Choosing the right electrical junction box size is crucial for safety and code compliance in your US projects. This guide helps you determine the correct dimensions based on wire fill capacity, device requirements, and installation environment, ensuring a safe and efficient electrical system.

Selecting the appropriate junction box size prevents overcrowding, overheating, and potential hazards. Learn how to calculate the necessary cubic inch volume according to the National Electrical Code (NEC) to accommodate your wiring needs and ensure a professional and safe installation in the United States.

Electrical Junction Box Sizes

Selecting the correct size of electrical junction box is a critical decision for any electrical project in the United States, directly impacting safety, code compliance with the NEC, and the functionality of your wiring. Understanding the common sizes available and their typical applications will help you choose the right enclosure to accommodate your wiring needs without overcrowding.

This guide explores some of the most frequently used electrical junction box sizes in the US market.

| Size Category | Typical Dimensions | Applications | Notes |

|---|---|---|---|

| Small | 150×150×75 mm (6″×6″×3″) 200×150×100 mm | Terminal blocks, small controllers, small relays | Ideal for compact installations where space is limited. |

| Medium | 300×200×150 mm (12″×8″×6″) 400×300×150 mm | PLCs, small power supplies, basic automation panels | Common for smaller automation setups with limited wiring or components. |

| Large | 600×400×200 mm (24″×16″×8″) 800×600×200 mm | Multiple modules, drives, relays, larger control panels | Used in medium-to-large-scale applications requiring more space. |

| Extra Large | 1000×800×250–300 mm 1200×1000×300 mm | Bigger control panels, industrial control systems | Suitable for large and complex control systems with extensive wiring. |

| Shallow Footprint | 600×400×100–150 mm | Panels with low mounting depth or shallow depth control | Space-efficient for installations where depth is restricted. |

| DIN-Rail / Modular | 1U/2U/3U equivalents (varies by supplier) | Modular components, DIN-rail mounted terminal blocks | Space-saving, flexible for modular setups with standardized rails. |

Key Considerations:

- Size Selection: Choose based on the components (PLCs, drives, terminal blocks, etc.) and required clearance for wiring/heat dissipation.

- Enclosure Rating: Ensure the IP (Ingress Protection) or NEMA (National Electrical Manufacturers Association) rating meets environmental and safety requirements.

- Mounting Type: Whether the enclosure is wall-mounted or floor-standing impacts size choice and installation.

- Internal Mounting Plate: Account for the space needed for mounting components like terminal blocks, relays, or power supplies.

4×4 Inch Square Boxes

These are among the most versatile and commonly used junction box sizes in residential and commercial wiring in the United States. Typically available in depths ranging from 1-1/2 inches to 2-1/8 inches, their square shape provides ample internal volume for making multiple wire connections and housing various types of wiring devices when used with appropriate covers. Their size makes them suitable for situations where several wires need to be spliced or where a single device, like a receptacle or switch, needs to be installed with multiple incoming or outgoing cables.

4×2 Inch Rectangular Boxes (Single Gang)

These are the standard rectangular boxes you often see used for single light switches or electrical outlets in US homes. Their dimensions are generally around 2 inches wide by 4 inches tall, with depths varying from 1-1/2 inches to 3-1/2 inches. The specific depth you choose will depend on the number of wires and the size of the device being installed, ensuring there’s enough space to safely accommodate everything within the box without overcrowding, which is a concern addressed by the National Electrical Code (NEC).

4-11/16 Inch Square Boxes (5S Boxes)

Slightly larger than the standard 4×4 square boxes, these offer even greater internal volume and are often used in commercial or industrial applications in the United States where a higher number of conductors or larger wire sizes are involved. Common depths range from 2-1/8 inches to 2-1/2 inches. These boxes are particularly useful for complex wiring scenarios or when pulling larger gauge wires that require more bending space, adhering to NEC guidelines for proper wire management and fill capacity.

Round or Octagonal Boxes (Ceiling Boxes)

These boxes, typically 4 inches in diameter with depths ranging from 1-1/2 inches to 3 inches, are commonly used for mounting light fixtures on ceilings or walls in US residential settings. The octagonal shape provides convenient points for securing mounting brackets for light fixtures. While they can be used as junction boxes, their primary purpose is to support the weight of light fixtures (up to a certain limit, usually indicated on the box) and provide a safe enclosure for the wiring connections. Shallower “pancake” versions are also available for situations with limited ceiling depth, primarily for lightweight fixtures.

Gang Boxes (Multi-Gang Boxes)

These are rectangular boxes designed to house multiple switches or outlets side-by-side. Common configurations include 2-gang, 3-gang, and 4-gang boxes, with their width increasing to accommodate each additional device (approximately 3-4 inches wide for a 2-gang, 4.5-6.5 inches wide for a 3-gang, etc., while maintaining a height of around 4 inches). The depth of multi-gang boxes also varies, similar to single-gang boxes, to provide adequate wiring space for the multiple devices they contain, ensuring compliance with wire fill requirements outlined in the NEC for installations in the United States.

Common Electrical Junction Box Sizes (Illustrative)

| Box Type | Approximate Dimensions (W x H x D) | Common Uses |

| 4×4 Square | 4″ x 4″ x 1.5″ to 2.125″ | Multiple wire connections, single devices |

| Single Gang (4×2) | 2″ x 4″ x 1.5″ to 3.5″ | Single switches or outlets |

| 4-11/16 Square (5S) | 4.6875″ x 4.6875″ x 2.125″ to 2.5″ | Higher wire counts, larger wires, commercial/industrial applications |

| Round/Octagonal (Ceiling) | 4″ Diameter x 1.5″ to 3″ | Ceiling/wall light fixtures, can also serve as junction points |

| 2-Gang | 3″ to 4″ x 4″ x 1.5″ to 3.5″ | Two switches or outlets |

| 3-Gang | 4.5″ to 6.5″ x 4″ x 1.5″ to 3.5″ | Three switches or outlets |

| Pancake (Round/Octagonal) | 4″ Diameter x 0.5″ to 0.75″ | Lightweight, surface-mounted light fixtures in shallow ceiling spaces |

Note: These are approximate and common sizes. Actual dimensions can vary slightly between manufacturers. Always consider the National Electrical Code (NEC) requirements for wire fill capacity when selecting a junction box size for your specific electrical project in the United States.

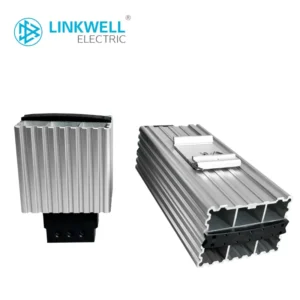

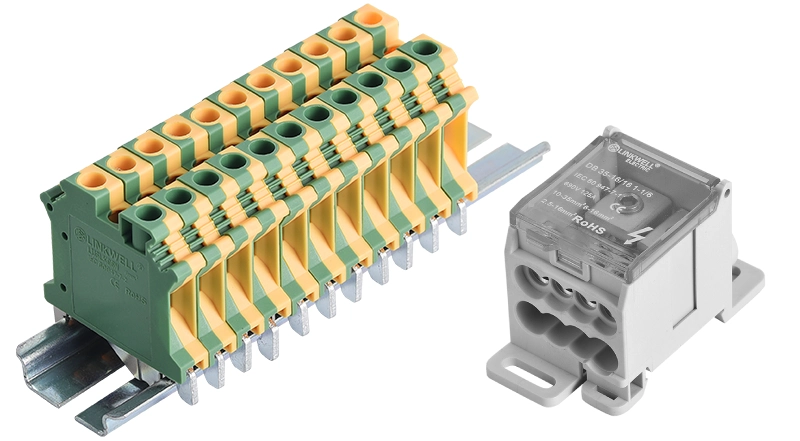

Junction Box Component

Recommended products

Standard Junction Box Sizes

What is the size of a standard junction box?

Selecting the correct size for an electrical junction box is a critical aspect of any electrical installation in the United States, ensuring safety and compliance with the National Electrical Code (NEC). Standard sizes are manufactured to meet a wide range of wiring needs, from simple single-device installations to more complex multi-conductor scenarios. Understanding these common dimensions and their typical applications will help you choose the appropriate enclosure for your project, while always keeping NEC wire fill requirements in mind.

4×4 Inch Square Boxes

These are a very common and versatile size in both residential and commercial electrical work in the US. Typically available in depths of 1-1/2″, 2-1/8″, and sometimes deeper, their square shape offers ample wiring space for multiple conductors and can accommodate a single device (like a switch or receptacle) when used with a suitable cover. Their larger volume makes them a go-to choice for situations where several wires need to be joined or where future circuit modifications might be anticipated.

4×2 Inch Rectangular Boxes (Single Gang)

These are the standard-sized boxes used for mounting single electrical devices such as light switches or outlets in US homes. Their approximate dimensions are 4 inches tall by 2 inches wide, with depths commonly ranging from 1-1/2″ to 3-1/2″. The specific depth selected depends on the number of wires entering the box and the size of the device being installed, ensuring sufficient space without exceeding the NEC’s fill capacity guidelines.

Round or Octagonal Boxes (Ceiling Boxes)

Typically 4 inches in diameter and available in depths from 1-1/2″ to 3 inches, these boxes are primarily used for mounting light fixtures on ceilings and walls in residential buildings across the United States. The octagonal shape provides convenient points for attaching fixture mounting brackets. While their main purpose is fixture support, they also serve as junction boxes for the fixture’s wiring connections. Shallower “pancake” versions exist for low-profile mounting.

Gang Boxes (Multi-Gang Boxes)

These rectangular boxes are designed to house two or more electrical devices side-by-side. Common configurations include 2-gang, 3-gang, and 4-gang boxes, with their width increasing to accommodate each additional device (approximately 4″, 6″, and 8″ wide, respectively, while maintaining a standard height of around 4″). The depth of these boxes also varies (similar to single-gang boxes) to provide adequate wiring space for the multiple devices they contain, adhering to NEC fill requirements for multi-device installations in the US.

Standard Junction Box Sizes Chart (Illustrative)

| Box Type | Approximate Dimensions (W x H x D) | Common Uses |

| 4×4 Square | 4″ x 4″ x 1.5″ to 2.125″ | Multiple wire connections, single devices |

| Single Gang (4×2) | 2″ x 4″ x 1.5″ to 3.5″ | Single switches or outlets |

| Round/Octagonal (Ceiling) | 4″ Diameter x 1.5″ to 3″ | Ceiling/wall light fixtures, wiring connections for fixtures |

| 2-Gang | 4″ x 4″ x 1.5″ to 3.5″ | Two switches or outlets |

| 3-Gang | 6″ x 4″ x 1.5″ to 3.5″ | Three switches or outlets |

| 4-Gang | 8″ x 4″ x 1.5″ to 3.5″ | Four switches or outlets |

| Pancake (Round/Octagonal) | 4″ Diameter x 0.5″ to 0.75″ | Low-profile mounting for lightweight fixtures in shallow spaces |

Note: These are common and approximate sizes found in the United States. Always refer to the manufacturer’s specifications for exact dimensions and, most importantly, calculate the required box volume based on the National Electrical Code (NEC) for your specific wiring configuration.

Round Junction Box Sizes

Selecting the correct size for a round electrical junction box in the United States, often used for lighting fixtures, involves considering the number and size of wires that will be connected within it, as mandated by the National Electrical Code (NEC). Round boxes, including the shallower “pancake” styles and deeper versions, come in various dimensions to accommodate different wiring needs and fixture mounting requirements. Understanding these standard sizes is key to ensuring a safe and code-compliant installation.

4 Inch Diameter Round/Octagonal Boxes

These are the most common sizes for ceiling and wall-mounted light fixtures in US residential wiring. Typically, they are available with depths ranging from 1-1/2 inches to 3 inches. The octagonal shape, often used interchangeably with round boxes for lighting, provides convenient points for securing fixture mounting brackets. The internal volume of these boxes must be sufficient to accommodate the fixture wires and the branch circuit conductors according to NEC fill requirements, ensuring no overcrowding occurs.

3-1/2 Inch Diameter Round/Octagonal Boxes

Slightly smaller than the 4-inch variety, these round or octagonal boxes are also used for mounting smaller or lighter light fixtures in residential settings in the United States. Their depth also varies, typically from 1-1/4 inches to 2 inches. While they offer a more compact footprint, their wire fill capacity is correspondingly less than the larger 4-inch boxes, so careful consideration of the number and size of conductors is necessary to comply with NEC standards.

Pancake Round Boxes

These are shallow, round junction boxes, typically with a diameter of 4 inches and a depth of only 1/2 to 3/4 inches. They are specifically designed for surface mounting of lightweight light fixtures in situations where ceiling or wall depth is limited. Due to their shallow depth, their internal volume is minimal, restricting the number of wires they can safely accommodate under NEC guidelines. They are generally not suitable for making numerous wire splices or for heavier fixtures.

Chart of Common Round Junction Box Sizes (Illustrative)

| Box Type | Approximate Diameter | Common Depths | Typical Uses |

| Standard Round/Octagon | 4 inches | 1-1/2″ to 3″ | Most ceiling and wall-mounted light fixtures |

| Standard Round/Octagon | 3-1/2 inches | 1-1/4″ to 2″ | Smaller, lighter ceiling and wall-mounted light fixtures |

| Pancake Round | 4 inches | 1/2″ to 3/4″ | Surface mounting of lightweight fixtures in shallow spaces |

| Weatherproof Round | 4 inches (typical) | Varies (1-1/2″ to 3″+) | Outdoor lighting fixtures, often with threaded hubs for conduit connections |

Note: These are common and approximate sizes found in the United States. Always consult the manufacturer’s specifications for exact dimensions and, crucially, calculate the required box volume based on the National Electrical Code (NEC) for your specific wiring configuration to ensure safety and code compliance.

Junction Box Size Calculator

Determining the correct size of an electrical junction box is crucial for safety and compliance with the National Electrical Code (NEC) in the United States. An undersized box can lead to overcrowding of wires, potentially causing overheating and increasing the risk of electrical hazards. Conversely, an excessively large box might be unnecessary and add to material costs.

A junction box size calculator helps you determine the minimum required volume of a box based on the number and size of conductors entering it, as well as any devices like switches or receptacles you plan to install within the enclosure.

The junction box size calculation typically operates based on the NEC’s wire fill capacity rules, which assign a specific cubic inch volume allowance for each conductor size. By inputting the quantity of each wire gauge (e.g., 14 AWG, 12 AWG) and the number of devices, the calculator sums up the minimum required volume.

Remember that additional space might be needed for ease of wiring and future modifications. Always double-check the calculator’s output against the NEC’s specific requirements to ensure compliance for your electrical project in the United States.

Junction Box Size Calculator

- Calculates the minimum required junction box volume based on the number and gauge of wires.

- Takes into account the volume occupied by standard wiring devices like switches and receptacles.

- Uses cubic inch values per conductor size as specified by the NEC (check the latest NEC table for exact values).

- Provides an estimated minimum size; always verify with the NEC and consider additional space.

- This is a simplified calculator; complex scenarios might require a more detailed analysis based on the NEC.

How to Size a Junction Box

Selecting the correct size for an electrical junction box in the United States is not just about fitting the wires; it’s a critical safety consideration mandated by the National Electrical Code (NEC). An appropriately sized box ensures sufficient space for conductors, prevents overcrowding that can lead to overheating, and allows for safe and proper wire connections.

This guide outlines the essential steps in determining the right size for your electrical project.

Step 1: Counting the Number of Conductors

The first step in sizing a junction box is to accurately count the total number of conductors that will enter the box. According to the NEC, this count includes all wires that originate outside the box and terminate or are spliced within it, as well as any conductors that pass through the box without being spliced or terminated. Each individual conductor counts once.

Do not include equipment grounding conductors in this initial count, as they are handled separately in a later step according to specific NEC rules in the United States.

Step 2: Determining the Volume Allowance per Conductor

Once you have the total number of conductors, you need to determine the required volume allowance for each conductor based on its size (American Wire Gauge – AWG). NEC Table 314.16(B) provides these values in cubic inches. For example, a 14 AWG conductor requires a volume of 2.0 cubic inches, a 12 AWG requires 2.25 cubic inches, and so on.

Identify the size of each conductor you counted in Step 1 and note the corresponding volume allowance from the NEC table. If you have conductors of different sizes, you’ll need to account for each size accordingly.

Step 3: Calculating the Total Conductor Volume

Multiply the number of conductors of each specific AWG size by their respective volume allowances (determined in Step 2). Then, sum these values together to find the total cubic inch volume required to accommodate all the conductors entering the junction box.

This total represents the minimum volume needed based solely on the number and size of the wires. Remember that this calculation is a baseline, and other factors, as outlined by the NEC in the United States, also need to be considered.

Step 4: Accounting for Internal Devices and Fittings

If you plan to install any devices within the junction box, such as switches, receptacles, or internal cable clamps, you must add additional volume allowance as per NEC guidelines. Each device yoke (the mounting strap of a switch or receptacle) typically requires a double volume allowance based on the largest conductor connected to the device.

Internal cable clamps, whether factory or field-supplied, require a single volume allowance based on the largest conductor entering the box through the clamp. Fixture studs or hickeys also require a volume allowance based on the largest conductor attached to them.

Step 5: Including Equipment Grounding Conductors

Equipment grounding conductors entering the junction box also require volume allowance, but the NEC has specific rules for counting them. You count a single volume allowance based on the largest equipment grounding conductor entering the box.

If there are more than four equipment grounding conductors, you might need to add a quarter of the volume allowance for each additional grounding conductor, based on the largest grounding conductor. Always refer to the latest version of NEC Section 314.16(B)(5) for the precise rules on counting equipment grounding conductors in the United States.

Step 6: Determining the Minimum Box Volume

Finally, sum up the total conductor volume (from Step 3), the volume allowances for internal devices and fittings (from Step 4), and the volume allowance for equipment grounding conductors (from Step 5). This final sum represents the minimum cubic inch volume required for the junction box to comply with the NEC’s fill capacity requirements in the United States.

You will then need to select a junction box that has an internal volume equal to or greater than this calculated minimum volume. Always check the manufacturer’s markings on the junction box for its cubic inch capacity.

Junction Box Size Requirements

Selecting the correct size for an electrical junction box in the United States is governed by strict requirements outlined in the National Electrical Code (NEC) to ensure safety and prevent hazardous conditions. Understanding these requirements is crucial for any electrical installation or modification. This guide will break down the key aspects of NEC regulations concerning junction box sizing to help you ensure compliance and safety in your electrical projects.

Conductor Fill Requirements

The NEC specifies the maximum number of conductors permitted in a junction box based on the box’s volume and the size of the conductors. Section 314.16(B) provides tables detailing the cubic inch volume required per conductor size (AWG). Each conductor that originates outside the box and terminates or is spliced within it, as well as each conductor that passes through without being spliced, must be counted. Ensuring you don’t exceed the box’s fill capacity is vital to prevent overcrowding, which can lead to insulation damage and overheating.

Device and Equipment Fill

When a junction box contains devices such as switches, receptacles, or fixture canopies, the NEC requires additional space allowance. Each single gang device yoke (mounting strap) counts as two conductors based on the largest conductor connected to the device’s terminals. Internal cable clamps and fixture studs also require a volume allowance based on the largest conductor they secure. These allowances must be added to the total volume required for the conductors to determine the minimum box size.

Equipment Grounding Conductor Fill

Equipment grounding conductors (EGCs) also factor into the box fill calculations, but the NEC has specific rules for their count. Typically, all EGCs entering the box are counted as a single conductor based on the largest EGC present. However, if the number of EGCs exceeds a certain limit (usually more than four), additional allowances might be required. Always refer to NEC Section 314.16(B)(5) for the precise method of calculating the volume allowance for equipment grounding conductors to ensure compliance with US electrical standards.

Minimum Box Volume and Calculations

To determine the minimum required volume for a junction box, you must sum the cubic inch allowances for all conductors (based on their size), all devices and equipment within the box, and the equipment grounding conductors. The total volume must be equal to or less than the marked cubic inch capacity of the junction box. Using a junction box size calculator or carefully applying the rules outlined in NEC Section 314.16 will help you select an appropriately sized enclosure for your specific wiring needs in the United States, ensuring safety and code compliance.

Junction Box Size for Lighting

Selecting the correct size of a junction box for lighting fixtures in your US home is a critical step in ensuring a safe and code-compliant electrical installation, as mandated by the National Electrical Code (NEC). The primary consideration is providing adequate space within the box for all the necessary wire connections associated with the light fixture. Overcrowding can lead to potential hazards like overheating and difficulty in making secure connections, so understanding the key factors in sizing is essential for any lighting project.

When sizing a junction box for lighting, you need to consider the number and size of the wires that will be inside the box. This includes the incoming power supply wires, the wires connected to the light fixture itself, and any grounding conductors.

According to the NEC, each conductor entering the box contributes to the box fill calculation based on its American Wire Gauge (AWG) size. For instance, a 14 AWG wire requires a certain cubic inch volume, and larger gauge wires require more space. Accurately counting all conductors is the first step in determining the minimum required box size.

Furthermore, the physical characteristics of the light fixture and its mounting hardware can influence the required junction box size. Some light fixtures have canopies that need to fit over the junction box, and smaller “pancake” style boxes are often used for low-profile surface-mounted fixtures. However, even with these specialized boxes, ensuring adequate internal volume for the wire connections remains paramount for safety and NEC compliance in the United States. Always check the fixture’s installation instructions for any specific requirements regarding the junction box size.

How to Choose the Right Junction Box Size

Selecting the appropriate size for an electrical junction box in the United States is a critical step in any wiring project, directly impacting safety and compliance with the National Electrical Code (NEC). An undersized box can lead to overcrowding of wires, potentially causing overheating and increasing the risk of electrical fires. Conversely, an unnecessarily large box can add to material costs and might not fit well in certain installations. The key is to calculate the minimum required volume based on the number and size of conductors, as well as any devices you plan to install within the enclosure.

To determine the right junction box size, you need to follow a systematic approach based on NEC guidelines. This involves counting all the wires that will enter the box, calculating the cubic inch volume allowance for each conductor based on its gauge, accounting for the volume occupied by any devices (like switches or receptacles), and including space for equipment grounding conductors. By carefully considering these factors and comparing your calculated minimum volume to the marked cubic inch capacity of various junction boxes, you can ensure a safe and code-compliant electrical installation in the United States.

Here are the key factors to consider when choosing the right junction box size:

- Number and Gauge of Conductors: The more and the larger the wires, the greater the required box volume. Refer to NEC Table 314.16(B) for cubic inch requirements per conductor size.

- Internal Devices: Switches, receptacles, and other devices installed within the box require additional volume allowance as per NEC Section 314.16(B)(4).

- Equipment Grounding Conductors: While counted differently, grounding wires also contribute to the required box volume according to NEC Section 314.16(B)(5).

- Internal Fittings: Items like cable clamps and fixture studs located inside the box require a volume allowance based on the largest conductor entering or attached to them.

- Future Expansion: Consider if you might need to add more wires or devices to the box in the future. It’s often wise to choose a slightly larger box to accommodate potential modifications.

- Physical Space Constraints: While important to meet minimum volume requirements, the physical location where the junction box will be installed might limit the size you can use.

- Type of Box: Different box shapes (square, rectangular, round) and materials have varying internal volumes for similar external dimensions.

- NEC Regulations: Always consult the latest version of the National Electrical Code for the most up-to-date and specific requirements for junction box sizing in the United States.

Conclusion

Selecting the correct size of electrical junction boxes is paramount for ensuring safety, compliance with the National Electrical Code (NEC) in the United States, and the long-term reliability of your electrical installations. As this guide illustrates, factors like wire fill capacity, device accommodation, and future expansion play crucial roles in determining the appropriate dimensions. Choosing the right size prevents overcrowding, facilitates proper wire management, and ensures safe operation.

For projects with unique spatial constraints or specific wiring configurations, we offer custom junction box solutions tailored to your exact requirements in the USA. Our custom boxes can be manufactured to precise dimensions and specifications, ensuring a perfect fit and optimal functionality for your electrical needs while adhering to all relevant safety standards.

Ready to obtain junction boxes precisely sized for your electrical project? Contact us today to discuss your custom requirements and discover how our tailored solutions can streamline your installations and guarantee safety and compliance in the United States.