Custom Feed Through Terminal Block Manufacturer in China

Our Feed Through Terminal Blocks provide a straightforward, secure method for connecting and extending electrical wires within a control panel or enclosure. Designed for reliable conductivity and robust insulation, they simplify wiring by allowing wires to pass directly through the block. Ideal for general industrial applications, they ensure organized, stable, and durable electrical connections for various voltage and current ratings.

Linkwell Electrics - Your Trusted Feed Through Terminal Block Manufacturer from China

Linkwell Electrics is your trusted Feed Through Terminal Block manufacturer from China. With over 20 years of experience and a 45,000 m² production base, we deliver innovative, low-voltage electrical solutions. Our commitment to excellence, global presence across 100+ countries, and certifications like ISO, CE, RoHS, and UL ensure reliable performance and customer satisfaction.

Various Feed Through Terminal Block

wholesale feed through terminal blocks

We wholesale feed through terminal blocks designed for efficiency and reliability. Our extensive range includes various wire sizes, mounting types, and current ratings to meet diverse project needs. Ideal for distributors and large-scale applications, we supply high-quality, durable blocks that ensure secure connections and streamline panel wiring. Benefit from competitive pricing and consistent supply directly from our terminal manufacturer.

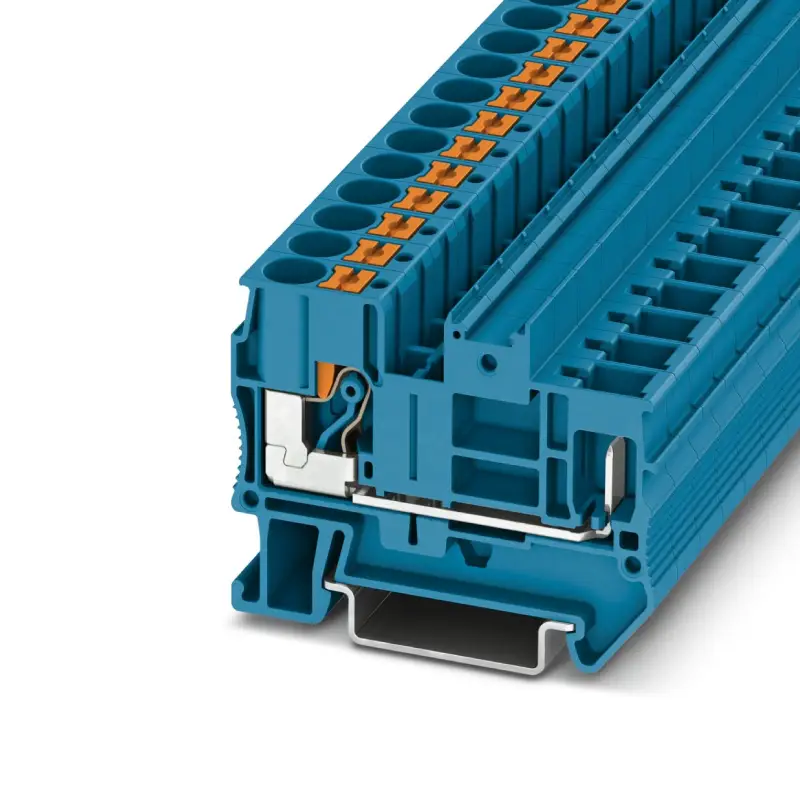

feed through modular terminal block

we supply feed through modular terminal blocks, offering flexible and efficient wiring solutions. their modular design allows for easy expansion and customization to fit any panel layout. these blocks provide secure, reliable wire connections for various applications, simplifying installation and maintenance. count on our dependable feed-through solutions for organized and stable electrical systems.

feed through modular terminal block custom

We provide custom feed through modular terminal blocks tailored to your project needs. Select specific pole configurations, material grades, and connection technologies like screw clamp or spring cage. We supply blocks with varied current and voltage capacities, ensuring optimal performance and space utilization. Our solutions simplify wiring, enhance system reliability, and meet diverse industrial requirements.

feed through type barrier terminal block

We supply feed-through type barrier terminal blocks, ideal for organized and insulated wiring. These blocks feature integrated barriers between terminals, enhancing safety by preventing accidental short circuits. They offer secure, reliable connections for routing wires directly through panels, simplifying complex circuits. Available in various pole counts, they provide a robust solution for diverse industrial and commercial applications.

panel mount feedthrough terminal block

We provide panel mount feedthrough terminal blocks for secure, organized wiring directly on your enclosure panels. These blocks offer a reliable connection point, allowing wires to pass through a bulkhead or panel while maintaining electrical continuity. They’re ideal for applications needing clear wire segregation and robust panel-mounted connections, ensuring stability and simplified assembly.

aluminum alloy junction box

We provide the PT 2.5 feed through terminal block, engineered for reliable electrical connections. Its compact design saves space in panels while offering robust wire termination for conductors up to 2.5 mm². This block ensures efficient current flow and simplifies wiring, making it ideal for various industrial and control applications needing secure, straight-through connections.

PT 6 feed through terminal block

We offer PT 6 feed-through terminal blocks, providing secure and reliable electrical connections. These compact, easy-to-wire blocks feature push-in technology for quick installation, saving you time and effort. Ideal for various industrial applications, they ensure excellent conductivity and long-term stability.

Customize Your Feed Through Terminal Block

Color Coding

We understand that clear identification is crucial for efficient wiring and troubleshooting. We can provide terminal blocks in a wide array of colors, allowing you to easily differentiate circuits, phases, or functions within your control panels. This visual distinction simplifies installation, reduces errors, and speeds up maintenance, contributing to a more organized and safer electrical system.

Printing and Marking

To further enhance organization and safety, we offer custom printing directly on the terminal block bodies. This can include circuit numbers, wire designations, company logos, or any specific text required for your application. Clear, permanent marking eliminates the need for external labels, reduces misidentification risks, and streamlines wiring processes, ensuring your systems are both efficient and compliant.

Number of Positions/Poles

Your application’s specific needs dictate the number of connections required. We can customize the number of positions or poles on your feed-through terminal blocks, from single-pole units to multi-pole assemblies. This flexibility ensures you get precisely the right configuration, optimizing space utilization within your enclosures and simplifying your wiring designs, whether for simple or complex systems.

Material and Environmental Considerations

Different operating environments demand specific material properties. We can customize the material of your terminal blocks to withstand extreme temperatures, corrosive agents, or vibrations. Whether you need UL94-V0 flame-retardant materials, UV-resistant plastics for outdoor use, or specific chemical resistance, we ensure your terminal blocks perform reliably and safely in your unique environmental conditions.

what is a feed through terminal block?

A feed-through terminal block is an electrical connector designed to establish a secure and reliable connection between two or more wires. It typically consists of an insulated housing with conductive elements that allow current to pass directly through, from one side of the block to the other.

These feed through terminal blocks are commonly used to organize and terminate wiring within control panels, distribution boards, and industrial equipment, providing a clean, safe, and easily maintainable way to manage electrical circuits without the need for soldering or direct splicing. They are often mounted on DIN rails and come in various connection technologies, such as screw clamp, push-in, or spring clamp, to suit different application needs and wiring preferences.

feed through terminal block uses

Feed-through terminal blocks are fundamental components in electrical and industrial systems, offering a highly organized and safe method for wire management. Their primary function is to create reliable, semi-permanent connections between conductors, simplifying installation, troubleshooting, and maintenance. They are particularly useful in environments where complex wiring layouts need to be streamlined and clearly identified.

Common feed through terminal block uses include:

- Control Panels and Enclosures: They are extensively used in industrial control panels to organize and distribute power and control signals to various components like PLCs, sensors, and actuators.

- Power Distribution: Feed-through blocks effectively manage power distribution from a main source to multiple circuits, ensuring a clean and efficient flow of electricity.

- Industrial Automation: In automated systems, they provide critical connection points for instrumentation, motor controls, and signaling, facilitating the interconnection of devices.

- Building Automation: From HVAC systems to lighting controls, these blocks help in neatly wiring and managing electrical installations within commercial and residential buildings.

- Telecommunications: They are used in telecommunication infrastructure for organizing and terminating communication cables and power lines.

- Machine Building: Feed-through terminal blocks are essential in machine manufacturing to manage internal wiring, ensuring robust and reliable connections for machine operations.

what are benefits of feed through terminal blocks

Aluminum junction boxes serve as protective enclosures for electrical connections in a wide array of applications, both indoors and outdoors. Their primary function is to provide a safe and organized space to join and terminate electrical wires, safeguarding them from environmental factors like moisture, dust, and physical damage.

The robust yet lightweight nature of aluminum makes these boxes suitable for installations ranging from residential wiring to industrial settings, ensuring the longevity and reliability of electrical circuits. They are particularly favored in situations where corrosion resistance and thermal management are critical.

Beyond basic protection, aluminum junction boxes are also utilized in specialized applications due to their unique properties. Their non-magnetic nature makes them ideal for housing sensitive electronic components where electromagnetic interference could cause disruptions.

Furthermore, their good electrical conductivity facilitates effective grounding and bonding, essential for safety in electrical systems. The durability of aluminum ensures these boxes can withstand harsh conditions, making them a reliable choice for demanding environments such as manufacturing plants, construction sites, and outdoor installations exposed to the elements.

Here are some typical uses of aluminum junction boxes:

Outdoor Electrical Wiring: Aluminum’s excellent corrosion resistance makes these boxes ideal for outdoor installations such as landscape lighting, security systems, and exterior outlets. They effectively protect connections from rain, snow, UV radiation, and other environmental elements, ensuring the long-term reliability and safety of outdoor electrical circuits and preventing premature degradation of wiring and connectors.

Industrial Applications: In manufacturing plants and other industrial settings, aluminum junction boxes provide durable protection for wiring exposed to dust, chemicals, and physical impact. Their robust construction safeguards critical electrical connections for machinery, control systems, and power distribution, minimizing downtime and ensuring operational safety in demanding industrial environments.

Housing Sensitive Electronics: Due to their non-magnetic properties, aluminum junction boxes are used to enclose sensitive electronic components and wiring where electromagnetic interference (EMI) could disrupt performance. This is crucial in applications like data centers, communication equipment, and medical devices, ensuring the integrity and accuracy of electronic signals and preventing malfunctions.

Grounding and Bonding: Aluminum’s good electrical conductivity makes these boxes suitable for use as grounding and bonding points within electrical systems. They provide a reliable and low-resistance path for fault currents, enhancing the safety of the installation by facilitating the proper operation of protective devices and minimizing the risk of electrical shock in case of a fault.

Heat Dissipation: The effective thermal conductivity of aluminum allows these junction boxes to help dissipate heat generated by electrical connections, particularly in high-current applications. This prevents overheating of wires and components, contributing to the overall safety and efficiency of the electrical system and extending the lifespan of the enclosed electrical devices.

How to choose feed through terminal blocks?

Choosing the right feed-through terminal blocks is crucial for ensuring the safety, efficiency, and longevity of your electrical system. This selection process involves a careful assessment of your application’s specific requirements, encompassing electrical parameters, mechanical considerations, and adherence to relevant safety standards. Overlooking any of these aspects can lead to premature failure, safety hazards, and increased downtime.

Here are key factors to consider when choosing feed-through terminal blocks:

Electrical Ratings:

- Voltage and Current: The terminal block must have a voltage and current rating that exceeds the maximum expected voltage and current of your circuit. It’s often recommended to choose a block rated for at least 150% of the maximum anticipated current to account for surges and ensure optimal performance.

- Wire Size and Type: Ensure the terminal block can accommodate the specific wire gauge (AWG or mm²) and type (solid or stranded) you plan to use. Different connection methods are optimized for different wire types.

Connection Technology:

- Screw Clamp: A traditional and highly reliable method, offering strong clamping force. Ideal for applications with some vibration, but can be more time-consuming to wire.

- Push-in: Offers fast and tool-free wiring, especially suitable for solid or ferruled wires. Excellent for high-vibration environments due to the spring-loaded connection.

- Spring Clamp: Similar to push-in, providing quick connections and good vibration resistance, often used with a tool to open the clamp.

Mechanical Considerations:

- Mounting Type: Most feed-through terminal blocks are designed for DIN rail mounting (e.g., 35mm DIN rail), which provides a standardized and organized installation method within control panels.

- Number of Positions/Poles: Determine the number of individual connections required for your circuit. Single-level, dual-level, and triple-level blocks offer different densities to optimize space.

- Space Constraints: Consider the overall size and footprint of the terminal block to ensure it fits within your enclosure or panel without hindering accessibility or airflow.

- Accessories: Think about necessary accessories like end plates, end brackets, jumpers (for bridging connections), and marking tags for circuit identification.

Environmental and Safety Compliance:

- Operating Temperature: Ensure the terminal block’s material can withstand the operating temperature range of your application, including any self-heating from current flow.

- Environmental Conditions: For harsh environments (e.g., high humidity, corrosive chemicals, excessive vibration), select blocks made from robust materials with appropriate ingress protection (IP) ratings.

- Certifications and Standards: Verify that the terminal blocks comply with relevant industry standards such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) standards (e.g., IEC 60947-7-1 for low-voltage terminal blocks). These certifications ensure the product meets specific safety and performance criteria.

- Flammability Rating: For fire safety, check the flammability rating of the insulating material, such as UL94-V0, which indicates self-extinguishing properties.

Send Your Inquiry Now

All-in-one Feed Through Terminal Block Solutions for Your Project

We offer all-in-one feed-through terminal block solutions designed to simplify your project. Our comprehensive range provides various connection technologies, including screw and push-in, along with diverse configurations like multi-level blocks. We ensure optimal organization, space efficiency, and reliable connections for any application, from industrial automation to building infrastructure. Customize color, marking, and materials for a perfect fit.