In today’s industrial and electrical enclosure fans, you’ll encounter a variety of Fan Motor Bearing Types. The most common Fan Motor Bearing Types include:

- Sleeve bearings, which remain quiet, are cost-effective, and perform reliably in demanding environments.

- Ball bearings, suitable for any mounting position, excel in high-temperature settings, and offer extended service life.

- Roller bearings, designed to support heavy loads, provide excellent resistance to wear.

- Fluid dynamic bearings, which deliver smooth and silent operation, are ideal for advanced HVACR motors.

Linkwell offers top-tier Fan Motor Bearing Types in our fan products, ensuring your equipment stays protected and efficiently cooled.

Key Takeaways

- Choose sleeve bearings for quiet, cost-effective fans in low-load environments.

- Opt for ball bearings when you need durability and high-temperature resistance.

- Select roller bearings for heavy-duty applications that require strong load support.

- Use fluid dynamic bearings for silent operation and long lifespan in sensitive settings.

- Regular maintenance of bearings extends their life and improves fan performance.

Fan Motor Bearing Types

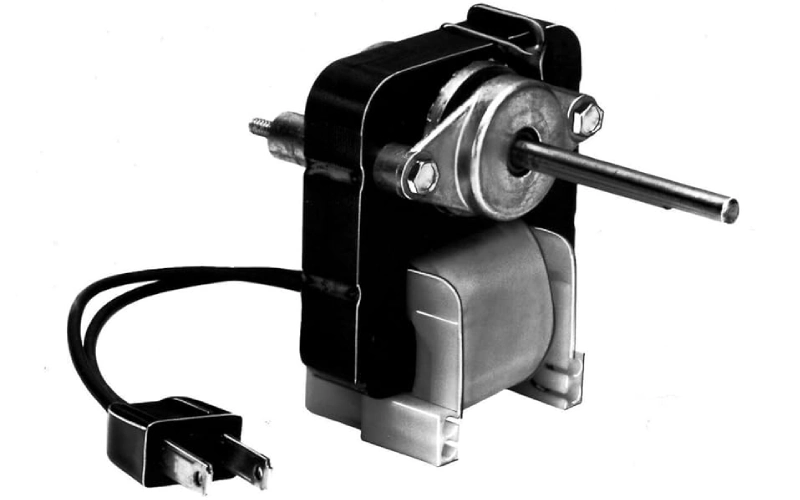

When you look at fan motor bearing types, you’ll find several designs that keep your equipment running smoothly. Each type has its own strengths and works best in certain situations. Let’s break down the main types of bearings you’ll see in fan motors, including split pillow block, two-bolt roller, solid pillow block ball, sleeve, ball, and fluid dynamic bearings. You’ll also notice that Linkwell’s Electrical Enclosure Fans and fan filter units use high-quality bearings to deliver reliable performance in industrial settings.

Sleeve Bearings

Sleeve bearings are one of the most common fan motor bearing types. You’ll see them in small electric motors and fans where quiet operation matters. These bearings use a simple design—a thin-walled hollow cylinder that wraps around the shaft. A film of lubricant sits between the shaft and the bearing, which helps reduce friction and wear.

Here’s a quick look at sleeve bearings:

| Characteristic/Principle | Description |

|---|---|

| Structure | Thin-walled hollow cylinders without rolling elements |

| Operating Principle | Lubricant film reduces friction between shaft and bearing |

| Applications | Light to moderate load and speed, small motors and fans |

| Advantages | Simple, low cost, easy maintenance, sometimes self-lubricating |

| Disadvantages | Limited load/speed, needs periodic lubrication |

You’ll appreciate how sleeve bearings minimize wear and keep rotation smooth. The design maintains a critical gap between the rotor and stator, which helps with efficiency. Most sleeve bearing fans run for about 3 to 4 years without trouble. Around 90% of them will still work after that time. Manufacturers often quote a life expectancy of 200,000+ hours, but in practice, sleeve bearings last about half as long as ball bearings.

Linkwell uses sleeve bearings in some fan filter units, especially where low noise and cost-effectiveness are important. If you need a fan for moderate loads and quiet environments, sleeve bearings are a solid choice.

- Sleeve bearings are simple, rugged, and affordable.

- They keep the shaft turning smoothly with a lubricated sleeve.

- You’ll find them in fans that need easy maintenance and quiet operation.

Ball Bearings

Ball bearings are another popular option among fan motor bearing types. You’ll find them in fans that need to handle higher temperatures and work in any mounting position. Ball bearings use small steel balls between two rings, which helps reduce friction and wear.

Let’s compare ball bearings and sleeve bearings:

| Feature | Ball Bearings | Sleeve Bearings |

|---|---|---|

| Wear and Tear | Less prone to wear and tear | More prone to wear |

| Orientation | Operate in any orientation | Limited orientation |

| Temperature Resistance | Higher temperature operation | Lower temperature operation |

| Complexity | More complex and expensive | Simpler and cheaper |

| Noise | Tend to create more noise | Quieter operation |

| Impact Resistance | Performance affected by impacts | More rugged |

| Friction | Reduced friction | Higher friction |

| Application | High-density applications | General use |

You’ll notice that ball bearings last longer than sleeve bearings. In electrical enclosure fans, ball bearings usually run for 60,000 to 70,000 hours under normal conditions. Some manufacturers claim lifespans of 200,000 hours or more, but that’s based on MTBF calculations. Cooler environments can help ball bearings last even longer.

Linkwell’s Electrical Enclosure Fans feature double ball bearing structures. This design supports 360° circular air discharge and keeps your equipment cool and efficient. If you need a fan for high-temperature or heavy-duty use, ball bearings are a smart pick.

Roller Bearings

Roller bearings stand out among fan motor bearing types when you need to support heavy loads. You’ll see them in industrial fans that move a lot of air or handle tough conditions. Roller bearings use cylindrical or barrel-shaped rollers instead of balls, which lets them carry more weight.

Here’s a breakdown of roller bearings:

| Bearing Type | Structure Description | Load Support Characteristics |

|---|---|---|

| Spherical Roller Bearings | Barrel-shaped convex rollers between spherical outer and inner rings | Support large loads, accommodate shaft bending |

| Radial Roller Bearings | Rollers support forces perpendicular to the shaft | Greater load support than radial ball bearings |

| Tapered Roller Bearings | Tapered rollers support both radial and one-directional axial loads | Handle combined loads when used in pairs |

You’ll find roller bearings in fans that need to run under heavy stress. Spherical roller bearings, for example, can handle radial loads of over 11,000 N. Depending on the load, their basic rating life can reach 22,000 to 33,000 hours. These bearings work well in split pillow block and two-bolt roller designs, which you’ll see in larger industrial fans.

If your application involves high airflow, vibration, or heavy machinery, roller bearings are the go-to choice. Linkwell uses roller bearings in fan filter units designed for demanding environments, so you get reliable cooling even under tough conditions.

- Roller bearings support heavy loads and resist wear.

- You’ll see them in industrial fans, split pillow block designs, and applications with high vibration.

- They offer longer life and better performance when your equipment faces tough challenges.

Fluid Dynamic Bearings

Fluid dynamic bearings are the most advanced among fan motor bearing types. You’ll find them in high-performance fans where quiet operation and long life matter most. These bearings use a thin layer of lubricating fluid to support the load, which minimizes friction and wear.

Here’s what makes fluid dynamic bearings unique:

| Feature | Description |

|---|---|

| Load Support | Lubricating fluid supports the load, reducing friction and wear |

| High Rotational Speeds | Achieve high speeds, ideal for fan motors |

| Low Vibration | Operate with low vibration, improving performance |

| Low Noise Levels | Run quietly, perfect for noise-sensitive environments |

| Durability | Lifespans of 100,000 to 300,000 hours |

| Application | Used in hard disk drives, cooling fans, and advanced HVACR motors |

Recommended products

Fluid dynamic bearings work efficiently at moderate temperatures, usually between 40 and 70°C. You’ll get lifespans of up to 300,000 hours, which means less downtime and fewer replacements. These bearings operate with very low noise, making them ideal for telecom cabinets, control panels, and places where silence is golden.

If you want a fan that runs quietly and lasts for years, fluid dynamic bearings are the best option. Linkwell’s advanced fan filter units use fluid dynamic bearings in models designed for continuous operation and minimal maintenance.

Tip: For environments that demand silent operation and long-lasting performance, fluid dynamic bearings are your best bet.

Types of Bearings in Electric Fans

Construction

When you look inside an electric fan, you’ll find several types of electric motor bearings. Each type has its own unique construction. Sleeve bearings use a sintered body made from copper and iron powder. These bearings have tiny holes inside that store lubricating oil, so the shaft can spin smoothly. Ball bearings are built with steel balls sandwiched between two rings. This design lets the fan run in any position and handle higher temperatures. Roller bearings use barrel-shaped rollers to support heavy loads, which makes them perfect for industrial fans. Fluid dynamic bearings use pure copper and have special turning chutes inside. These chutes increase pressure and help the shaft rotate with less friction.

Here’s a quick look at how some bearings are made:

| Bearing Type | Construction Materials | Design Features |

|---|---|---|

| Sleeve Bearing | Sintered copper and iron powder | Porous body with oil storage holes |

| Ball Bearing | Hardened steel balls and rings | Multiple balls between rings for smooth rotation |

| Roller Bearing | Steel rollers and rings | Barrel or cylindrical rollers for heavy load support |

| Fluid Dynamic Bearing | Pure copper | Turning chutes for pressure and shaft support |

Pros & Cons

You’ll notice that each type of electric motor bearings comes with its own set of strengths and weaknesses. Sleeve bearings run quietly and cost less, but they don’t last as long as other types. Ball bearings last longer, work in any orientation, and handle heat well, but they cost more. Roller bearings support heavy loads and resist wear, but they need regular maintenance. Fluid dynamic bearings offer long life and low noise, but their design is more complex.

Check out this table for a quick comparison:

| Bearing Type | Advantages | Disadvantages |

|---|---|---|

| Sleeve Bearings | Quiet, affordable, great for noise-sensitive spots | Shorter lifespan |

| Ball Bearings | Durable, versatile, good for high temperatures | Higher cost |

| Roller Bearings | Handles heavy loads, resists wear | Needs regular maintenance |

| Fluid Bearings | Long-lasting, super quiet, efficient at moderate temperatures | Complex design, higher price |

Tip: If you want a fan that stays quiet and doesn’t break the bank, sleeve bearings are a solid choice. For high-temperature or heavy-duty use, ball or roller bearings work best. If you need long life and silent operation, fluid dynamic bearings are the way to go.

Applications

You’ll find different types of electric motor bearings in all sorts of electric fans. Sleeve bearings fit best in small fans for offices or telecom cabinets where quiet operation matters. Ball bearings show up in Linkwell Electrical Enclosure Fans, which need to run in any position and handle tough conditions. Roller bearings work well in large industrial fans and split pillow block designs, especially when you need to move lots of air. Fluid dynamic bearings shine in advanced fan filter units, like those from Linkwell, where you want silent operation and long-lasting performance.

- Use sleeve bearings for low-noise, budget-friendly fans.

- Pick ball bearings for high-temperature or versatile mounting.

- Choose roller bearings for heavy-duty, industrial fans.

- Go with fluid dynamic bearings for silent, long-life applications.

You can match the right types of electric motor bearings to your needs. Linkwell offers fans and filter units with high-quality electric motor bearings, so your equipment stays cool and reliable, no matter the environment.

Comparing Types of Electric Motor Bearings

Performance

When you compare electric motor bearings, you’ll notice each type brings something different to the table. Sleeve bearings work well in fans that run at lower speeds and don’t face heavy loads. Ball bearings handle higher speeds and temperatures, making them perfect for tough environments. Roller bearings shine in industrial fans that move lots of air and deal with vibration. Fluid dynamic bearings offer smooth, silent operation and last a long time. Linkwell Electrical Enclosure Fans and fan filter units use advanced bearing designs to boost airflow and keep your equipment safe. You get reliable cooling, whether you need quiet operation or heavy-duty performance.

Noise & Lifespan

Noise and lifespan matter when you choose electric motor bearings for your fans. Take a look at this table to see how the main types stack up:

| Bearing Type | Noise Level Comparison | Life Expectancy Comparison |

|---|---|---|

| Sleeve Bearings | Quieter at low speeds, louder as they age | Shortest lifespan, becomes noisier faster |

| Ball Bearings | Noisy in a short time due to grease issues | Longer lifespan than sleeve bearings |

| Roller Bearings | N/A | N/A |

| Fluid Dynamic | N/A | N/A |

- Sleeve bearing fans stay quiet at first but get louder as they wear out.

- Ball bearing fans can become noisy quickly if grease dries up, but they last longer.

- Sleeve bearings handle shocks without much noise increase, while ball bearings may get noisier over time.

- Fluid dynamic bearings run quietly and offer long life, making them ideal for places where silence is important.

Linkwell’s fan filter units use ball and fluid dynamic bearings to keep noise low and extend service life, so you spend less time on maintenance.

Cost

Cost plays a big role in your decision. Sleeve bearings usually cost less because of their simple design. Ball bearings cost more up front, but they last longer and need fewer replacements. Roller bearings and fluid dynamic bearings come with higher price tags, but they deliver top performance and durability. Ball bearings can last up to ten times longer than sleeve bearings, which saves you money in the long run. Linkwell’s electric motor bearings help you balance cost and reliability, giving you options for every budget.

Tip: If you want a fan that’s affordable and quiet, go with sleeve bearings. For long-term savings and tough jobs, ball or fluid dynamic bearings are worth the investment.

Choosing the Right Fan Motor Bearing

Maintenance Tips

Keeping your fan running smoothly starts with proper care for electric motor bearings. You want to make sure your bearings stay lubricated and clean. Regular checks help you spot problems before they get worse.

Always maintain and inspect your bearings. Pick the right grease for your electric motor bearings. Watch out for issues like wrong lubricant, grease incompatibility, or contamination. These can shorten the life of your fan.

Here are some simple tips to help you extend the lifespan of your bearings:

- Lubricate your bearings as recommended by the manufacturer.

- Use only the suggested lubricants for your fan.

- Clean and lubricate your electric motor bearings on schedule.

- Avoid overfilling pillow blocks with grease.

- Don’t tighten locknuts while the bearings are loaded.

- Fix only one bearing per shaft so it can move axially.

If you follow these steps, your fan will last longer and work better. Linkwell offers technical support and guidance, so you can keep your equipment in top shape.

Selection Guide

Choosing the right electric motor bearings depends on your environment and needs. You should think about the temperature, humidity, and dust in your workspace. High temperatures call for bearings that can handle heat and special lubricants. Humid or wet areas need corrosion-resistant materials and sealed bearings. Dusty places require shielded bearings and regular cleaning.

Here’s what you should consider:

- Sleeve bearing fans work well if you want something rugged, simple, and quiet. They cost less but need more attention to lubrication.

- Ball bearing fans last longer, run in any position, and resist wear. They cost more and can be noisier.

- For heavy-duty jobs, roller bearings handle big loads and vibration.

- Fluid dynamic bearings give you silent operation and long life, perfect for sensitive environments.

Linkwell helps you pick the best electric motor bearings for your project. You get reliable products, custom solutions, and fast support. If you need extra warranty or service, Linkwell’s team is ready to help you every step of the way.

| Manufacturer | Warranty Period |

|---|---|

| AirPro | 3 years |

Tip: Always match your bearing choice to your environment and workload. Linkwell’s experts can help you find the perfect fit for your industrial or electrical enclosure fans.

Choosing the right fan motor bearing makes a big difference in how your equipment runs. Each type offers unique benefits:

| Bearing Type | Noise Level | Lifespan (hours) |

|---|---|---|

| Sleeve Bearings | Quiet | Shorter |

| Fluid Bearings | Very low noise | 100,000–300,000 |

| Dual Ball Bearings | Moderate | Longer |

You want quiet fans for offices? Go with sleeve bearings. Need long life in tough conditions? Dual ball or fluid bearings work best. The right choice boosts reliability and keeps costs down. If you need help, Linkwell’s experts can guide you to the perfect solution for your project.

FAQ

What type of bearing should I choose for high-temperature environments?

You should pick ball bearings or fluid dynamic bearings. These types handle heat better and last longer in tough conditions. Linkwell fans with these bearings work great in hot industrial or telecom cabinets.

How often do I need to maintain fan motor bearings?

Check your bearings every few months. Clean and lubricate them as needed. If you use Linkwell fans, you’ll find maintenance easy, especially with ball or fluid dynamic bearings.

Can I use Linkwell fans in outdoor or dusty environments?

Yes! Many Linkwell fans and fan filter units come with IP-rated housings. These protect the bearings and internal parts from dust and moisture, making them perfect for outdoor or harsh settings.

What’s the quietest bearing type for office or telecom use?

Fluid dynamic bearings run almost silently. Sleeve bearings also stay quiet in low-speed fans. If you want a peaceful workspace, look for Linkwell fans with these bearing types.

How do I know which bearing is in my Linkwell fan?

Check the product label or manual. You can also contact Linkwell’s support team for details. They’ll help you identify the bearing type and recommend the best option for your needs.