Greenhouse Fan

High-Performance Axial Fan Solutions for Electrical and Telecom Cabinets

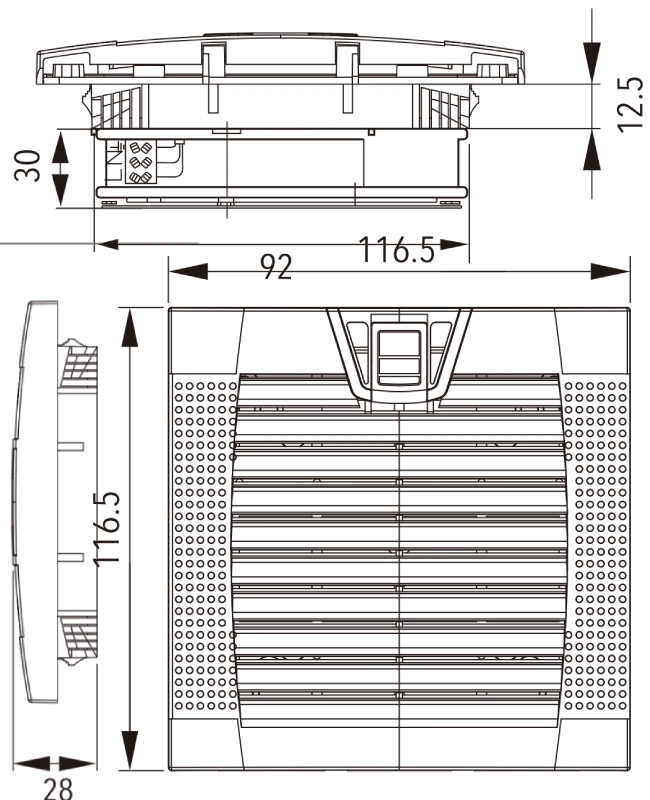

We specialize in custom Axial Fan solutions, including size, airflow capacity, voltage, blade material, mounting style, and noise level adjustments.

Size range

From 140mm to 254mm

Voltage

230V/110V/24V

Operating temperature range

-30℃ ~ 70℃

Protection Level

IP54

Air flow

65-85m³/h

Our greenhouse fan meet international standards including CE, RoHS, and ISO9001. Products are tested for safety, durability, and performance, ensuring compliance with global industrial requirements.

Our Greenhouse Fan Series

We provide customized axial fan solutions with flexible sizes, fast delivery, and OEM/ODM support. Contact us now for a free quote!

FU Series

Available in various sizes with embedded nuts for easy mounting; optional air duct enhances airflow performance.

LK32 Series

Convenient buckle-opening design allows fast servicing; optional power indicator for operation status.

LK66 Series

Straight-line grill structure improves air circulation and enhances cabinet ventilation efficiency.

FF Series

Made of UV-resistant PC alloy; optional corrugated filter mat provides superior dust protection.

FK55 Series

Thinner cover ideal for compact spaces; stylish curved-line grill enhances cabinet appearance.

Greenhouse Fan Performance from Our Quality Materials

Conquer the Heat: Unrivaled High-Temperature Performance

Engineered with specialized heat-resistant components, this fan maintains peak operational performance and structural integrity under extreme thermal loads. It is specifically designed for continuous, reliable cooling in demanding high-temperature cabinet environments, preventing thermal degradation.

Sealed for Safety: Maximum Protection in Extreme Environments

Featuring an advanced ingress protection (IP) rating, our fan delivers unmatched defense against dust, moisture, and corrosive particles. This robust sealing ensures dependable functionality and minimal maintenance, even when exposed to the harshest industrial conditions.

Enduring Power: Guaranteed Stable Airflow and Durability

Optimized motor design and precision-balanced impellers ensure consistent, maximum airflow over extended operating cycles. This superior durability minimizes vibration and power consumption, providing reliable cooling efficiency crucial for mission-critical systems.

Zero Downtime: Premium Bearings for Supreme Longevity

Utilizing premium ball or fluid dynamic bearings (FDB), the fan boasts significantly reduced friction and wear. This advanced engineering extends the service life far beyond standard models, ensuring maximum uptime and dramatically lowering total cost of ownership.

01 Flexible Cooling Solutions

We offer a comprehensive selection of DC fan models in various sizes and common agricultural voltages (12V, 24V, 48V). This diversity ensures an optimal fit for various greenhouse sizes and allows for tailored airflow distribution patterns critical for uniform crop growth.

02. Precise Environmental Management

Our fans incorporate PWM (Pulse Width Modulation) for highly precise speed adjustment, essential for maintaining narrow temperature and humidity bands. FG (Frequency Generation) signal output provides real-time RPM feedback to your automated climate control systems for immediate adjustments.

03. Guaranteed Operational Uptime

Optional motor protection modules, such as RP (Reverse Polarity Protection) and AS (Auto Restart), safeguard the fan motor against voltage spikes or blockage from crop debris. These features ensure long-term reliability and uninterrupted ventilation during critical growing phases.

04. Resilience to Heat and Moisture

Customizable components allow for stable operation up to 120℃. Enhanced with nano-coating technology, our fans resist the combined stress of high summer heat and internal humidity, guaranteeing efficient cooling and longevity in the challenging greenhouse microclimate.

05. Protection Against Rigorous Cleaning

We customize fans with IP67 or IP68 ratings, providing robust defense against dust and water immersion. This extreme waterproofing ensures safe, reliable performance, standing up to high-pressure misting systems and regular disinfectant wash-downs without failure.

06. Optimized Airflow for Crop Health

Speed is adjustable from 1,000 to 30,000 RPM to meet the exact CFM (Cubic Feet per Minute) required for pathogen control and air exchange. High-speed models feature copper-core stability to prevent vibration and ensure consistent laminar airflow across the canopy.

From Concept to Manufacturing: How We Produce Top-Notch DC Fans

Design & Development

We adhere strictly to the principles of advanced fan manufacturing, defining product specifications by analyzing your specific ventilation needs and agri-tech trends. Our engineers utilize 3D modeling and CNC precision machining to rapidly prototype all components—impellers, casings, and control circuitry—to ensure optimum performance in high-humidity and fluctuating temperature environments.

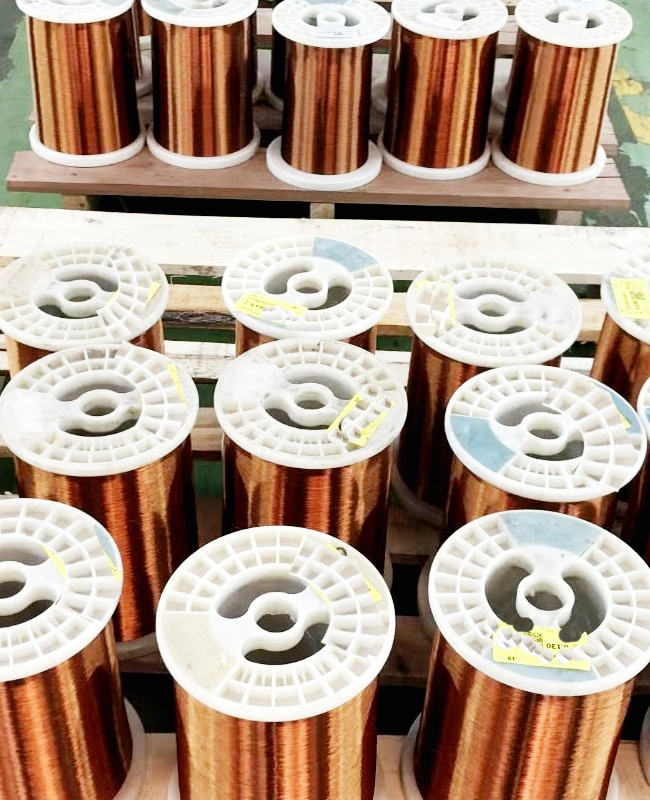

Premium Raw Materials

We source high-grade materials globally, selecting for durability under agricultural use: long-life motors, sealed bearings, corrosion-resistant aluminum alloy frames, and UV-stable plastic impellers. Each material is intensely scrutinized to guarantee it meets our rigorous standards for enduring the harsh, damp greenhouse environment before entering production.

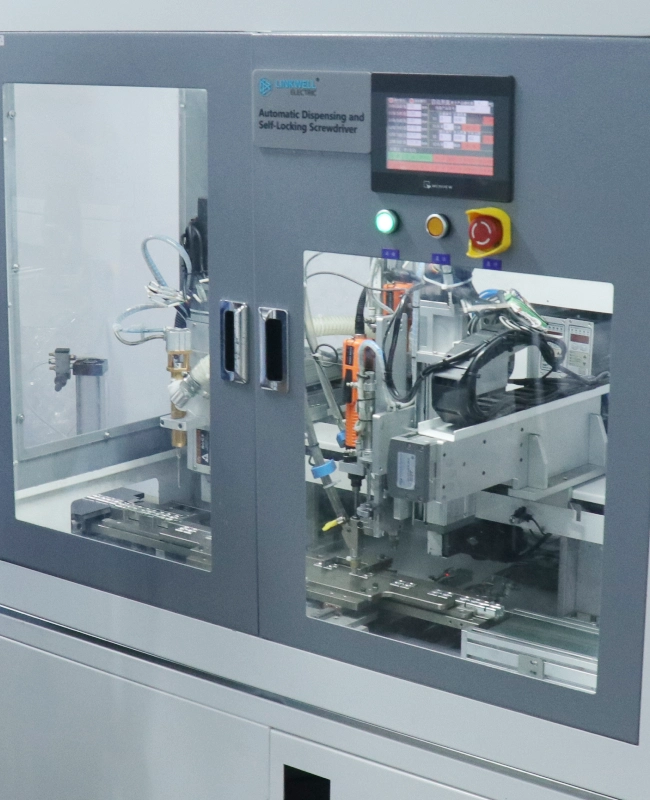

Precision Component Manufacturing

Our fan motors undergo meticulous vacuum sealing and potting treatments to ensure superior waterproofing and moisture resistance. Impellers are precision injection-molded, while frames are cast and machined from ADC-12 Aluminum alloy, ensuring dimensional accuracy and robust durability for continuous operation.

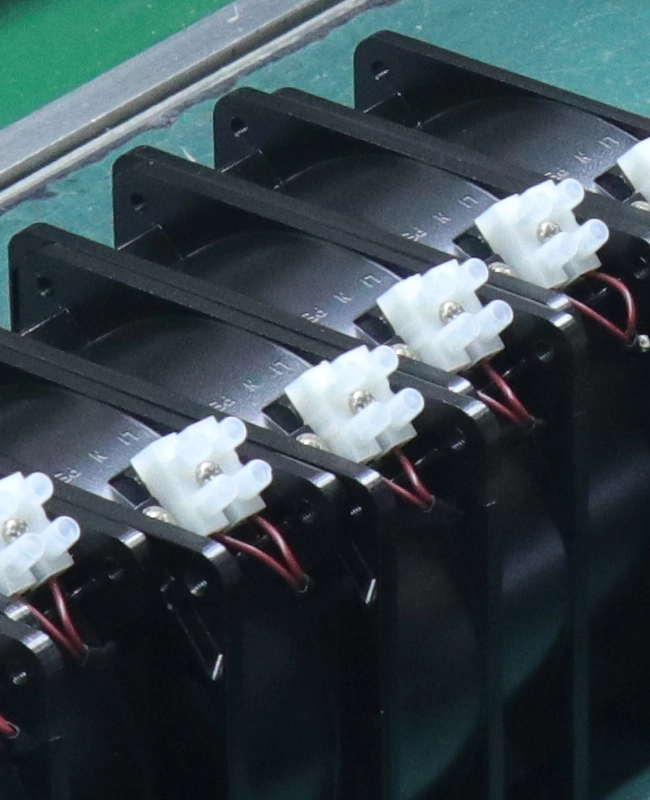

Assembly Process

Core components—motors, bearings, impellers, and frames—are carefully assembled. These initial assemblies immediately undergo functional tests to check for stable startup, minimal operational noise, and energy consumption efficiency at low-speed settings, crucial for reliable, low-maintenance use in climate control systems.

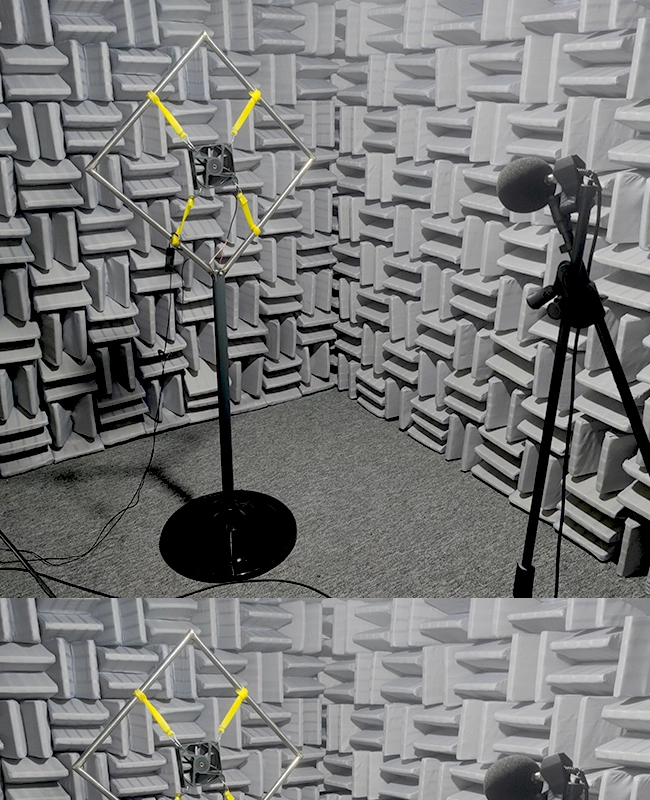

Testing & Calibration

We conduct comprehensive performance checks on speed, power draw, and consistent airflow delivery. Crucially, our fans face environmental testing, simulating the extreme conditions of a greenhouse, including high-humidity spray cycles and radical day/night temperature swings, to verify the unit’s ingress protection (IP) rating and anti-condensation integrity.

Packaging & Shipping

Every single fan is meticulously inspected and packaged to ensure flawless arrival. We use high-quality honeycomb insert packaging that creates individual, protected slots for each fan. This prevents impact damage and safeguards the critical sealing and coating integrity during rough handling and transit.

Why Choose Us: The DC Axial Fan Manufacturer You Can Trust

Innovative R&D Capability

With over 20 patents, we maintain a rapid development pace, releasing new products monthly. Our R&D focuses on eco-friendly materials and sustainable technologies, providing you with cutting-edge, energy-efficient cooling options that align with modern agricultural environmental standards.

Fast and Reliable Shipping

We guarantee quick turnaround times, with standard ventilation fans and blowers shipping within 2–4 weeks. This efficiency helps your greenhouse projects stay on schedule, minimizes construction downtime, and ensures your growing systems are operational when needed.

Premium Protective Packaging

We utilize heavy-duty honeycomb boxes and pallets with individual fan slots to prevent movement and collision during long-distance transit. This specialized packaging drastically reduces damage rates, lowers replacement costs, and ensures your critical ventilation products arrive in perfect, ready-to-install condition.

Rapid Response & Development

We commit to responding to all inquiries and resolving after-sales issues within 12 hours. For customized fan designs, we leverage 3D printing for rapid prototyping, delivering initial samples in just 10 days, significantly shortening your product development cycle.

Comprehensive Warranty Protection

Our standard cooling fans come with a 2-year warranty, while custom solutions are protected by a 1-year warranty. This robust coverage provides you with the peace of mind that your essential greenhouse ventilation system is backed by reliable support and protection.

Expert Technical Support

Our highly trained technical team is always ready to provide professional application advice, virtual installation assistance, and in-depth troubleshooting. This expert support ensures the smooth running, efficient performance, and optimized maintenance of your cooling fans within your system.

Clients

Our clients include leading distributors, engineering firms, and telecom operators worldwide. From Asia to Europe and North America, our fans support large-scale projects in power distribution, data centers, and telecom networks, proving reliability in critical global industries.

FAQs

What makes Linkwell fans suitable for the high-humidity environment of a greenhouse?

Linkwell fans are specifically engineered with superior moisture protection essential for greenhouses. We achieve this through specialized IP67 or IP68 waterproofing measures and nano-coating technology on critical internal components. This protection prevents damage from condensation, high-pressure misting systems, and general high humidity, ensuring the motor and circuitry remain functional and durable for long-term agricultural use.

How do your fans help with precise climate control for different types of crops?

Our fans support precise climate control through advanced integration capabilities, primarily via PWM (Pulse Width Modulation) speed control. This allows the fan speed to be dynamically adjusted based on real-time sensor data (temperature and humidity). This precision prevents “hot spots” and sudden drops in humidity, providing the consistent and uniform airflow required to support the specific needs of sensitive or high-value crops.

Why is high-temperature resistance important for a greenhouse fan, and what is your rating?

Greenhouses, especially during summer or under full sunlight, can experience extreme internal temperatures that accelerate equipment failure. Our fans are customized to resist operational temperatures up to 120℃. This high-temp resilience is critical because it ensures the fan maintains its mechanical integrity and cooling efficiency during the most stressful periods, guaranteeing uninterrupted ventilation when it is needed most to protect crops.

We need a large volume of fans. What is your capacity for timely delivery?

We prioritize minimizing project downtime. Our robust manufacturing capacity allows us to maintain a reliable shipping window of 2–4 weeks for standard volume orders of our greenhouse fans and blowers. For urgent or complex large-scale projects, our rapid prototyping (initial samples in 10 days) and efficient supply chain are structured to keep your construction or system integration on track and on budget.

What kind of warranty and technical support can we expect for your customized fans?

We back our quality with a comprehensive warranty: 2 years for standard models and 1 year for customized fan solutions. Beyond the warranty, our expert technical team provides professional guidance on fan integration, application advice, and troubleshooting. This support ensures optimal setup and maintenance, drastically reducing the total cost of ownership and maximizing fan lifespan.

Contact & Inquiry

Contact us today for detailed product information, quotes, or expert technical support. Simply complete the form with your name, email, company, country, and inquiry, and our team will get back to you quickly. You can also connect with us directly via WhatsApp, email, or phone for fast and reliable assistance.