In electrical systems, transformers are crucial components, but not all serve the same purpose. Control Power Transformers (CPTs) and Potential Transformers (PTs), while both voltage transformers, have distinct roles and characteristics.

Understanding the differences between CPTs and PTs is essential for proper system design and operation. This blog post will explore their primary functions, construction, and applications to clarify what sets them apart.

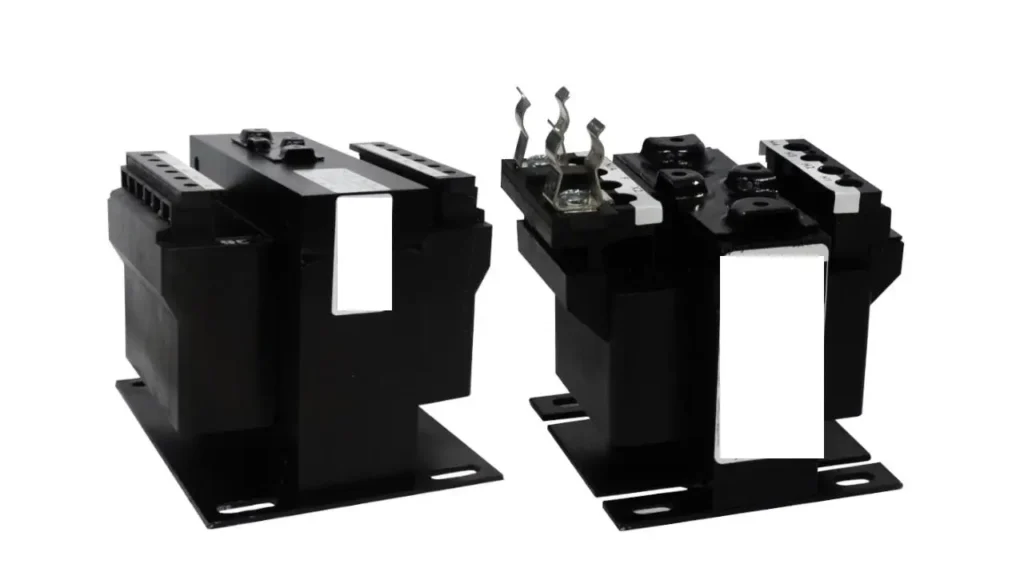

What is a Control Power Transformer?

A Control Power Transformer (CPT) is a type of transformer specifically designed to provide a stable and reliable voltage source for control circuits in electrical systems. Unlike power transformers that supply power to loads, CPTs are built to handle the transient voltage drops caused by the high inrush currents of inductive components like contactors, solenoids, and relays.

They are crucial for ensuring consistent and accurate operation of control logic and components, often featuring compensated windings to maintain stable secondary voltage even under momentary overload conditions during equipment startup. CPTs are essential in industrial control panels and automation systems where maintaining a steady control voltage is critical for safety and performance.

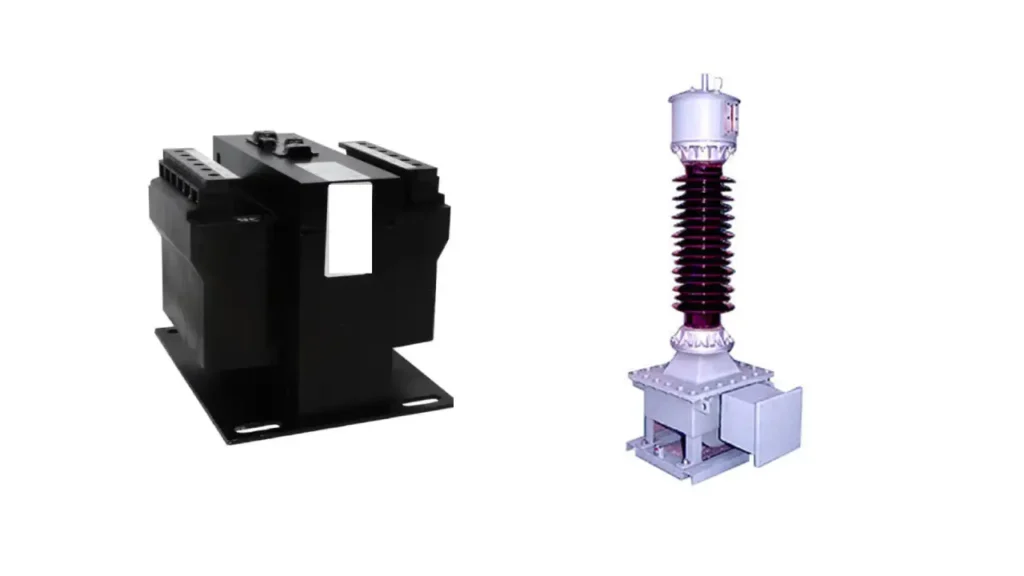

What is a Potential Transformer?

A Potential Transformer (PT), also known as a Voltage Transformer (VT), is an instrument transformer used in electrical power systems to accurately step down high voltages to a lower, safer voltage level for measurement, metering, and protective relaying.

Connected in parallel with the circuit, PTs provide a voltage proportional to the system voltage but at a reduced magnitude, typically 120V or less on the secondary side. They are designed for high accuracy and have a high impedance to minimize current draw from the primary circuit, ensuring that the voltage measurement is not significantly affected. PTs are crucial for the safe and precise monitoring and protection of high-voltage equipment and systems.

Control Power Transformer vs Potential Transformer

Electrical systems rely on various types of transformers to manage voltage and current for different purposes. Among these are Control Power Transformers (CPTs) and Potential Transformers (PTs). While both modify voltage levels, their fundamental roles and design priorities differ significantly. Understanding these differences is key.

Function

Control Power Transformers (CPTs) are primarily used to provide a stable and isolated voltage source for control circuits within electrical panels and systems. Their main function is to step down a higher primary voltage to a lower, usable voltage suitable for powering components like relays, contactors, timers, and PLCs. A key characteristic of CPTs is their ability to handle the high inrush currents associated with energizing inductive control devices without significant voltage drop, ensuring reliable operation of the control logic.

Potential Transformers (PTs), also known as Voltage Transformers (VTs), are instrument transformers specifically designed for accurate voltage measurement and monitoring in high-voltage power systems. Their purpose is to step down the system voltage to a standardized, low voltage level (typically 120V or less) that can be safely and accurately measured by meters, protective relays, and other monitoring equipment. PTs are connected in parallel with the circuit being measured and are designed to maintain a precise voltage ratio across a range of operating conditions.

Design and Construction

CPTs are constructed with robust windings and cores designed to withstand the mechanical forces and thermal stress caused by frequent high inrush currents. They often incorporate compensated windings to help maintain a stable output voltage under varying load conditions, particularly during the momentary overloads from control device activation. The insulation and physical structure are optimized for their role in industrial control environments.

PTs, on the other hand, are built with a focus on high accuracy and linearity in their voltage transformation ratio. They feature high-quality core materials and precise winding turns to ensure that the secondary voltage is a faithful, scaled-down representation of the primary voltage. The insulation system in PTs is critical due to their connection to high-voltage power circuits, and their design minimizes impedance to avoid affecting the circuit being measured.

Application

CPTs are widely used in industrial automation, motor control centers, machinery, and building management systems. They provide the necessary control voltage for the operation of switching devices and control logic, ensuring that automated processes function correctly and safely. Their application is generally limited to providing power for the control side of a system, not the main power to the load.

PTs are essential components in power generation, transmission, and distribution substations. They are used for revenue metering, where accurate voltage measurement is required for billing, and for protective relaying, where precise voltage information is needed to detect fault conditions and initiate protective actions. They are also used in synchronization circuits and for voltage monitoring in SCADA systems.

Accuracy Requirements

CPTs typically do not have stringent accuracy requirements in terms of voltage transformation ratio, as their primary role is to provide a stable voltage source for control components. While voltage regulation under load is important, the exact ratio is less critical than in measurement applications.

PTs are precision instruments with strict accuracy classes defined by standards (e.g., IEEE or IEC). Their accuracy is paramount for reliable metering and protection. They are designed to maintain a precise voltage ratio and minimal phase angle error across their operating range to ensure accurate representation of the system voltage.

| Feature | Control Power Transformer (CPT) | Potential Transformer (PT) |

| Primary Function | Provide stable voltage for control circuits | Step down high voltage for measurement/protection |

| Key Design Focus | Handle inrush current, voltage regulation | Accuracy of voltage ratio and phase angle |

| Typical Application | Industrial control panels, automation systems | Power substations, metering, protective relaying |

| Accuracy Needs | Voltage regulation under load is important | High accuracy of ratio and phase angle is critical |

| Connection | Typically connected to supply voltage | Connected in parallel with the circuit to measure |

How to Choose Control Power Transformer and Potential Transformer

Choosing between a Control Power Transformer (CPT) and a Potential Transformer (PT) hinges primarily on the intended function within the electrical system.

If the requirement is to provide a stable and reliable power source for control circuits powering devices like contactors, relays, and PLCs, then a CPT is the appropriate choice. Key factors when selecting a CPT include:

- The required secondary voltage and the available primary voltage.

- The total VA (Volt-Ampere) burden of all connected control circuit components, including considering the high inrush VA during startup of inductive loads.

- Environmental factors such as operating temperature and the need for specific enclosure types.

- Any requirements for voltage regulation under load.

Conversely, if the objective is to accurately measure, monitor, or provide voltage signals for protective relaying in a high-voltage system, a Potential Transformer (PT) is necessary. When selecting a PT, the crucial considerations are related to accuracy and system parameters:

- The high system voltage that needs to be stepped down and the required standard low secondary voltage (e.g., 120V).

- The accuracy class required for the application (e.g., metering or protection), which dictates the permissible voltage ratio and phase angle errors.

- The burden (VA rating) imposed by the connected metering instruments, relays, or other loads.

- The insulation level required for the primary voltage of the system to ensure safety and reliability.

Conclusion

Control Power Transformers (CPTs) are engineered to supply stable voltage to control circuits and handle high inrush currents from devices like contactors and relays. They prioritize voltage regulation for reliable control system operation.

Potential Transformers (PTs), also known as Voltage Transformers (VTs), are designed for accurate voltage measurement and relaying in power systems. They scale down high voltages to safer levels for metering and protection, working with high impedance loads.

In essence, CPTs power control systems requiring stable voltage under variable loads, while PTs provide precise voltage replicas for measurement and protection purposes. Get wholesale control transformers from Linkwell Electrics.