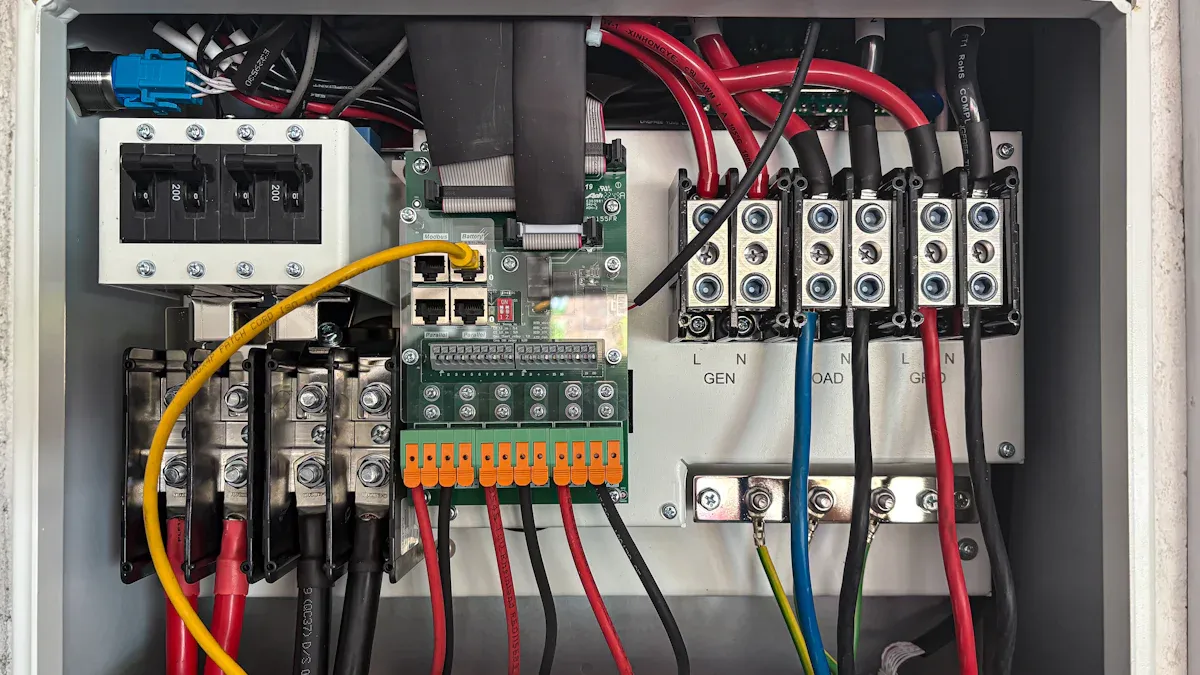

If you want to learn how to install control panel terminal blocks in a control cabinet, proper planning is essential to avoid wiring mistakes. Organizing and labeling wires reduces risks such as old wiring, rodent damage, poor installations, and moisture that can cause rust. Using Linkwell Screw Terminals and Din Rails ensures a robust and reliable setup. By following safety guidelines, you protect your cabinet from issues like loose contacts and insulation damage. Knowing how to install control panel terminal blocks in a control cabinet not only keeps your electrical system safe but also simplifies maintenance.

Key Takeaways

- Think about your terminal block layout before you start. This helps keep wires tidy and easy to get to. Leave some extra space for upgrades later.

- Sort and label every wire with colors and strong labels. This helps stop mistakes and makes fixing things faster.

- Use the right tools and certified Linkwell parts like Din Rails and screw terminals. This makes your setup safe and dependable.

- Put the Din Rail on straight and make sure it is tight. Attach terminal blocks firmly and leave enough space between them. This stops loose connections.

- Get wires ready the right way and tighten screws well. Test all connections to keep your system safe and working right.

Tools and Preparation

Essential Tools and Materials

Get your tools and materials ready before you begin. You need screwdrivers that fit the screws on your terminal blocks. Use wire strippers to take off insulation without hurting the wires. Crimpers are needed if you use ferrules, which keep wire ends tidy and safe. A multimeter helps you check your connections and see if electricity flows.

Pick a terminal block that matches your wire size and how much current you need. Din-rail terminal blocks come in many types, like installation terminal blocks, neutral-conductor disconnect terminal blocks, and feed-in terminals. You might also need cable glands to keep out dust and water, end covers for safety, and mounting parts like Linkwell Din Rails and end clamps. These things help you keep wires neat, make connections safe, and make fixing things easier later.

Always pick certified and good-quality parts. Items with UL or CE marks meet tough safety rules. Linkwell Screw Terminals and Din Rails are made for factories and follow world standards, so they are a smart pick for your job.

Safety Equipment and Precautions

You need the right safety gear when working with electrical cabinets. The table below lists common safety gear and what it does:

| Safety Equipment | Purpose |

|---|---|

| Insulated Gloves | Keep hands safe from electric shock |

| Hard Hats | Protect your head from things that fall |

| Safety Glasses/Goggles | Keep eyes safe from flying bits and sparks |

| Flame-Resistant Clothing | Lowers burn risk from arc flashes |

| Safety Footwear | Stops slips and keeps feet safe from shocks |

| Arc Flash Suits | Protects you from arc flash burns |

Check all your safety gear before you use it. Make sure gloves and shoes fit and are not broken. Wear flame-resistant clothes to help stop burns. Always follow safety rules, like turning off power before you start and keeping your area clean and dry. Training and practice help you stay safe and avoid getting hurt.

Tip: Keeping your workspace neat and using the right safety gear helps you install din-rail terminal blocks safely and easily.

How to Install Control Panel Terminal Blocks in a Control Cabinet

Plan the Layout

The first thing to do is plan your layout. This helps you install control panel terminal blocks in a control cabinet the right way. You want your setup to look neat and be easy to reach. Pick terminal blocks that fit your wire size and the voltage or current you need. Make sure there is enough space for all your wires. Leave extra room for new wires later. Put similar parts together, like switches with power supplies. This makes it easier to find things.

Here are some steps to help you plan:

- Pick terminal blocks with the right ratings for your job.

- Count how many terminals you need, and add some extra.

- Check if the screws and barriers fit your wire size.

- Choose if you will use DIN rail mounting or another way.

- Add things like clear covers or grounding terminals if you need them.

- Use modular blocks to keep wires tidy and make fixing things easier.

- Leave about 20% more space for new wires or upgrades.

Tip: Keep high voltage and low voltage terminals apart. Use partitions and clear labels to stop mistakes.

A good layout stops messy wires and makes fixing problems easy. You can reach each terminal block without moving other wires. Good planning keeps your cabinet safe and helps it last longer.

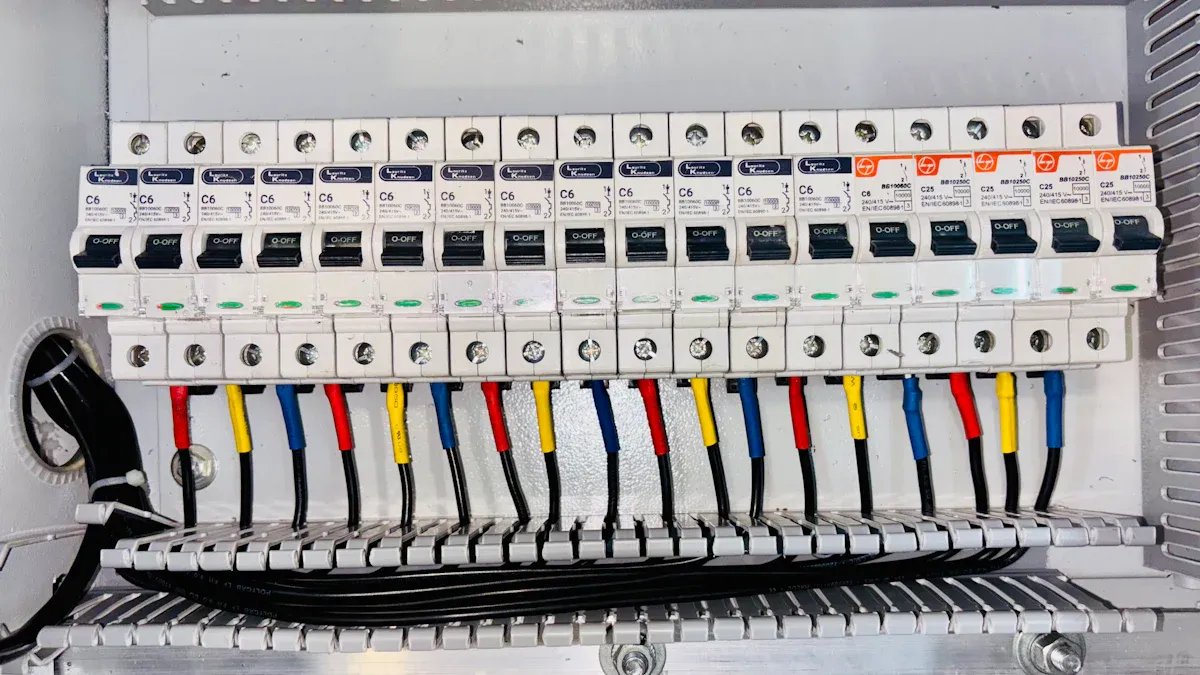

Organize and Label Wires

It is important to organize and label wires when you install control panel terminal blocks in a control cabinet. If you skip this, you might get confused and make mistakes later. Use wire ducts and cable ties to keep wires neat. Run wires around terminal strips, not over them, so you can see each one.

Try these tips for organizing and labeling wires:

- Use colors to show what each wire does. For example, black for ground and red for positive.

- Label every wire, terminal strip, and device with names or numbers. This helps you find problems fast.

- Keep a wiring diagram for your cabinet. Update it if you change anything.

- Bundle wires with cable clamps or zip ties. This keeps wires neat and easy to follow.

- Use multi-core cables to group wires and cut down on mess.

- Tag each wire and terminal with clear, strong labels that match your diagram.

- Plan wire runs so you do not mix up different wires. Strip the sheath only near the ends.

- Test each wire after you put it in to make sure it works.

- Leave some slack in wire bundles to help with repairs.

- Do not use temporary, unlabeled wires. They can cause problems later.

| Labeling Tip | Why It Matters |

|---|---|

| Use strong labels | Labels last longer and stay readable |

| Match schematic IDs | Makes tracing wires easier |

| Color code wires | Prevents mix-ups and errors |

Note: Clear labels and neat wires help you fix your cabinet fast. You can avoid mistakes like tangled wires, bad contacts, and wrong connections.

When you organize and label wires, your setup is safe and looks professional. You also follow important rules that protect your equipment and people. Good organization saves time and money when you need to fix things.

Mount the Din Rail with Linkwell

Secure the Din Rail

Pick the right Din Rail for your cabinet before you start. Linkwell has many types and sizes to choose from. Make sure the rail fits your equipment and where you will use it. The table below can help you pick:

| Aspect | Details and Selection Criteria |

|---|---|

| Types Available | Din Rail Distribution Blocks (varied by current, voltage, connection type) |

| Current Ratings | Up to 310A |

| Voltage Range | 12V, 48V, 600V |

| Connection Types | Screw, Push-in, Spring-clamp |

| Housing Material | Flame-retardant polyamide |

| Certifications | UL, CE, RoHS |

| Customization | Labeling, colors, OEM branding |

| Selection Criteria | Match current and voltage to load; choose connection type for your needs; check for safety compliance |

First, measure the space inside your cabinet. Mark where you need to drill holes with a pencil. Use a level to make sure the rail will be straight. Drill holes at the marks you made. Hold the rail against the back panel. Use screws or steel clips to attach it. Add end stoppers so the rail does not move. If your cabinet shakes a lot, use stronger stoppers and anti-vibration washers.

Tip: Use the right tools like a tape measure, level, and drill to do the job well.

Check Alignment and Stability

After you put the rail in, check if it is flat and straight. Run your hand along the rail to feel for bumps or loose spots. The rail should not move when you press on it. Spacers help keep space between din-rail terminal blocks and let air flow. Good alignment makes it easier to install din rail terminal blocks and keeps wires tidy.

Linkwell Din Rails are strong and follow important rules. They meet standards like IEC 60715, CE, and UL. The rails are made from zinc-plated or stainless steel for extra strength. This helps stop rust and makes them last longer. Their design can hold heavy loads and fits many din-rail terminal blocks. You can count on Linkwell rails for safe and easy setups that last a long time.

Note: When you install din-rail terminal blocks on a steady rail, your equipment stays safe and upgrades are easier.

Attach the Terminal Blocks

Linkwell Screw Terminal Block Installation

You can attach the terminal blocks to the Din Rail in a few easy steps. Start by gathering your tools and materials. You need your din-rail terminal blocks, a screwdriver, and the mounted Din Rail. Check that your terminal blocks match the size and type of your Din Rail. This helps you avoid problems during terminal block installation.

Follow these steps to mount the terminal block:

- Hold the din-rail terminal block so the identification surface faces you.

- Align the back of the terminal block with the Din Rail notches.

- Snap the terminal block onto the Din Rail. Some blocks use spring clips, while others need you to tighten a screw.

- Make sure the block clicks or locks into place. You should feel or hear it secure.

- Repeat these steps for each din-rail terminal block you want to install.

Tip: Always double-check the orientation before you attach the terminal blocks. This keeps your labels visible and your wiring neat.

Ensure Proper Fit and Spacing

After you mount the terminal block, check that each one sits firmly on the Din Rail. Press gently on each block to make sure it does not move. Proper fit stops wires from coming loose and keeps your cabinet safe.

Leave enough space between din-rail terminal blocks. This prevents wires from crossing or touching. Good spacing also helps with airflow and makes future repairs easier. Use end stoppers to keep the blocks from sliding along the rail.

You can use different terminal block mounting methods, but always follow the manufacturer’s instructions. Linkwell din-rail terminal blocks support both snap-in and screw-mounting options. This gives you flexibility for your project.

Note: Careful spacing and secure mounting help you avoid wiring mistakes and make your terminal block installation last longer.

Terminal Block Installation and Wiring

Prepare and Insert Wires

You need to prepare the wire before you start wiring a terminal block. This step is important for a safe and strong terminal block installation. Follow these installation steps to get the best results:

- Use a wire stripper to remove just enough insulation from the end of the wire. Match the stripped length to the depth of the terminal screw.

- If you use stranded wire, add a ferrule to the end. This keeps the strands together and helps you secure wire connections.

- For solid wire, you can form a small hook at the end. Place the hook around the screw in a clockwise direction.

- Insert the wire into the Linkwell Screw Terminal. Make sure the wire sits fully inside the terminal and does not leave any exposed strands.

- Check that the wire fits snugly. Gently tug on it to see if it stays in place.

When you prepare the wires and insert the wire correctly, you avoid loose wiring connections and make future maintenance easier. Linkwell Screw Terminals work with both solid and stranded wires, so you can use the type that fits your project.

Tip: Always match the wire gauge to the terminal size. This helps you secure the connection and prevents problems later.

Tighten Screws and Test Connections

After you insert the wire, you need to tighten the screw to finish wiring a terminal block. Use the right screwdriver and turn the screw clockwise until the wire feels tight. Do not overtighten, or you might damage the wire or the terminal block.

You should always verify connections after you finish wiring a terminal block. Here are some ways to test the installation:

- Use a multimeter to check for continuity. This shows if electricity can flow through the terminal block connection.

- Gently pull on each wire to make sure it does not come loose.

- Look for any exposed wire or pinched insulation.

- If your panel has test points, use them to check voltage and make sure everything works as planned.

You can use both solid and stranded wires with Linkwell Screw Terminals. Ferrules help stranded wires stay together and make wiring a terminal block easier. The flame-retardant and corrosion-resistant materials in Linkwell products help your terminal block installation last longer, even in tough environments.

Note: Regular checks and retightening help you keep your wiring connections safe and reliable. Always follow these steps when you connect the wires in your control cabinet.

Final Checks and Best Practices

Labeling and Documentation

Labeling each wire and terminal block keeps your cabinet neat. Good labels help you fix and upgrade things faster. Use clear and strong labels that last a long time. Always label wires and terminal blocks the same way. This stops mistakes and confusion.

Here is a table with best ways to label:

| Best Practice Aspect | Description |

|---|---|

| Consistency | Use the same style for all labels. |

| Clarity | Pick fonts and sizes that are easy to read. |

| Durability | Use labels that can handle water, heat, and chemicals. |

| Organization | Group wires by what they do for easy tracing. |

| Documentation | Keep wiring diagrams and schematics up to date. |

You can use snap-on markers or heat-shrink tubing for labels. These last longer than stickers. Make sure labels are easy to see before you remove anything. Numbered labels work better than just using colors.

Keep a wiring diagram for your cabinet. Update it every time you make a change. Use electrical CAD software if you can. This helps you track changes and makes your records more accurate. Teach everyone who works on the cabinet to use the same labeling and documentation rules.

Maintenance and Troubleshooting Tips

Regular maintenance helps your terminal blocks work well. Check all connections often. Tighten screws so wires do not get loose. Clean terminals with a brush or cloth to remove dust and rust. Replace any broken or cracked terminals right away.

Follow these steps for maintenance:

- Look at all terminal connections to check tightness and cleanliness.

- Clean contact surfaces to get rid of dirt or rust.

- Tighten any screws that are loose.

- Use anti-corrosion oil if you need it.

- Replace broken terminals with the right kind.

- Check for hot spots by feeling for heat.

- Keep the area dry and use covers to stop moisture.

When you troubleshoot, look for loose wires or screws. Use a multimeter to see if electricity flows through each terminal. Make sure no wire insulation is under the screw. Only put one wire in each terminal unless the block allows more. Use the right tools and do not tighten screws too much.

If you need help, Linkwell gives support by phone, email, and online guides. You can ask their team for advice or help picking products. Their resources help you keep your cabinet safe and working well.

You can put in control panel terminal blocks if you follow these steps. First, get your tools and Linkwell parts that are certified. Next, put the DIN rail in place and make sure it is straight. Then, add the terminal blocks and leave space between them. After that, get your wires ready, put them in, and tighten the screws. Test every connection and put clear labels on everything.

When you use good, certified parts, your system stays safe and works well. Planning ahead and checking often helps you stop problems before they start. If you need help or want special solutions, you can ask Linkwell for advice. Doing these things keeps your equipment safe and helps it last a long time.

FAQ

What is a terminal block used for?

A terminal block lets you connect wires safely inside a control cabinet. You can organize wires and make changes easily. This helps you keep your electrical system neat and safe.

How do you choose the right Din Rail?

You should check the size of your cabinet and the type of equipment you want to mount. Pick a Din Rail that matches your terminal blocks and meets safety standards like IEC 60715.

Can you reuse Linkwell Screw Terminals?

- Yes, you can loosen and retighten Linkwell Screw Terminals many times.

- The terminals last for over 10,000 cycles.

- This makes them great for projects that need updates or changes.

What safety steps should you follow before installation?

| Step | Why It Matters |

|---|---|

| Turn off power | Prevents electric shock |

| Wear safety gear | Protects you from injury |

| Check tools | Ensures safe installation |

Where can you get help with Linkwell products?

You can contact Linkwell by phone, email, or visit their website. Their team gives support and advice for installation, product selection, and troubleshooting.