If you want to know how to use horizontal cable management in 2025, you’re in the right place. You can keep your server cabinet, industrial control panel, or main control cabinet neat by choosing the right cable management solution, planning your layout, and organizing your cables. When you use horizontal cable management, you get real benefits:

- Improved airflow boosts cooling efficiency, which protects your equipment and can save energy.

- Less cable clutter means you reclaim rack space and make troubleshooting faster.

- Organized cables help you avoid downtime and keep maintenance simple.

Linkewell makes it easy to upgrade your setup with reliable, customizable cable management options trusted by industry leaders.

Horizontal Cable Management Key Takeaways

- Choose a horizontal cable manager that fits your rack size and cable volume to keep your setup neat and easy to maintain.

- Plan your cable routes carefully and label every cable clearly to save time during troubleshooting and future upgrades.

- Install cables gently using guides and secure them with quality ties without over-tightening to protect cables and maintain airflow.

- Use horizontal cable management together with vertical solutions to improve airflow, reduce clutter, and keep equipment cool.

- Regularly inspect and maintain your cables to avoid damage, prevent downtime, and ensure your system runs smoothly for years.

Choosing a Manager

When you start looking for the right horizontal cable management for your rack, you want a solution that fits your needs and makes your setup easier to handle. Linkewell offers rack cable management solutions that you can customize for your cabinet, server rack, or industrial control panel. You get to pick the size, material, and even the cable management accessories that work best for your space.

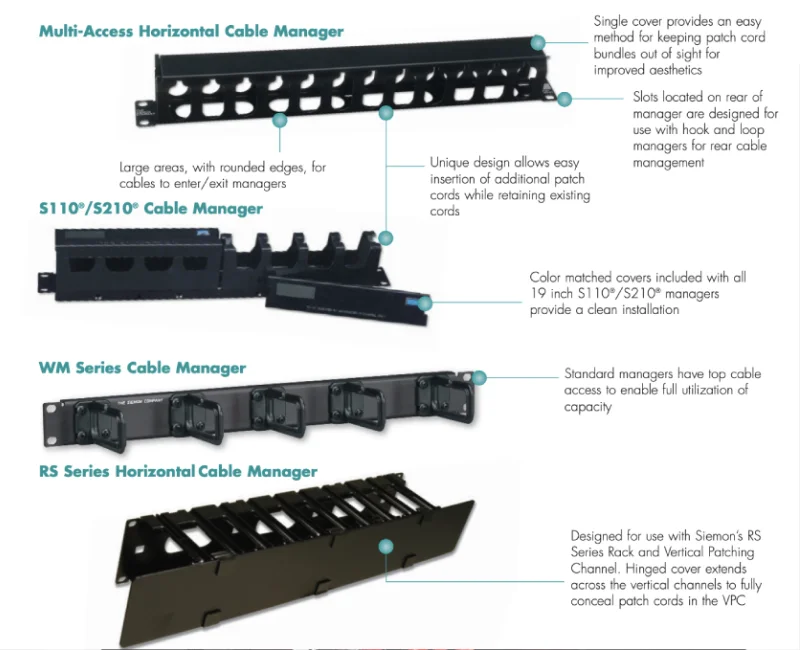

Types Available

You have a lot of choices when it comes to horizontal cable managers. Most options in 2025 come in 1U or 2U rack-mountable sizes. They help you organize cables like fiber, coax, patch cables, and copper wiring. Here’s a quick look at the most common types:

| Type | Features & Benefits |

|---|---|

| Finger Duct | Fingers and pass-through holes, removable cover, reduces strain, keeps cables separated |

| D-Ring | Open D-shaped rings, easy cable access, neat vertical routing |

| Brush Strip | Steel frame with nylon bristles, lets cables pass through, keeps dust out, maintains airflow |

| Cable Trough/Tray | Channels for holding and routing cables |

| Cable Rings | Bundles and guides cables |

Finger duct cable managers keep cables separated and reduce strain. D-ring managers let you add or move cables quickly. Brush strip managers allow cables to pass through while blocking dust and keeping airflow steady. You can also add cable management accessories like cable ties, labeling systems, and custom rings for even more control.

What to Consider

Picking the right horizontal cable manager is important. You want your cable management system to match your rack’s size and the number of cables you need to organize. Here are some things to think about:

- Count the cables and check their thickness.

- Make sure you have enough space in your rack.

- Choose a size that fits your cable volume.

- Look for features like breakaway fingers or removable covers.

- Think about your budget and future needs.

- Make sure the manager works with your current setup.

- Use cable management accessories to label and bundle cables.

- Pick materials that fit your environment and reduce interference.

- Plan for easy maintenance and future upgrades.

Customizable options from Linkewell help you get the perfect fit. You can select the right dimensions, materials, and cable management accessories. This makes your cable management more reliable, keeps airflow strong, and makes maintenance simple. With the right horizontal cable management, you keep your rack, industrial control panel, or server cabinet neat and ready for anything.

Preparing for Installation

Getting ready for horizontal cable management in your server rack, industrial control panel, or main control cabinet makes the whole process smoother. You want to set yourself up for success by gathering the right tools and planning your cable routes before you start.

Tools and Materials

You need the right gear to install cable management systems. Here’s a handy table to help you check off what you need:

| Tool/Material | Purpose |

|---|---|

| Patch Panel Rack Mounts | Centralize cable connections and reduce clutter |

| Cable Trays/Raceways | Route cables neatly and prevent tangling |

| Cable Ties/Velcro Straps | Bundle cables securely; Velcro straps are reusable |

| Cable Management Panels | Organize and guide cables for a tidy setup |

| Cable Organizers | Separate cables for easy identification |

| Cable Hooks/Clips | Secure cables along rack sides or bottoms |

| Screwdrivers/Screws | Attach panels and accessories |

| Labeling Systems | Mark cables for easy identification and future maintenance |

Linkewell offers cable management accessories like cable ties and labeling systems that make your job easier. Choose metal cable management panels made from cold-rolled steel for durability and a smooth finish. Electrostatic spraying helps prevent rust and keeps your setup looking sharp.

Planning and Labeling

Before you install anything, take a few minutes to plan your cable routes. Think about where each cable will go and how you can avoid sharp bends or interference from other equipment. Try to minimize 90-degree turns and keep cables away from power sources that might cause signal loss.

Labeling is a game-changer for cable management. Use clear, durable labels on both ends of every cable. This step saves you time during troubleshooting and helps prevent accidental disconnections. Stick to a standard labeling system and keep a record of your scheme. Color coding and matching your labels to your structured cabling plan make future upgrades and repairs much easier.

Tip: Good planning and labeling now mean less stress and faster fixes later. You’ll thank yourself when you need to trace a cable or add new equipment.

With the right tools, cable management accessories, and a solid plan, you’ll breeze through installation and keep your rack organized for years.

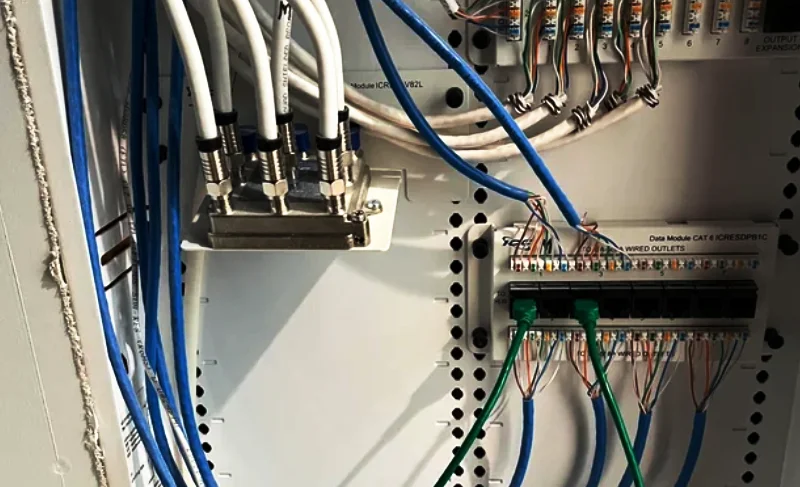

How to Use Horizontal Cable Management

Installation Steps

Ready to get started? Here’s how to use horizontal cable management in your server rack, industrial control panel, or main control cabinet. First, clear your workspace and gather all your tools and cable management accessories. You want everything within reach before you begin.

Follow these steps for a smooth installation:

- Mount the Horizontal Cable Manager

Attach the horizontal cable manager to your rack or cabinet. Use the correct screws and make sure it sits level. A secure fit keeps your cables safe and prevents hazards. - Plan Your Cable Paths

Decide where each cable will run. Think about which devices connect to each other. Try to keep power and data cables separate to avoid interference. - Prepare Cables

Cut cables to the right length. Avoid extra slack that can cause tangles or tightness that might damage the wires. - Route Cables Through the Manager

Feed cables through the finger ducts, D-rings, or brush strips. Keep cables grouped by type or function. This makes future changes much easier. - Secure Cables

Use cable ties, Velcro straps, or hook-and-loop fasteners to bundle cables. Don’t pull them too tight. Leave a little room for movement. - Label Everything

Place labels on both ends of each cable. Use a clear system so you can identify cables quickly during maintenance.

Tip: Always check that your installation follows local fire codes and safety standards. Keep cables separated and avoid overcrowding to maintain airflow and reduce fire risk.

Routing and Securing

You want your cables to stay neat and easy to manage. Here’s how to use horizontal cable management for the best results:

- Bundle Cables by Type

Group similar cables together. For example, keep all network cables in one bundle and power cables in another. This helps you find the right cable fast. - Avoid Sharp Bends

Route cables gently. Sharp bends can damage the wires inside and cause signal loss. Use the built-in guides on your cable management system to keep bends smooth. - Keep Cables Snug, Not Tight

Secure cables along their path, but don’t over-tighten. You want cables to stay in place without being pinched. - Use High-Quality Materials

Choose durable cable ties and sleeves. Good materials last longer and protect your cables from wear. - Maintain Consistent Direction

Run cables in the same direction within the rack. This keeps your setup organized and makes it easier to trace cables later. - Combine Horizontal and Vertical Management

For the cleanest look and best airflow, use both horizontal cable management and vertical cable management together. Horizontal cable management routes cables above or below devices, while vertical solutions hold cables along the sides of the rack. This combo keeps everything tidy and accessible.

Note: Regularly check your cables for signs of wear or damage. Replace any worn ties or labels to keep your system in top shape.

Organizing for Airflow

Good airflow keeps your equipment cool and running smoothly. Here’s how to use horizontal cable management to optimize airflow:

- Plan Cable Routes with Airflow in Mind

Think about where air flows in your rack or cabinet. Avoid blocking vents or fans with cables. - Use Cable Managers and Accessories

Install cable managers above or below devices. Add blanking panels to block unused spaces and improve airflow. Use grommets to seal cable openings and prevent air leaks. - Keep Pathways Clear

Route cables along the sides of the rack. This keeps the center open for air to move freely. - Color Code and Label Cables

Use different colors for different types of cables. This makes it easy to spot and fix problems without disturbing airflow. - Secure Cables to Prevent Movement

Fasten cables so they don’t shift and block airflow. Use ties and clips to keep everything in place. - Document Your Setup

Draw a simple diagram of your cable layout. Write down which cables go where. This helps with future upgrades and keeps your airflow plan intact.

When you combine horizontal cable management with vertical solutions, you get the best of both worlds. Your cables stay organized, your equipment stays cool, and you spend less time troubleshooting. Studies show that good cable management can improve cooling by up to 20% and cut troubleshooting time nearly in half. That means less downtime and longer equipment life.

Pro Tip: Plan for future growth. Leave space for extra cables and equipment so your airflow stays strong as your setup expands.

Best Practices

Avoiding Tangles

Keeping cables neat in your server rack, industrial control panel, or main control cabinet can feel like a full-time job. You want to avoid tangles because they slow you down and make troubleshooting a headache. Here’s how you can keep your horizontal cable management system organized:

- Use cable trays, raceways, and horizontal cable management accessories to keep cables off the floor and in order.

- Bundle related cables together with sleeves or combs. This keeps everything grouped and reduces clutter.

- Secure cables with Velcro straps or zip ties. Velcro straps work great if you need to make changes later.

- Cut cables to the right length. If you have extra slack, bundle and secure it so it doesn’t get tangled.

- Label and color-code cables for quick identification.

- Teach your team to follow the same cable management practices every time.

Tip: Plan your cable pathways before you start. This helps you avoid crossing cables and keeps your setup looking professional.

Maintenance Tips

You want your horizontal cable management to last and keep working well. Regular maintenance makes a big difference. Here are some easy routines you can follow:

- Inspect cables every three months for wear, loose connections, or dust buildup.

- Clean cables and connectors with a soft cloth or compressed air.

- Replace any cables that show signs of damage.

- Update your cable management layout during upgrades. Remove unused cables to reduce clutter.

- Monitor network performance with diagnostic tools to catch cable issues early.

- Keep power and data cables separated to prevent interference and signal loss.

- Document your cable layout and update labels as you make changes.

A good maintenance routine keeps your horizontal cable management system running smoothly. You’ll spend less time fixing problems and more time focusing on what matters.

Common Mistakes

When you use horizontal cable management in your server rack, industrial control panel, or main control cabinet, you want to avoid some common mistakes that can cause big headaches later. Let’s look at the two most frequent issues and how you can steer clear of them.

Overfilling

It’s easy to underestimate how many cables you’ll need to manage. You might think you have enough space, but as your system grows, things can get crowded fast. Overfilling your cable management trays or ducts leads to tangled wires, poor airflow, and even damaged cables. Here’s what can happen:

- Patch cords get kinked and tangled, making it tough to add or move cables.

- You lose easy access, so tracing or replacing a cable takes much longer.

- Future upgrades become a hassle because there’s no room left for new cables.

- Airflow drops, which can cause your equipment to overheat.

Best practice: Always leave at least 30% of your cable manager empty. This gives you room to grow and keeps everything running smoothly.

Linkewell’s customizable cable management solutions help you avoid overfilling. You can choose the right size and layout for your setup, so you never run out of space.

Bend Radius Issues

Another mistake is ignoring the bend radius of your cables. If you bend cables too sharply, you risk damaging the insulation or even breaking the wires inside. This can lead to signal loss, slower data speeds, or even safety hazards like electrical shorts.

- Sharp bends can deform the cable jacket and expose the wires.

- Fiber optic cables may lose signal strength if bent too tightly.

- Power cables can overheat or fail if the bend is too sharp.

- Damaged cables need to be replaced more often, which costs time and money.

Tip: Use cable management systems with built-in bend radius protectors. Linkewell offers custom dividers and brackets that keep your cables safe and maintain the right bend radius.

With Linkewell’s modular and scalable horizontal cable management, you get features like bend radius guides, labeling systems, and tailored layouts. These help you avoid the most common mistakes and keep your rack, control panel, or cabinet organized for the long haul.

You can keep your server rack, industrial control panel, or main control cabinet organized by following a few simple steps. Use horizontal cable managers, label every cable, and plan for future growth. Clean, labeled cables make troubleshooting fast and keep your equipment cool. Regular reviews and updates help you spot issues early. Choose Linkewell for reliable solutions trusted by Industrial Control Panel Manufacturers worldwide.

A tidy rack saves time, reduces downtime, and supports long-term network reliability.

FAQ

What is horizontal cable management used for?

You use horizontal cable management to organize cables in electrical control cabinets, main control cabinets, signal cabinets, and server racks. It keeps your setup neat, improves airflow, and makes maintenance much easier.

How do I choose the right horizontal cable manager?

First, count your cables and check your rack size. Pick a manager that fits your cabinet and cable volume. Look for features like finger ducts, D-rings, or brush strips to match your needs.

Can I install horizontal cable management myself?

Yes, you can! Most systems come with simple instructions. Gather your tools, plan your cable routes, and follow the steps. If you get stuck, Linkewell’s support team can help you out.

How often should I check my cable management system?

Check your cables every three months. Look for dust, loose ties, or damaged wires. Regular checks help you catch problems early and keep your equipment running smoothly.

Why should I label my cables?

Labeling saves you time. You find cables faster during upgrades or repairs. It also helps prevent mistakes, like unplugging the wrong cable. A good labeling system keeps your cabinet organized.

Conclusion

Horizontal cable management keeps your electrical control cabinets, main control cabinets, signal cabinets, and server racks organized. You get better airflow, less clutter, and faster troubleshooting. When you use Linkewell’s customizable solutions, you make your setup future-ready. Regular checks and good labeling help you avoid downtime. Choose Linkewell for reliable, efficient cable management trusted by Industrial Control Panel Manufacturers worldwide.