Selecting the right terminal block is a critical decision in any electrical or electronic project. The choice directly impacts the safety, reliability, and long-term performance of your circuit. A well-chosen terminal block ensures optimal current flow, simplifies wiring, and provides effective protection.

This guide will walk you through the essential considerations for making an informed selection. Understanding the various types, features, and specifications will help you find the perfect terminal block to meet your application’s unique demands.

Why is Terminal Block Selection Important

Recommended Terminal Blocks

Terminal block selection is critically important because it directly impacts the safety, reliability, and long-term performance of any electrical circuit. Choosing the wrong terminal block can lead to various problems, from minor inconveniences to severe hazards, compromising the entire system.

A proper selection ensures that the terminal block can safely handle the electrical parameters and environmental stresses of the application, preventing failures and maintaining circuit integrity. It’s a foundational step for durable and compliant electrical installations.

- Ensures Electrical Safety: Selecting the correct voltage and current rating prevents overheating, arcing, and potential fires, protecting personnel and equipment from electrical hazards. This is paramount for preventing serious accidents and ensuring compliance with safety standards.

- Guarantees Circuit Reliability: Matching the terminal block to wire sizes and environmental conditions prevents loose connections, signal loss, and intermittent failures, ensuring consistent and stable operation of the circuit. A robust connection reduces downtime and troubleshooting efforts.

- Optimizes Performance and Longevity: Choosing materials resistant to specific environmental factors like vibration, temperature extremes, or corrosive agents ensures the terminal block maintains its integrity and functionality over extended periods. This contributes to the overall lifespan of the electrical system.

- Facilitates Maintenance and Troubleshooting: Properly selected and organized terminal blocks, with clear labeling and accessible connection points, significantly simplify future maintenance, inspection, and troubleshooting tasks. This reduces labor time and costs in the long run.

How to Select Terminal Blocks

Selecting the appropriate terminal block is crucial for ensuring the safety, reliability, and efficiency of any electrical system. A well-chosen terminal block will seamlessly integrate into your application, providing secure connections and simplifying future maintenance. Conversely, a poor selection can lead to performance issues, safety hazards, and increased costs.

The process involves evaluating several key factors related to the electrical requirements, environmental conditions, and specific application needs. Understanding these criteria will guide you to the most suitable terminal block type, size, and material, ensuring a robust and long-lasting connection solution for your project.

Determine Electrical Requirements

The first and most critical step is to accurately determine the electrical specifications of your application. This includes the maximum voltage, current, and wire gauge that the terminal block will need to accommodate. Overlooking these ratings can lead to dangerous situations, such as overheating, arcing, or even fire, if the terminal block is subjected to electrical loads beyond its design limits.

Additionally, consider if the application involves AC or DC current, and if there are any specific insulation requirements. The terminal block’s material and design must be able to withstand the anticipated electrical stress and provide adequate isolation between conductors, preventing short circuits and ensuring operational safety.

Consider Environmental Conditions

The environment in which the terminal block will operate significantly influences material selection and overall design. Factors such as operating temperature range, humidity, exposure to dust, moisture, chemicals, or corrosive agents must be carefully assessed. For instance, a terminal block used in a harsh industrial environment might require a robust, chemically resistant housing, whereas a standard indoor application might be less demanding.

Vibration is another critical environmental factor, especially in industrial machinery or transportation. Applications with high vibration levels will necessitate terminal blocks with superior clamping mechanisms, such as spring-clamp or robust screw-clamp designs, to ensure connections remain secure over time and prevent intermittent failures.

Evaluate Application-Specific Needs

Beyond electrical and environmental factors, consider the specific needs of your application. This includes the type of wiring (e.g., control, power, signal), the required density of connections, and any space limitations within the enclosure. Multi-level terminal blocks or miniature types might be necessary for compact designs, while disconnect or fuse terminal blocks offer specialized functionalities.

Also, think about ease of installation, maintenance, and future modifications. Features like clear labeling options, test points, and tool-less wiring methods can significantly reduce installation time and simplify troubleshooting, contributing to long-term efficiency and reduced operational costs for the entire system.

Assess Mounting Method

The method of mounting the terminal block is another practical consideration that impacts panel layout and installation time. The most common mounting method is DIN rail mounting, which provides a standardized, flexible, and quick way to install multiple terminal blocks in an organized fashion. Other options include panel mounting directly with screws or adhesive.

The chosen mounting method should align with the available space and the structural integrity required for the application. Ensure that the terminal block’s design is compatible with your chosen mounting solution, and that it provides sufficient stability to withstand vibrations or physical stresses encountered during operation.

Review Certifications and Standards

Finally, always verify that the terminal blocks comply with relevant industry standards and certifications for your specific region and application. This includes certifications like UL, CSA, VDE, or IEC standards, which ensure the product meets specific safety and performance criteria. Compliance is crucial for regulatory approval and overall system safety.

Checking for these certifications guarantees that the terminal block has undergone rigorous testing and meets established quality benchmarks. This step is particularly important for applications in regulated industries or for products intended for export, as it helps prevent costly delays and ensures long-term reliability and safety compliance.

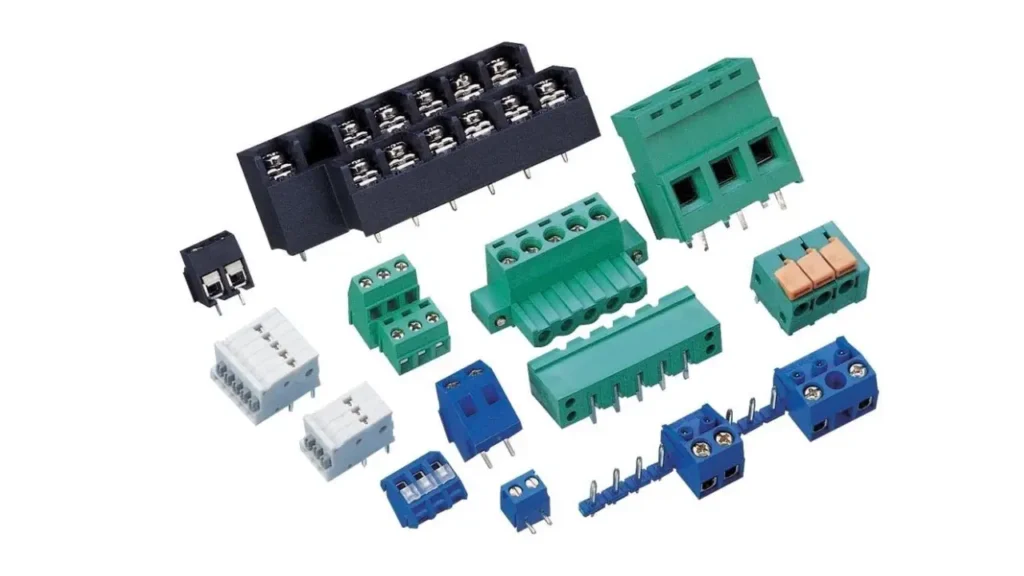

Types of Terminal Blocks

Terminal blocks are versatile electrical components that come in numerous forms, each designed to meet specific wiring requirements and application demands. Understanding these different types is essential for selecting the correct block to ensure optimal performance and safety within an electrical system.

Feed-Through Terminal Blocks

These are the most common type, providing a simple, insulated connection for two wires to pass through. They create a continuous electrical path, often used for extending circuits, creating junction points, or connecting devices in a series.

Grounding Terminal Blocks

Designed specifically for earthing applications, these blocks feature a direct electrical connection to the DIN rail they’re mounted on. This establishes a secure and reliable ground path for electrical safety and system protection. They are typically green/yellow for easy identification.

Disconnect Terminal Blocks

These blocks allow for quick and easy interruption of a circuit without physically removing wires. They typically feature a lever, knife switch, or plug that can be easily opened or removed to isolate a circuit for testing, maintenance, or troubleshooting purposes.

Fuse Terminal Blocks

Integrating a fuse directly into the terminal block, these provide overcurrent protection for individual circuits within a compact footprint. They eliminate the need for separate fuse holders, saving valuable panel space and simplifying wiring while offering easy fuse replacement.

Sensor Terminal Blocks

Often featuring multiple levels and integrated components like LEDs for status indication, these are specialized for connecting sensors and actuators. They provide organized connections for power, ground, and signal wires, streamlining complex control wiring.

Power Distribution Terminal Blocks

These are designed to efficiently distribute a single input power source to multiple output circuits. They streamline wiring by consolidating numerous connections from a single point, significantly reducing clutter and complexity in control panels.

Multi-Level Terminal Blocks

Offering several independent connection levels within a single housing, these blocks save significant space in control panels. They are ideal for dense wiring applications, allowing for more compact circuit designs and efficient use of limited panel real estate.

Miniature Terminal Blocks

Smaller in size and profile than standard blocks, miniature terminal blocks are specifically designed for applications with very limited mounting space. They maintain the full functionality of larger blocks while offering a compact footprint for tight installations.

Mistakes to Avoid When Choosing Terminal Blocks

When selecting terminal blocks, just as important as knowing what to consider is knowing what pitfalls to avoid. Overlooking certain aspects or making common misjudgments can lead to compromised safety, system unreliability, and increased costs down the line. Avoiding these common mistakes ensures a more robust and efficient electrical installation.

Proper terminal block selection requires a meticulous approach, as even seemingly minor oversights can have significant consequences. By being aware of these factors to avoid, you can make more informed decisions and prevent potential issues from arising during installation or operation.

- Underspecifying Current and Voltage Ratings: A critical mistake is choosing a terminal block with ratings lower than the actual or maximum expected operating conditions. This can lead to dangerous overheating, arcing, melting insulation, and potential fire hazards, severely compromising safety and system integrity.

- Ignoring Wire Type and Gauge Compatibility: Assuming a terminal block suitable for solid wire will also work perfectly with fine-stranded wire without a ferrule can result in unreliable connections. Mismatched wire types or gauges lead to poor contact, increased resistance, and potential for wire pull-out, leading to intermittent failures.

- Neglecting Environmental Factors: Failing to account for the specific operating environment (e.g., extreme temperatures, high humidity, vibration, corrosive chemicals, dust) can lead to premature degradation and failure of the terminal block’s materials. This compromises long-term reliability and necessitates costly early replacements.

- Overlooking Space Constraints and Accessibility: Choosing terminal blocks that are too large for the available enclosure space or that make wiring and maintenance difficult is a common oversight. This can lead to cramped wiring, reduced airflow (causing heat buildup), and time-consuming troubleshooting, impacting overall efficiency.

- Disregarding Regulatory Compliance and Certifications: Opting for terminal blocks that do not meet relevant industry standards (e.g., UL, IEC, CSA) for your region or application can lead to non-compliance issues, project delays, and potential safety violations. Always ensure the product has the necessary certifications for its intended use.

Conclusion

Selecting the right terminal block is a critical decision that impacts the safety, reliability, and efficiency of your electrical system. By carefully considering1 factors like application requirements, electrical specifications, and environmental conditions, you ensure optimal performance and compliance with industry standards.

Making an informed choice prevents common wiring issues, reduces maintenance, and enhances the overall longevity of your installation. It’s an investment in the stability and functionality of your circuits, providing peace of mind and operational excellence for the long term.

For a comprehensive range of high-quality wholesale terminal blocks, engineered for diverse applications and environments, contact us. We offer robust and reliable solutions to fit all your industrial and commercial needs.