Dry type transformers are essential components in countless industrial settings, safely stepping down voltage for various operations. A critical aspect of selecting the right transformer is understanding its KVA rating, which directly correlates to its power handling capacity. This blog post will demystify KVA ratings, helping you make informed decisions.

Properly sizing a dry type transformer is vital for efficiency, safety, and operational longevity. We’ll explore what KVA signifies, how it relates to your specific industrial needs, and the key factors to consider when determining the optimal KVA rating for your applications.

What are Dry Type Transformers

Dry type transformers are electrical devices that transfer energy between circuits by electromagnetic induction, stepping up or stepping down voltage levels without the use of liquid insulation or cooling mediums like oil.

Instead, they rely on air or solid insulating materials, such as epoxy resin or high-temperature insulation systems, to dissipate heat and prevent overheating. This design makes them inherently safer due to the absence of flammable liquids, making them ideal for indoor installations in places like commercial buildings, hospitals, and industrial facilities where fire safety and environmental concerns are paramount.

How to Measure Dry Type Transformer Sizes

Accurately measuring dry-type transformer sizes is crucial for proper installation and system integration. This involves understanding key electrical parameters and physical dimensions.

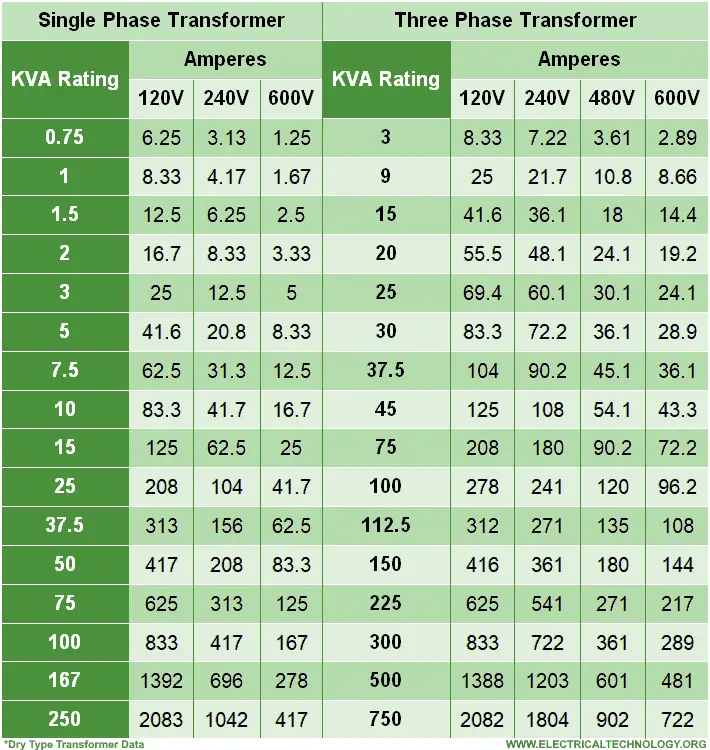

Calculating KVA Requirements

Determining the necessary KVA (kilovolt-ampere) rating is the first step in sizing a dry-type transformer. This involves assessing the total power demand of the connected load, considering both continuous and intermittent loads, as well as potential future expansion. It’s often recommended to include a safety margin to accommodate unexpected spikes and ensure longevity.

To calculate KVA, you’ll need to know the voltage and current of your connected equipment. For single-phase loads, KVA = (Volts x Amps) / 1000. For three-phase loads, KVA = (Volts x Amps x 3) / 1000. Be sure to account for power factor if known, as it affects the true power drawn.

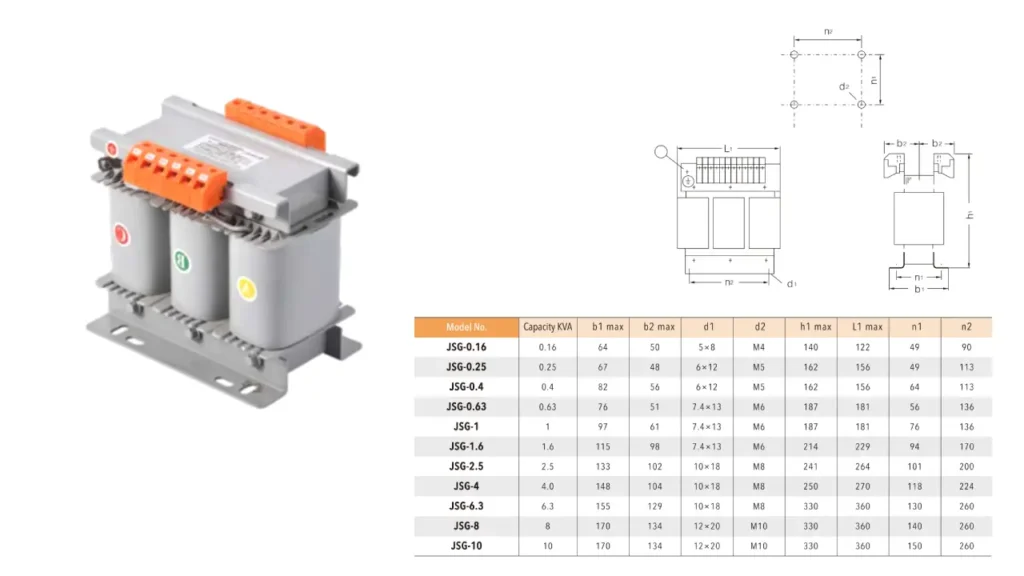

Physical Dimensions and Footprint

Once the electrical requirements are established, consider the transformer’s physical dimensions. This includes its height, width, and depth, all of which are critical for fitting the unit into its designated space. Access for maintenance, ventilation, and future upgrades must also be factored into the spatial planning.

The weight of the transformer is another important physical measurement, as it impacts structural considerations and transportation logistics. Ensure that the mounting surface or platform can adequately support the transformer’s weight, and plan for appropriate lifting equipment during installation.

Standard Dry Type Transformer Sizes

Understanding standard dry type transformer sizes is crucial for efficient power distribution and system design. These standardized ratings simplify selection and ensure compatibility across various applications.

Common KVA Ratings

Dry type transformers are manufactured in a range of standardized KVA ratings to meet diverse power requirements.

For single-phase applications, common sizes often include 1.5 KVA, 3 KVA, 5 KVA, 7.5 KVA, 10 KVA, 15 KVA, 25 KVA, 37.5 KVA, 50 KVA, 75 KVA, 100 KVA, 167 KVA, and 333 KVA. Three-phase units typically come in sizes such as 15 KVA, 30 KVA, 45 KVA, 75 KVA, 112.5 KVA, 150 KVA, 225 KVA, 300 KVA, 500 KVA, 750 KVA, 1000 KVA, 1500 KVA, 2000 KVA, and larger.

These standardized dry type transformer ratings help ensure that replacement parts are readily available and that equipment from different manufacturers can be integrated seamlessly.

The selection of a specific KVA rating depends heavily on the total connected load and the need for future expandability. It’s generally good practice to choose a transformer with a slightly higher KVA rating than the calculated continuous load to prevent overloading and allow for growth. This also helps in managing inrush currents from motor starting or other transient loads, ensuring stable operation and prolonged transformer life.

| Single-Phase KVA Ratings | Three-Phase KVA Ratings |

| 1.5 KVA | 15 KVA |

| 3 KVA | 30 KVA |

| 5 KVA | 45 KVA |

| 7.5 KVA | 75 KVA |

| 10 KVA | 112.5 KVA |

| 15 KVA | 150 KVA |

| 25 KVA | 225 KVA |

| 37.5 KVA | 300 KVA |

| 50 KVA | 500 KVA |

| 75 KVA | 750 KVA |

| 100 KVA | 1000 KVA |

| 167 KVA | 1500 KVA |

| 333 KVA | 2000 KVA |

Industry Standards (NEMA/IEC)

Dry type transformer sizes and their performance characteristics are often governed by industry standards set by organizations like the National Electrical Manufacturers Association (NEMA) in North America and the International Electrotechnical Commission (IEC) globally. These standards ensure consistency in manufacturing, performance, and safety. For instance, NEMA standards often specify voltage classes (e.g., 600V class, medium voltage), insulation classes (e.g., 220°C insulation system), temperature rise limits (e.g., 80°C, 115°C, 150°C), and enclosure types (e.g., NEMA 1 for indoor, NEMA 3R for outdoor).

Compliance with these standards guarantees a certain level of quality and interoperability. When specifying a dry-type transformer, referencing the relevant NEMA or IEC standard ensures that the unit will meet specific performance criteria and safety requirements.

This standardization simplifies the design and procurement process for engineers and contractors, providing confidence in the transformer’s reliability and its ability to function as expected within an electrical system.

Here is our Transformer Catalog you can download to know all about out transformer sizes in the following:

https://linkwellelectrics.com/wp-content/uploads/2025/05/Transformer-Catalog-Linkwell-Electrics.pdf

What Are the Different Types of Dry Transformers?

Dry-type transformers are categorized by their insulation and cooling methods, each offering distinct advantages for various applications. Understanding these types is key to selecting the most suitable transformer for a given environment.

Cast Resin Transformers (CRT)

Cast resin transformers, often referred to as cast coil transformers, encapsulate their windings in epoxy resin under vacuum. This creates a highly durable, solid, and moisture-resistant block that protects the windings from environmental contaminants like dust and humidity. The robust construction provides excellent mechanical strength and resistance to short circuits, making them highly reliable in challenging conditions.

Due to their sealed, non-flammable nature and minimal maintenance requirements, cast resin transformers are ideal for indoor installations where fire safety is paramount. They are commonly found in commercial buildings, hospitals, data centers, and industrial facilities, particularly in areas with high humidity or corrosive atmospheres, as the resin prevents moisture penetration and corrosion.

Vacuum Pressure Impregnated (VPI) Transformers

Vacuum Pressure Impregnated (VPI) transformers use a “dip and bake” method where the transformer coils are impregnated with a high-temperature polyester varnish or resin under vacuum and pressure. This process thoroughly fills any voids within the winding insulation, eliminating air pockets that could otherwise lead to partial discharge and insulation breakdown. The impregnated coils are then baked to cure the resin, forming a solid, moisture-resistant, and mechanically strong winding.

VPI transformers offer excellent resistance to moisture and contaminants, making them suitable for a wide range of industrial and commercial applications. They are known for their good mechanical and short-circuit strength, and their robust construction provides a safe and reliable option for environments where fire safety is a concern but a fully encapsulated unit isn’t strictly necessary. They are often lighter and more cost-effective than cast resin transformers for certain applications.

Dry Type Transformer Rating

Dry type transformer ratings define the operational capabilities and limits of the transformer, crucial for proper selection and safe application in electrical systems. These ratings specify various parameters including power handling capacity, voltage levels, insulation class, and temperature rise. Understanding these ratings ensures that the transformer can reliably meet the demands of the connected load and operate safely within its designed parameters, preventing overheating, insulation breakdown, and premature failure.

Key dry type transformer ratings include:

- kVA Rating (Kilovolt-Ampere): This is the apparent power rating, indicating the maximum continuous output power the transformer can deliver without exceeding its temperature limits. It’s the primary indicator of the transformer’s size and capacity. Standard kVA ratings vary widely, from small units (e.g., 15 kVA) up to large power transformers (e.g., 5000 kVA or more).

- Voltage Ratings: These specify the primary (input) and secondary (output) voltage levels the transformer is designed to operate at (e.g., 11kV/0.415kV, 480V/208Y/120V). Taps may also be included to adjust the voltage ratio.

- Insulation Class: This rating defines the maximum allowable temperature of the transformer’s insulation system. Common classes include Class B (130°C), Class F (155°C), Class H (180°C), and Class C (220°C). A higher insulation class indicates greater thermal resilience.

- Temperature Rise: This refers to the average temperature increase of the windings above the ambient temperature when the transformer is operating at its full rated load. Common temperature rise ratings are 80°C, 115°C, and 150°C. A lower temperature rise generally indicates higher efficiency and a longer lifespan.

- Frequency: Typically 50 Hz or 60 Hz, depending on the region’s electrical grid standard.

- BIL Rating (Basic Impulse Level): This indicates the transformer’s ability to withstand voltage surges from lightning strikes or switching operations without insulation breakdown.

- Efficiency: Measured in percentage, indicating how effectively the transformer converts input power to output power, with lower losses being more efficient. Regulations often specify minimum efficiency levels.

- Enclosure Type: Often rated according to NEMA (National Electrical Manufacturers Association) or IP (Ingress Protection) standards, defining the level of protection against environmental elements like dust, moisture, and foreign objects (e.g., NEMA 1, 2, 3R, 4X).

Conclusion

Understanding KVA ratings is paramount when selecting dry-type transformers for industrial applications. Correctly sizing your transformer ensures efficient power delivery, prevents overload, and extends equipment lifespan. This knowledge empowers you to make informed decisions, optimizing your electrical infrastructure.

Choosing the right KVA rating directly impacts operational efficiency and safety. Overlooking this crucial step can lead to costly downtime, power quality issues, and premature equipment failure. Therefore, a thorough assessment of your industrial load requirements is indispensable.

For all your industrial transformer needs, including a wide range of dry-type options, remember to get wholesale transformers from us. We offer competitive pricing and expert guidance to help you select the perfect transformer for your specific application.