Looking for the best cooling fan for industrial or new energy applications? The right bearing selection makes all the difference. Cooling fan bearing types—sleeve bearings, ball bearings, and fluid dynamic bearings—each bring unique strengths. For quiet, budget-friendly needs, sleeve bearings work well. Ball bearings handle higher speeds, loads, and vertical mounting better. Fluid dynamic bearings offer top performance for advanced systems. Check out this table to compare the main features:

| Feature | Sleeve Bearings | Ball Bearings |

|---|---|---|

| Noise | Quiet | Louder |

| Lifespan | Moderate | Long |

| Load Handling | Light | Heavy |

| Cost | Low | Higher |

| Orientation | Horizontal | Any |

Think about your speed, load, temperature, orientation, noise, and budget needs during selection. That way, you’ll pick the best fit for your new energy applications.

Key Takeaways

- Choose sleeve bearings for quiet, budget-friendly cooling solutions in low-temperature environments.

- Opt for ball bearings when you need durability and performance in high-speed or heavy-load applications.

- Consider fluid dynamic bearings for advanced systems requiring minimal noise and excellent heat dissipation.

- Evaluate your cooling needs, budget, and environment to select the best bearing type for your project.

- Investing in high-quality bearings can save you money on maintenance and replacements in the long run.

Bearing Choice Impact

Efficiency and Airflow

When you choose a fan bearing, you directly affect how well your cooling fan works. The right bearing keeps your fan spinning smoothly and helps your system stay cool. Here’s what happens with different fan motor bearing types:

- Some bearings, like ball bearing fans and hybrid ceramic bearings, handle heat better. They keep your system running even when temperatures rise.

- Sleeve bearings work best in cooler spots. They don’t get rid of heat as well, so they fit low-temperature jobs.

- Less friction means your fan uses less energy and moves more air. That’s why bearing selection matters for airflow and efficiency.

If you use a Linkwell Electrical Enclosure Fan in your control cabinet, you get reliable airflow and energy savings. The Computer Chassis Fan also uses high-quality bearings to keep your electronics cool, even under heavy loads.

Lifespan and Reliability

You want your cooling system to last. The bearing selection you make can add years to your equipment’s life. Here’s how it works:

- The right bearing reduces friction, so your fan runs longer without wearing out.

- Smooth rotation means less stress on the fan and fewer breakdowns.

- You save money because you don’t have to replace fans as often.

Linkwell’s fans use top-grade bearings to boost reliability. When you pick the right bearing, you protect your investment and avoid unexpected downtime.

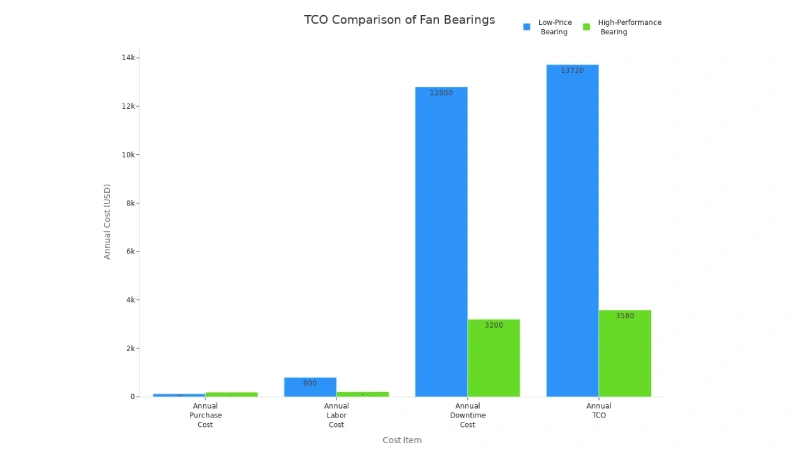

Cost and Maintenance

At first, a cheaper bearing might look like a good deal. But think about the total cost over time. Here’s a quick look at how costs add up:

| Cost Item | Low-Price Bearing | High-Performance Bearing |

|---|---|---|

| Annual Purchase Cost | $120 | $180 |

| Annual Labor Cost | $800 | $200 |

| Annual Downtime Cost | $12,800 | $3,200 |

| Annual TCO | $13,720 | $3,580 |

A high-performance bearing may cost more upfront, but it saves you money on repairs and lost time. It’s like buying a car that needs fewer repairs and uses less gas. Linkwell’s fans, with their quality bearings, help you cut down on maintenance and keep your systems running smoothly.

Recommended products

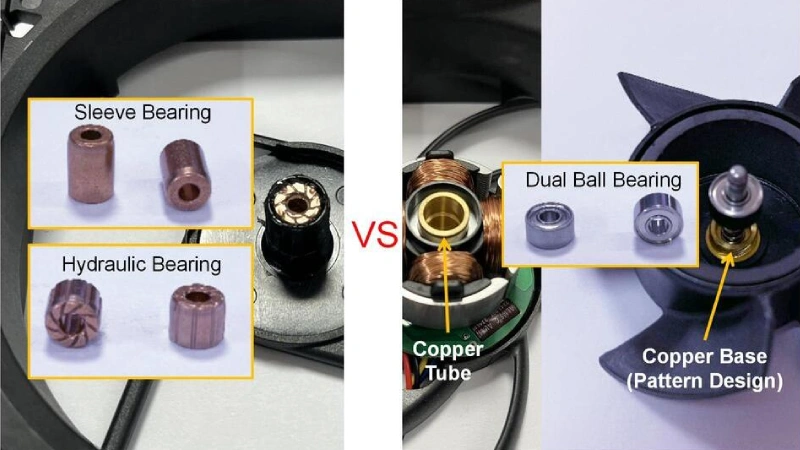

Cooling Fan Bearing Types

When you look at cooling fan bearing types, you’ll see three main options: sleeve bearings, ball bearings, and fluid dynamic bearings. Each type has its own strengths, and you’ll want to match the right bearing to your application. Let’s break down what makes each one unique and see how Linkwell uses high-quality bearings in their Electrical Enclosure Fans and Computer Chassis Fans.

Sleeve Bearings Overview

Sleeve bearings are the classic choice for many cooling fan bearing types. You’ll find them in fans that need quiet operation and cost-effective solutions. The design is simple—a cylindrical sleeve supports the fan shaft, letting it spin with minimal friction.

- You get a basic construction that’s easy to produce and install.

- Sleeve bearings work well in horizontal mounting positions.

- They offer small starting torque, which helps if your fan stops and starts often.

- These bearings are affordable, making them great for projects with tight budgets.

Tip: If you need a cooling fan for a control cabinet or telecom enclosure, sleeve bearings can be a smart pick. Linkwell’s Electrical Enclosure Fans use high-quality sleeve bearings to deliver reliable airflow and long service life.

Ball Bearings Overview

Ball bearings step up the game for cooling fan bearing types. You’ll see them in fans that run at higher speeds or face heavier loads. Ball bearings use small steel balls to reduce friction and support the fan shaft.

- You can mount ball bearing fans in any orientation—horizontal or vertical.

- They handle higher temperatures and last longer than sleeve bearings.

- Ball bearings are less prone to wear and tear, so you get more reliability.

- These bearings tend to make more noise, but they’re perfect for demanding environments.

Note: If you need a cooling fan for a computer chassis or industrial system, ball bearings are a solid choice. Linkwell’s Computer Chassis Fans use top-grade ball bearings to keep your electronics cool, even under heavy workloads.

Fluid Dynamic Bearings Overview

Fluid dynamic bearings represent the most advanced cooling fan bearing types. These bearings use a thin layer of fluid to support the fan shaft, reducing friction and noise to a minimum.

- You get ultra-quiet operation, which is ideal for noise-sensitive areas.

- Fluid dynamic bearings offer excellent durability and can handle high speeds.

- They provide smooth rotation, which helps extend the lifespan of your cooling fan.

- These bearings are more complex and usually cost more, but they deliver top performance.

If you’re working on a high-tech project or need the best in reliability, fluid dynamic bearings are worth considering. Linkwell continues to innovate with advanced bearing technology, making sure their fans meet the highest standards for industrial and new energy applications.

Quick Table: Cooling Fan Bearing Types at a Glance

| Bearing Type | Key Features | Linkwell Product Example |

|---|---|---|

| Sleeve Bearings | Quiet, affordable, simple design | Electrical Enclosure Fan |

| Ball Bearings | Durable, versatile, high performance | Computer Chassis Fan |

| Fluid Dynamic | Ultra-quiet, long lifespan, advanced | Advanced Industrial Cooling Fans |

When you choose a cooling fan, think about which bearing type fits your needs. Linkwell’s product range covers all the main cooling fan bearing types, so you can find the right solution for your project.

Sleeve Bearings

Construction and Principle

You might wonder how sleeve bearings work inside a cooling fan. These bearings use soft metals or polymers to form a smooth, cylindrical sleeve. The fan shaft spins inside this sleeve, separated by a thin film of oil. This oil reduces friction and helps the fan run quietly.

- The design often includes oil rings and Mylar washers. These parts keep the lubricant in place and stop leaks.

- The gap between the shaft and the sleeve must stay just right. If it gets too wide, the fan can wobble or make noise.

- Over time, the sleeve can wear down, especially if the fan runs all day. This wear can change the shape of the sleeve, which may shorten fan lifespan.

Advantages

Sleeve bearings offer several benefits for your cooling fan needs:

- They operate quietly, so you won’t hear much noise from your equipment.

- The simple design means fewer parts that can break.

- Manufacturing costs stay low, making these bearings a budget-friendly choice.

- You can save up to 40% on costs compared to roller bearings.

- If you need a quiet workspace or want to keep expenses down, sleeve bearings are a smart pick.

Disadvantages

There are a few things to keep in mind with sleeve bearings:

- They have a limited lifespan and can wear out faster than other types.

- If you mount your fan vertically, sleeve bearings may not last as long.

- High-performance systems or places with lots of heat can push these bearings past their limits.

- As the sleeve wears, you might notice more noise or less airflow.

Application Suitability

Sleeve bearings fit best in certain situations.

- You’ll find them in places where quiet operation matters, like offices or control cabinets.

- Their simple and sturdy design works well in tough environments.

- They’re a great choice when you want reliable performance without spending a lot.

- Linkwell Electrical Enclosure Fans use high-quality sleeve bearings to deliver steady airflow and long service life in industrial settings.

Tip: If you need a cooling fan for a control cabinet or telecom enclosure, sleeve bearings can help you balance cost, noise, and durability.

Ball Bearings

Construction and Principle

You might wonder how ball bearings work inside a cooling fan. These bearings use small metal balls placed between two smooth rings. The balls roll as the fan spins, which reduces friction and helps the fan move smoothly. This design is different from sleeve bearings, which use a simple sleeve to support the shaft. Ball bearings give you more durability and let your fan run in any position, even vertical. Here’s a quick comparison:

| Bearing Type | Structure | Best Use Case |

|---|---|---|

| Sleeve Bearings | Cylindrical sleeve, oil-lubricated | Quiet, horizontal mount |

| Ball Bearings | Metal balls between inner and outer rings | High speed, any mount |

Advantages

Ball bearings bring you several important benefits:

- You get longer lifespan and better durability, especially in high-speed or high-load situations.

- These bearings handle higher temperatures and keep working even when your system heats up.

- Ball bearings reduce friction, so your fan runs smoother and lasts longer.

- You can mount your cooling fan in any direction—vertical, horizontal, or even upside down.

- They offer stable performance, which means less vibration and more reliable airflow.

If you need a fan for a tough job, ball bearings are a smart choice. Linkwell Computer Chassis Fans use high-quality ball bearings to deliver strong cooling for computers and industrial systems.

Disadvantages

Ball bearings do have a few drawbacks you should know about:

- They tend to make more noise than sleeve bearings, especially as they age.

- The noise level can go up by 1 to 3 dBA compared to sleeve bearing fans.

- Ball bearings usually cost more upfront than other types.

Note: If you want a super quiet fan for a noise-sensitive area, you might want to look at other fan bearing types.

Application Suitability

You’ll find ball bearings in many demanding environments. Here are some common uses:

- Industrial cooling fans for de-dusting and air quality control.

- HVAC systems that face frequent temperature changes.

- Duct exhaust and boiler systems that need to move hot air or gases.

- Ventilation systems in factories and data centers.

Ball bearings help your cooling fan handle heat, high speeds, and tough conditions. They keep your equipment running smoothly and extend its life. If you need a reliable solution for your industrial or new energy project, ball bearings are a top pick.

Fluid Dynamic Bearings

Construction and Principle

Fluid dynamic bearings bring a new level of technology to cooling fans. You get a bearing that uses a thin layer of fluid—usually oil—between the moving shaft and the bearing surface. This fluid creates a cushion, so the parts barely touch. When your fan spins, the fluid forms pressure patterns that keep the shaft centered. This design cuts down on friction and helps with smooth rotation. You will notice better heat dissipation because the fluid spreads heat away from the shaft. The result is a fan that runs quietly and stays cool, even during heavy use. This advanced construction makes fluid dynamic bearings a top choice for fans where heat dissipation and reliability matter most.

Advantages

You will see several big benefits when you use fluid dynamic bearings in your cooling fans:

- Minimal friction means less wear and tear, so your fan lasts longer.

- The fluid layer keeps things quiet, making these fans much quieter than traditional bearings.

- You get better heat dissipation, which protects sensitive electronics and keeps your system stable.

- The design helps your fan handle high speeds and heavy workloads without breaking down.

- Extended lifespan means you spend less time and money on replacements.

Fluid dynamic bearings shine in advanced cooling fans. You get a perfect mix of quiet operation, strong heat dissipation, and long-term reliability.

Disadvantages

While fluid dynamic bearings offer many perks, you should know about a few drawbacks:

- These bearings cost more than basic types because of their advanced design.

- The intricate construction can make installation and maintenance a bit tricky.

- You might need special tools or skills to service these fans.

If you want the best in heat dissipation and quiet performance, the extra investment often pays off.

Application Suitability

Fluid dynamic bearings work best in places where you need top-notch heat dissipation and silent operation. You will find them in high-end industrial systems, data centers, and new energy equipment. These fans handle tough jobs, like cooling sensitive electronics or running nonstop in harsh environments. Linkwell leads the way by using innovative bearing technology in their advanced cooling fans. You get products that deliver reliable heat dissipation, energy savings, and long service life. When you choose Linkwell, you pick a partner committed to quality and smart engineering.

Cooling Fans Performance Comparison

Lifespan and Durability

When you look at industrial cooling fans, you want them to last. The lifespan of each fan bearing type can make a big difference in your system’s reliability. Sleeve bearings work well in moderate conditions, but their lifespan drops fast in high heat. Ball bearing fans last about 50% longer than sleeve bearings, especially when temperatures rise above 70°C. Fluid dynamic bearings take durability to the next level, often reaching up to 100,000 hours even in tough industrial cooling environments. You get more uptime and fewer replacements.

| Bearing Type | Lifespan (25º-60ºC) | Lifespan (>70ºC) | Durability in Harsh Use |

|---|---|---|---|

| Sleeve Bearing | Moderate | Inoperable | Lower |

| Ball Bearing | 50% longer | 45,000 hours | High |

| Fluid Dynamic | Up to 100,000 hours | Up to 100,000 hours | Highest |

Noise Levels

Noise matters in many industrial cooling setups. Sleeve bearings start out quiet, but as lubrication dries, noise increases. Ball bearing fans keep a steady noise profile and work well in most environments. Fluid dynamic bearings offer the quietest operation, even as they age. You get less vibration and a more peaceful workspace.

- Sleeve bearings: Quiet at first, but get louder over time.

- Ball bearings: Consistent noise, suitable for most industrial cooling needs.

- Fluid dynamic: Quietest, best for noise-sensitive areas.

Temperature Range

Industrial cooling often means high temperatures. Ball bearing fans handle up to 120°C and keep working for thousands of hours. Fluid dynamic bearings also perform well in extreme heat, often surpassing 70,000 hours of use. Sleeve bearings struggle in high heat and may stop working if temperatures climb too high.

Cost and Maintenance

You want to balance cost and durability. Sleeve bearings cost less upfront, which helps with large industrial cooling projects. However, you may spend more on replacements and maintenance. Ball bearing fans require a higher initial investment but save you money over time with less maintenance. Fluid dynamic bearings cost the most but deliver the longest lifespan and lowest maintenance needs.

| Bearing Type | Initial Cost | Maintenance Needs | Long-Term Value |

|---|---|---|---|

| Sleeve Bearing | Low | High | Lower |

| Ball Bearing | Medium | Low | High |

| Fluid Dynamic | High | Lowest | Highest |

Mounting Flexibility

Mounting options matter in industrial cooling. Sleeve bearings work best in horizontal positions. Ball bearing fans and fluid dynamic bearings let you mount your fan in any direction—vertical, horizontal, or even upside down. This flexibility helps you fit fans into tight or unusual spaces.

Tip: For the best durability, lifespan, and performance in industrial cooling, match your fan bearing type to your system’s needs. Ball bearing fans and fluid dynamic bearings give you more options and longer service life.

Selecting the Right Cooling Fan Bearing

Choosing the right bearing type for your cooling fan can feel overwhelming, but you can break it down into a few simple steps. Let’s walk through how you can make the best choice for your industrial or new energy project.

Assessing Requirements

Start by looking at your application requirements. Every system is different, so you want to match your fan bearing to what your equipment needs.

- Think about the speed and load your fan will handle.

- Check if your system needs quiet operation or can tolerate some noise.

- Look at how often you’ll need to maintain the fan. Regular lubrication and cleaning help extend the life of any fan bearing.

- Monitor the temperature where your fan will run. Keeping things cool helps prevent early failures.

- Decide if you need a bearing type that works in any position or just horizontal.

Understanding these points helps you narrow down your options. For example, if you need a fan for a control cabinet that runs quietly and doesn’t need much maintenance, a sleeve bearing might be your best bet. If you expect heavy loads or high speeds, a ball bearing fan could be the answer.

Matching to Application

Now, let’s match your needs to the right bearing type. Here’s a simple process you can follow:

- List your application requirements, like airflow, noise level, and mounting position.

- Set your budget for the project.

- Decide how much noise your environment can handle.

- Match the bearing type to your cooling fan’s purpose. For example, use a ball bearing fan for high-performance applications or a sleeve bearing for quieter, cost-effective jobs.

- Weigh the pros and cons of each option. Some bearings last longer, while others cost less upfront.

Tip: Always compare the pros and cons of each bearing type before making your final decision. This helps you avoid surprises down the road.

Environmental Factors

Your environment plays a huge role in how long your fan bearing lasts. Here are some things to watch out for:

- High temperatures can shorten the life of your fan motor bearing types. Oil inside the bearing can evaporate faster, leading to more wear.

- Dusty environments cause extra friction and can block airflow, making your fan work harder.

- Humidity and corrosive air can damage the inside of your fan, especially if you use it near chemicals or seawater.

- Poor duct design can create back pressure, which reduces efficiency.

If you work in a tough environment, you might want to choose a ball bearing fan or a fluid dynamic bearing. These types handle harsh conditions better than a basic sleeve bearing.

Budget and Performance

Budget always matters, but you don’t want to sacrifice performance for a lower price. Here’s how different bearing types stack up:

- Sleeve bearings are the most affordable. They’re great if you need a lot of fans and want to keep costs down.

- Ball bearings cost a bit more, but they last longer and work well in demanding jobs.

- Fluid dynamic bearings are the most expensive, but they offer the best energy efficiency, quiet operation, and long lifespan for high-performance applications.

Note: If you want efficient operation and energy efficiency, sometimes it’s worth spending a little more upfront for a better bearing type.

Linkwell Product Recommendations

You don’t have to guess which fan is right for your project. Linkwell offers solutions for almost every scenario:

- The Linkwell Electrical Enclosure Fan uses high-quality sleeve bearings. It’s perfect for control cabinets, telecom enclosures, and charging piles. This fan keeps your equipment cool and stable, even in tough industrial settings.

- The Linkwell Computer Chassis Fan features durable ball bearings. It’s ideal for data centers, electronics manufacturing, and any place where you need reliable, high-performance cooling.

Both fans deliver efficient operation and help you save on maintenance. You get energy efficiency and long service life, no matter which option you choose.

If you’re working in renewable energy, like wind power or charging stations, Linkwell fans help you keep your systems running smoothly. You can trust their fans to handle the demands of modern industrial and new energy environments.

Quick Table: Matching Bearing Types to Applications

| Application Scenario | Recommended Bearing Type | Linkwell Product Example |

|---|---|---|

| Control Cabinets | Sleeve Bearing | Electrical Enclosure Fan |

| Data Centers | Ball Bearing | Computer Chassis Fan |

| Charging Piles | Sleeve Bearing | Electrical Enclosure Fan |

| High-Performance Applications | Ball Bearing/Fluid Dynamic | Computer Chassis Fan |

| Renewable Energy | Ball Bearing | Computer Chassis Fan |

Remember, the right bearing type makes all the difference. Take time to review your application requirements, weigh the pros and cons, and choose a fan that delivers both performance and value.

Choosing the right fan bearing type makes your cooling system work better and last longer. You need to look at speed, load, temperature, orientation, noise, and budget. Check out this table for quick tips:

| Environment Condition | Recommended Bearing Type | Key Benefits |

|---|---|---|

| High-Temperature | Ball bearing fan | Durable, reliable |

| Medium-Temperature, Budget | Sleeve bearing | Quiet, cost-effective |

| High Load | Ball bearing fan | Handles vibration |

Follow these steps:

- Figure out your cooling needs.

- Set your budget.

- Decide how much noise you can handle.

- Match the fan bearing types to your project.

- Compare sleeve bearing vs ball bearing features.

Use Linkwell’s product examples to help you pick the best option for your system.

FAQ

What is a sleeve bearing and how does it work in a cooling fan?

A sleeve bearing uses a smooth sleeve and oil to let the fan shaft spin quietly. You get low noise and simple design. This type works best in horizontal positions and is great for budget-friendly cooling.

When should you choose a ball bearing fan over a sleeve bearing?

Pick a ball bearing fan if you need longer life, higher speeds, or vertical mounting. Ball fans handle heat and heavy loads better than sleeve bearings. You get more flexibility and durability for tough jobs.

What are the main differences between sleeve bearing vs ball bearing?

Sleeve bearing vs ball bearing comes down to cost, noise, and lifespan. Sleeve bearings are quieter and cheaper. Ball bearing fans last longer and work in any position. Think about your needs before you choose.

Can you use different fan bearing types in the same system?

Yes, you can mix fan bearing types in one system. Just match each baring fan to its job. Use sleeve bearings for quiet spots and ball bearing fans for high-performance areas.

How do you decide between ball bearing vs sleeve bearing for your project?

Look at your cooling needs, budget, and mounting position. If you want low noise and low cost, go with a sleeve bearing. For longer life and more flexibility, choose a ball bearing fan. Always check the fan motor bearing types for your application.