels and circuit breakers.

Here are some of the most common ways you use electrical enclosures:

- Industrial automation: Shielding sensitive controls from harsh environments.

- Commercial facilities: Housing electrical panels and switches.

- Telecommunications: Protecting networking gear from weather and tampering.

- Renewable energy: Enclosing inverters and battery systems for solar and wind.

- Transportation: Weatherproofing traffic signals and railway controls.

- Marine and offshore: Providing corrosion resistance on ships and oil rigs.

- Hazardous locations: Containing sparks in chemical plants and refineries.

- Outdoor power: Safeguarding irrigation wiring, pool equipment, and dock circuits.

You also see different types of electrical enclosures based on the job. Some offer watertight protection for outdoor use, while others handle corrosive chemicals or even temporary submersion. The right electrical enclosure keeps your equipment safe, no matter the challenge.

Linkwell Solutions

When you choose Linkwell, you get more than just a box. Linkwell electrical enclosures use high-quality, waterproof, and corrosion-resistant materials. This means your equipment stays protected in dusty, humid, or outdoor environments. You benefit from stable internal temperatures, which helps your devices last longer and cuts down on maintenance.

Linkwell designs electrical enclosures with smart features. You get energy-efficient fans that only run when needed, so you save on power. Low-noise designs work well in quiet spaces. Smart monitoring lets you spot problems early, thanks to RPM detection and fault alerts. These enclosures handle extreme temperatures and even resist vibration, making them perfect for tough industrial settings.

You can customize your Linkwell electrical enclosure to fit your exact needs. Whether you need a clear window, special size, or extra protection, Linkwell has you covered. With so many options, you can match the right enclosure to any application.

Choosing the Right Solution

Key Factors to Consider

Picking between a control panel and an enclosure can feel tricky, but you can make the right choice by focusing on a few key points. Start by thinking about your project’s environment. If your application sits in a clean, indoor space, an open control panel might work. For dusty, wet, or outdoor spots, you need an enclosure that shields your equipment from the elements.

Next, look at safety. Open panels leave parts exposed, so you must be extra careful. Enclosed panels keep everything locked away, which helps prevent accidents. Accessibility matters too. Open panels make maintenance quick, but enclosures add a layer of protection that can slow down the installation process or repairs.

Budget and timeline also play a big role. Custom enclosures fit unique needs but cost more and take longer to build. Standard enclosures save money and speed up the installation process, but you might need to adjust them later if your application changes.

Environmental factors can’t be ignored. High temperatures, humidity, dust, or even snow can damage your equipment. You may need extra features like ventilation, heaters, or sealed doors to keep things running smoothly. Always check for certifications like UL508A or NEMA ratings to make sure your solution meets safety standards.

Tip: Think about where your equipment will live and how often you’ll need to access it. This helps you pick the best fit for your application.

Application Checklist

Before you decide, run through this quick checklist to match your needs with the right solution:

- What is the environment? (Indoor, outdoor, dusty, wet, hot, cold)

- Does your application require extra protection from water, dust, or chemicals?

- How important is quick access for maintenance?

- What is your budget and timeline?

- Do you need a custom design or will a standard enclosure work?

- Are there any special cooling or heating needs?

- What certifications or safety standards must you meet?

- Will the installation process be simple or complex?

Here’s a handy table to help you compare:

| Factor | Open Control Panel | Enclosed Panel/Box |

|---|---|---|

| Best Environment | Clean, indoor | Dusty, wet, outdoor |

| Safety | Lower (exposed parts) | Higher (protected parts) |

| Maintenance | Easy access | Moderate access |

| Cost | Lower upfront | Higher, but safer long-term |

| Installation Process | Faster | May take longer |

Take a moment to answer these questions. You’ll feel more confident choosing the right control panel or enclosure for your next application.

FAQ

Got questions about control panels vs enclosures? You’re not alone! Here are answers to the most common things people ask:

- How do I pick the right size enclosure?

Start by listing all the components you need to fit inside. Leave extra space for airflow and future upgrades. If you cram everything in, you risk overheating and tricky maintenance. - What’s the best way to keep my enclosure cool?

Good ventilation matters. You can use filter fans, but remember, they only work if the outside air is cooler than the inside. For hot environments, you might need active cooling like air conditioners or heat exchangers. Don’t forget to check for condensation—sometimes you need heaters or pressure compensation devices to keep things dry. - Which material should I choose for my enclosure?

Think about where you’ll use it. Stainless steel works well in wet or corrosive places. Powder-coated steel fits most indoor jobs. Polycarbonate or other non-metallic options resist impact and don’t rust. Always check the enclosure’s NEMA or IP rating to match your environment. - How do I make sure my enclosure is safe for hazardous locations?

Look for special designs that handle risks like flammable gases or dust. These enclosures often have extra seals and follow strict safety standards. Always check for the right certifications. - Can I put components anywhere inside the enclosure?

Not really. You need to plan the layout for good airflow and easy cable management. Poor placement can cause hot spots and make troubleshooting harder.

Tip: Don’t think of enclosures as just simple boxes. The design, material, and cooling all play a big role in keeping your equipment safe and running smoothly.

Bonus Table: Common Misconceptions

| Myth | Reality |

|---|---|

| All control panels are the same if UL listed | Quality and design still matter—choose trusted brands like Linkewell |

| Sealed enclosures always stay dry | Condensation can form inside—use heaters or vents if needed |

| Filter fans always cool things down | In hot areas, fans might raise the temperature—consider active cooling |

Still have questions? Reach out to Linkewell’s experts for advice on your next project!

Conclusion

Choosing between control panels and enclosures can feel overwhelming, but you can make the right call by focusing on your environment, safety needs, and how you plan to use your equipment. Here’s a simple way to get started:

- Test for Safety: Always check for proper insulation and make sure your overcurrent protection devices and GFCIs work as they should. This keeps your system safe from electrical faults.

- Label Everything: Use clear labels for every wire, device, and connection point. Good labeling makes maintenance much easier and helps you avoid mistakes down the road.

- Follow the Rules: Stick to standards like NFPA 79, especially the chapters on documentation and safety markings. This helps you stay compliant and keeps your team safe.

- Keep It Clear: Mark all devices and cable ends so anyone working on your panel knows exactly what’s what—even years later.

- Ask the Experts: Bring in a compliance specialist or an external expert to double-check that your setup meets all codes and certifications.

Tip: Taking these steps now saves you time, money, and headaches later.

When you need a solution that fits your unique project, Linkewell has your back. You get more than just off-the-shelf products. Here’s how Linkewell supports you:

- Expert consultations and layout design help you plan the perfect setup.

- Custom options let you pick mounting styles, cooling capacity, voltage, finishes, and smart features.

- OEM and private-label services allow you to add your own branding and labels.

- The engineering team brings over 15 years of experience and tests every unit for top performance.

- Fast lead times and competitive pricing keep your project on track.

You don’t have to figure it out alone. With Linkewell’s customization and support, you can build a safer, smarter, and more reliable system—no matter where you work or what you need.

Choosing between control panels and enclosures shapes how safe and efficient your setup will be. Here’s a quick recap:

| Feature | Control Panel (Active) | Enclosure (Protective) |

|---|---|---|

| Purpose | Manages and automates | Shields from hazards |

| Components | PLCs, relays, breakers | Usually empty, strong shell |

| Safety | Active protections | Passive, physical barrier |

Pick the right solution for your environment and needs. You can trust Linkewell for certified, customizable products and expert support. Want peace of mind? Reach out to Linkewell’s team for tailored advice.