DC Fan

High-Performance Axial Fan Solutions for Electrical and Telecom Cabinets

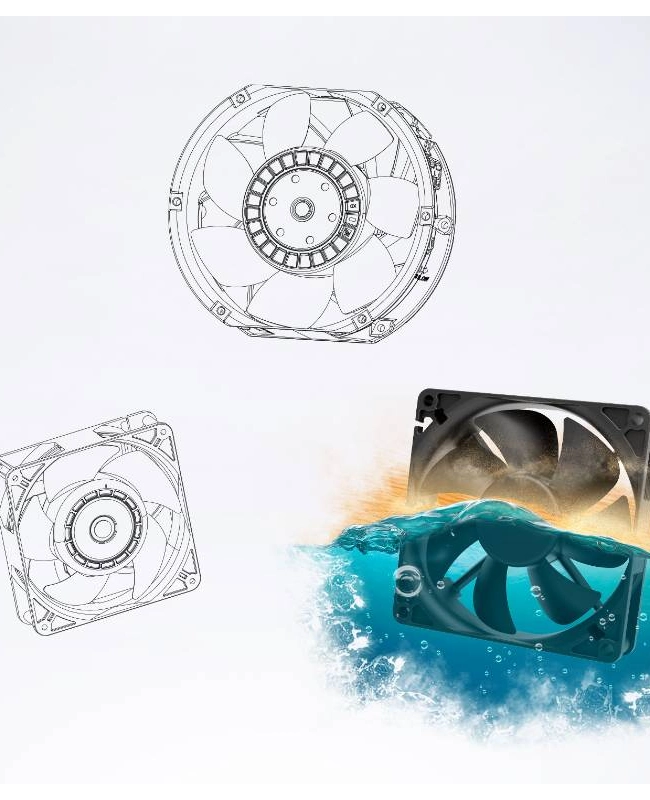

We specialize in custom Axial Fan solutions, including size, airflow capacity, voltage, blade material, mounting style, and noise level adjustments.

Size range

From 25mm to 254mm

Voltage

5V, 12V, 24V, 48V

Operating temperature range

-30℃ ~ 70℃

Speed

2000 rpm to 20,000 rpm

Service life

30,000 – 70,000 hours

Our DC Fan Series

We provide customized axial fan solutions with flexible sizes, fast delivery, and OEM/ODM support. Contact us now for a free quote!

FU Series

Available in various sizes with embedded nuts for easy mounting; optional air duct enhances airflow performance.

LK32 Series

Convenient buckle-opening design allows fast servicing; optional power indicator for operation status.

LK66 Series

Straight-line grill structure improves air circulation and enhances cabinet ventilation efficiency.

FF Series

Made of UV-resistant PC alloy; optional corrugated filter mat provides superior dust protection.

FK55 Series

Thinner cover ideal for compact spaces; stylish curved-line grill enhances cabinet appearance.

Exceptional Brushless DC Fan Performance from Our Quality Materials

High Temperature Resistance for Demanding Applications

As a trusted DC fan manufacturer with years of industry experience, we engineer our cooling fans to thrive where ordinary products fail. Each fan is designed with high-grade PBT plastic blades and precision-crafted aluminum frames, enabling reliable operation across extreme temperature ranges from -40℃ to 120℃. This ensures consistent airflow performance even under the most punishing industrial conditions, including heavy-duty automation systems, power electronics, and outdoor enclosures exposed to fluctuating climates.

Unmatched Protection Against Harsh Environments

Our fans are specifically built for industries where reliability is non-negotiable. Leveraging a proprietary encapsulated motor design combined with an advanced potting process, our DC ventilation fans achieve IP65 and IP68 protection ratings, compliant with international standards. This means our fans are fully shielded from water intrusion, dust accumulation, and moisture damage. The reinforced construction also delivers superior resistance to vibration, external shocks, and corrosive exposure, making them a preferred choice for telecommunications, renewable energy, and ruggedized equipment applications.

Durability and Stable Airflow Performance

Longevity is engineered into every detail of our design. The fan frames are built from ADC-12 aluminum alloy, strengthened with 3–5% copper to enhance structural toughness while ensuring compliance with RoHS 2.0 environmental regulations. Paired with PBT plastic blades that offer 10% higher resistance to deformation than industry-standard materials, our DC exhaust fans deliver 30% more stability in air performance, even after long hours of continuous operation. This translates into consistent airflow, reduced maintenance cycles, and greater system reliability for our clients.

Premium Bearings for Extended Service Life

At the heart of our fans lies Japanese NMB bearings, available in both ball and sleeve configurations. Renowned for precision and endurance, these bearings are designed to support continuous operation up to 70,000 hours at 40℃, significantly outlasting conventional bearing systems. This advanced bearing technology minimizes friction, reduces operational noise, and enhances fan stability, ensuring that our products provide long-term reliability and cost efficiency for mission-critical industrial environments.

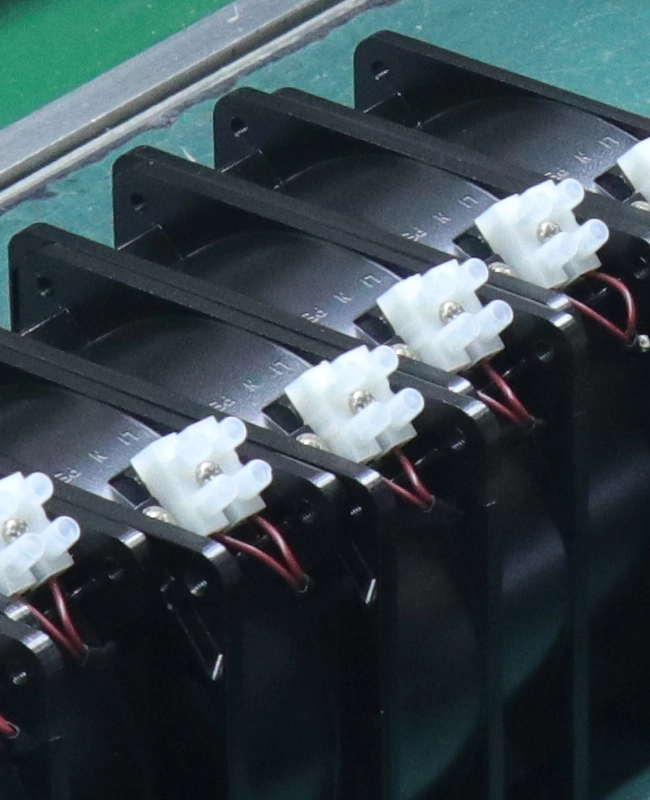

01. Diverse Product Range

With nearly 40 different DC cooling fan models in our portfolio, we provide solutions to meet a wide spectrum of industrial and commercial needs. Our fans are available in both square and round designs, covering multiple voltage options—5V, 12V, 24V, and 48V—to ensure seamless integration with diverse applications. Whether you need compact cooling for electronics or high-capacity ventilation for industrial equipment, our product range offers maximum flexibility.

02. Advanced Control Solutions

We recognize that precision matters. That’s why our DC fans support PWM (Pulse Width Modulation) for dynamic speed control, FG (Frequency Generation) for accurate speed monitoring, and RD (Rotation Detection) for performance feedback. These customizable control options enable engineers and OEMs to achieve optimal efficiency, noise reduction, and system reliability, tailored exactly to their requirements.

03. Comprehensive Motor Protection

RP (Reverse Protection): Prevents damage from incorrect wiring.

SS (Soft Start): Ensures a smooth and controlled startup.

AS (Auto Restart): Automatically restores operation after unexpected shutdowns.

04. High-Temperature Resistance

Built to endure, our fans can be customized to operate in environments up to 120℃. Leveraging nano-coating technology, we deliver enhanced heat resistance while maintaining stability under prolonged stress. This makes our fans ideal for industries such as automotive, telecommunications, and power electronics, where thermal management is critical.

05. All-Weather Waterproofing

For outdoor and demanding environments, we provide IP67 and IP68-rated waterproofing solutions. These standards guarantee resilience against rain, dust, humidity, and even submersion, ensuring that our DC fans operate safely and reliably under extreme weather conditions. Clients in renewable energy, outdoor LED displays, and marine equipment particularly benefit from this rugged, all-weather design.

06. Customizable Speeds

Every application requires the right balance of airflow and pressure. Our DC fans offer adjustable speed ranges from 1,000 to 30,000 RPM, ensuring precise alignment with your system’s cooling needs. For high-performance applications, we incorporate copper-core motor designs to enhance stability, reduce vibration, and prevent blade breakage, guaranteeing both efficiency and durability.

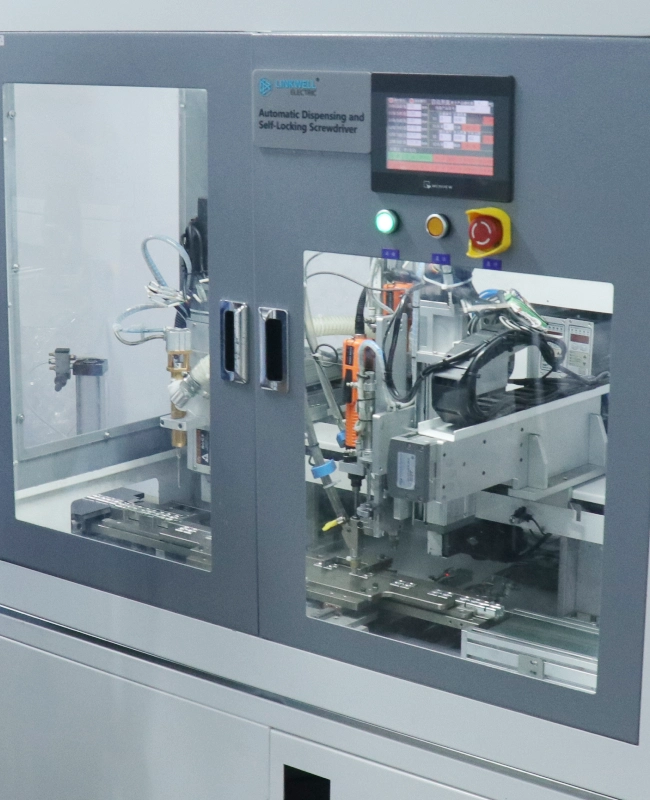

From Concept to Manufacturing: How We Produce Top-Notch DC Fans

Design & Development

As a forward-thinking DC blower and fan manufacturer, we begin with a deep understanding of customer requirements and evolving market trends. Our engineering team defines product specifications with precision, using 3D printing and CNC machining to create prototypes of circuit boards, fan blades, and housings. These prototypes undergo rigorous evaluation, allowing us to refine performance and durability before moving into large-scale production.

Premium Raw Materials

We believe that exceptional products start with superior materials. That’s why we partner with globally trusted suppliers to source only the finest components: motors, bearings, ADC-12 aluminum alloy frames, and PBT plastic blades. Every incoming batch is carefully inspected and tested to ensure it meets our stringent quality standards. This unwavering commitment guarantees reliability, compliance, and long-lasting performance.

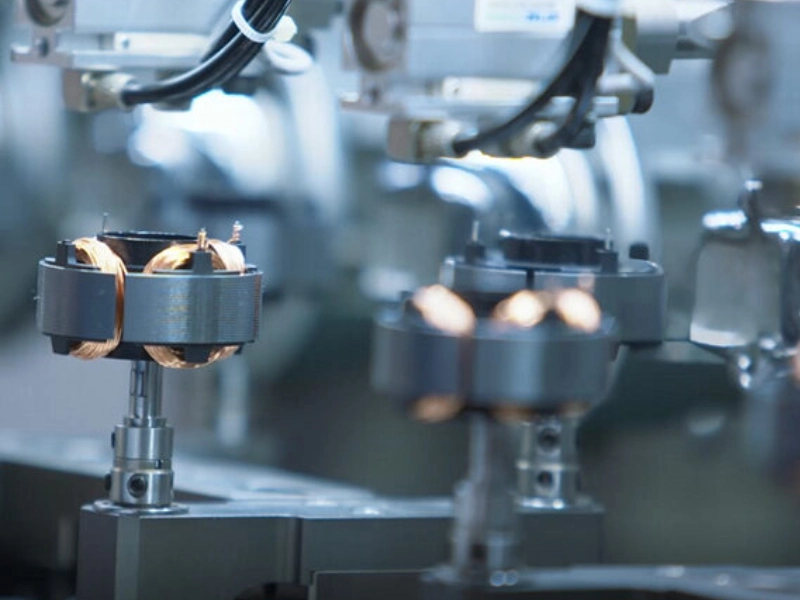

Precision Component Manufacturing

Each component of our DC fans is manufactured with meticulous attention to detail:

Motors are expertly wound, encapsulated, and treated for waterproofing and dustproofing.

Fan blades are precisely injection molded from durable PBT plastic or lightweight metals.

Frames are both cast and CNC-machined from ADC-12 aluminum alloy, ensuring structural strength and dimensional accuracy.

Assembly Process

The core elements—motors, bearings, blades, and frames—are carefully assembled in controlled environments. Initial assemblies are subjected to functional testing, measuring motor speed, vibration, acoustic performance, and power efficiency. Following this, a final precision assembly guarantees seamless integration of all parts, ensuring the highest standards of performance and longevity.

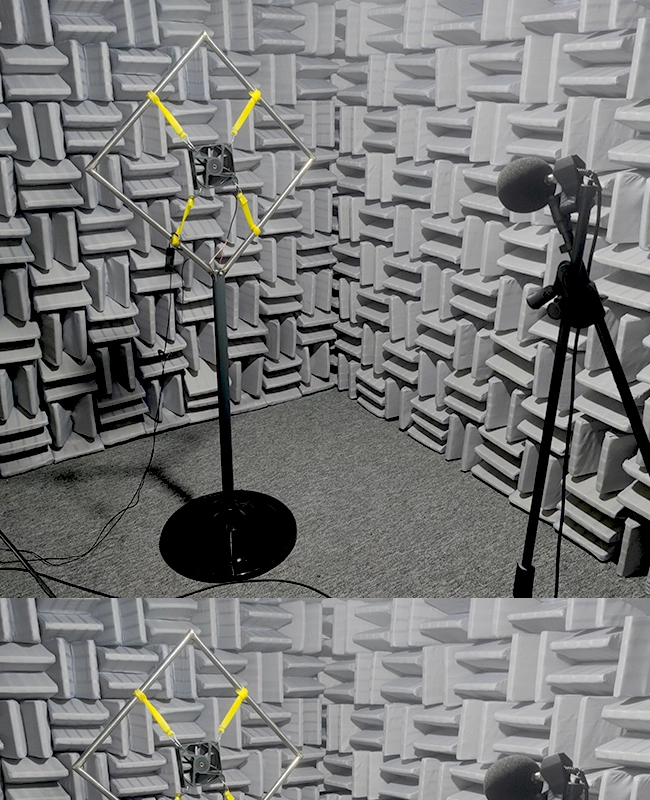

Testing & Calibration

Before reaching the market, each unit undergoes a comprehensive testing protocol. This includes performance evaluations of speed, power, current, and noise levels, alongside environmental simulations that replicate extreme operating conditions such as high/low temperatures, humidity, and continuous operation stress. These rigorous checks validate that our fans consistently perform under the harshest industrial demands.

Packaging & Shipping

Quality control doesn’t stop at production. Every DC fan is individually inspected before packaging. To safeguard against damage in transit, we use reinforced honeycomb packaging with individual slots that hold each fan securely in place. This ensures our products arrive in pristine condition, ready to deliver top-tier cooling performance upon installation.

Why Choose Us: The DC Axial Fan Manufacturer You Can Trust

Innovative R&D Capability

Innovation drives us forward. With 20+ patents and monthly new releases, our R&D focuses on eco-friendly materials and sustainable cooling technologies. Partnering with us means access to energy-efficient solutions that meet today’s demands and global standards.

Fast and Reliable Shipping

Time is critical in every project. That’s why we guarantee delivery of DC fans and blowers within 2–4 weeks. Our streamlined production and logistics systems minimize delays, helping you maintain schedules, reduce costly downtime, and meet tight deadlines with confidence.

Premium Protective Packaging

We go the extra mile to ensure your products arrive in perfect condition. Using high-quality honeycomb boxes and reinforced pallets, each fan is placed in an individual slot to prevent movement during transit. This advanced packaging reduces shipping damage, lowers costs, and preserves the integrity of your investment from factory to facility.

Rapid Response & Development

We understand that responsiveness matters. Our support team provides inquiry replies and after-sales solutions within 12 hours. For custom projects, we leverage 3D printing technology to accelerate development, enabling initial samples in just 10 days. This rapid turnaround helps shorten product development cycles and bring innovations to market faster.

Comprehensive Warranty Protection

Every product we ship is backed by a strong warranty. Our standard DC motor fans include a 2-year warranty, while custom-designed fans carry a 1-year warranty. This coverage ensures you receive reliable support and added peace of mind, knowing your investment is protected against unexpected issues.

Expert Technical Support

Our commitment to customers extends beyond the sale. A dedicated team of trained specialists is always available to provide: Professional application advice Installation guidance Performance optimization tips Troubleshooting assistance

FAQs

What materials are your DC fans made of?

Our DC fans are built using premium PBT plastic blades, ADC-12 aluminum alloy frames, and high-quality copper motor windings. These materials are selected for their durability, heat resistance, and compliance with RoHS 2.0 standards. By using advanced raw materials, we ensure reliable performance, reduced deformation under stress, and long service life in demanding industrial environments.

How long do your DC fans typically last?

Lifespan depends on application and conditions, but thanks to NMB bearings (available in ball and sleeve types), our fans can last up to 70,000 hours at 40℃ of continuous operation. Rigorous testing ensures consistent airflow, low noise, and long-term reliability, making them ideal for mission-critical applications where downtime is unacceptable.

Can your DC fans operate in harsh environments?

Yes. Our fans are engineered to withstand extreme environments. With options for IP65, IP67, or IP68 waterproofing, they resist dust, moisture, rain, and even submersion. Combined with nano-coating technology and reinforced aluminum frames, they remain stable in conditions ranging from -40℃ to 120℃, ensuring safe and uninterrupted cooling in industrial and outdoor applications.

Do your DC fans support speed and control customization?

Our fans can be customized with PWM (Pulse Width Modulation) for speed adjustment, FG (Frequency Generation) for monitoring, and RD (Rotation Detection) for feedback. This allows precise airflow control, energy savings, and integration into automated systems, making them ideal for industries requiring tailored cooling performance and real-time system optimization.

Do you provide custom design and manufacturing services?

Yes, we specialize in OEM and ODM services. From fan size and speed to voltage and waterproofing levels, every aspect can be customized. Our R&D team, with over 20 patents, uses 3D printing and CNC machining for prototypes, helping clients develop unique solutions that match their exact system requirements quickly and efficiently.

What kind of after-sales support do you offer?

Our after-sales service is designed for quick and reliable response. We reply to inquiries within 12 hours and provide troubleshooting, technical guidance, and replacement support when necessary. With a 2-year warranty on standard fans and 1-year on custom units, customers can rest assured that they’re fully backed even after purchase.

How do you ensure quality consistency across large orders?

We follow a strict quality management system in compliance with ISO 9001 standards. From raw material inspection to final assembly, every step includes rigorous checkpoints. Multi-batch testing guarantees uniform performance, so whether you order 100 or 10,000 fans, you receive the same high-quality standard, protecting your brand reputation and supply chain reliability.

Contact & Inquiry

Contact us today for detailed product information, quotes, or expert technical support. Simply complete the form with your name, email, company, country, and inquiry, and our team will get back to you quickly. You can also connect with us directly via WhatsApp, email, or phone for fast and reliable assistance.