Custom DIN Rail Mount Terminal Block Manufacturer in China

We offer a comprehensive range of DIN rail mount terminal blocks designed for diverse industrial applications. Our selection includes popular connection technologies like screw, spring-cage, and push-in, ensuring secure and efficient wiring. You’ll find various types such as feed-through, ground, fuse, and multi-level blocks, accommodating a wide range of wire sizes and current ratings. We also provide essential accessories like jumpers, end plates, and marking systems for complete and organized installations.

Linkwell Electrics - Your Trusted DIN Rail Mount Terminal Block Manufacturer from China

Linkwell Electrics stands as a trusted DIN rail mount terminal block manufacturer from China, recognized for high-quality and reliable solutions. With decades of experience, we specialize in a broad range of terminal blocks including screw, spring, and push-in types, alongside various accessories. Our commitment to innovation and customer satisfaction ensures efficient and secure electrical connections for diverse industrial and automation applications worldwide.

Various DIN Rail Mount Terminal Block

DIN rail mounted terminal blocks

We offer a comprehensive selection of DIN rail mounted terminal blocks, engineered for reliable and organized electrical connections. Our range includes versatile screw, spring-cage, and push-in connection types to suit various installation needs. You’ll find standard feed-through, ground, fuse, and multi-level blocks, accommodating a wide spectrum of wire sizes and current capacities. We also provide essential accessories for complete, efficient, and safe wiring solutions in diverse applications.

15mm din rail terminal block

We offer 15mm DIN rail terminal blocks, ideal for compact applications where space is at a premium. Our range includes mini screw connection blocks, like the JMBK3/E-Z series, crafted from flame-retardant PA 6.6 with brass conductive elements for robust and reliable connections. These miniature terminals are perfect for solar combiners, power distribution, and other systems requiring organized wiring in limited enclosures, ensuring easy installation and excellent electrical performance.

din rail blade fuse terminal block

We offer a specialized range of DIN rail blade fuse terminal blocks, providing crucial overcurrent protection in a compact design. These blocks integrate a fuse holder directly into the terminal, saving valuable panel space and simplifying wiring. Our selection includes various types, often featuring visual blown fuse indication for quick troubleshooting, ensuring efficient and safe circuit protection for industrial and electrical applications.

din rail busbar terminal block

We offer a robust selection of DIN rail busbar terminal blocks, designed for efficient power distribution in various industrial applications. These specialized blocks facilitate organized and secure connections to a central busbar, providing a common potential point for multiple circuits. Our range includes options for different current ratings and wire cross-sections, with various connection technologies like screw and stud terminals. We also provide complementary accessories, such as insulation caps and mounting supports, to ensure a complete and reliable busbar system.

din rail fuse holder terminal blocks

We offer a variety of DIN rail fuse holder terminal blocks, providing circuit protection directly within your wiring. Our range includes options for various fuse types (e.g., fine-wire fuses, automotive fuses) and connection technologies like screw and push-in. These blocks feature integrated fuse holders for easy replacement and often include indicators for blown fuses, simplifying troubleshooting and maintenance in control cabinets and industrial applications.

DIN rail ground terminal block

We offer a robust selection of DIN rail ground terminal blocks, vital for ensuring electrical safety. These terminal blocks provide a reliable, low-resistance connection to the grounding system, featuring durable construction and clear green/yellow identification. Available in various wire sizes and connection types (screw, spring-cage, push-in), our ground terminals comply with international safety standards, making them ideal for industrial and automation applications demanding secure earthing.

DIN rail power distribution terminal blocks

We offer a specialized selection of DIN rail power distribution terminal blocks designed for efficient and safe power routing. These blocks feature high current carrying capacities and robust construction, often incorporating brass or tinned copper guides for excellent conductivity. Available in various pole configurations and connection types (screw, spring-cage, push-in), our power distribution blocks simplify wiring in control panels and switchgear, ensuring reliable and organized power distribution within electrical systems.

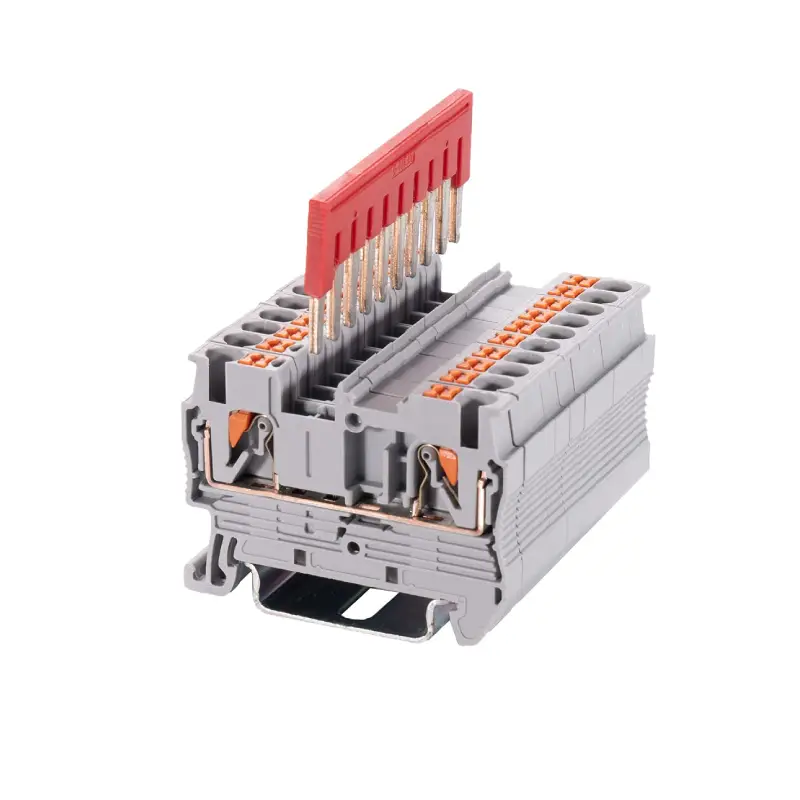

dIN rail terminal blocks with jumpers

We provide a wide selection of DIN rail terminal blocks, complemented by various jumper solutions for efficient potential distribution. Our offering includes internal jumpers (comb-type or plug-in) for connecting adjacent or non-adjacent blocks, external jumpers (screw-down or push-in) for flexible connections, and step-down jumpers for different terminal block sizes. These jumpers ensure reliable electrical commoning, simplify wiring layouts, and enhance system flexibility for your specific application needs.

high current dIN rail terminal block

We offer robust high-current DIN rail terminal blocks, ideal for demanding industrial power distribution. Our range includes options like the UKK series, capable of handling significant wire cross-sections (e.g., up to 240mm² for the KE series) and high current ratings (e.g., 150A for UKH 50, and up to 500A in other distribution block series). These blocks are available in screw, spring-cage, and push-in connection methods, ensuring reliable and safe connections for various heavy-duty applications.

modular dIN rail mounted terminal blocks

We provide a wide selection of modular DIN rail mounted terminal blocks, offering maximum flexibility for your wiring needs. Our range includes versatile feed-through, ground, fuse, and disconnect blocks, available with screw, spring-cage, and push-in connection technologies. These modular units can be easily combined to create custom terminal strips, saving space and streamlining installations for efficient and organized electrical systems.

screwless din rail terminal blocks

We proudly offer a comprehensive selection of screwless DIN rail terminal blocks, utilizing advanced spring-cage and push-in technologies. These innovative designs enable fast, tool-free wiring, significantly reducing installation time and effort. Our screwless blocks provide highly reliable, vibration-resistant connections, ideal for applications requiring quick changes or in environments prone to movement. This range includes various types like feed-through, ground, and multi-level, ensuring a versatile solution for modern electrical systems.

Why Choose Our DIN Rail Mount Terminal Block

Unmatched Reliability and Durability

Our terminal blocks are engineered for long-lasting performance in demanding industrial environments. Manufactured from high-grade, robust materials, they resist corrosion, vibration, and extreme temperatures, ensuring a secure and stable electrical connection over time. This superior durability minimizes downtime and maintenance, providing peace of mind and operational efficiency for your critical systems.

Versatile Connection Technologies

We offer a comprehensive range of connection methods to suit diverse application requirements. Whether you prefer the traditional security of screw clamps, the rapid efficiency of spring-cage technology, or the ultimate convenience of push-in connections, we have a solution. This versatility allows you to optimize wiring speed and ensure the most suitable connection for your specific project needs.

Enhanced Safety Features

Safety is paramount in electrical systems, and our terminal blocks are designed with multiple protective features. They incorporate robust insulation, touch-safe designs, and clear marking options to prevent accidental contact and ensure proper wire identification. Compliance with international safety standards further guarantees that our products contribute to a secure working environment and reliable system operation.

Streamlined Installation and Maintenance

Our DIN rail terminal blocks are designed for ease of use, significantly reducing installation time and simplifying future maintenance. The modular design allows for quick snap-on mounting and straightforward wiring, while clear labeling options facilitate rapid troubleshooting. This user-friendly approach translates to lower labor costs and improved efficiency throughout the lifecycle of your electrical installations.

what is a din rail mount terminal block?

A DIN rail mount terminal block is a modular electrical connector designed to provide a secure and organized point for connecting wires within an electrical system.

It consists of an insulating housing, typically made of plastic, encasing a conductive metal part. Wires are inserted into openings in the block and secured via various clamping mechanisms (e.g., screw, spring, push-in).

These DIN rail mounted terminal blocks are specifically designed to clip onto a standardized metal rail, known as a DIN rail, which offers a convenient and space-saving method for mounting and arranging electrical components in control cabinets, distribution boards, and industrial machinery, ensuring safe and efficient wiring management.

din rail terminal block connector types

DIN rail terminal blocks come in various types, each designed for specific wiring needs and applications.

Screw Type Terminal Blocks: These are perhaps the most traditional and widely used type. They feature a screw that, when tightened, clamps down on the wire, securing it against a conductive metal bar within the block. This method provides a very strong and reliable connection, making it suitable for applications where vibration might be an issue or where frequent disconnections are not anticipated. They are known for their robustness and ability to handle a wide range of wire sizes, offering a secure and enduring connection.

Spring-Cage Terminal Blocks: Also known as tension clamp or push-in spring-cage terminal blocks, these utilize a spring mechanism to exert continuous pressure on the wire. To make a connection, a tool (often a screwdriver) is inserted into a small opening to open the spring clamp, the stripped wire is inserted, and the tool is removed, allowing the spring to clamp the wire. They are valued for their vibration resistance, fast wiring times (compared to screw types), and maintenance-free operation as the spring continuously adjusts to wire movement or temperature changes.

Push-in Terminal Blocks: These represent a more modern and increasingly popular “screwless” option, especially for solid wires or stranded wires with ferrules. With push-in technology, the prepared wire can often be directly inserted into the terminal block without the need for any tools. An internal spring mechanism automatically secures the wire, providing a quick and efficient connection. They are highly favored for their speed of installation, reduced wiring effort, and suitability for high-density wiring applications where space might be limited.

Feed-Through Terminal Blocks: These are the most basic type, providing a simple, direct electrical connection between two wires entering and exiting the block. They essentially extend a single circuit, maintaining electrical continuity. They are used for general wiring applications where signals or power need to be passed from one point to another without any additional functionality like fusing or grounding.

Ground (PE) Terminal Blocks: Easily identifiable by their green and yellow coloration, ground terminal blocks are specifically designed to establish a protective earth (PE) connection. They feature a conductive foot that makes a direct, reliable electrical connection to the DIN rail itself, which serves as the ground busbar when properly earthed to the cabinet or enclosure. This ensures that any fault currents are safely directed to the ground, enhancing system and personnel safety.

Fuse Terminal Blocks: These blocks integrate a fuse holder directly into the terminal block, providing overcurrent protection for specific circuits. They allow for easy insertion and replacement of fuses, offering a convenient and compact way to protect sensitive equipment or circuits within a control panel. Many fuse terminal blocks also include a blown fuse indicator (often an LED) for quick fault detection and troubleshooting.

Multi-Level Terminal Blocks: Designed to save space in crowded control cabinets, multi-level terminal blocks provide multiple connection points (two, three, or even more) stacked vertically within a single block. This allows for connections to different potentials or circuits in a compact footprint, effectively maximizing wiring density on the DIN rail. They come in various configurations, including those with internal shorting links or ground connections on specific levels.

what Is DIN rail terminal block used for?

DIN rail terminal blocks are fundamental components used across a vast array of electrical and industrial applications for organizing, connecting, and distributing electrical wiring.

Their primary purpose is to provide a secure, reliable, and insulated interface for joining individual wires, ensuring continuity and preventing accidental short circuits. They are an indispensable part of electrical control panels, automation systems, machinery, and building installations, where neatness, safety, and ease of maintenance are critical. By centralizing connections, they simplify troubleshooting, modifications, and expansions of electrical circuits.

Key applications and uses include:

- Industrial Control Panels: They are extensively used in the wiring of PLCs, relays, contactors, motor starters, and other control devices, providing a structured way to connect power, control signals, and sensor inputs/outputs.

- Power Distribution: DIN rail terminal blocks are utilized to distribute power effectively from a main supply to various components or sub-circuits within an enclosure, often incorporating fuse or disconnect functionalities.

- Building Automation and HVAC Systems: For connecting sensors, actuators, thermostats, and control units, allowing for orderly wiring and system integration.

- Machinery Wiring: Essential for connecting motors, sensors, safety devices, and operator interfaces on industrial machinery, ensuring robust and vibration-resistant connections.

- Telecommunications and Data Networks: While specialized connectors are often used, basic terminal blocks can be found in some telecommunication cabinets for power distribution or signal routing.

- Test and Measurement Equipment: Providing convenient and reliable connection points for test leads and instrumentation.

What is the standard for terminal blocks?

The primary international standard governing DIN rail terminal blocks, and terminal blocks in general, is the IEC 60947 series, specifically IEC 60947-7. This series, published by the International Electrotechnical Commission (IEC), sets out the requirements for low-voltage switchgear and controlgear, with Part 7 focusing on “Ancillary equipment – Terminal blocks.” Within this part, there are further sub-standards that address different types of terminal blocks, such as:

- IEC 60947-7-1: Specifies requirements for terminal blocks with screw-type or screwless-type clamping units primarily intended for industrial or similar use, covering aspects like electrical and mechanical connection between copper conductors.

- IEC 60947-7-2: Focuses on protective conductor (PE) terminal blocks, ensuring safe grounding connections.

- IEC 60947-7-3: Deals with fuse terminal blocks, outlining safety requirements and test methods for their mechanical, electrical, and thermal characteristics.

Beyond the IEC standards, other regional or national standards are also important. In North America, UL (Underwriters Laboratories) standards, particularly UL 1059, are widely recognized for terminal blocks and connectors, focusing heavily on product safety and preventing hazards like electrical fires or shocks.

Similarly, CSA (Canadian Standards Association) standards, such as CSA C22.2 No. 158, apply in Canada. Adherence to these standards ensures global compatibility, safety, and reliability, covering crucial aspects like current-carrying capacity, insulation resistance, mechanical durability (e.g., resistance to vibration and shock), and proper clearances and creepage distances to prevent electrical breakdowns.

Send Your Inquiry Now

All-in-one DIN Rail Mount Terminal Block Solutions for Your Project

We provide all-in-one DIN rail mount terminal block solutions to streamline your projects. Our extensive range covers every need, from basic feed-through to specialized fuse and ground blocks, available with screw, spring, or push-in connections. We also offer a full complement of accessories like jumpers and markers, ensuring a complete, efficient, and organized wiring system for any industrial or automation application.