Enclosure Cooling

Reliable Enclosure Cooling Solutions for Electrical and Telecom Cabinets

Enclosure Cooling provides complete temperature control solutions for control cabinets, electrical enclosures, and telecom signal boxes. As Linkwellelectrics, we manufacture fans, air conditioners, thermostats, and more, delivering professional OEM/ODM services to global clients.

Key Features of Our Enclosure Cooling

We offer Enclosure Cooling solutions tailored for industrial-scale buyers, ensuring performance, safety, and energy savings through fans, air conditioners, thermostats, and related components.

High Cooling Efficiency

Powerful airflow keeps cabinets at safe operating levels.

Low Noise Design

Quiet performance suitable for office and industrial environments.

Durable & Reliable

Built for long service life under demanding conditions.

Energy Saving

Smart controls and efficient components reduce electricity costs.

Easy Installation

Designed for quick setup and integration into existing enclosures.

Our Enclosure Cooling Product Series

We provide customized Enclosure Cooling solutions with flexible sizes, fast delivery, and OEM/ODM support. Contact us now for a free quote!

FU Series

Multiple sizes with built-in mounting nuts; optional air duct improves airflow for high-efficiency cooling.

LK32 Series

Quick buckle-opening design enables easy maintenance; optional power indicator ensures clear operation status.

LK66 Series

Optimized straight-line grill design increases air circulation and enhances cabinet ventilation reliability.

EIA05

220V AC, 260/280W power rating, IP54 protection, operating temperature range -15°C to +55°C; designed for reliable indoor and outdoor applications.

Global Partnership

Enclosure Cooling Solution

Enclosure Cooling includes different solutions for cabinet temperature management, designed to fit industrial, telecom, and electrical enclosures of all sizes.

Enclosure Axial Fans

Enclosure axial fans provide efficient airflow for electrical cabinets, preventing overheating. Compact, durable, and low-noise, they ensure reliable cooling for industrial control panels, telecom cabinets, and automation systems.

Enclosure Air Conditioning

Enclosure air conditioning systems deliver precise temperature control for sealed electrical cabinets. Designed for demanding environments, they protect sensitive electronics from heat, dust, and humidity, ensuring long-term stability and performance.

Enclosure Control Transformer

Control transformers stabilize voltage within cabinet systems, powering cooling fans, thermostats, and auxiliary devices. Reliable and durable, they ensure safe and efficient operation of electrical enclosures across industrial and telecom applications.

Enclosure Cooling Combination Products

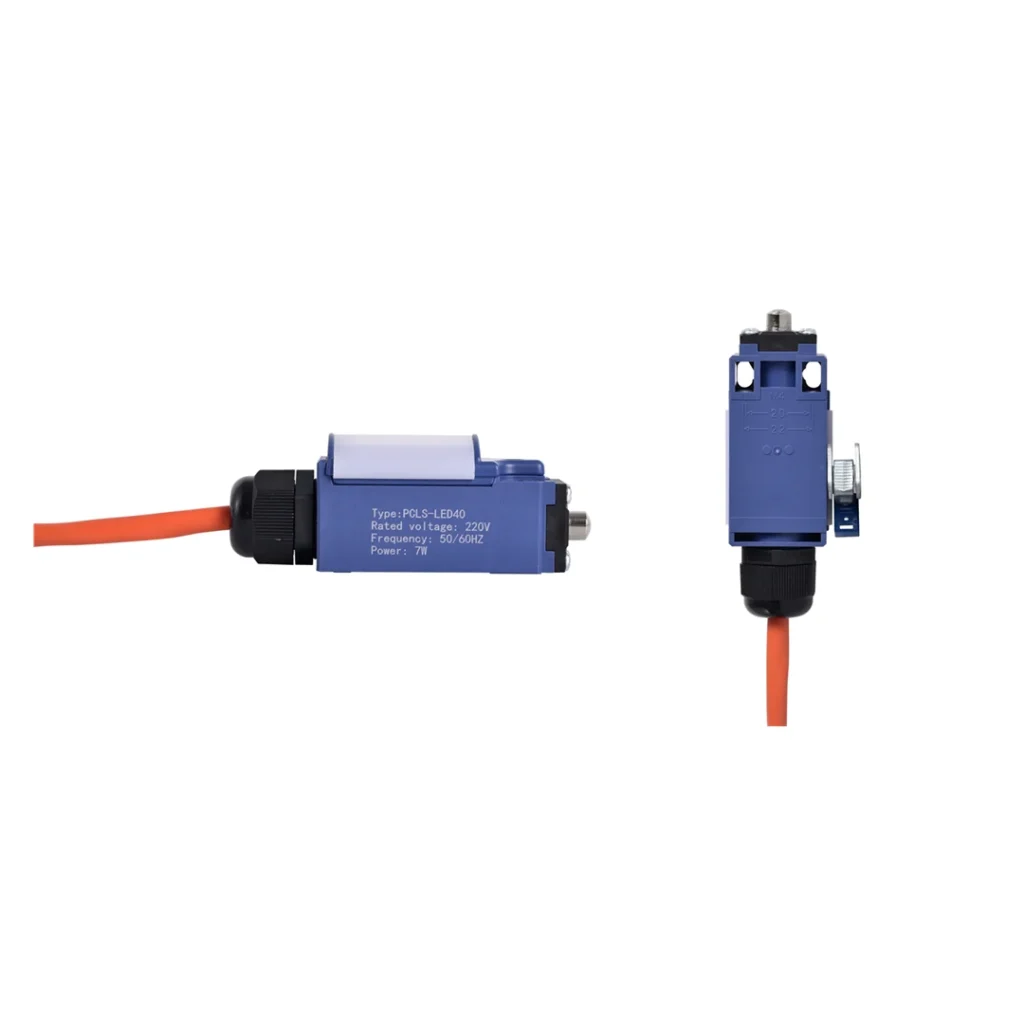

Lamp and Switch

Provides reliable cabinet lighting with easy switch control, ensuring visibility for maintenance and inspection inside electrical enclosures.

Distribution Terminal Blocks

Enable secure, organized electrical connections inside enclosures, ensuring safe power distribution for control systems and industrial equipment.

CMS Cable Management

Keeps cabinet wiring neat, organized, and safe, improving airflow, maintenance efficiency, and overall electrical system reliability.

Enclosure Heater

Prevents condensation and protects sensitive electronics by maintaining stable cabinet temperatures in cold or humid environments.

Rotary Cam Switch

Offers reliable manual switching for electrical enclosures, ensuring safe operation, control flexibility, and long service life.

Certifications & Clients

Our Enclosure Cooling products meet UL, CE, and RoHS standards, ensuring compliance with international markets. Our clients include leading OEMs, large-scale distributors, and global engineering companies, relying on us for stable and certified solutions.

Why Choose Linkwell?

We deliver Enclosure Cooling systems that combine high-quality design with strict certification. Our customization and fast delivery make us a trusted choice for global buyers.

At Linkwellelectrics, we focus on OEM/ODM services, working with wholesalers and distributors worldwide to provide reliable cabinet cooling products at competitive prices.

FAQs

How do I choose the right cooler fan for my cabinet?

Start by evaluating cabinet size, internal heat load, and airflow requirements. Check the fan’s CFM (Cubic Feet per Minute) rating to ensure it provides adequate ventilation. For harsh environments, consider models with filters or IP-rated protection. As manufacturers, we guide buyers in selecting the right fan type based on whether the cabinet is for telecom, automation, or industrial control applications.

Can cooler fans reduce cabinet condensation?

Yes. Cooler fans, when paired with a thermostat and hygrostat, regulate airflow and humidity levels. This prevents condensation inside electrical cabinets, which can cause short circuits, rust, and electronic failure. Our enclosure fans are specifically engineered for environments with temperature fluctuations, making them ideal for outdoor telecom cabinets or regions with high humidity.

Do cooler fans consume a lot of power?

No. Our energy-efficient cooler fans are designed to deliver strong airflow at low power consumption. They’re built with optimized motors that reduce electricity costs while ensuring long-term operation. For large-scale buyers, this means lower operational costs across hundreds or thousands of installed cabinets.

What is the lifespan of your cooler fans?

Our cooler fans are built with high-quality ball bearings and durable motor designs, achieving a service life of 30,000–50,000 hours under continuous use. With proper maintenance, many clients report reliable operation for over five years, even in demanding environments. This reduces downtime and saves replacement costs for wholesalers and OEMs.

Are your cooler fans safe for use in sensitive environments?

Yes. All our fans are UL, CE, and RoHS certified, ensuring compliance with international safety standards. They’re safe for automation cabinets, telecom systems, power distribution boxes, and CNC equipment. We also offer flame-retardant and IP-rated enclosures for environments where safety and durability are critical.

How do I maintain cooler fans?

Maintenance is simple. Regularly clean filters, fan blades, and ventilation paths to ensure optimal airflow. Our fans are designed with easy-to-access housings, making cleaning fast and cost-efficient. For OEMs and distributors, we also provide maintenance kits to help keep large installations running reliably.

Do you offer custom cooler fans?

We produce customized cooler fans in different sizes, voltages, airflow capacities, and protection ratings to meet specific OEM and distributor requirements. Whether you need branding customization, private labeling, or specialized engineering modifications, we provide flexible solutions to help clients strengthen their market competitiveness.

What makes your cooler fans reliable?

Our cooler fans are engineered for long service life under industrial conditions. We use high-precision ball bearings, UL-certified motors, and reinforced housings designed to withstand vibration, dust, and continuous operation. Each unit undergoes thermal balance testing, vibration resistance checks, and airflow calibration before shipment. This ensures consistent performance in automation cabinets, telecom enclosures, and power distribution systems where downtime is unacceptable.

Do you support OEM cooler fan branding?

Yes. We specialize in OEM and ODM solutions for distributors and global brands. Services include private labeling, packaging customization, and custom engineering to meet market-specific requirements. Our Kunshan facility has supported OEM partners across Europe, North America, and Asia, helping them expand their product portfolios. With ISO-certified manufacturing and strict quality control, clients can confidently rebrand our fans as part of their own product line.

Can I get a sample before bulk orders?

We encourage testing before large commitments. Samples allow buyers to evaluate airflow (CFM), noise levels (dB), energy efficiency, and build quality under real cabinet conditions. Standard samples are shipped within 7 business days, while customized versions may require additional lead time. This approach ensures distributors and OEMs can validate performance, durability, and compliance before launching our cooler fans into their markets.

How fast can you deliver bulk orders?

With a streamlined production system in our Kunshan factory, we deliver most bulk orders within 2–3 weeks, even for large volumes. For customized designs (special voltage, IP rating, or branding), lead times may extend slightly. We maintain safety stock of key models to support urgent orders. Our logistics team coordinates with global freight partners to ensure on-time delivery to Europe, North America, and Asia, minimizing downtime for distributors.

Contact & Inquiry

Contact us today for detailed product information, quotes, or expert technical support. Simply complete the form with your name, email, company, country, and inquiry, and our team will get back to you quickly. You can also connect with us directly via WhatsApp, email, or phone for fast and reliable assistance.