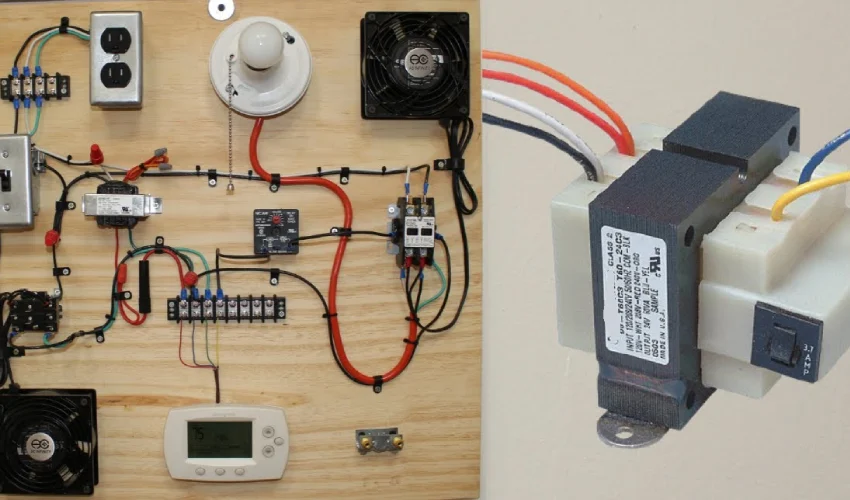

You want to know how to check transformer safely and effectively. Start by putting safety first and always use the right tools for the job. When you check transformer units from Linkwell, you work with some of the most reliable equipment in the industry. Check out the main types you might see:

| Transformer Type | Phase Options | Applications |

|---|---|---|

| Control Transformer | Single-phase | Machine tool equipment, construction machinery |

| Three-phase | Tower cranes, control distribution cabinets |

No matter your experience, you can handle transformer testing with confidence.

Key Takeaways

- Always prioritize safety by disconnecting power and wearing personal protective equipment (PPE) like gloves and safety glasses.

- Use essential tools like a digital multimeter and insulation resistance tester to perform accurate transformer checks.

- Conduct tests for continuity, voltage output, and insulation resistance to identify potential issues early.

- Read the transformer nameplate carefully to ensure correct testing settings and avoid damaging the equipment.

- If you encounter serious issues, consider replacement or seek professional help to maintain safety and reliability.

Safety Steps for Transformer Testing

Before you check transformer units, you need to put safety first. Mistakes can lead to serious injuries or equipment damage. Let’s walk through the key steps to keep you safe every time you work with a transformer.

Power Off and Discharge

Always disconnect the transformer from any power source before you begin. Don’t just flip a switch—double-check that all circuits are off. Use a voltage tester to confirm there’s no live current. After you power off, discharge any stored energy in the transformer windings. This step helps prevent electric shocks, which are one of the most common injuries during transformer testing. Electric shocks can cause burns, nerve damage, or even cardiac arrest. Take your time and never rush this process.

Personal Protective Equipment

You should always wear the right gear when you check transformer units. Put on insulated gloves, safety glasses, and flame-resistant clothing. These items protect you from electric shocks, fire, and explosions. Many accidents happen because people skip this step. Wearing proper PPE also helps you avoid mechanical hazards, like moving parts or falling objects. Remember, safety gear is your first line of defense.

Safe Work Environment

Set up your workspace so you can move safely and focus on the task. Keep the area dry and clear of clutter. Make sure you have good lighting and easy access to emergency exits. Human errors often happen when the environment is messy or distracting. You should also follow international safety standards, especially when working with Linkwell transformers. Here’s a quick look at some important IEC guidelines:

| IEC Standard | Title / Scope | Safety / Environmental Focus |

|---|---|---|

| IEC 60076-1 | General Requirements | Electrical, mechanical, and operational safety |

| IEC 60076-2 | Temperature Rise Limits | Prevents overheating and fire risk |

| IEC 60076-5 | Short-Circuit Withstand Strength | Protects against mechanical and thermal damage |

| IEC 60076-7 | Loading Guides | Prevents overload and insulation deterioration |

| IEC 60076-10 | Sound Level Limits | Noise pollution control |

| IEC 60076-14 | Environmental and Climatic Classes | Oil leakage prevention, corrosion resistance |

| IEC 60076-22-1 | Fire Safety and Liquid-Immersed Transformers | Fire prevention and containment |

| IEC 60076-19 | Digital Monitoring and Diagnostics | Condition-based risk management |

Tip: Following these standards helps you avoid risks like fire, explosions, and electromagnetic interference. Always check transformer safety guidelines before you start.

Tools Needed to Check Transformer

Before you start any transformer testing, you need the right tools. The right equipment helps you get accurate results and keeps you safe. You’ll find that Linkwell transformers work well with all standard testing tools, so you don’t have to worry about compatibility.

Basic Testing Tools

Let’s start with the basics. You don’t need fancy gear to get started. Here’s what you should have on hand:

- Digital Multimeter: This tool is your best friend. You can use it to measure voltage, current, and resistance. If you want to know how to check transformer primary and secondary with multimeter, this is the tool you’ll grab first.

- Insulation Resistance Tester (Megger): This device checks the insulation between transformer windings and the core. It helps you spot any breakdowns before they cause trouble.

- Screwdrivers and Wrenches: You’ll need these to open panels and access terminals safely.

- Test Leads and Clips: These help you connect your meter to the transformer without holding wires by hand.

Tip: Always inspect your tools before use. Damaged leads or meters can give false readings or even cause injury.

Advanced Testing Instruments

Sometimes, you need more than just the basics. Advanced instruments give you a deeper look into transformer health:

- CT Analyzer: This device tests current transformers quickly and accurately. It checks things like ratio, phase, and excitation. It follows both IEEE and IEC standards, so you know you’re getting reliable results.

- Electrical Test Systems: These systems can run several tests, such as magnetization characteristics, saturation behavior, transformation ratio, polarity, load, winding resistance, withstand voltage, and remanence. They help you spot issues that basic tools might miss.

You don’t need every tool for every job. Start with the basics, then use advanced instruments if you need more details. Linkwell transformers support both simple and advanced testing, making your job easier and safer.

Identify Transformer Parts

Primary and Secondary Windings

You need to know where the transformer primary and secondary windings are before you start any test. On a Linkwell transformer, you usually find the transformer primary and secondary windings marked clearly on the body or the wiring diagram. The transformer primary and secondary windings are the heart of the transformer. The transformer primary and secondary windings look like coils of copper wire wrapped around a laminated core. The transformer primary and secondary windings connect to the input and output terminals. You will see the transformer primary and secondary windings labeled as “H” for high voltage (primary) and “X” for low voltage (secondary). The transformer primary and secondary windings are often color-coded or have tags for easy identification.

When you open the panel, look for the transformer winding layout. The transformer winding closest to the power source is the primary. The transformer winding that leads to the control circuit or load is the secondary. If you check a Linkwell transformer, you will notice the transformer winding arrangement is neat and follows international standards. Always trace the transformer winding from the terminal block to make sure you have the right connection. This step helps you avoid mistakes during transformer testing.

Tip: Never touch the transformer winding with bare hands, even if you think the power is off. Use insulated tools to check the transformer winding connections.

Nameplate and Specifications

The nameplate on a transformer gives you all the critical data you need for safe and accurate transformer testing. You should always read the nameplate before you test the transformer primary and secondary windings. The nameplate tells you the transformer’s design, capacity, and operating limits. Here’s a quick table to help you understand what you’ll find:

| Critical Information | Description |

|---|---|

| Design | Information about the transformer’s design specs. |

| Capacity | The maximum load the transformer can handle safely. |

| Operating Limits | Voltage and current ratings for safe operation. |

You will also see these important details:

- Identification of the transformer type

- Rating data including voltage and current

- Electrical specifications for safe operation

If you skip the nameplate, you might connect the transformer winding to the wrong voltage or overload the transformer primary and secondary windings. That can damage the transformer or cause safety risks. Always match your test settings to the numbers on the nameplate. This habit keeps your transformer winding safe and extends the life of your Linkwell transformer.

Transformer Testing Methods

You want to know how to check transformer units the right way. Let’s walk through the most important transformer testing methods. These steps work for Linkwell Power Transformer, step down transformer, Control Transformer, and Industrial Control Transformer. You can use these methods for manual testing or with advanced tools.

Continuity and Resistance Test

Start with a continuity and resistance test. This test helps you find open or short circuits in the windings. You need a digital multimeter for this step.

- Turn off all power and discharge the transformer.

- Set your multimeter to the resistance (ohms) setting.

- Touch the probes to the primary winding terminals. You should see a low resistance value. If you see “OL” or infinite resistance, the winding is open.

- Move the probes to the secondary winding terminals. Again, look for a low resistance value.

- Check between each winding and the transformer core. You should see infinite resistance. If you see a low value, there may be a short to ground.

If you find an open circuit or a short, do not use the transformer. Replace it with a new Linkwell unit.

Voltage Output Test

The voltage output test shows if your transformer steps voltage up or down as expected. This is a key part of how to check transformer performance, especially for a step down transformer or Control Transformer.

Follow these steps:

- Double-check all connections with the power off. Make sure the transformer is mounted well and there are no loose wires.

- Reconnect the power source to the primary winding. Turn on the breaker or plug in the equipment.

- Use your multimeter to measure the voltage at the primary input terminals. The reading should match the source voltage.

- Move the probes to the secondary output terminals. The reading should be close to the transformer’s nameplate output voltage.

Here’s what your results mean:

- If the secondary voltage is within 5-10% of the nameplate rating, the transformer works well.

- If you see zero or very low output voltage but the primary voltage is correct, the transformer may have failed.

- If the output voltage is much higher than expected, check for wiring mistakes or the wrong transformer.

Always compare your readings to the nameplate. This step is vital when you test a transformer.

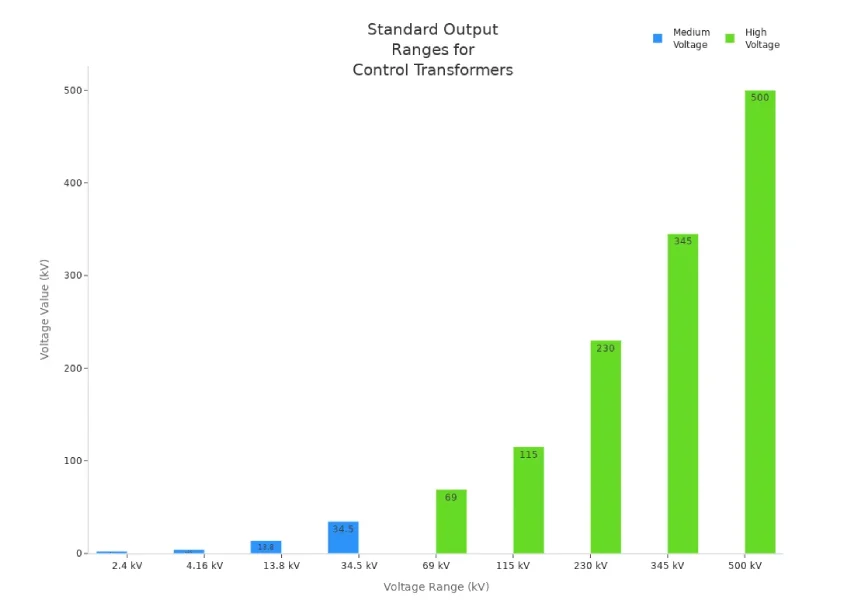

Standard Voltage Output Ranges

You may want to know the typical voltage ranges for industrial control transformers. Here’s a quick table:

| Transformer Type | Voltage Range |

|---|---|

| Medium Voltage | 2.4 kV, 4.16 kV, 13.8 kV, 34.5 kV |

| High Voltage | 69 kV, 115 kV, 230 kV, 345 kV, 500 kV |

Insulation Resistance Test

The insulation resistance test checks the health of the insulation between windings and ground. This test helps you avoid dangerous faults and keeps your transformer safe.

Here’s how you do it:

- For single-phase transformers:

- Test high voltage winding to low voltage winding and ground.

- Test low voltage winding to high voltage winding and ground.

- Test high voltage winding to low voltage winding.

- Test high voltage winding to ground.

- Test low voltage winding to ground.

- For three-phase transformers:

- Test high voltage winding to low voltage winding and ground.

- Test high voltage winding to ground with low voltage winding to guard.

- Test high voltage winding to low voltage winding.

- Test low voltage winding to ground with high voltage winding to guard.

Use an insulation resistance tester (megger) for these steps. Record the values for each test.

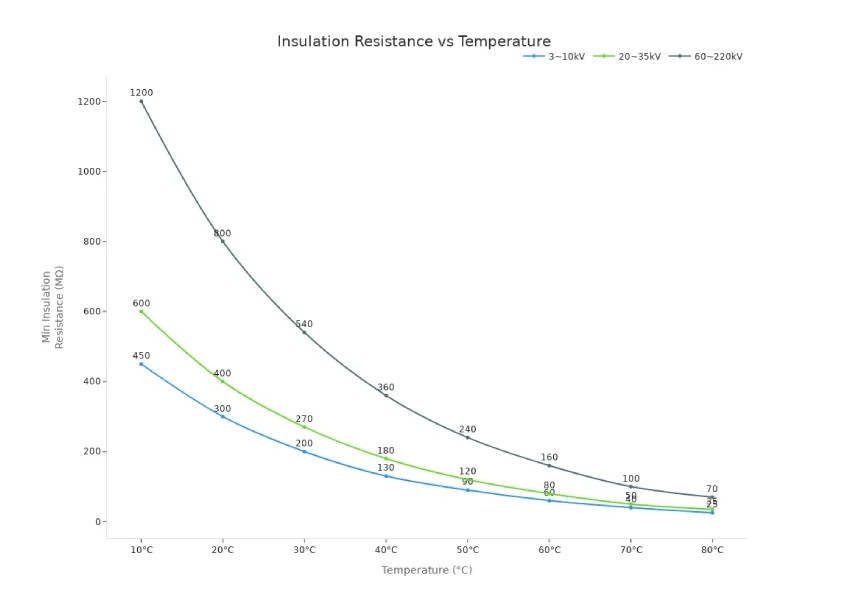

Here’s a table showing safe insulation resistance values for industrial transformers at different temperatures:

| Voltage Grade | 3~10kV | 20~35kV | 60~220kV |

|---|---|---|---|

| Temp. ℃ | Minimum Insulation Resistance (MΩ) | Minimum Insulation Resistance (MΩ) | Minimum Insulation Resistance (MΩ) |

| 10 | 450 | 600 | 1200 |

| 20 | 300 | 400 | 800 |

| 30 | 200 | 270 | 540 |

| 40 | 130 | 180 | 360 |

| 50 | 90 | 120 | 240 |

| 60 | 60 | 80 | 160 |

| 70 | 40 | 50 | 100 |

| 80 | 25 | 35 | 70 |

If your readings are much lower than the values in the table, the insulation may be failing. Replace the transformer or contact Linkwell support for help.

Polarity and Phase Test

The polarity and phase test makes sure the transformer windings are connected the right way. This step is important for parallel operation and safety.

Here’s how to check transformer polarity and phase:

- Isolate the transformer from all power sources. Identify the terminals on both the high voltage and low voltage sides.

- Connect a voltmeter or multimeter as shown in the wiring diagram.

- Apply a low AC voltage (like 230V or 400V) to the high voltage side.

- Watch the induced voltage on the low voltage side.

- Measure the voltage between the primary and secondary winding leads (H1–X1 and H2–X2). Use the readings to confirm the polarity type.

If you get the polarity or phase wrong, you can cause big problems:

- Measurement errors can happen.

- Protection devices may not work right.

- Equipment can wear out faster or even fail.

- The risk of electric shock goes up.

Always follow the wiring diagram and double-check your results. If you’re not sure, ask a professional or reach out to Linkwell for support.

You now know how to check transformer units using the main transformer testing methods. These steps help you spot problems early and keep your Linkwell transformer running safely and efficiently. If you want to learn more about transformer testing or need help with manual testing, Linkwell’s team is ready to support you.

Troubleshooting and Interpreting Results

Common Transformer Issues

You might run into a few common problems when you test your transformer. Spotting these early can save you time and money. Here’s what you should look out for:

- Insulation failure

- Overheating

- Oil leakage

- Winding short circuits

- Core faults

- Bushing failures

- Tap changer malfunctions

If you notice any of these issues, don’t ignore them. They can lead to bigger problems if you keep using the equipment.

Reading Test Results

Understanding your test results helps you decide what to do next. For example, when you use a digital multimeter to check continuity, follow these steps:

- Set your multimeter to Continuity Test mode.

- Press the continuity button if your meter has one.

- Insert the black lead into the COM jack and the red lead into the VΩ jack.

- Make sure the circuit is off, then connect the leads across the part you want to test.

- Listen for a beep. A beep means the circuit is good. No beep means the circuit is open.

- Turn off your multimeter when you finish.

If you see strange readings, you might have a winding problem. Here’s a quick table to help you match symptoms to possible causes:

| Symptoms | Underlying Issues |

|---|---|

| High current | Core joint loosening or lamination short |

| Unequal phase current | Flux asymmetry or air gap fault |

| High furan content | Paper insulation aging, winding collapse, or short-circuit |

| SFRA deviation | Mechanical deformation, winding dislocation |

Next Steps and When to Replace

Sometimes, you can fix a problem. Other times, you need to replace the transformer. Here are signs that it’s time for a new one:

- You see oil leaks or insulation breakdowns happening again and again.

- The transformer is too small for your current needs.

- You notice frequent faults or the equipment is getting old.

- Repair costs are more than 60% of what a new unit would cost.

Here’s a table to help you decide:

| Criteria for Replacement | Explanation |

|---|---|

| Safety or Reliability Is Compromised | Insulation problems make the transformer unsafe or unreliable. |

| Performance Requirements Have Changed | The transformer can’t keep up with new load demands. |

| The Transformer Is Near the End of Life | Old transformers need more repairs, so replacement saves money. |

| Repair Costs Exceed 60% of Replacement Costs | It’s smarter to buy new if repairs get too expensive. |

If you’re not sure what to do, reach out to Linkwell’s support team. They can help you figure out if you need a repair or a replacement. You can also ask about their product options to keep your system running safely.

Conclusion

You now have a clear path to check a transformer safely and effectively. Safety always comes first. You should power off and discharge equipment before you do anything else. Personal protective equipment keeps you safe from unexpected shocks or burns. A clean, organized workspace helps you avoid mistakes.

When you gather your tools, start with the basics. A digital multimeter and insulation tester will handle most jobs. If you want deeper insights, advanced instruments can help you spot hidden issues. Always check the nameplate and understand the primary and secondary windings before you begin any test.

You can use simple steps to test for continuity, resistance, voltage output, insulation, and polarity. Each method gives you important clues about the health of your equipment. If you see warning signs like low insulation resistance or strange voltage readings, take action right away.

Remember: If you ever feel unsure, reach out to a professional or contact Linkwell’s support team. They can guide you through tough situations and help you choose the right replacement if needed.

Here’s a quick checklist to keep in mind:

- Power off and discharge before testing

- Wear proper PPE

- Use the right tools for each test

- Read the nameplate and wiring diagram

- Compare your results to safe values

- Replace or repair if you find serious issues

Choosing Linkwell means you get reliable products and expert support. You can trust their transformers to deliver safe, stable power for your projects. If you need help with installation, troubleshooting, or replacement, Linkwell stands ready to assist you 24/7.

Stay safe, follow these steps, and you’ll keep your electrical systems running smoothly.

You’ve learned how to check a transformer safely and effectively. Always start with safety—wear PPE, keep your workspace clean, and use calibrated tools. Regular testing helps you catch problems early, extend equipment life, and avoid costly downtime. Linkwell transformers stand out for their reliability and long service life:

| Brand | Rating | On-time Delivery |

|---|---|---|

| Linkwell Electric (Shanghai) Co., Ltd. | 5.0/5.0 | 100% |

If you face complex issues, reach out to a professional. You’ll keep your system safe and running strong.

FAQ

How often should you test a transformer?

You should test your transformer at least once a year. If you notice any unusual sounds, smells, or performance drops, run a check right away. Regular testing helps you catch problems early.

What’s the safest way to discharge a transformer?

First, turn off all power. Use an insulated screwdriver to connect the winding terminals to ground. Wait a few minutes before touching anything. Always wear gloves and safety glasses.

Can you use a regular multimeter for all transformer tests?

A regular multimeter works for basic checks like continuity and voltage. For insulation resistance or advanced diagnostics, grab a megger or specialized tester. Always match your tool to the test.

What should you do if your transformer fails a test?

Stop using the transformer immediately. Check your connections and retest. If it still fails, contact Linkwell support or a qualified technician. Don’t try to repair high-voltage equipment yourself.