Push buttons are ubiquitous, found in everything from doorbells to complex industrial machinery. Despite their commonality, the ingenious simplicity of how they translate a physical press into an electrical signal often goes unnoticed.

This blog post will demystify the inner workings of push buttons, exploring their fundamental components and explaining how these unassuming devices effectively complete or break an electrical circuit with a single touch.

What are Push Buttons?

A push button is a type of switch mechanism that completes or breaks an electrical circuit when a button is pressed and released. Typically made of plastic or metal, its surface is designed to be easily actuated by a finger or hand.

Push buttons are fundamental components in a vast array of devices, from simple household appliances and toys to complex industrial machinery and control panels, providing a straightforward way for users to interact with and control electronic systems.

How Does a Push Button Work?

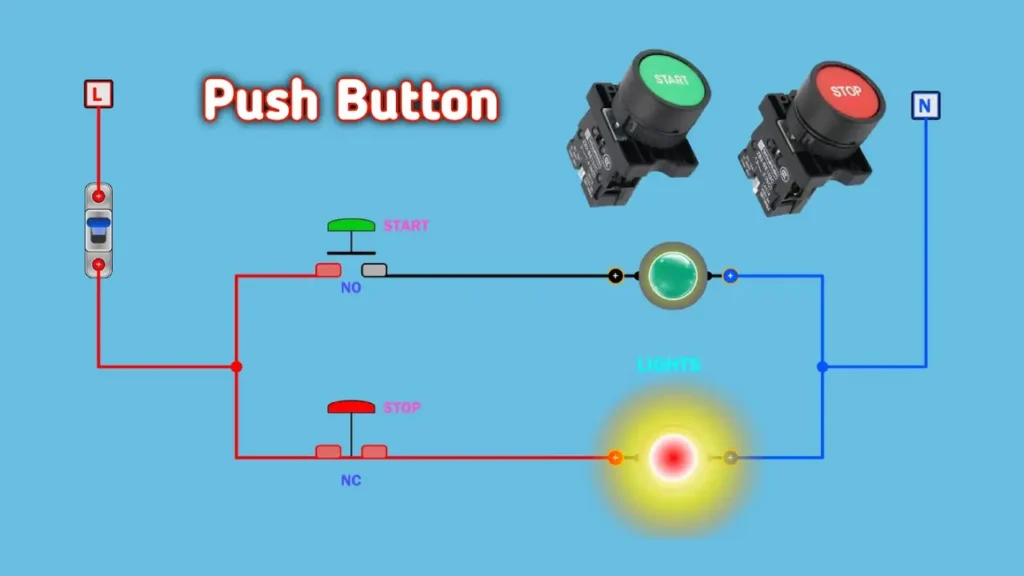

At its core, a push button operates by creating or breaking an electrical connection when a mechanical force is applied. Internally, it consists of a set of electrical contacts that are either normally open (NO) or normally closed (NC).

When the button is pressed, these contacts move, either closing an open circuit or opening a closed one, thereby controlling the flow of electricity.

The specific mechanism varies between momentary and latching types, but the fundamental principle of altering a circuit’s state through physical interaction remains constant. This simple yet effective design makes push buttons ubiquitous in nearly every electronic device we encounter daily.

- Internal Contacts: All push buttons contain conductive metal contacts. In a “normally open” (NO) configuration, these contacts are separated, preventing electricity flow. In a “normally closed” (NC) configuration, they are touching, allowing current to pass until the button is pressed.

- Actuation Mechanism: When the user presses the button, a plunger or similar mechanical component moves. This physical movement forces the internal contacts to change their state – either bringing NO contacts together to close the circuit or separating NC contacts to open it.

- Spring Return (Momentary): For momentary push buttons, a spring mechanism is crucial. Once the pressure on the button is released, this spring immediately pushes the plunger back to its original position, causing the contacts to revert to their default state (open or closed).

- Latching Mechanism (Latching): Latching push buttons employ a mechanism (often a detent or toggle lever) that physically holds the contacts in their new state even after the button is released. A second press is required to disengage this latch and return the contacts to their original position.

- Circuit Completion/Interruption: The ultimate goal is to control the flow of electricity. When contacts close, they complete a circuit, allowing current to flow to a component (like a light or motor). When they open, they interrupt the circuit, stopping the current.

What is the Principle of the Push Button Switches?

The fundamental principle behind all push button switches is the control of an electrical circuit through mechanical action. Essentially, a push button acts as a gatekeeper for electricity.

When a user applies pressure to the button, it triggers an internal mechanism that either brings two conductive contacts together to complete a circuit (allowing current to flow) or separates them to break a circuit (stopping current flow). This simple make-or-break action is what enables users to turn devices on or off, initiate processes, or send signals within an electronic system.

This principle is achieved through various internal components, primarily an actuator (the part you press), movable and fixed electrical contacts, and often a spring. The spring is particularly vital for momentary switches, ensuring the button returns to its default position and breaks the circuit once pressure is removed.

For latching switches, an additional mechanical or sometimes electrical “latch” mechanism is incorporated to maintain the changed contact state until the button is pressed again, allowing for sustained control without continuous physical engagement.

How Does a Latching Push Button Switch Work?

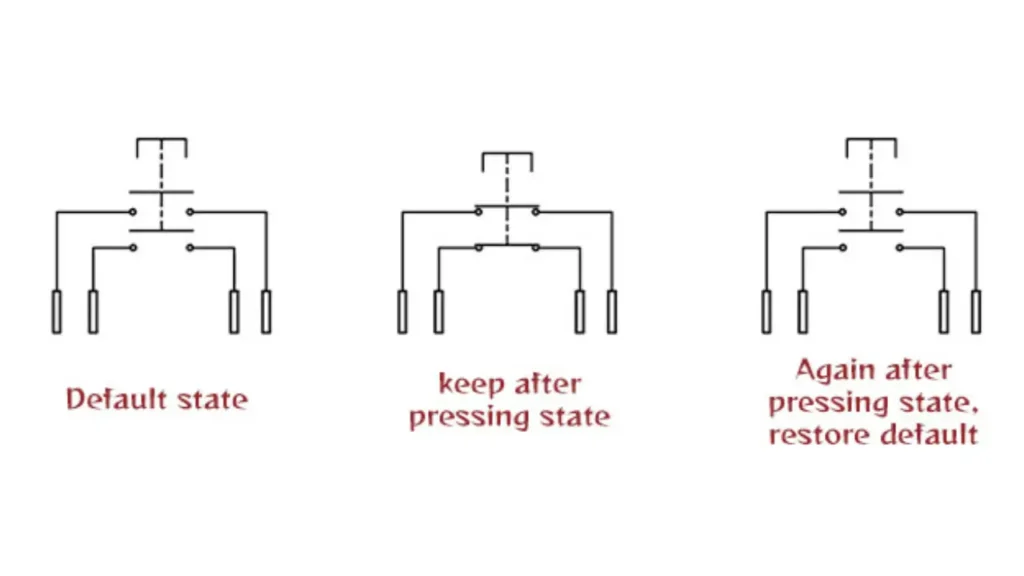

Latching push button switches are designed for sustained action, meaning they maintain their activated state after a single press, unlike momentary buttons that revert immediately. This “memory” function is achieved through a clever internal mechanism that physically or electrically locks the switch’s position.

When a latching button is pressed, it triggers this internal locking system, which keeps the electrical contacts in their new state (either connected or disconnected) even after the user removes their finger. A subsequent press is then required to release the latch and return the contacts to their original configuration.

- Initial Press and Latching: When the button is first pressed, an internal mechanical component (like a detent, cam, or toggle) engages. This engagement physically holds the moving contact in a new position, either connecting a circuit (normally open becoming closed) or disconnecting it (normally closed becoming open). This action is often accompanied by a tactile “click.”

- Maintained State: After the button is released, the mechanical latching mechanism ensures that the contacts remain in their new state. The button head itself may visibly stay depressed or protrude, providing a clear visual indication that the switch is “on” or “off” and the circuit is maintained.

- Second Press and Release: To change the switch’s state back, the button must be pressed again. This second press disengages the internal latching mechanism, allowing the contacts to return to their original position. The button head typically pops back out or moves to its alternate stable state.

- Mechanical vs. Electrical Latching: While many latching buttons use purely mechanical mechanisms, some also incorporate electrical components, like relays or flip-flop circuits, to achieve the sustained state. These electrical latching circuits can maintain the state even after a momentary input, offering flexibility in design.

- Contact Configuration: Like momentary buttons, latching switches also have internal contacts that are either normally open (NO) or normally closed (NC). The latching mechanism simply ensures that these contacts remain in their “activated” state until deliberately reset by a second press, thereby continuously completing or breaking the circuit.

How Does a Momentary Push Button Work?

A momentary push button operates on a simple yet effective principle: it creates a temporary electrical connection only for as long as it is actively being pressed. Its design is fundamentally geared towards providing an intermittent signal or action, making it suitable for applications where a continuous flow of electricity or action is not desired without constant user input.

Internally, a momentary push button typically consists of a spring-loaded mechanism and a set of electrical contacts. When the user presses the button, a plunger or similar component moves downwards, forcing the internal contacts together (if normally open) or apart (if normally closed). This physical movement is what completes or breaks the electrical circuit.

The key characteristic of a momentary push button lies in its spring return. As soon as the user releases the pressure on the button, the internal spring pushes the plunger back to its original, default position. This action simultaneously causes the electrical contacts to revert to their initial state, thereby immediately breaking the circuit connection that was established while the button was pressed.

Benefits of Using Push Button Switches

Push button switches are ubiquitous in modern electronics, offering a straightforward and intuitive interface for countless applications. Their widespread use stems from a variety of significant advantages that make them a preferred choice for designers and users alike.

Simplicity of Operation

Push button switches are incredibly simple to operate, requiring just a single press to actuate. This intuitive nature makes them accessible to users of all skill levels, minimizing confusion and reducing the likelihood of operational errors. Their straightforward on/off or momentary action simplifies user interaction with complex systems.

Reliability and Durability

Designed for repeated use, push button switches are known for their robust construction and long operational lifespan. They typically involve few moving parts, which contributes to their reliability and resistance to wear and tear, even in high-cycle applications or harsh industrial environments. This durability ensures consistent performance over time.

Versatility in Application

The adaptability of push button switches is remarkable, allowing them to be integrated into an enormous range of devices and systems. From simple household appliances and toys to advanced industrial control panels, medical equipment, and automotive systems, their various types (momentary, latching, illuminated) cater to diverse functional requirements.

Clear User Feedback

Many push button switches provide immediate and clear feedback to the user upon actuation. This can be a tactile “click” or “thud,” a visual change (like an integrated LED illuminating or the button physically staying depressed), or both. This direct feedback assures the user that their input has been registered, enhancing the user experience.

Cost-Effectiveness

Compared to more complex input mechanisms like touchscreens or sophisticated rotary encoders, traditional push button switches are generally very cost-effective to manufacture and implement. Their simple design and widespread production make them an economical choice for both small-scale projects and large-volume manufacturing, helping to keep overall product costs down.

Conclusion

Understanding how a push button works, from its fundamental internal contacts to its role in completing or breaking an electrical circuit, is key to successful electronics projects. This seemingly simple component is a cornerstone of user interaction in countless devices.

By grasping the mechanics of push buttons, you can confidently integrate them into your designs, ensuring precise control and reliable functionality for various applications, from simple household gadgets to complex industrial machinery.

For all your push button requirements, including a wide range of types and specifications, consider Linkwell Electrics as your trusted source for wholesale push buttons, providing quality components for your every need.