The efficient and reliable operation of a dry-type transformer heavily depends on its cooling system. Selecting the appropriate cooling method is crucial to prevent overheating, extend the transformer’s lifespan, and ensure optimal performance under varying load conditions. Understanding the different cooling classifications and their implications is the first step towards making an informed decision.

This blog post will delve into the primary cooling methods employed in dry-type transformers, such as natural air (AN) and forced air (AF). We’ll explore the principles behind each technique, discuss their respective advantages and limitations, and provide guidance on choosing the right cooling method tailored to your specific needs and application environment.

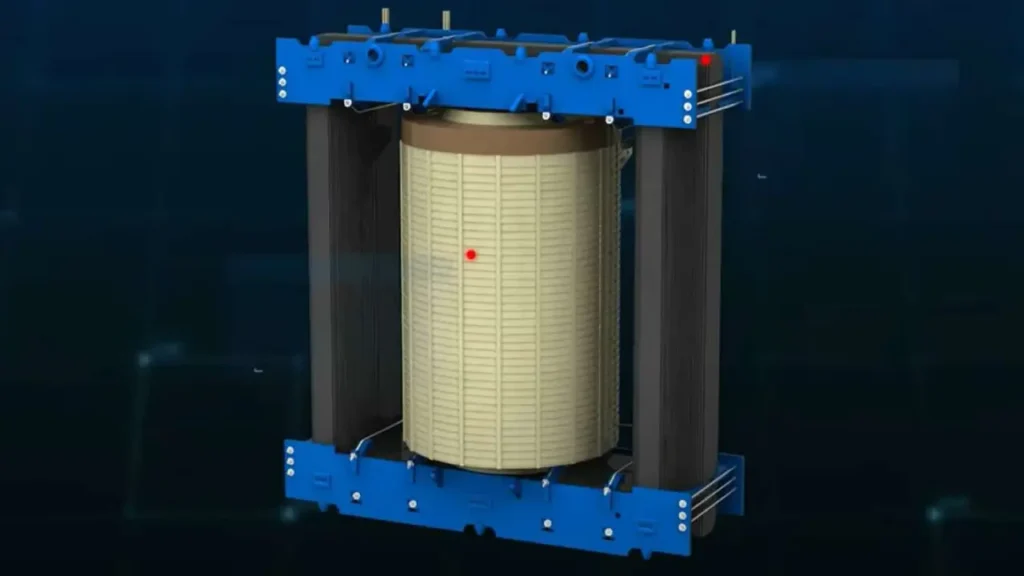

What is Dry Type Transformer

A dry-type transformer is an electrical transformer that uses air or a non-flammable solid insulating material, such as epoxy resin, as the primary insulation medium for its windings, rather than relying on oil or other liquids.

This design inherently eliminates the risk of oil leaks and reduces flammability concerns, making them suitable for indoor and environmentally sensitive applications. While typically having a lower cooling capacity compared to liquid-filled transformers, they offer benefits like reduced maintenance and enhanced safety in specific environments.

What is Dry Type Transformer Cooling

Dry-type transformer cooling refers to the methods used to dissipate the heat generated within the transformer’s core and windings during operation, as they do not rely on oil or other liquids for cooling.

The primary goal is to maintain the transformer’s temperature within its design limits to ensure efficient performance and prolong its lifespan. The two main cooling methods for dry-type transformers are natural air cooling (AN) and forced air cooling (AF).

Dry Type Transformer Cooling Methods

Efficient cooling is paramount for the reliable operation of dry-type transformers, preventing overheating and ensuring a long service life. Unlike liquid-filled units, dry-type transformers dissipate heat through air circulation.

Understanding the different cooling methods available is essential for selecting the appropriate transformer for specific applications and environmental conditions. The two primary methods are natural air cooling and forced air cooling, each with its own benefits and applications.

Natural Air Cooling

Natural air cooling (AN) relies on the natural convection of air to dissipate heat generated by the transformer’s core and windings. As the transformer operates, the heated air surrounding it rises, and cooler ambient air flows in to replace it, creating a continuous cycle of heat transfer. This method is simple, reliable, and doesn’t require any moving parts like fans, resulting in minimal maintenance and quiet operation.

Benefits of natural air cooling include its simplicity, low initial cost, and minimal maintenance requirements. It is particularly well-suited for smaller transformers and applications with relatively low power ratings where the heat generated can be effectively dissipated by natural air circulation. Common applications include commercial buildings with good ventilation, low-power industrial controls, and residential complexes where noise levels need to be kept low.

Forced Air Cooling

Forced air cooling (AF) enhances the heat dissipation process by using fans or blowers to direct a stream of air across the transformer’s windings and core. This forced airflow significantly increases the rate at which heat is removed compared to natural convection, allowing the transformer to operate at higher load capacities or in environments with higher ambient temperatures. Forced air cooling is often employed for medium to large-sized dry-type transformers where natural cooling alone is insufficient.

The benefits of forced air cooling include its ability to increase the transformer’s power rating (typically by 25% to 50% over natural air-cooled ratings), making it suitable for higher load demands and enclosed spaces with limited natural ventilation. It is commonly used in industrial facilities with heavy machinery, data centers with significant heat generation, and in situations where a smaller transformer footprint is desired for a given power output. While effective, forced air cooling introduces the need for fan maintenance and can result in increased noise levels and energy consumption for the fans.

Here are the differences between natural air cooling and the forced air cooling method for dry type transformer cooling:

| Feature | Natural Air Cooling (AN) | Forced Air Cooling (AF) |

| Cooling Mechanism | Natural convection of air | Fans/blowers forcing air circulation |

| Power Rating | Suitable for lower power ratings | Suitable for medium to high power ratings |

| Overload Capacity | Lower | Higher (with fans operating) |

| Maintenance | Minimal, no moving parts | Requires fan/blower maintenance |

| Noise Level | Low, quiet operation | Higher due to fan noise |

| Initial Cost | Generally lower | Higher due to fans/blowers |

| Energy Consumption | Lower | Higher due to fan power usage |

| Complexity | Simpler design | More complex with fan controls |

| Ventilation Needs | Requires good natural ventilation | Can operate with less natural ventilation |

| Typical Applications | Small commercial, low-power industrial | Large commercial, heavy industrial, data centers |

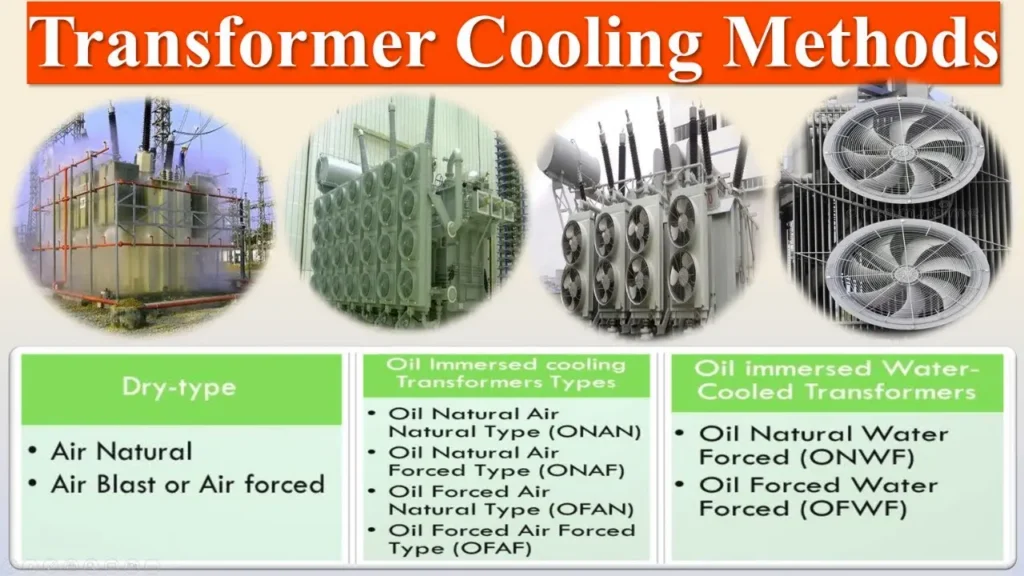

Dry Type Transformer Cooling Classes

Dry-type transformers are categorized into different cooling classes based on how heat is dissipated from their windings and core. These classifications, defined by standards like ANSI/IEEE C57.12.01, help users understand the transformer’s cooling capabilities and limitations. The most common cooling classes involve variations of air cooling, utilizing either natural convection or forced air circulation to manage the heat generated during operation and maintain safe temperature levels for the insulation materials.

The primary dry-type transformer cooling classes include AA (Air Natural), AFA (Air Forced Air), AA/FA (Air Natural/Forced Air), and ANV (Air Natural Non-Ventilated). AA relies solely on natural air convection through ventilation openings in the enclosure.

AFA uses fans to force air through specific ventilation ports for enhanced cooling. AA/FA transformers have a dual rating, operating with natural air cooling at lower loads and automatically engaging fans for forced air cooling at higher loads. ANV transformers are enclosed without ventilation ports, relying on natural air circulation around the enclosure, often with external fins to increase the cooling surface area.

- AA (Air Natural): Cools solely through natural air convection via enclosure vents. Simple, reliable, and requires no fans. Suitable for lower power ratings and well-ventilated areas.

- AFA (Air Forced Air): Uses fans to force air through dedicated enclosure vents, significantly increasing cooling efficiency. Allows for higher power ratings but requires fan maintenance and increases noise.

- AA/FA (Air Natural/Forced Air): Operates with natural air cooling at lower loads and automatically activates fans for forced air cooling at higher loads, providing dual capacity.

- ANV (Air Natural Non-Ventilated): Cooled by natural air circulation around a sealed enclosure, often with external fins. Suitable for specific environments needing protection from external air contaminants.

How to Choose the Best Dry Type Transformer Cooling Methods

Selecting the optimal dry-type transformer cooling method involves evaluating your specific operational needs and environmental conditions.

Begin by determining the transformer’s required power rating and the expected load demands, as higher loads often necessitate forced air cooling. Consider the ambient temperature and the ventilation available at the installation site; poorly ventilated or high-temperature environments may also benefit from forced air. Noise sensitivity is another crucial factor, as natural air cooling offers quieter operation.

Finally, weigh the initial cost of the transformer against the long-term operational expenses, including potential fan maintenance and energy consumption for forced air systems.

- Power Rating and Load Demands: Higher kVA ratings and consistently heavy loads often require forced air cooling for adequate heat dissipation.

- Ambient Temperature and Ventilation: High ambient temperatures or poorly ventilated installation locations may necessitate forced air to prevent overheating.

- Noise Sensitivity: For environments where noise is a concern (e.g., offices, hospitals), natural air cooling is the quieter option.

- Budget (Initial vs. Operational): Natural air-cooled transformers typically have a lower initial cost, while forced air units incur additional expenses for fans and their energy consumption but may allow for a smaller transformer footprint.

- Space Constraints: Forced air cooling can enable a smaller transformer to handle a higher load, which can be beneficial in space-limited installations.

- Reliability and Maintenance: Natural air cooling is inherently more reliable due to the absence of moving parts, while forced air systems require periodic fan maintenance.

- Future Load Growth: If future increases in load are anticipated, selecting a transformer with forced air cooling capabilities provides greater flexibility.

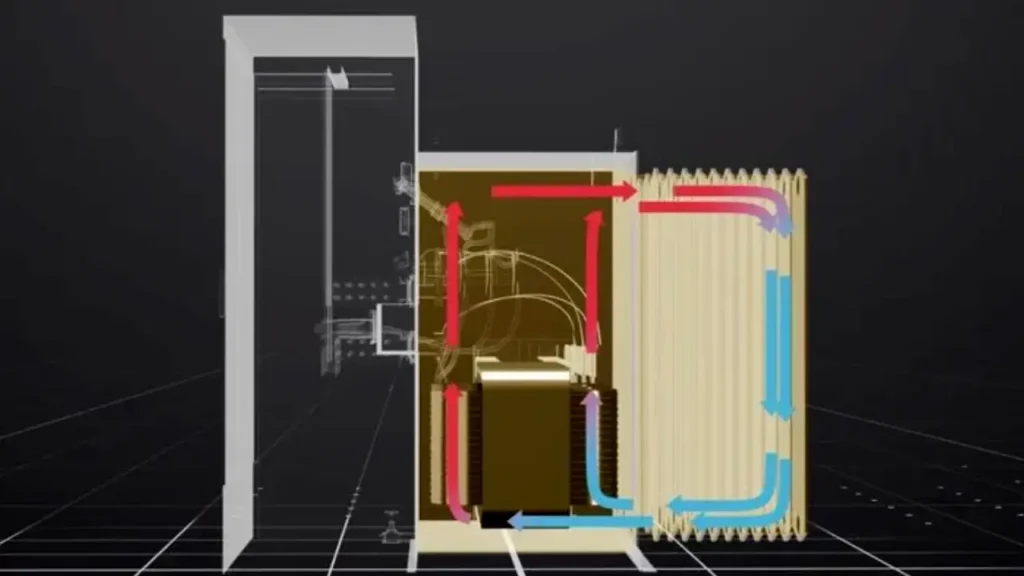

Dry Type Transformer Cooling System

A dry-type transformer cooling system is essential for managing the heat generated during operation, ensuring efficiency and longevity without the use of oil or other liquids.

The primary method is air-based, relying on the circulation of air around the transformer’s core and windings to dissipate heat and maintain optimal operating temperatures. Different techniques are employed to enhance this air cooling process based on the transformer’s size, load, and environmental conditions.

- Natural Air (AN): This method utilizes the natural convection of air. As the transformer heats up, the surrounding air becomes warmer and rises, allowing cooler ambient air to flow in and take its place. It’s a simple and reliable method suitable for lower power ratings and well-ventilated environments.

- Forced Air (AF): This system employs fans or blowers to actively circulate air across the transformer’s surfaces. By increasing the airflow, the rate of heat removal is significantly enhanced, allowing the transformer to handle higher loads or operate in warmer environments.

- Open Ventilation: The transformer’s windings and core are directly exposed to the surrounding air, maximizing the surface area for heat dissipation through natural or forced air circulation. This is common in relatively clean and dry indoor environments.

- Enclosed Ventilation: The transformer is housed in an enclosure with specific ventilation openings designed to control airflow and protect the internal components from dust and moisture while still allowing for effective air cooling, often utilizing natural or forced air.

Conclusion

Selecting the appropriate cooling method for your dry-type transformer is crucial for ensuring its efficient operation, longevity, and reliability. Understanding the differences between natural air (AN) and forced air (AF) systems, as well as considering factors like load demands and ambient temperature, will lead to optimal thermal management and prevent premature failure. Making an informed decision here directly impacts the overall performance and lifespan of your transformer.

For businesses seeking a dependable supply of wholesale dry-type transformers with various cooling options, Linkwell Electrics offers a comprehensive selection. Their expertise can guide you in choosing the right transformer and cooling method to meet your specific technical requirements and operational environment.

Contact Linkwell Electrics today, your trusted manufacturer from China, to explore their wholesale dry-type transformer offerings and find the ideal cooling solution for your needs.