Custom Enclosure Heater Manufacture in China

As a leading Enclosure Heater Manufacture, Linkwellelectrics is committed to delivering high-performance heating solutions for control cabinets, electrical enclosures, and telecom signal cabinets. Our heaters are engineered to prevent moisture, condensation, and freezing—ensuring long-lasting performance in harsh environments like factories and outdoor telecom stations.

We design, build, and test our heaters in-house for strict quality control. Whether you’re outfitting a base station or an industrial control panel, we’re here to help. Contact us today for a solution tailored to your needs.

Linkwell Electrics - Your Trusted Enclosure Heater Manufacture Manufacturer from China

1. Cost-Effective Ventilation for Electrical Enclosures

2. Highly Versatile and Built for Long-Lasting Use

3. Effectively Regulates Internal Component Temperatures

4. Certified to Meet UL and CE Standards

Beyond production, we support clients with layout optimization, installation guidance, thermal simulation, and compliance consulting.

Our team adheres to global standards for moisture prevention and thermal safety. We offer technical documentation, mounting accessories, and remote setup advice.

Whether your cabinets are in dusty factory zones or humid telecom sites, our heaters are designed to work safely. We serve OEMs, system integrators, and facility engineers with prompt delivery and responsive service. Partner with us for your next project—we’re here to support you at every step.

Global Partnership

Various Enclosure Heater Manufacture Series

As a custom Enclosure Heater Manufacture, we offer flexible design choices: size, power rating, voltage input, mounting type, and safety features like touch-safe housing or thermal limits. These options reduce energy waste, improve protection, and simplify system compatibility. Our pricing models are competitive, and our lead times are among the fastest in the industry. Whether for industrial automation, outdoor telecoms, or data center systems, our solutions bring long-term value. Talk to our team today to start your custom heater plan.

Small PTC Heaters

Small PTC heaters are compact and ideal for preventing condensation in telecom and electrical cabinets. They self-regulate to avoid overheating and operate quietly. Their slim size makes them perfect for small enclosures with limited space. As a manufacturer, we provide different power ratings for different climates. These heaters improve system life and reduce maintenance.

Hazardous Location Heaters

Designed for explosive environments, these heaters meet ATEX and IECEx standards. They are used in oil refineries, chemical plants, or flammable storage. These heaters prevent ignition risks by having enclosed, spark-free components. We offer rugged, corrosion-resistant housings. Safety, durability, and reliability are the top priorities. Contact us to ensure your cabinet meets local codes.

Touch-Safe PTC Heaters

Touch-safe models feature built-in protective grilles that make them safe for technicians. Perfect for telecom signal cabinets and server racks where servicing may happen regularly. The PTC element regulates heat output and prevents overheating. These heaters are low-maintenance and energy-efficient, ideal for continuous operation in control panels or switchgear.

Compact PTC Loop Heaters

Loop-style heaters provide uniform heat around their structure, ideal for space-limited applications. They are quick to install, efficient, and typically used in base station cabinets and automation control enclosures. The compact loop design offers 360° heating without hotspots. We supply multiple wattages to suit diverse climates.

flat heaters

Flat surface heaters mount easily to walls or back panels inside cabinets. They save space while providing consistent heat to avoid condensation and frost. With quick warm-up times and minimal energy consumption, they’re perfect for indoor or sheltered telecom applications. We offer various sizes, voltages, and mounting styles.

6 Steps Enclosure Heater Design and Assembly

Determine Heating Requirements

Begin by calculating the heat load of the enclosure. Consider ambient temperature, enclosure size, material, and internal components' sensitivity to cold or condensation. The goal is to maintain a stable internal temperature above dew point to prevent moisture. Use formulas or software to estimate the necessary wattage. This ensures efficient and cost-effective performance while avoiding overheating or underheating.

Choose the Heater Type

Select the most suitable heater type—PTC, or fan-forced—for your specific application. Factors include temperature control needs, heating speed, available space, and airflow requirements. For example, fan-assisted heaters offer faster, more even heat distribution, while convection heaters suit sealed or compact spaces. The right type improves performance and reduces energy waste.

Select Heating Element Material

Pick a heating element made of reliable materials like Nichrome or Kanthal, known for high-temperature resistance and long life. The material must resist oxidation and thermal fatigue while maintaining stable resistance over time. For specific environments (e.g., corrosive or wet), stainless steel or ceramic sheathing may be necessary to ensure safety and durability.

Integrate Thermal Controls

Add thermal controls such as thermostats, hygrostats, or temperature sensors to regulate internal climate. A basic bimetal thermostat offers simple on/off control, while digital or programmable controls allow precise settings. These components help prevent overheating, optimize power use, and extend heater life. In some applications, temperature sensors are connected to alarms or automation systems.

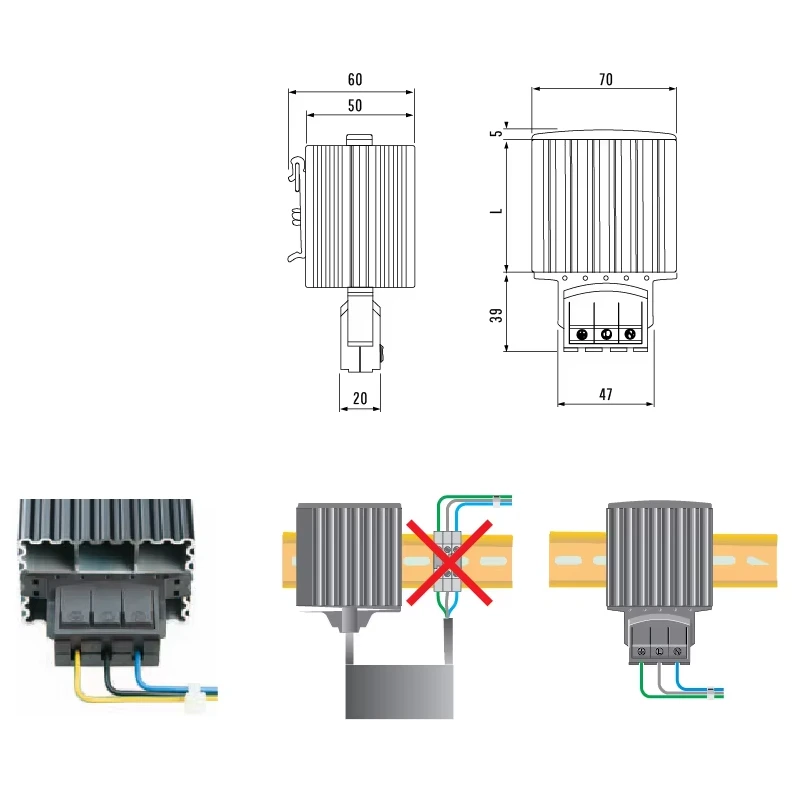

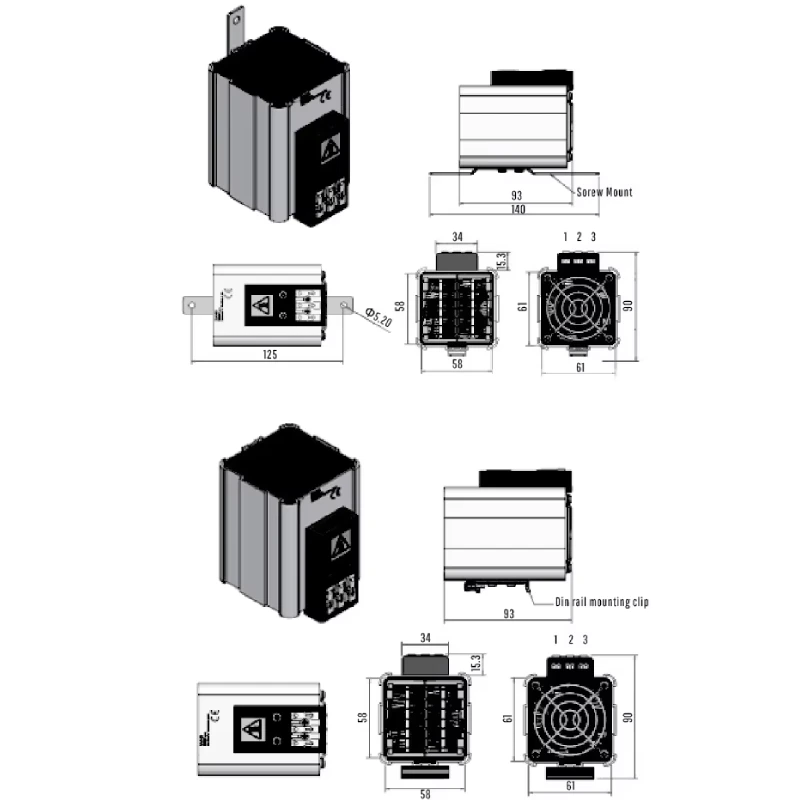

Ensure Proper Mounting

Design the heater for easy and secure mounting—DIN rail or screw installation are common. Ensure it fits within the enclosure layout without obstructing other components. Correct mounting also ensures efficient heat transfer and airflow. Pay attention to safety clearance, especially near heat-sensitive or flammable elements, and confirm stability under vibration or movement.

Perform Testing and Validation

Before deployment, test the heater in real or simulated conditions. Monitor thermal performance, airflow, electrical load, and safety shutoff functions. Validate that it meets applicable standards (UL, CE, etc.) and environmental conditions (IP ratings, humidity). Proper validation ensures long-term reliability and customer confidence in harsh or mission-critical environments.

Benefits of Enclosure Heater

As Electrical Control Panel Manufacturers, our products offer high safety, smart design, reliable performance, and full customization—built to meet global standards and real-world industrial needs.

Condensation Prevention

Enclosure heaters maintain internal temperatures above the dew point, effectively preventing condensation. Moisture inside cabinets can damage sensitive electronics, cause corrosion, and reduce insulation resistance. By ensuring a dry internal atmosphere, the heater extends component life and reduces failure risk in outdoor or high-humidity environments.

Freeze Protection

In cold climates, enclosure heaters protect equipment from freezing. This is essential for applications in telecom, utilities, and traffic control where freezing may disable components or affect functionality. Freeze protection ensures continued operation and prevents costly downtime or system resets.

Improved Equipment Longevity

Temperature fluctuations and moisture accelerate wear on electronics and control systems. Enclosure heaters help stabilize the internal environment, reducing thermal stress and oxidation. As a result, internal components last longer, require less frequent replacement, and improve overall system reliability.

Reliable Outdoor Performance

Heaters allow control panels and enclosures to function in extreme outdoor environments—rain, snow, or sub-zero temperatures. They ensure the system performs consistently, reducing the chance of environmental failure in solar, wind, and transportation systems deployed remotely.

Enhanced Safety

By reducing humidity and stabilizing temperatures, enclosure heaters minimize the risk of short circuits, insulation failure, and electrical fires. Especially in mission-critical systems like railways or power grids, stable internal climates reduce hazards and meet safety compliance standards.

Easy Integration

Modern enclosure heaters are compact, DIN-mountable, and compatible with standard enclosures. They can be easily retrofitted or integrated into new systems without major layout changes. This simplifies installation and reduces engineering complexity during design and commissioning.

Energy Efficiency

PTC and thermostatically controlled heaters only activate when needed, conserving energy while maintaining target temperatures. Efficient thermal regulation ensures optimized power usage, contributing to long-term operational cost savings without compromising performance.

Environmental Protection

In corrosive, wet, or dusty environments, enclosure heaters help prevent internal contamination and damage. Coupled with proper enclosure sealing (e.g., IP65), heaters contribute to environmental resistance by maintaining internal dryness and temperature stability.

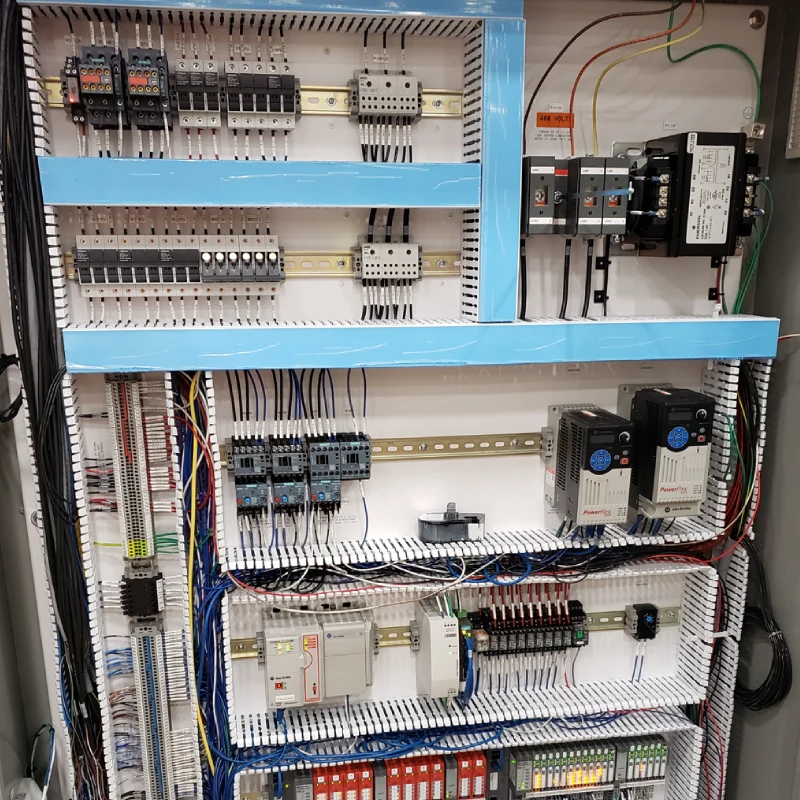

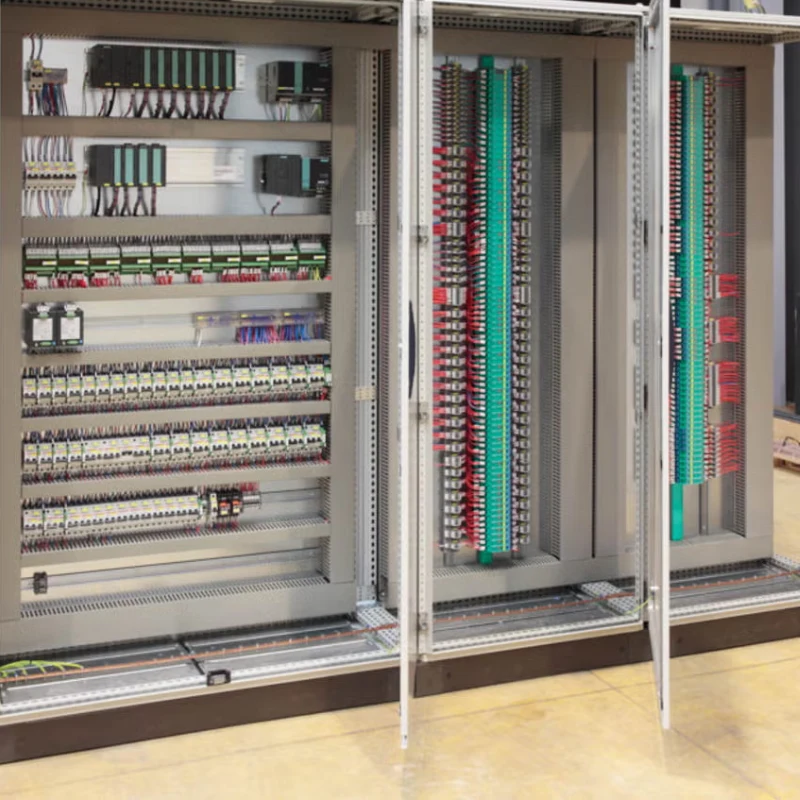

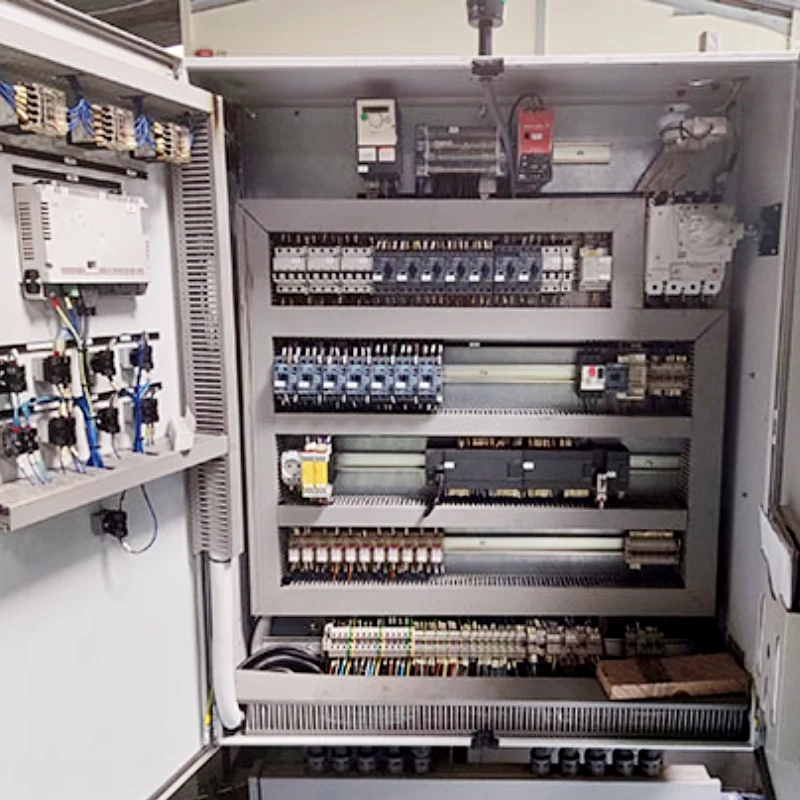

Enclosure Heater Display

Application of Enclosure Heater in Different Industries

Telecom Base Stations

EV Charging Infrastructure

Industrial Automation

Custom Enclosure Heater Manufacture - Our Manufacturing Expertise

Engineering & Design

Schematic diagrams meet international safety codes.

Customized layouts based on space and cooling.

Simulation tools verify load performance.

Production & Assembly

Skilled workers follow UL/IEC practices.

Automated wire cutting and labeling.

Clean, efficient assembly line operations.

Quality Assurance

100% tested for thermal and load limits.

Documentation provided for third-party inspection.

Continuous improvement via customer feedback.

Customer Support

Quick response with technical drawings.

On-call support for installation or servicing.

Fast spare parts delivery and manuals.

Prototypes include ISIR/PSW and meet ISO, UL, and IPC standards.

This requirement, in addition to our ISO9001:2015, ISO14001:2015, UL, NICEIC and IPC accreditation’s, is observed whether we are dealing with wiring harnesses, cable assemblies, control boxes or panel wiring.

Customer Testimonials

FAQ of Enclosure Heater Manufacture

What does an enclosure heater do in a control cabinet?

An enclosure heater prevents moisture buildup and freezing inside electrical cabinets. This protects sensitive components like relays and sensors from damage, especially in outdoor or humid environments like telecom towers or cold factories.

Where should I install an enclosure heater?

Place the heater near the bottom of the enclosure where cold air collects. This ensures even heat distribution. Use a thermostat or hygrostat to automatically switch it on or off based on internal conditions.

Can I use enclosure heaters in hazardous environments?

Yes. For explosion-risk areas, we offer ATEX-certified hazardous location heaters. These are sealed, spark-free, and safe for chemical plants, mining zones, or flammable storage areas.

Do you offer custom enclosure heaters?

Yes. We can customize size, mounting options, voltage, and power levels. We can even include integrated thermostats or touch-safe covers. Contact us for a tailored solution.

How energy-efficient are your heaters?

Our PTC technology ensures low power draw once the enclosure reaches the target temperature. This saves energy and extends heater life, making it perfect for 24/7 control panel operation.

What certifications do your heaters carry?

We manufacture heaters in compliance with CE, RoHS, UL, and ATEX standards. Certification documents and test reports are included with ev

All-in-one Enclosure Heater Manufacture Solutions for Your Project

We specialize in custom Air Conditioner For Electrical Cabinet units that match your exact needs. Choose your voltage (12/24/48 V DC or 220 VAC), compressor type, fan speed, and control interface. We also customize mounting brackets, filter access, and wire harnesses. This flexibility delivers economic benefits—reducing energy costs and installation time. All units undergo strict quality checks before fast delivery. Market trends show increasing demand for tailored solutions: we are ready to help you meet that demand. Let’s discuss your specifications today and we’ll provide a detailed drawing and price within 48 hours.